Patents

Literature

190results about How to "Fully leached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alga microorganism fertilizer agent and preparation method thereof

ActiveCN102924134AStable structureWide range of functionsOrganic fertilisersMonosodium glutamateBiology

The invention relates to an alga microorganism fertilizer agent and a preparation method thereof and belongs to the technical field of aquiculture and the like. The alga microorganism fertilizer agent is fermented in such a way that monosodium glutamate waste liquid, alga paste, photosynthetic bacteria, actinomycetes, azotobacters and bacillus subtilis are compounded, and meanwhile, chitosan, chitosan oligosaccharide, microelements and molasses are added according to appropriate parts. The alga microorganism fertilizer agent is formed in such a way that the monosodium glutamate waste liquid is adopted for fermentation, and the raw materials preparation is simple; high-content compound bacteria are contained (the content of the bacillus subtilis is larger than three hundred million / mL, and the total content of the photosynthetic bacteria, the actinomycetes and the azotobacters is larger than one hundred million / mL) and the fertilizing effect is obvious; and the alga microorganism fertilizer agent also has a function of purifying water body, has a wide application range, and is suitable for sea-water and fresh-water cultivation.

Owner:日照巴斯德生物科技有限公司

Instant green tea powder processing method

The invention relates to an instant green tea powder processing method which comprises the following steps of: killing out fresh tea leaves by adopting a vacuum microwave method, carrying out superfine grinding after deep freezing, extracting and superfinely filtering by adopting secondary vacuum ultrasonic wave, and freezing and drying to obtain the instant green tea powder. The killing, extraction and drying steps are completed under a vacuum condition, and the action temperature is low, so that the oxidation of effective ingredients in fresh tea leaves can be effectively avoided; and vacuum ultrasonic extraction after freezing and superfine grinding ensures the full leaching of the effective ingredients. The product produced by the processing method has the advantages of high production efficiency, good product color, fresh taste, good dissolvability, incapability of generating tea cream and the like.

Owner:HEBEI STRONG FOOD

Process of extracting dihydromyricitrin from vine tea

The present invention discloses the process of extract dihydromyricitrin from vine tea. The process includes soaking vine tea leaf in solvent, filtering, microwave irradiating wet vine tea leaf, merging filtrate, extracting in heating water bath, filtering the hot extracting liquid, dissolving the filtrate, and recrystallization in cold water for purifying. The process has high extraction rate, simple operation and less side product.

Owner:GUANGZHOU UNIVERSITY

Pericarpium citri reticulatae dark green tea and processing method thereof

ActiveCN102960491AUnique tasteGreat tastePre-extraction tea treatmentPericarpium citri reticulataeGreen tea

The invention provides pericarpium citri reticulatae dark green tea and a processing method thereof aiming at the problem of single type of dark green tea. The pericarpium citri reticulatae dark green tea provided by the invention comprises dark green tea and pericarpium citri reticulatae and is prepared according to the mass ratio of the dark green tea and the pericarpium citri reticulatae of 1:(0.35-0.45). The processing method of the pericarpium citri reticulatae dark green tea comprises the steps of scenting the dark green tea and the pericarpium citri reticulatae which are prepared primarily, and then uniformly mixing the scented dark green tea and pericarpium citri reticulatae particles according to the mass ratio of 15:(0.8-1). The pericarpium citri reticulatae dark green tea has the superior advantages of the dark green tea and the pericarpium citri reticulatae and has the double health protection effects. According to the pericarpium citri reticulatae dark green tea, the types of the dark green tea are added, and a new road is searched for the tea industry.

Owner:YIBIN CHUANHONG TEA IND GRP

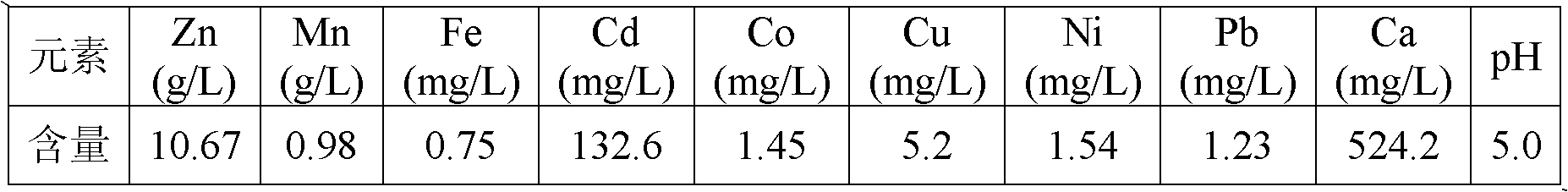

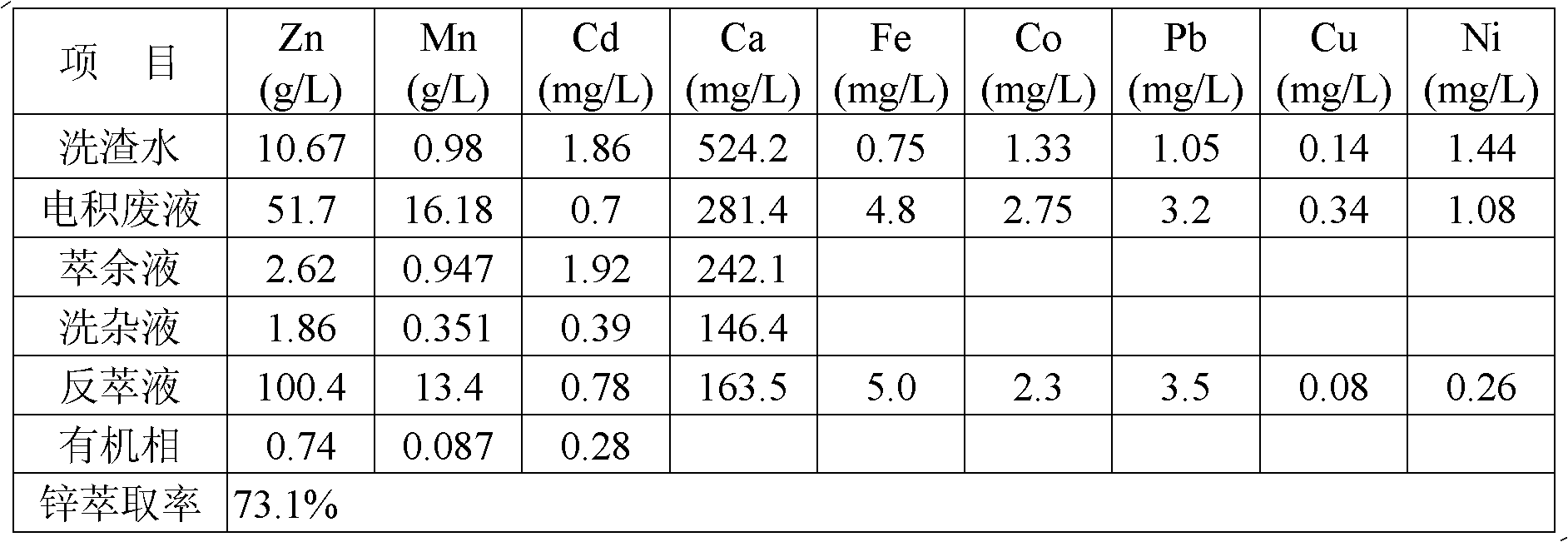

Method for recycling zinc from zinc leaching slag cleaning solution

The invention discloses a wet process for recycling zinc from a zinc leaching slag cleaning solution, belonging to wet processing methods for zinc ore, in particular relating to a method for further recycling zinc from zinc slag generated by a zinc hydrometallurgy system. The method comprises the following steps of: washing leaching slag or rinsing the leaching slag with dilute acid; then preparing an organic phase by taking P204 as an extractant and kerosene as a diluent to extract a water phase; preparing a solution containing zinc and sulphuric acid; eluting impurities in the loaded organic phase; back-extracting the loaded organic phase with waste electrolyte and sulphuric acid; shifting zinc in the organic phase into a water phase again; carrying out deoiling treatment on all water phases in contact with the organic phase; and finally, adding a back-extracted solution as a new solution into a zinc electrodeposition system. The method has the advantages of simplicity of operation and high metal recovery rate, can effectively recycle zinc included in the zinc leaching slag so as to save resources and avoide environment pollution, and can be well linked with a zinc hydrometallurgy process so that the recovery rate of zinc is increased.

