Cross guide type plastic bag packaging structure and manufacturing method of plastic bags of this type

A technology of packaging structure and manufacturing method, applied in the field of cross-reference type plastic bag packaging structure, can solve the problems of inconvenience, incomplete cutting of plastic bags, inconvenience to grasp plastic bags, etc., achieves low cost, ensures processing accuracy and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

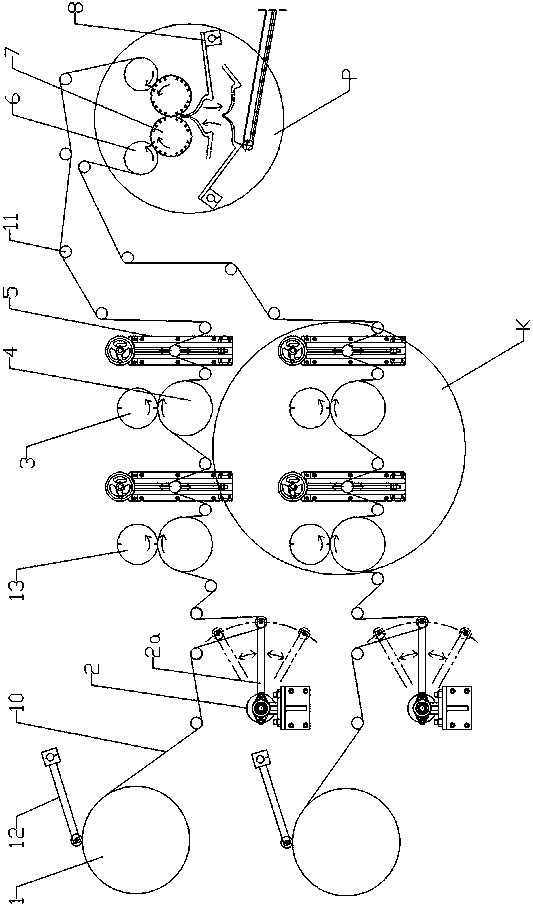

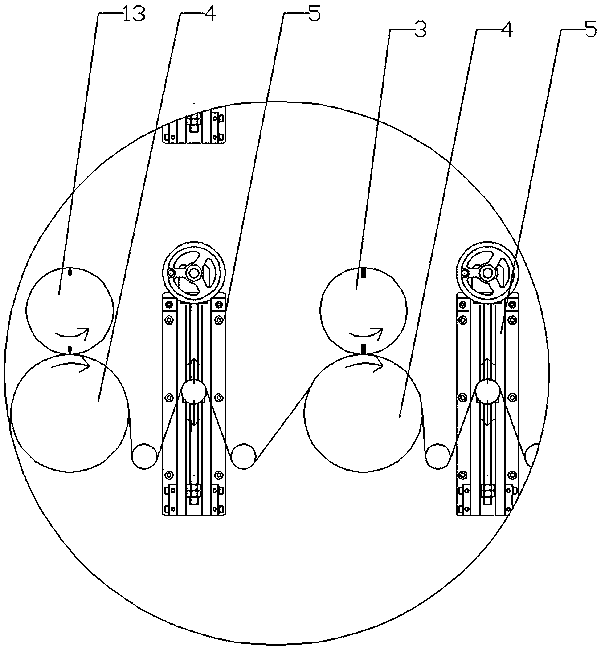

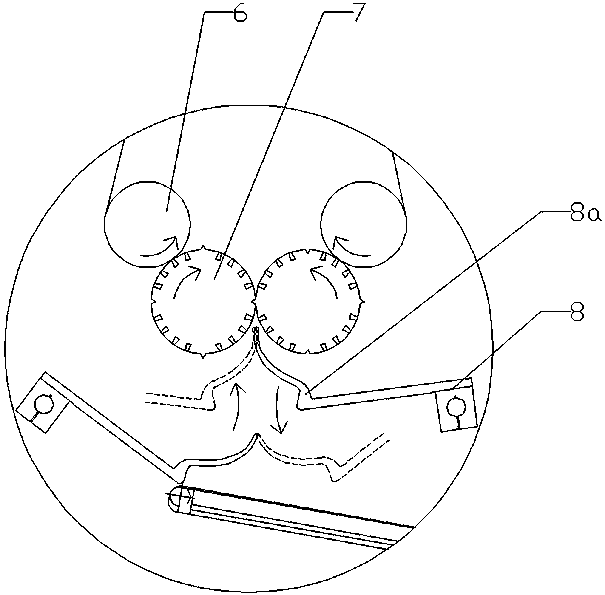

[0033] In the following description of the embodiments, reference is made to the accompanying drawings which form a part hereof, and in which are shown by way of example specific embodiments in which they may be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the various embodiments.

[0034] According to the present invention, with reference to the attached Figure 4 And attached Figure 5 , providing a cross-retrieval plastic bag 9 packaging structure, wherein the structure of the plastic bag 9 is heat-sealed on three sides, and a heat-press seal 94 is provided at the end 92 of the bag; the plastic bag 9 is also provided with an 8-shaped through hole for lifting 95; the packaging structure is formed by overlapping plastic bags (9) folded in half at the bag head 91 and the bag tail 92. In this embodiment, the plastic bags 9 are stacked up and down, and the bag head 91 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com