Retractable clamping jaw with changeable pitch

A gripper and pitch technology, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problem of whether the grippers are clamped to the product can not be determined, the grippers do not have the detection function, and the grippers cannot adapt to multi-station gripping work and other issues to achieve high production efficiency, ensure production yield, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

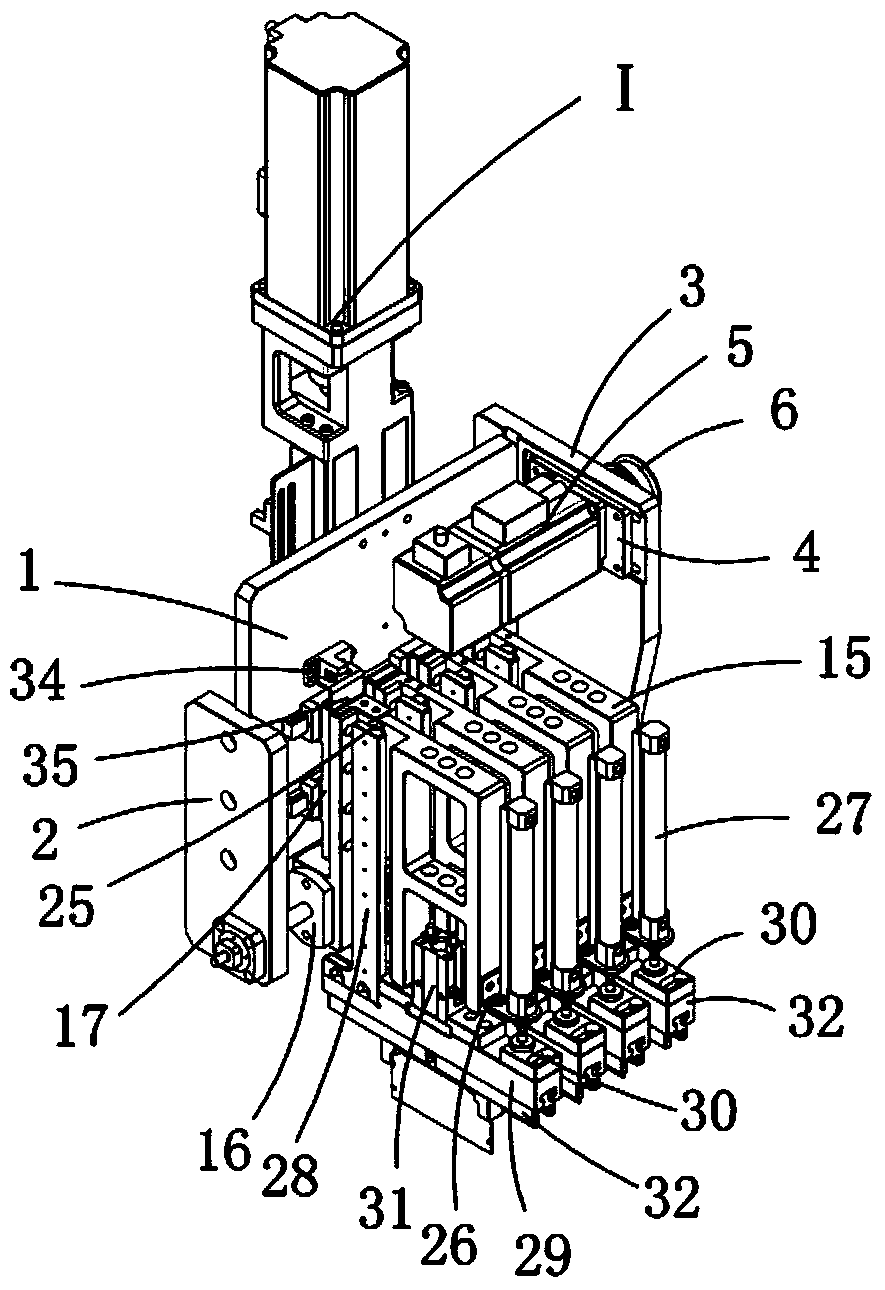

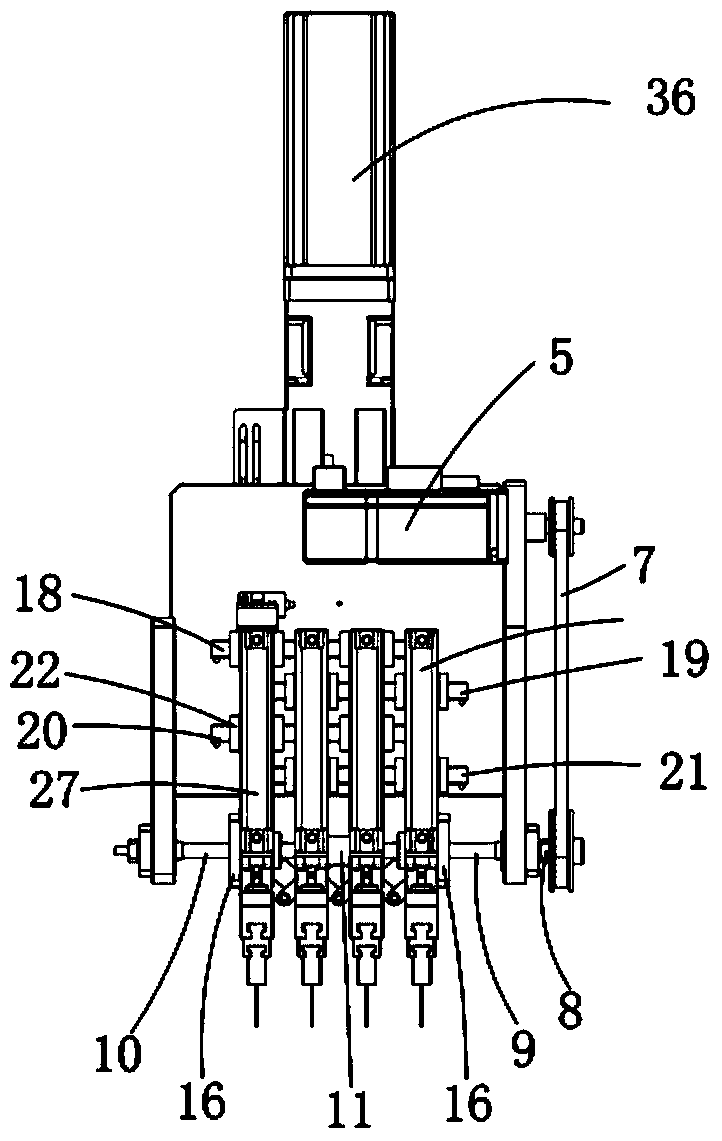