Owner:KUNMING UNIV OF SCI & TECH +1

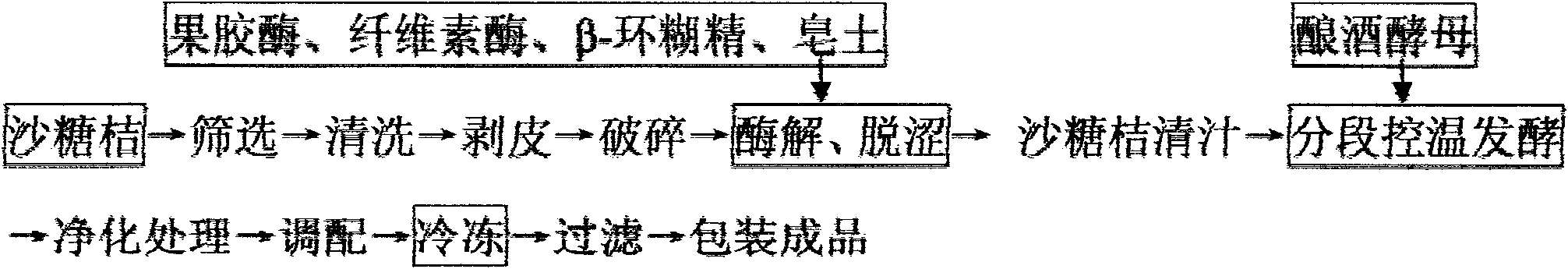

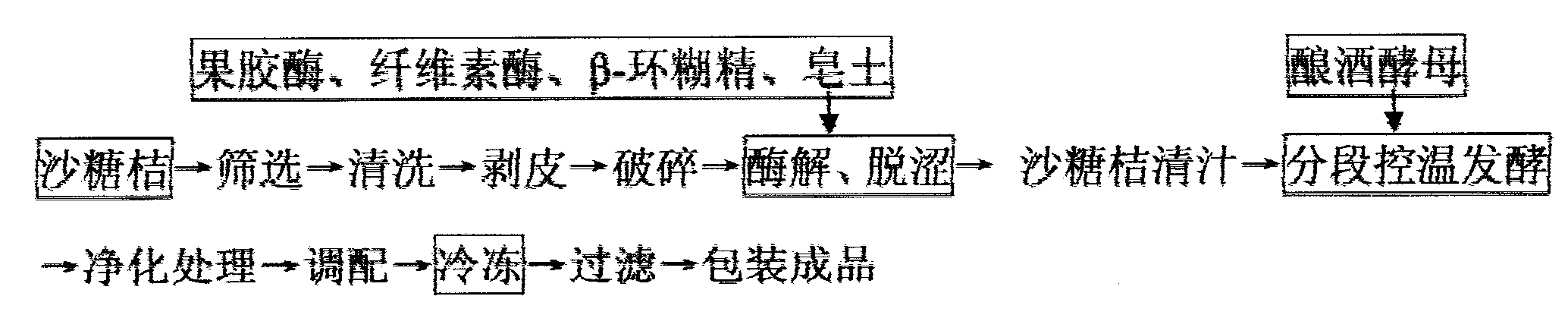

Production method of sugar orange fruit wine

InactiveCN101899372AImprove qualityGood relief from bitternessAlcoholic beverage preparationMicroorganism based processesPectinaseFruit wine

The invention provides a production method of sugar orange fruit wine, which comprises the following steps: taking fresh fruits of sugar oranges as a raw material; carrying out processes of separation, cleaning, peeling off, crushing and the like; then adding various enzymes including pectinase, cellulase, bentonite and the like; carrying out enzymolysis at 12-18DEG C; then adding puckery-losing agent to removing the bitter and astringent; transferring ferment serum in a fermentation tank; carrying out sectionalized low temperature fermentation by utilizing Saccharomyces cerevisiae, i.e. fermenting at 15-20DEG C for 3-5 days and carrying out tanks switching; fermenting again at 18-20DGE C for 7-15 days after the serum separation; adding clarifying agent to clarify the obtained raw wine; standing for 8-10 days; racking and filtering; storing at 15-18 DEG C and ageing for 3-6 months; freezing over 7 days at the temperature of 0.5DEG C higher than the freezing point of the wine; and then carrying out rough filtration and refining filtration. The invention has good enzymolysis and puckery-losing effect, has high juice yield over 85% and clear juice, can keep the fruity smell of wine products, avoids the entering of the harmful arene, and has good stability after tartar is separated out through freezing.

Owner:YUNFU HUANAN LIQUOR

Method for extracting beryllium oxide from low-grade beryllium ore

InactiveCN102168184AIncrease concentrationLow firing temperatureProcess efficiency improvementKeroseneSlag

The invention discloses a method for extracting beryllium oxide from low-grade beryllium ore. The method is characterized by comprising the following steps of: grinding the low-grade beryllium ore, pelletizing, drying, roasting, and crushing to obtain a roasted material; adding concentrated sulfuric acid, stirring, leaching, and separating to obtain acidified liquid and acidified slag; adding the acidified liquid into the other roasted material, and stirring and leaching to obtain primary steep and primary leaching residue; adding concentrated sulfuric acid into the primary leaching residue, adding water, and stirring and leaching to obtain secondary steep and secondary leaching residue, wherein the acidified liquid is replaced by the secondary steep for recycling; extracting the primary steep by adopting an extracting agent in a volume ratio of phosphors extracting agents: alkanol: kerosene of (25-45):(5-1):(50-70) to obtain a beryllium-loaded organic phase and raffinate; washing the beryllium-loaded organic phase by adopting solution of oxalic acid, and performing back extraction by using solution of NaOH to obtain a blank organic phase and stripping solution; and regulating the concentration of hydroxyl ions in the stripping solution to ensure that beryllium is hydrolyzed and precipitated, and calcining a precipitate to obtain the beryllium oxide. The method is easy to operate, the cost is low, the beryllium oxide with the content of over 97 percent is obtained, and the recovery rate of the beryllium is about 80 percent. The method is suitable for extracting the beryllium oxide from low-grade beryllium ore with low BeO content and high CaF2 content.

Owner:广东省资源综合利用研究所

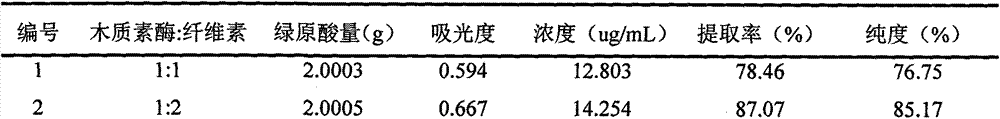

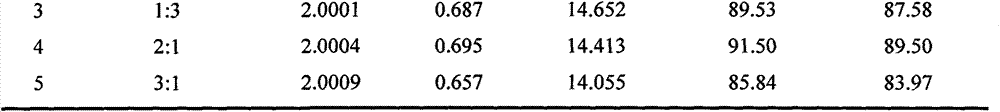

Method for extracting chlorogenic acid from Lonicera japonica leaves activated under catalysis of enzyme

InactiveCN103086889AImprove permeabilityReduce mass transfer resistanceCarboxylic acid esters separation/purificationChemistryDigestion

The invention discloses a method for extracting chlorogenic acid from Lonicera japonica leaves activated under catalysis of enzyme, belonging to the technical field of chlorogenic acid extraction. According to the method, the solid waste of Lonicera japonica leaves, used as raw material, is prepared into the target product by the simple processes of treatment on Lonicera japonica leaves, enzymatic hydrolysis, ultrasonic wave synergistic digestion and chlorogenic acid preparation. The raw material used in the method provided by the invention is cheap and easily available, and the method has the characteristics that the waste is fully used, the prepared chlorogenic acid product is high in extraction ratio and purity and complete in biological activity, energy consumption in production process is low, the production equipment is hardly corroded, the consumption of organic solvent is low, environment protection is facilitated, and so on. The method provided by the invention can be widely used for extracting natural products, such as chlorogenic acid, isochlorogenic acid and Ginnol, from the solid waste of Lonicera japonica leaves, and effectively realizes the resource utilization of the Lonicera japonica leaves.

