Reaction chamber and semiconductor processing apparatus

A reaction chamber and cavity technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of residual reaction by-products, affecting etching results, affecting product yield, etc., to reduce deposition and simplify the maintenance process of opening the cavity , Guarantee the effect of process results and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order for those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

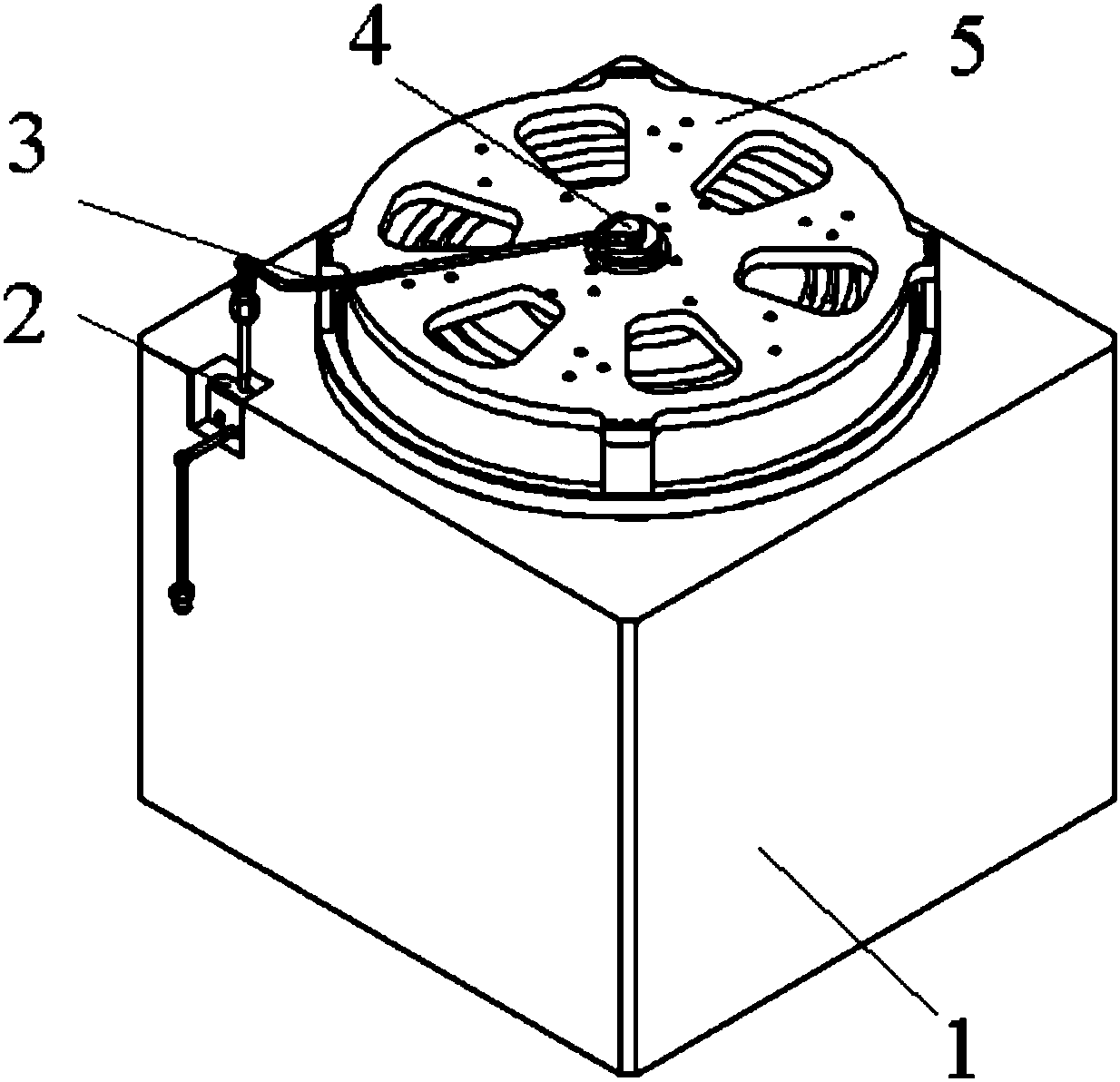

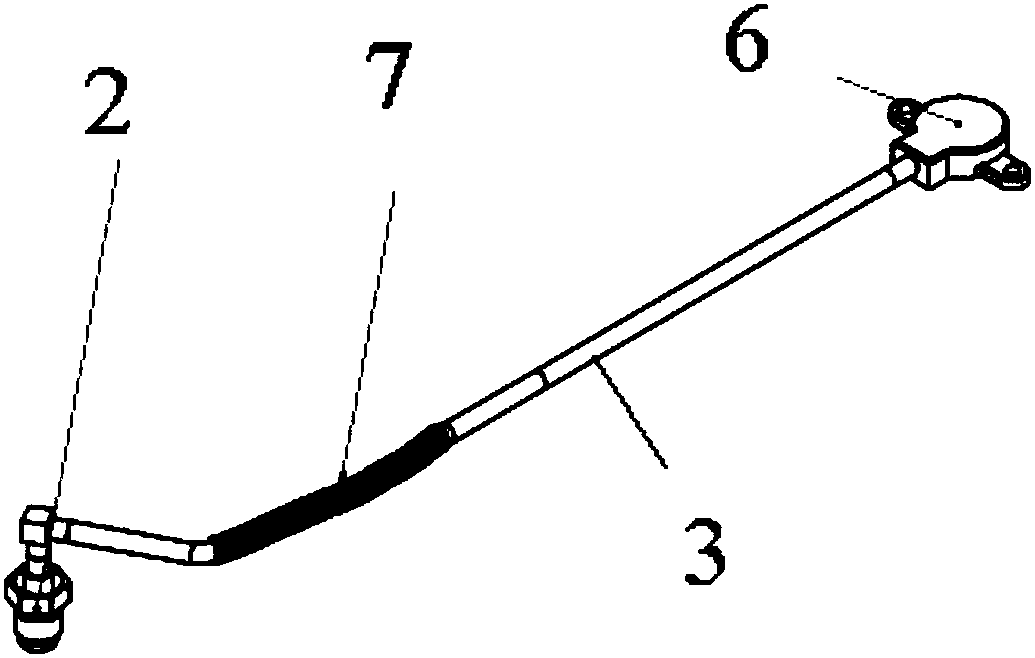

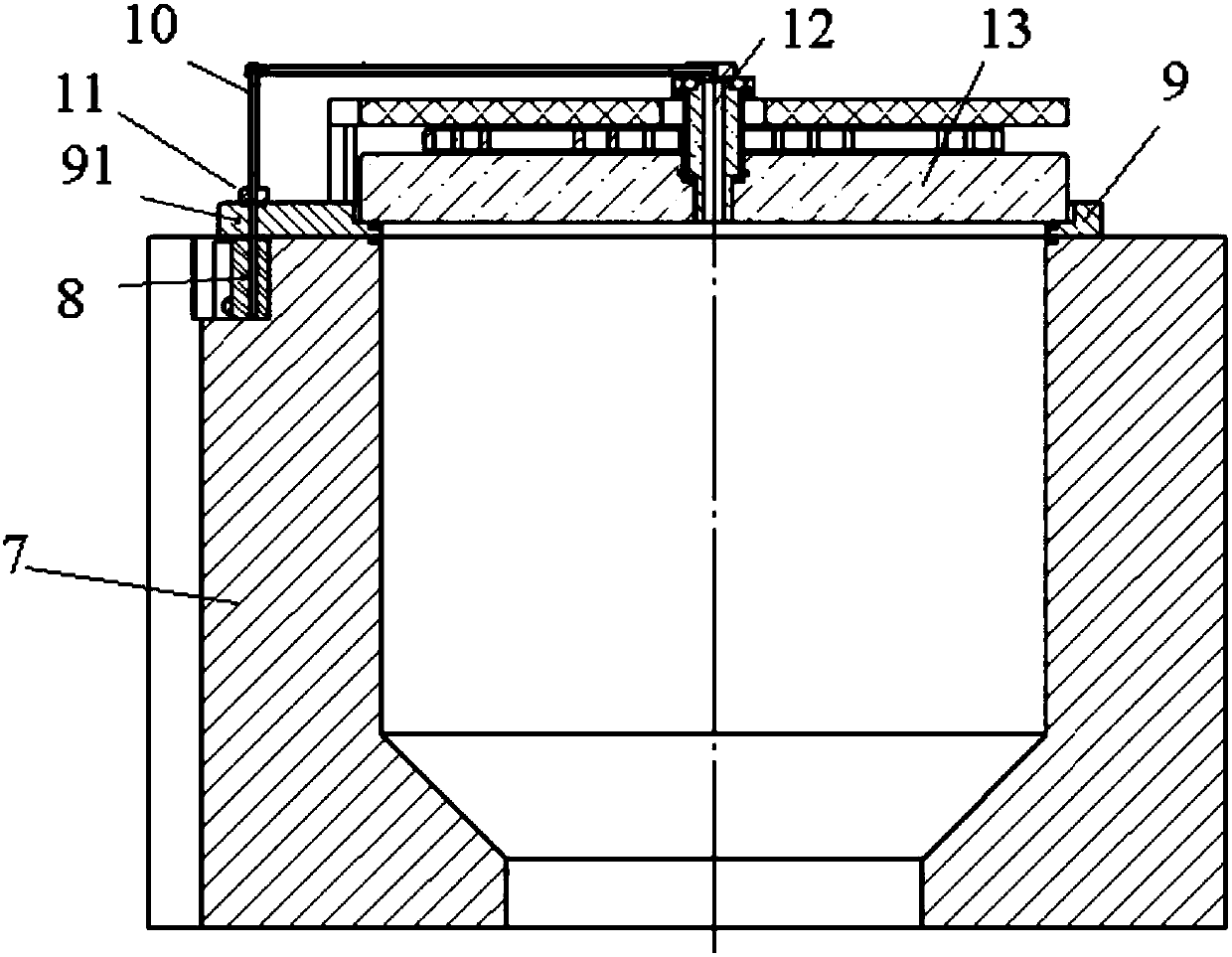

[0033] see image 3 , the reaction chamber provided by the embodiment of the present invention, which includes a cavity 7, a dielectric window 13, a support member 9 for fixing the dielectric window 13 on the top of the cavity 7, and a gas for delivering gas to the inside of the cavity 7 intake mechanism. Wherein, the air intake mechanism includes an air intake channel 91 arranged in the support member 9, and a first pipeline 8 and a second pipeline 10, wherein the first pipeline 8 is arranged on the cavity 7, and is connected with the air inlet One end of the channel 91 is detachably sealed and connected, and the first pipeline 8 is used to deliver gas to the second pipeline 10 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com