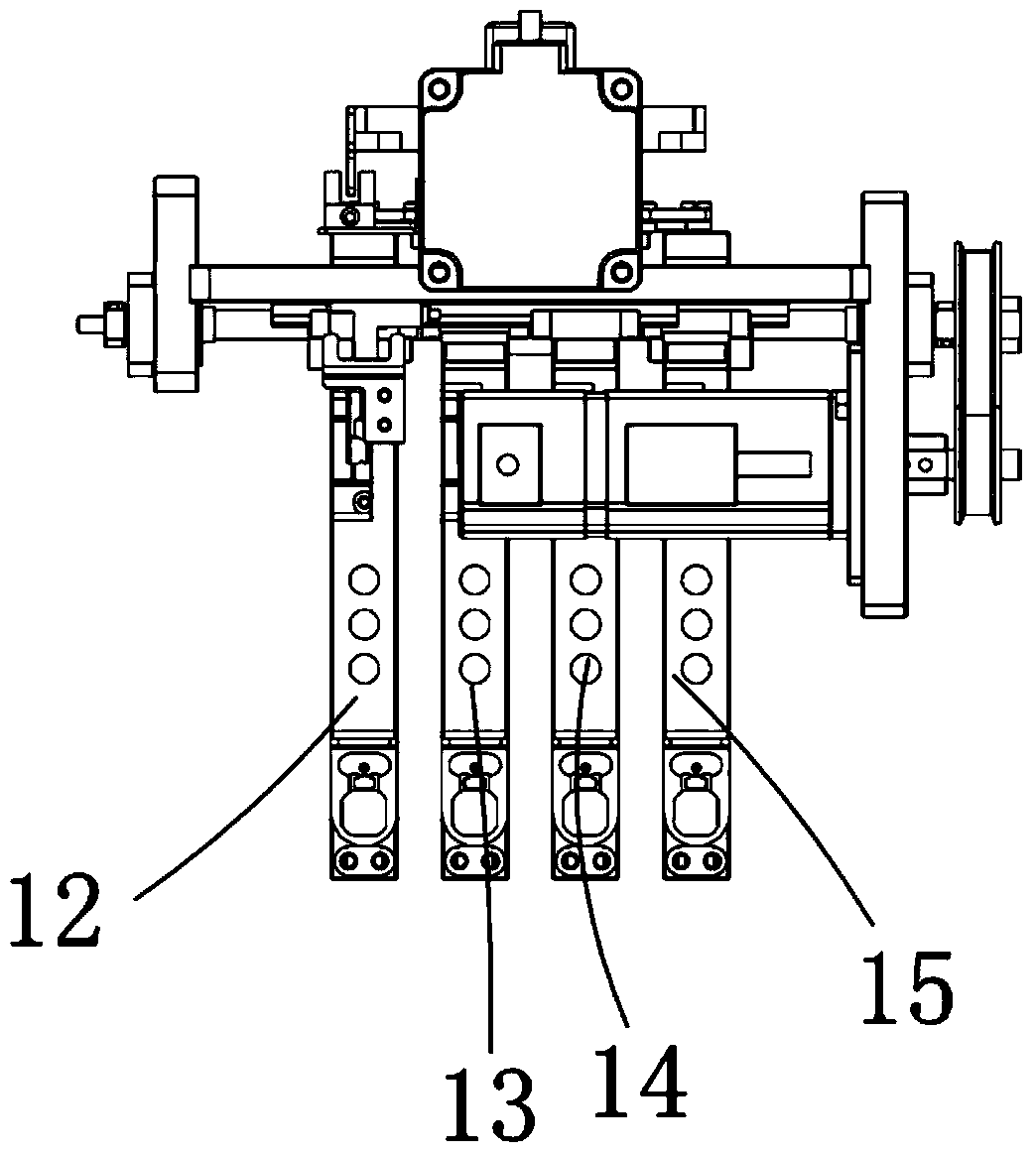

[0028] Examples, see attached Figure 1~6 , a variable-pitch telescopic gripper, which includes a Z-axis mechanism I, a fixed plate 1, a left plate 2, a right plate 3, a motor mount 4, a pitch adjustment motor 5, a synchronous wheel a6, a synchronous belt 7, Synchronous wheel b8, lead screw a9, lead screw b10, rigid coupling 11, first connecting plate 12, second connecting plate 13, third connecting plate 14 and fourth connecting plate 15, reverse nut 16, slider Connecting plate 17, first slide rail 18, second slide rail 19, third slide rail 20 and fourth slide rail 21, slider 22, connecting rod 23, connecting rod shaft 24, vertical lift slide rail 25, vertical lift cylinder Fixed plate 26, vertical lifting cylinder 27, slide rail connecting plate 28, jaw connecting plate 29, lifting plate 30, pneumatic finger 31, jaw head 32, material leakage detection sensor 33, origin sensor 34 and origin induction sheet 35, The Z-axis mechanism includes a Z-axis motor 36, a Z-axis couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com