Owner:王星敏

Tellurobismuthite leaching method

InactiveCN106987706AFully leachedSimple processSelenium/tellurium compundsProcess efficiency improvementIndustrial scaleMaterials science

The invention discloses a tellurobismuthite leaching method. The method comprises the steps that crude tellurobismuthite is subjected to crushing treatment, and grinding is conducted to enable the particle size to meet the requirement that 90% of ore powder can pass through a 200-mesh sieve; treated tellurobismuthite is put into a roasting furnace, roasting is conducted for 4 h to 6 h at the temperature ranging from 400 DEG C to 450 DEG C, and tellurobismuthite subjected to roasting is collected; grinding is continuously conducted to enable the particle size to meet the requirement that 90% of ore powder can pass through the 200-mesh sieve, pretreated tellurobismuthite is put into a sulfuric acid medium, ozone with the concentration ranging from 10 mg / h to 50 mg / h is introduced, an appropriate amount of surfactant is added, leaching is conducted at 70 DEG C to 80 DEG C, and leachate is obtained, wherein 100 r / min to 200 r / min mechanical stirring is conducted in the leaching process, and the leaching stirring time ranges from 3 h to 4 h. According to the tellurobismuthite leaching method, the technological process is simple, operation is convenient, no special equipment requirement exists, the cost is low, the method is suitable for industrial scale production, the leaching rate of tellurium is 98% or above, the leaching rate of bismuth is 97% or above, and tellurium and bismuth in tellurobismuthite are fully leached; meanwhile, leached leachate provides a good condition for extraction of downstream tellurium and bismuth.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

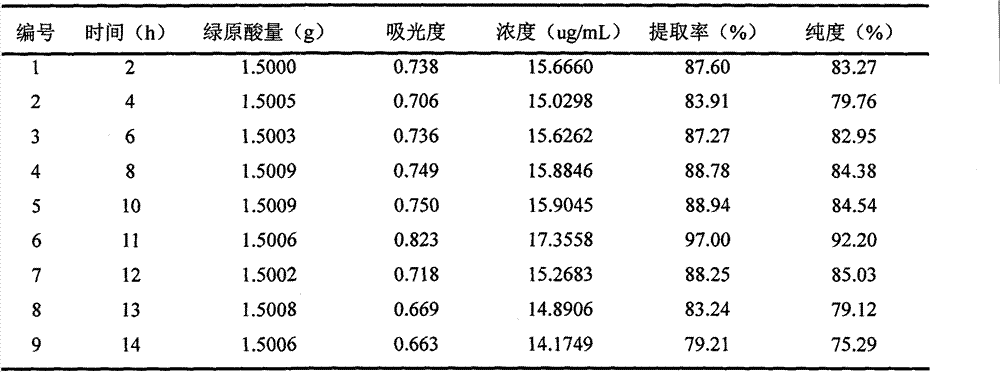

Production method and product of structured flexible conductive porous material

InactiveCN106750500AControllable pore sizeHigh porosity interconnection ratePorosityConductive materials

The invention discloses a preparation method of a structured flexible conductive porous material. The preparation method comprises the following steps: designing a structured mold according to the real requirement; successively adding filling particles and polydimethylsiloxane prepolymer into the mold, and preparing a flexible porous material with a structured appearance; and rapidly and sufficiently filling the structured flexible porous material with a conductive material to obtain the structured flexible conductive porous material. The invention also discloses a structured flexible conductive porous material prepared by using the method. The preparation method integrates the technologies such as structured molding, grading and screening of the filling particles, surface trace fusion curing and negative-pressure permeation promotion of the filling particles and the like, so that the prepared flexible conductive porous material has the structured appearance, a porosity of the flexible porous material is controllable, the pore interconnection rate is relatively high, the filling particle is sufficient to leach, and the overall preparation speed is increased by two to three times compared with the traditional method.

