Display mother board, preparation method thereof and electroluminescence display panels

A display panel and display substrate technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems affecting the production yield of OLED display products, cutting damage, affecting cutting, etc., to achieve the effect of ensuring the production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

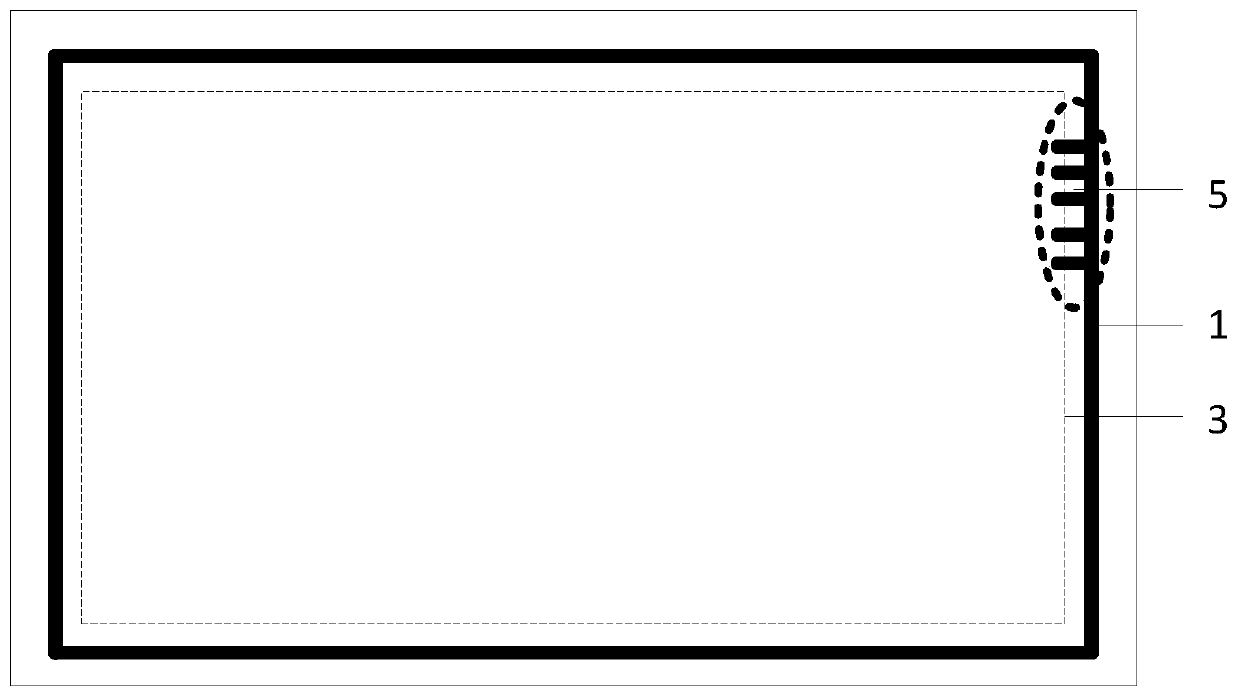

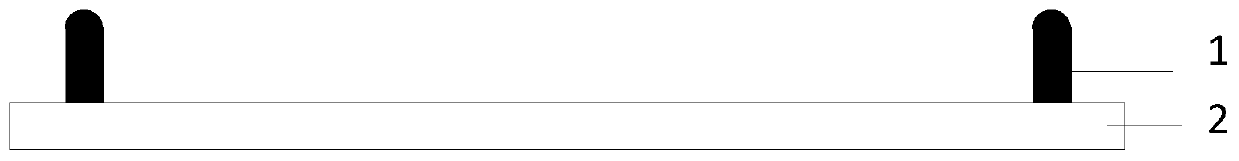

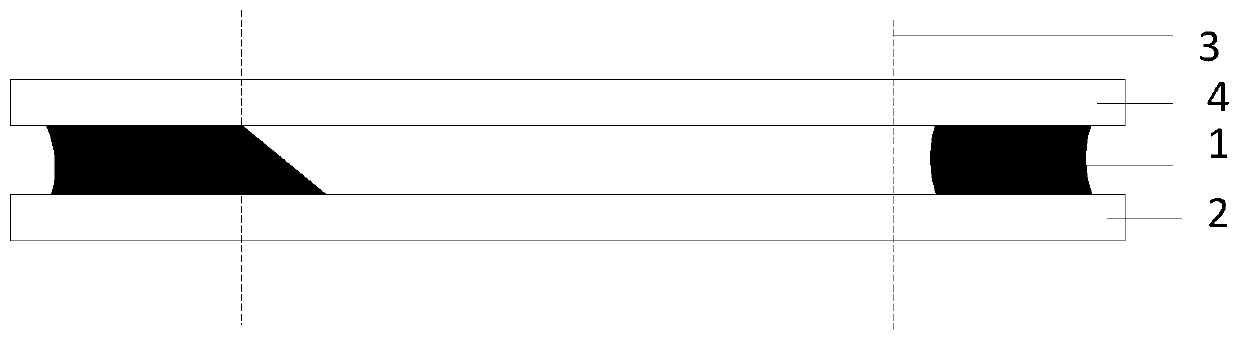

[0036] The embodiment of the present application provides a display motherboard provided in the embodiment of the present application, such as Figure 4 , Figure 5 As shown, among them, Figure 5 for Figure 4 In the cross-sectional view along AA', the display motherboard includes: a display substrate 6 and a cover plate 7 arranged oppositely; the display motherboard is divided into a display panel area 8 and a peripheral area 9 surrounding the display panel area 8; The display panel area 8 includes a plurality of electroluminescent display panels 14; the peripheral area 9 includes: a cutting area 10 and a packaging area 11 surrounding the cutting area 10; the packaging area 11 includes: sealing the display substrate 6 and the cover plate 7 and the sealant 12 surrounding the cutting area 10 , and the sealant blocking structure 13 located on the side of the sealant 12 facing the cutting area 10 .

[0037] In the display motherboard provided in the embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com