Owner:HUAZHONG UNIV OF SCI & TECH

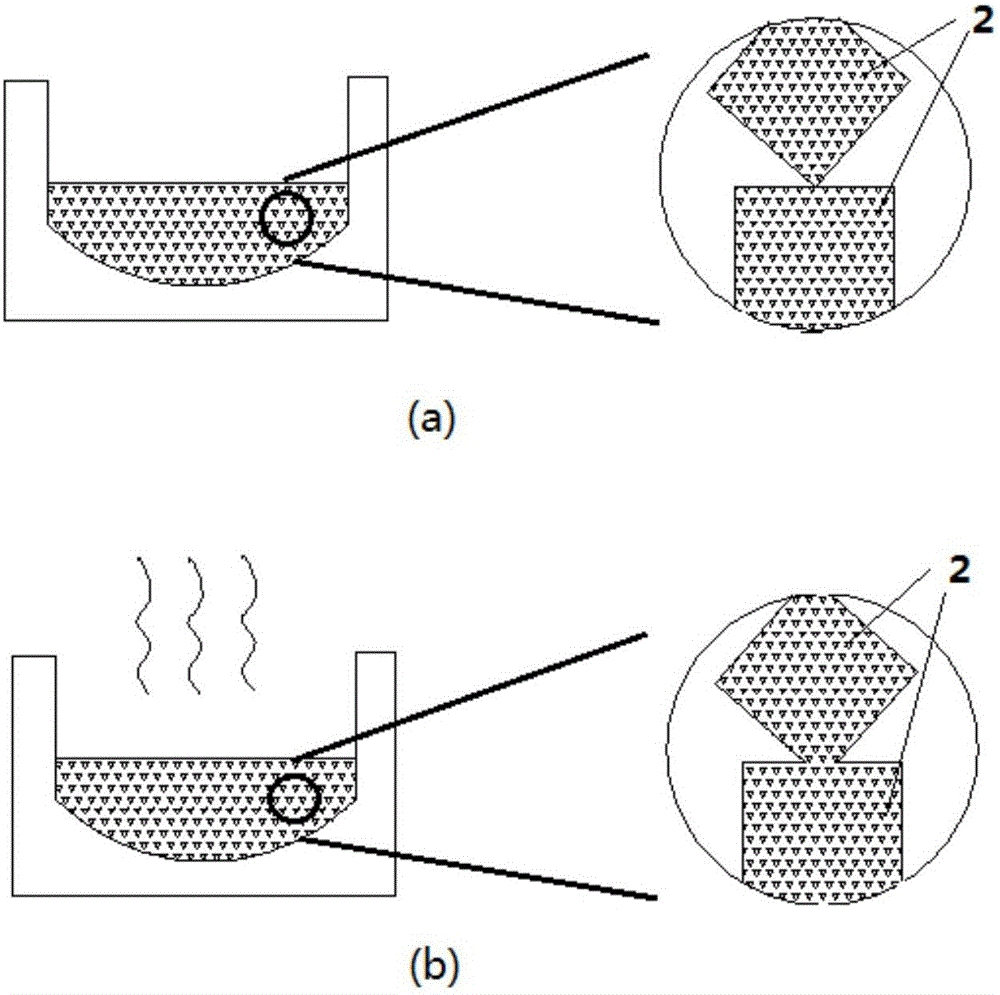

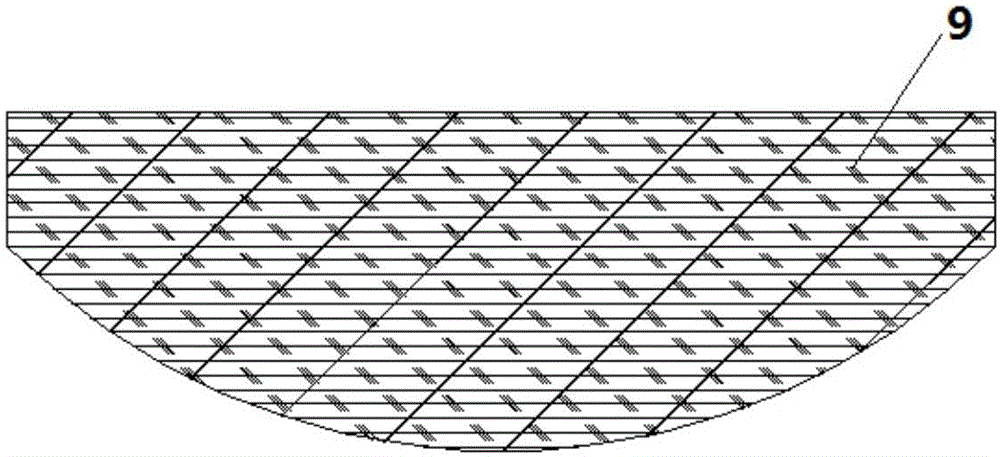

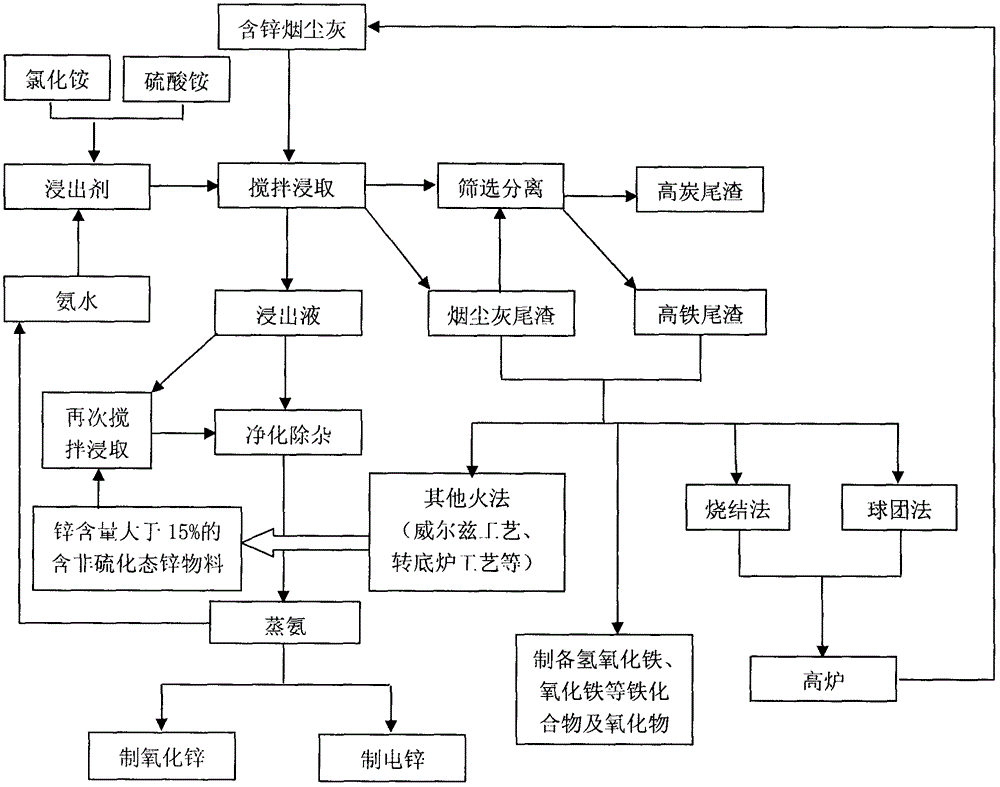

Utilizing method of zinc-containing dust ash of steel plant

InactiveCN106119556AIncrease concentrationSolve the problem of continuous enrichmentPhotography auxillary processesZinc oxides/hydroxidesEnvironmental resistanceAmmonia

The invention relates to a utilizing method for producing zinc oxide products by utilizing zinc-containing dust ash of a steel plant and recycling ferric carbon for returning to smelting. Zinc in the dust ash is leached by use of an ammonia method; materials which have the zinc content greater than 15% and contain non-vulcanized zinc are added for increasing the concentration of a zinc solution; leachate is purified, cleaned and subjected to ammonia distilling, and zinc oxide is prepared after electrolytic zinc preparation or zinc deposition; and original dust ash tailings or screened dust ash tailings are sent into a blast furnace for smelting, or a conventional pyrogenic process is adopted for recycling ferric carbon from the original dust ash tailings or the screened dust ash tailings, and collected secondary zinc oxide dust ash is used for the front end leaching, so that the zinc concentration of the leachate is increased. The utilizing method can be applicable to dust ash, with the zinc content as lower as 4% or even lower, of the steel plant; by use of a conventional method, the zinc extraction rate and the removing rate of harmful substances including alkali metal, fluorine and chlorine are both above 90%; the dust ash tailing recovery process is high in equipment adaptability, and appropriate treatment processes can be chosen according to existing equipment; and efficiency is high, the environment is protected, and comprehensive cyclic utilization of the zinc-containing dust ash is achieved.

Owner:李果

Red raspberry complex fruit wine and preparing method thereof

InactiveCN106350418ASignificantly protects eyesightRelieve eye fatigueSenses disorderAlcoholic beverage preparationAdditive ingredientSemen

The invention relates to the technical field of food processing and particularly relates to red raspberry complex fruit wine and a preparing method thereof. The complex fruit wine is prepared from the following effective ingredients: 200-300 parts of red raspberry, 100-200 parts of black raspberry, 20-40 parts of sea buckthorn fruit, 20-40 parts of blueberry, 20-40 parts of bilberry fruit, 10-15 parts of Lycium ruthenicum, 10-15 parts of mulberry leaves, 10-15 parts of carrots, 10-15 parts of jujubes, 5-10 parts of green tea, and 5-10 parts of semen cassiae. With synergistic effect of nutritional ingredients in all raw materials, the red raspberry complex fruit wine has the function of obviously protecting eye vision, relieving visual fatigue and enhancing immunity. In the preparing method, the quality of fruit wine is improved by controlling fermentation and enzyme hydrolysis and extracting effective ingredients, and the fruit wine is aromatic in fragrance and appropriately sweet and sour in taste and perfectly bright red in color.

Owner:LIFE FRUIT ORGANIC FOOD

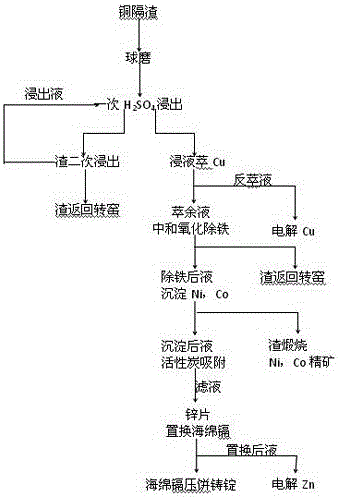

Method for recovering Cu, Cd, Ni, Co and Zn from copper-cadmium slag

ActiveCN105018738AReduce consumptionRaise the gradePhotography auxillary processesProcess efficiency improvementThree levelKerosene

The invention provides a method for recovering Cu, Cd, Ni, Co and Zn from copper-cadmium slag. The copper-cadmium slag is subjected to two times of oxidizing acid leaching, and Cu is extracted from leach liquor; after Fe in raffinate is removed through neutralization oxidation, Ni and Co are precipitated through cobalt purification reagents, and Co and Ni concentrate is obtained through calcinations; after liquor obtained after Co precipitation is subjected to activated carbon adsorption, an electrolytic metal zinc plate is used for replacing spongy cadmium, and a metal cadmium ingot is obtained through melting; and liquor after replacement is delivered to a zinc electrolyzing system. H2SO4 leaching is adopted during the two times of oxidizing acid leaching, and the final PH value after the first time of oxidizing acid leaching is 2 to 3; in the second time of oxidizing acid leaching, the concentration is 50-100 g / L, time is 2 hours, and an oxidizing agent is MnO2 of 5-10% or H2O2 of 5-10%; extraction agents of copper are Cp180 of 20-40% and kerosene of 60-80%, the extraction PH value is 2 to 3, the concentration of reverse extraction H2SO4 is 250-300 g / L, and three levels of extraction, two levels of reverse extraction and two levels of regeneration from washing are carried out; the amount of the cobalt purification reagents is 1.2-1.4 times the sum of the content of Co and the content of Ni, and the temperature ranges from 50 DEG C to 60 DEG C; the replacement PH value of the spongy cadmium is 3 to 4, and the temperature ranges from 40 DEG C to 50 DEG C. According to the method, the process is short, and the recovery rate is high.

Owner:六盘水中联工贸实业有限公司

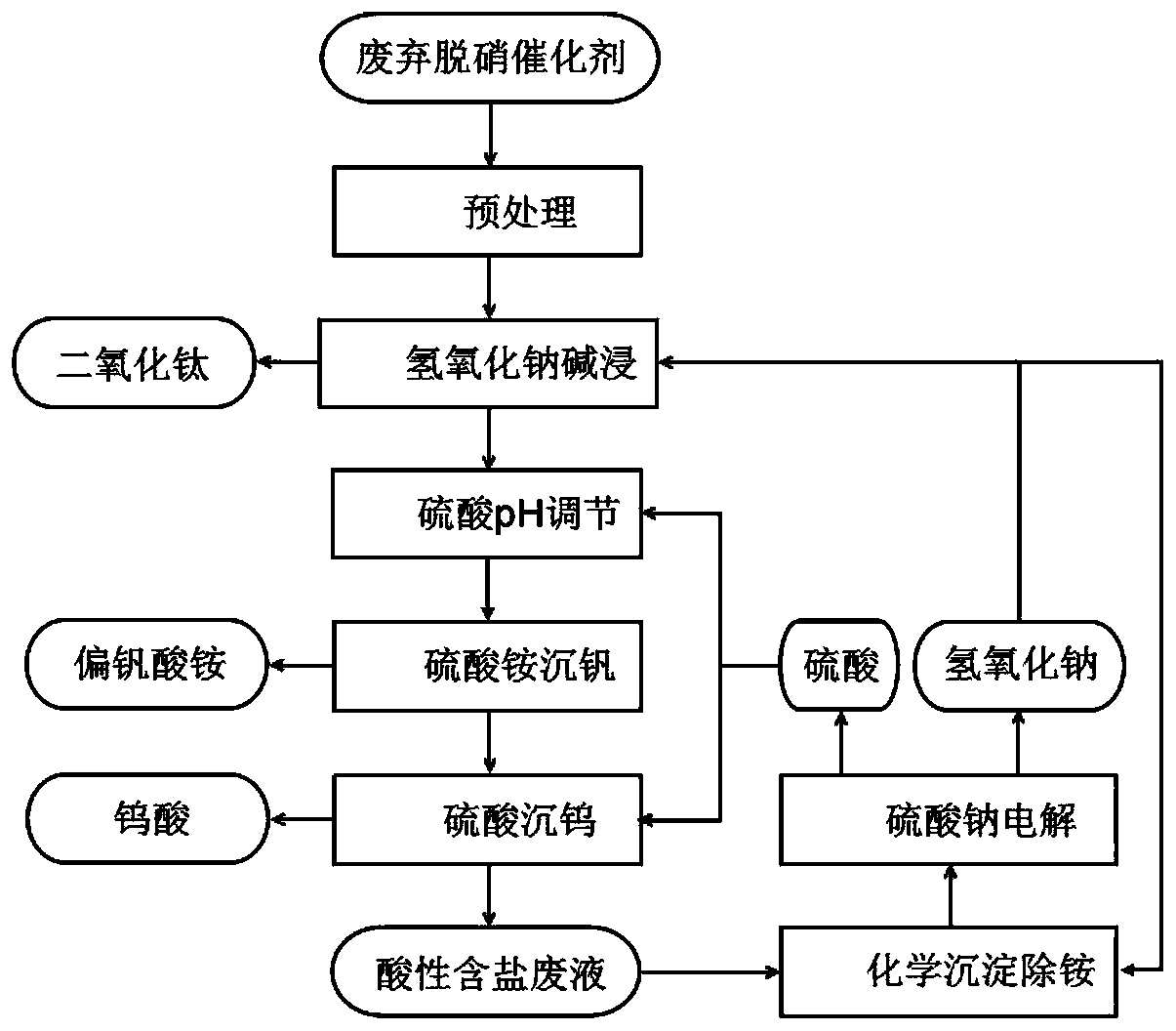

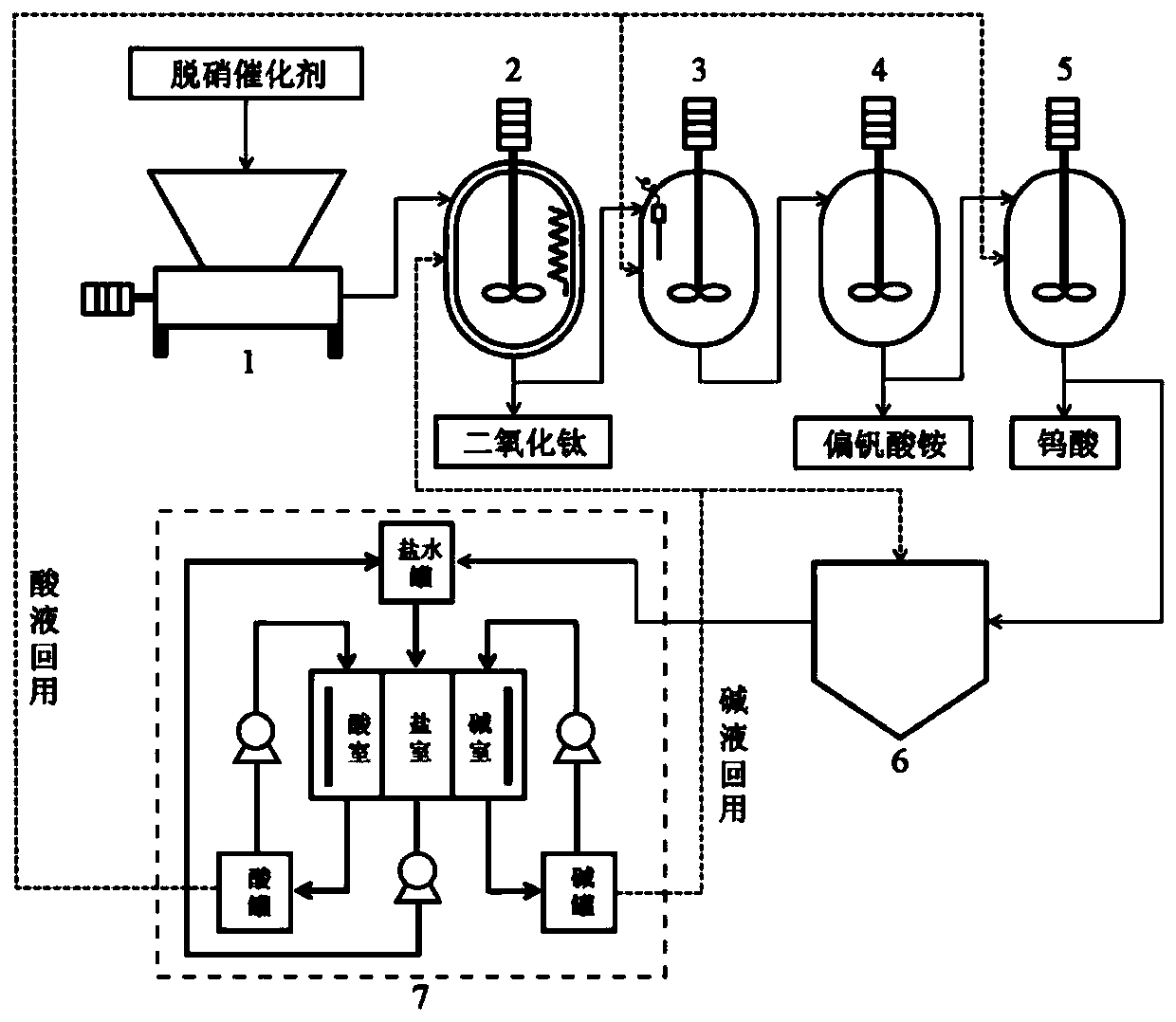

System and method for resource recycling of vanadium-titanium-tungsten series denitration catalysts and water recycling use

PendingCN110117722AImprove recycling efficiencyReduce waste water generationElectrolysis componentsMultistage water/sewage treatmentAmmonium sulfateChemistry

The invention provides a method for resource recycling of vanadium-titanium-tungsten series denitration catalysts and water recycling use. The method for resource recycling of the vanadium-titanium-tungsten series denitration catalysts and water recycling use comprises the step that after alkali liquid titanium-removing reaction, acid liquid impurity-removing, ammonium sulfate vanadium precipitation and sulfuric acid tungsten precipitation reaction are conducted on catalyst powder and a filtered liquid acquired is electrolyzed, sulfuric acid and alkaline liquid are recycled and utilized. The invention further discloses a system applicable to the method. The system comprises a preprocessing unit, an alkaline leaching unit, a pH adjustment unit, an ammonium sulfate vanadium precipitation unit, a sulfuric acid tungsten precipitation unit, a chemical precipitation ammonium-removing unit and a sodium sulfate electrolysis unit which are sequentially connected. The acid liquor outlet of the sodium sulfate electrolysis unit is connected with the pH adjustment unit and the sulfuric acid tungsten precipitation unit. The alkaline liquid outlet of the sodium sulfate electrolysis unit is connected with the alkaline leaching unit and the chemical precipitation ammonium-removing unit. With a resource recycling technology of the denitration catalysts and a saliferous waste water processing recycling technology combined, saliferous waste water generated in the production process can be utilized cyclically, and generation of waste water is reduced so that the resource recycling process of the catalysts is more environmentally-friendly.

Owner:HUANENG CLEAN ENERGY RES INST

Method for increasing dissolution rate of water extracted tea saponin

ActiveCN107556359AHigh dissolution rateImprove leaching effectNon-ionic surface-active compoundsSugar derivativesCamellia oleiferaResource utilization

The invention discloses a method for increasing a dissolution rate of water extracted tea saponin, which belongs to the technical field of further processing of agricultural and sideline product leftovers. According to a extraction method disclosed by the invention, the tea saponin in a tea seed meal residue phase is extracted in different stages, so that compared with an ethanol water extractionmethod, the cost for utilizing ethanol is decreased, and the method has the advantages of simple process, no pollution, high resource utilization rate, high product yield and the like. The tea saponinobtained by utilizing the method is high in dissolution rate which is higher than that of a water extraction effect without adding sodium carbonate. The tea saponin in the camellia seed meal residuephase is sufficiently extracted by adopting the method disclosed by the invention. The product additional value is increased, the cost is decreased, and the economic benefit is increased.

Owner:JIANGNAN UNIV

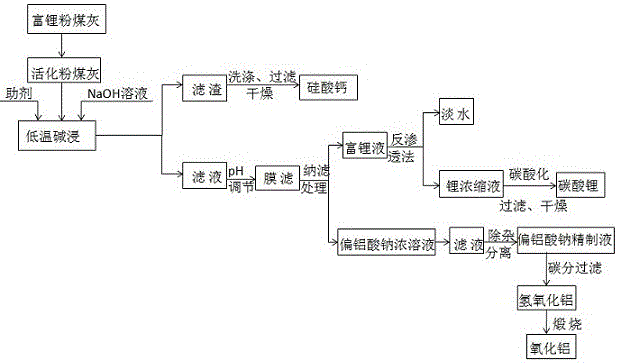

Method for separating and enriching lithium, aluminum and silicon from fly ash

ActiveCN106745016AEasy to recycleImprove leaching rateAlkaline-earth metal silicatesLithium carbonates/bicarbonatesCalcium silicateReverse osmosis

The invention discloses a method for separating and enriching lithium, aluminum and silicon from fly ash. The method comprises the following steps: (1) pretreating fly ash; (2) carrying out low-temperature alkali dip reaction on the treated fly ash, aids and a sodium hydroxide solution, and filtering; (3) washing the filter residue, removing the impurities, filtering, and drying to obtain calcium silicate; (4) regulating the pH value of the filtrate to alkalinity, separating the lithium / aluminum-containing filtrate to obtain a sodium metaaluminate concentrated solution and a lithium-rich solution, carrying out reverse osmosis on the lithium-rich solution to obtain a lithium concentrated solution, and mixing the sodium metaaluminate concentrated solution with the lithium / aluminum-containing filtrate to obtain a refined solution; (5) precipitating the sodium metaaluminate refined solution, filtering to obtain aluminum hydroxide, and calcining to obtain the aluminum oxide finished product; (6) treating the lithium-rich solution to obtain a lithium-rich concentrated solution and fresh water; and (7) carrying out carbonating precipitation on the lithium-rich concentrated solution, filtering, and drying to obtain the lithium carbonate finished product. The method is a short-stage extraction process, reduces the lithium loss, and implements separation, enrichment and extraction of calcium silicate, aluminum oxide and lithium carbonate.

Owner:HEBEI UNIV OF ENG

Method for processing phosphate rock tailings

ActiveCN106315530APromote decompositionFully leachedCalcium/strontium/barium carbonatesMagnesium carbonatesEcological environmentPhosphorite

The invention relates to a method for processing phosphate rock tailings. According to the invention, the phosphate rock tailing pre-treated by sulfuric acid is processed through calcination digestion, then a processing mode with two-step leaching is used, a magnesium element in the phosphate tailing is fully separated, and the phosphate tailing quality is enhanced. Waste liquid and waste gas which are generated in the process are recycled, a treated solvent is reused, a filtrate is subsequently processed while the high-quality phosphate rock is obtained, the obtained calcium and magnesium are effectively recycled, discharge of the waste liquid and the waste gas is avoided, tailings are prevented from accumulating, and therefore, the ecological environment is improved.

Owner:铜仁市万山区盛和矿业有限责任公司

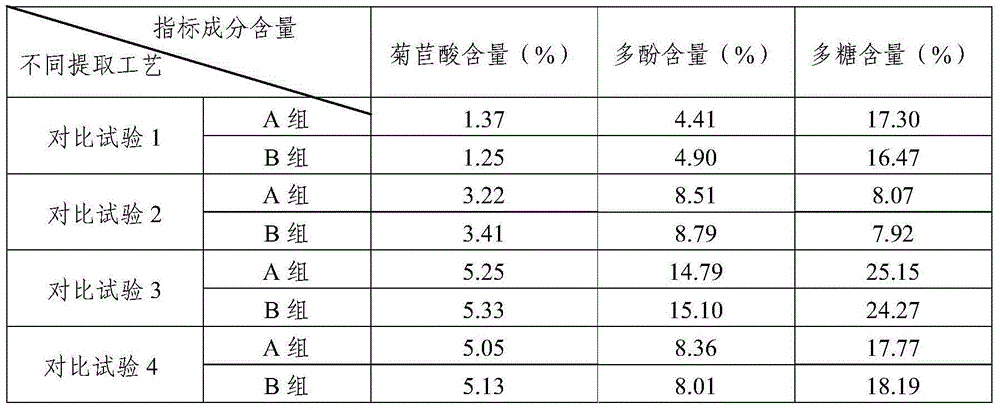

Echinacea extract product, preparation method and application thereof

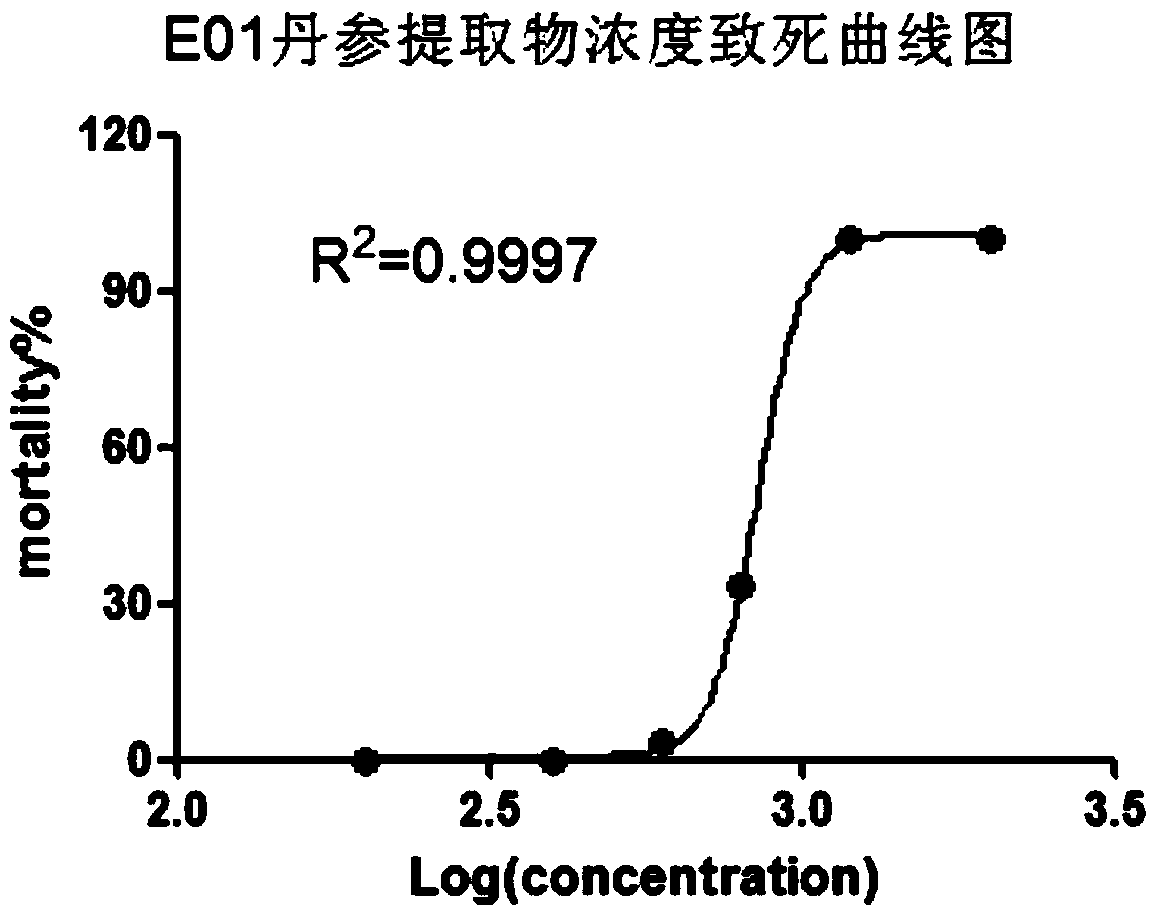

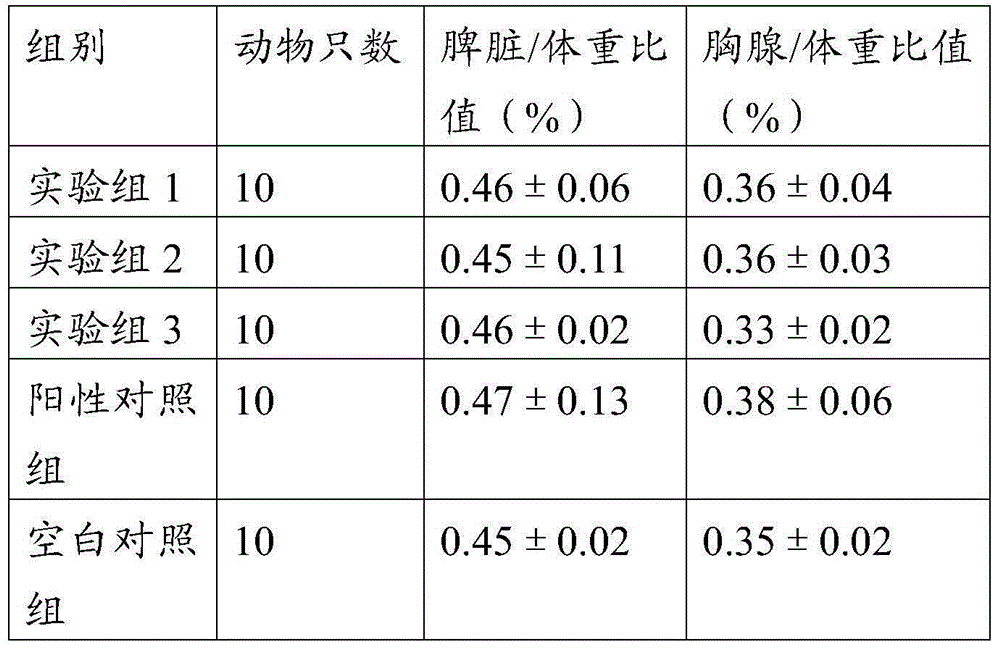

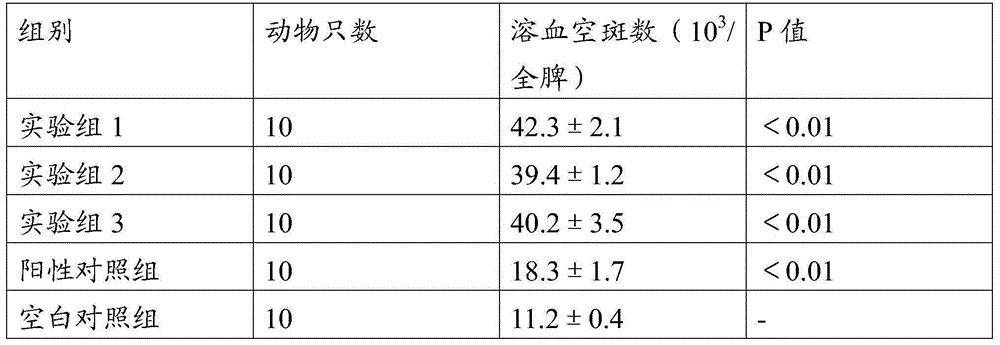

ActiveCN104127463AEasy to leachGuaranteed spatial structureAntipyreticAnalgesicsHemolysinHumoral immunity

The invention relates to an echinacea extract product, a preparation method and an application, the extract product comprises the following components by weight percentage: content of phenolic compounds is higher than 12%, content of Echinacea polysaccharide is higher than 20%, and chicoric acid content is higher than 4%. The extract product has obvious promotion effect to the generation of mice hemolysin antibody, the echinacea extract product can enhance humoral immunity, and the effect of the echinacea extract product is better than that of the prior art.

Owner:QINGDAO KDN BIOTECH +1

Method for rapidly determining soil available phosphate

ActiveCN105300979ASimple measurement stepsImprove work efficiencyMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationOptical pathEdaphic

The invention relates to a method for rapidly determining soil available phosphate, which is suitable for neutral and lime soil. The method comprises the following steps: 1) extraction: weighing a certain amount of a soil sample, adding phosphorus-free active carbon, adding a NaHCO3 aqueous solution with concentration being 0.6 mol / L, oscillating for 3-5 minutes, filtering a mixture; 2) colorimetric reaction: respectively taking a blank control solution, an phosphor standard solution and a liquid to-be-measured, respectively adding a soil available phosphate developer and a soil available phosphate reducing agent, standing the solution; and 3) colorimetric determination: adjusting an optical path wavelength of a photometer or a photoelectric colorimeter to 700 nm, performing colorimetric determination, and calculating or reading the available phosphate content in a soil sample to-be-measured. On base of rapid determination, the reagent stability is good, the quantity is less, the preservation period is long, the operating method is simple, the cost is low, and the method is suitable for neutral and lime soil.

Owner:郑州欧柯奇仪器制造有限公司

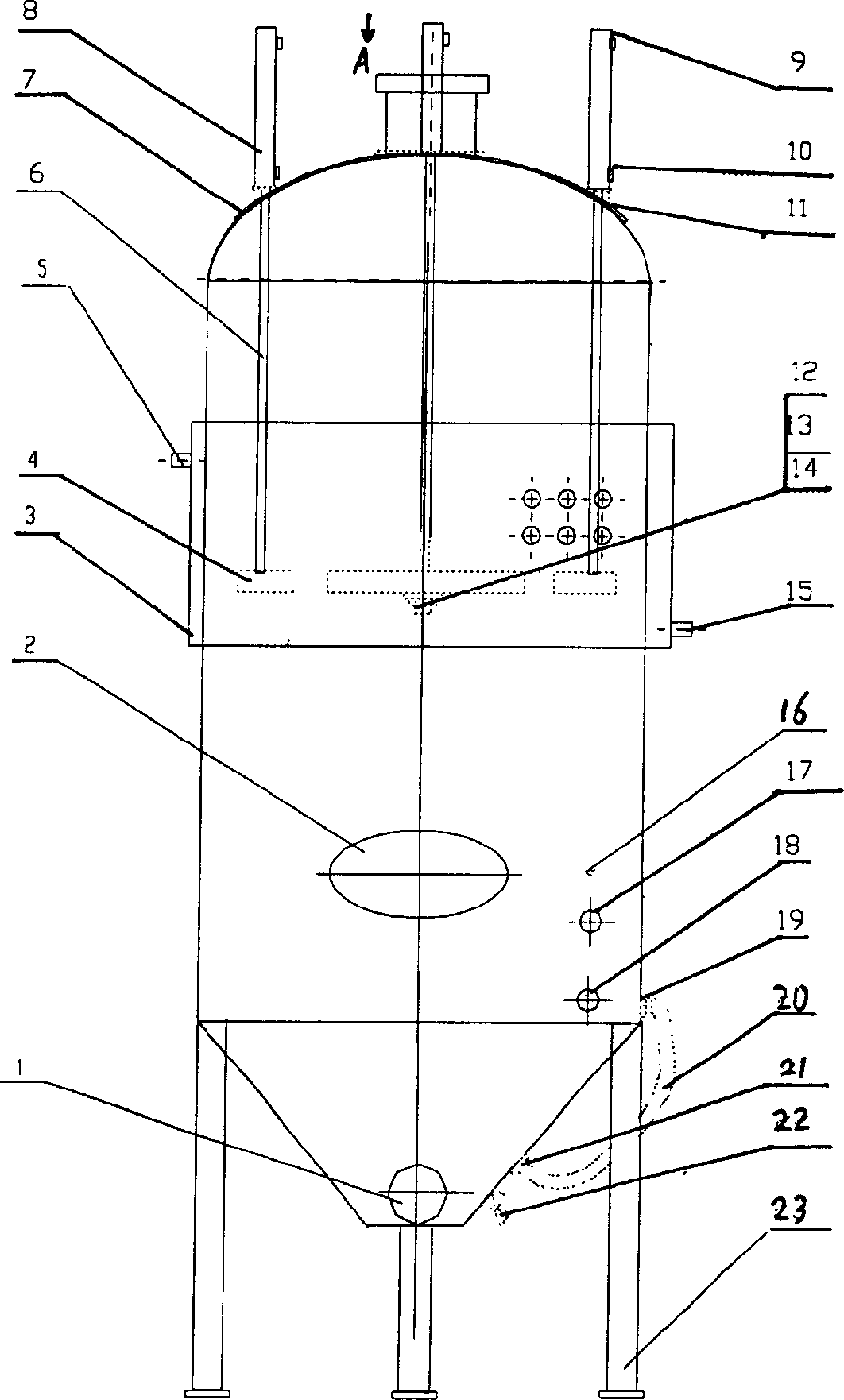

Fermentation tank of dry red winew ith press function and fruit seed discharge during fermentation process

InactiveCN1680524AImprove impregnation effectFully leachedWine preparationPulp and paper industryFermentation

Owner:NORTHWEST A & F UNIV

Tea seed processing method

InactiveCN101974365ALow in benzo(α)pyreneImprove adsorption capacitySugar derivativesFatty-oils/fats refiningTriple effectChemistry

The invention provides a tea seed processing method which comprises the following steps of: firstly, pulverizing tea seeds into powder with particles of 100-120 meshes; carrying out rough processing to obtain crude oil; primarily filtering and de-gumming; and then detecting the content of benzo (alpha) pyrene of the crude oil; placing active carbon into a decoloring pan according to the weight ratio of the crude oil to the active carbon of 1,000:1 when the content of the benzo (alpha) pyrene is in the range of 10-2ug / kg; heating and stirring to decolor; deodorizing, filtering and polishing to produce product oil; leaching tea seed dregs with ethanol to obtain a tea saponin leaching solution; carrying out triple-effect concentration to obtain a crude tea saponin product; and refining and sub-packaging obtained refined tea saponin to obtain a finished product of the tea saponin. By the tea seed processing method, because tea oil is extracted from the tea seeds, the transparency of the product oil can be enhanced, the nutrient loss of the obtained product oil is less, and the product oil has higher nutritive value; and because the tea saponin is prepared from the tea seed dregs, the utilization efficiency of the raw material is fully improved.

Owner:ANHUI LONGMIANSHAN FOOD

New extraction method of agaricus bisporus polysaccharide

The invention provides an extraction method of agaricus bisporus polysaccharides, comprising the following steps of: carrying out pretreatments, i.e. rinsing, cooking, grinding, pulp refining, homogenizing, and the like, and then carrying out enzyme reaction and extracting; then removing proteins; precipitating the agaricus bisporus polysaccharides under the action of ethanol; and freeze-drying to obtain the agaricus bisporus polysaccharides. The method has simplified process and low cost and is easy for industrialized production.

Owner:宜昌益农科技开发有限公司

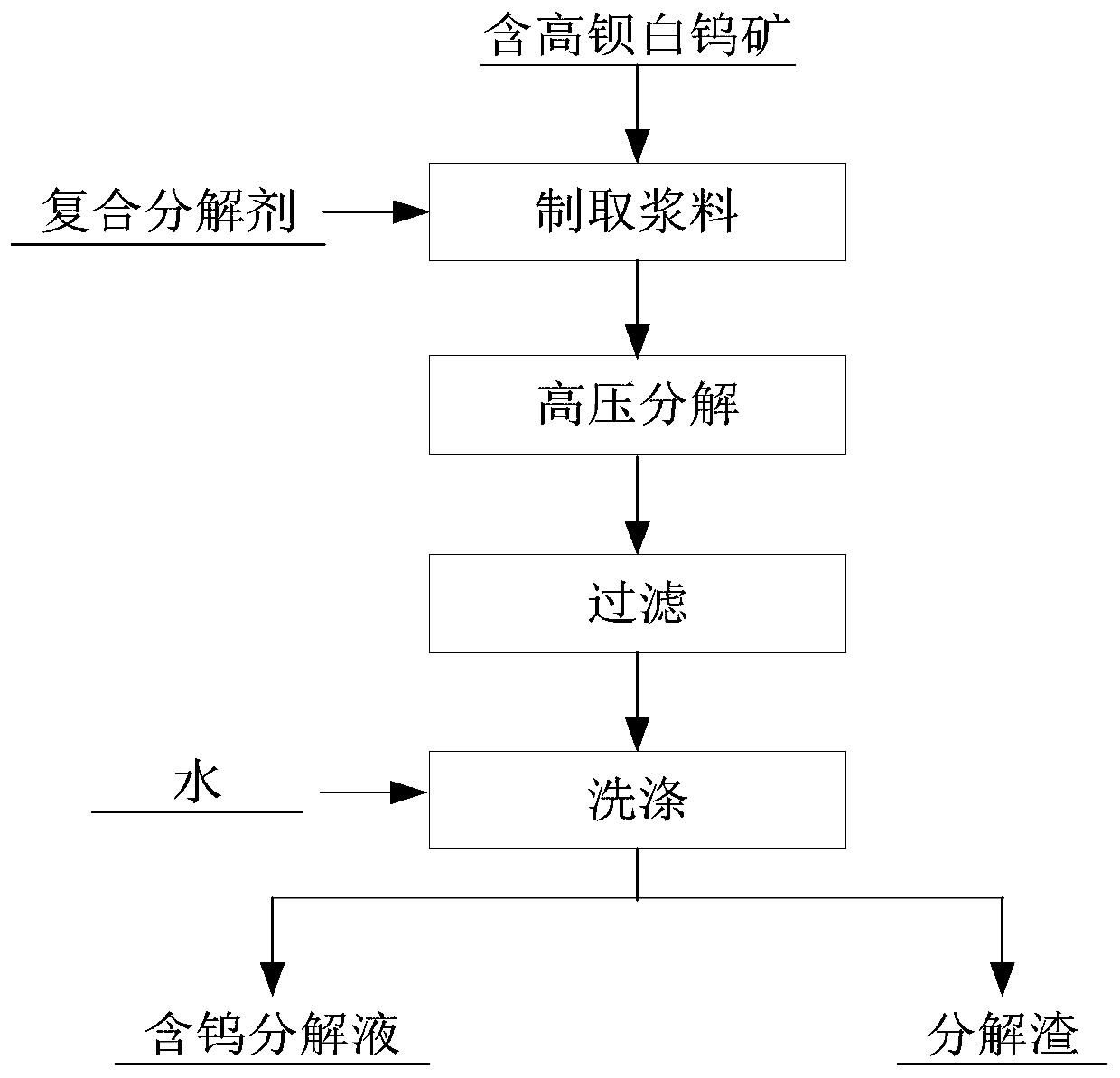

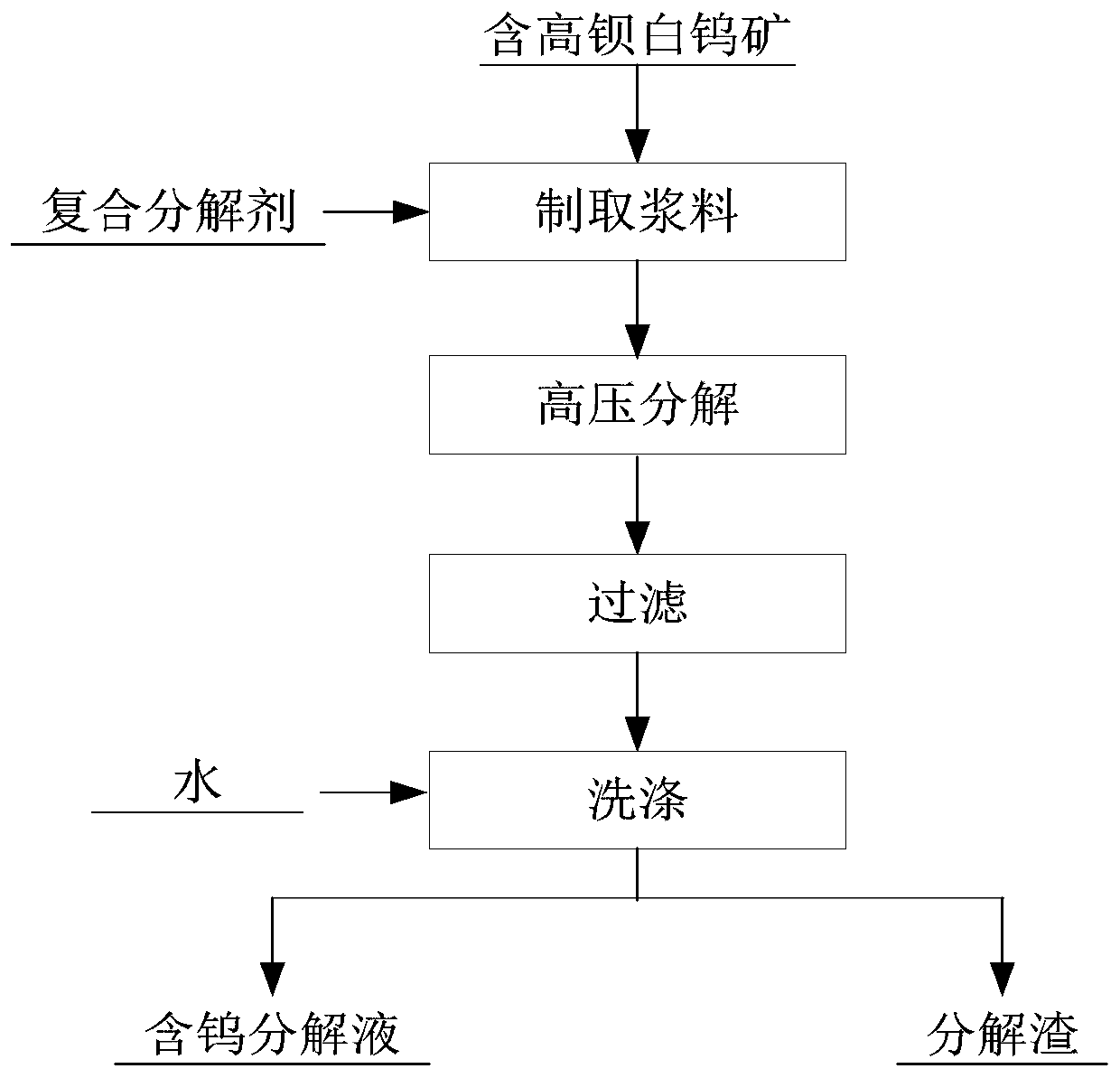

Scheelite decomposing agent and method for extracting tungsten from scheelite through same

ActiveCN110042232AImprove decomposition rateImprove leaching rateProcess efficiency improvementSlagSodium nitrate

The invention provides a scheelite decomposing agent. The scheelite decomposing agent comprises sodium nitrate, sodium hydroxide and sodium carbonate. The invention further provides a method for extracting the tungsten from the scheelite. The method comprises the following steps of S1, mixing the scheelite with the scheelite decomposing agent to prepare a thick liquid; S2, carrying out decomposition reaction on the scheelite and the scheelite decomposing agent to obtain a decomposed thick liquid; S3, filtering and separating the decomposed thick liquid to obtain a tungsten decomposition liquidand decomposition slag. According to the scheelite decomposing agent and the method, a mixture of sodium nitrate, sodium hydroxide and sodium carbonate is adopted as a decomposing agent, the decomposing agent and the scheelite are subjected to decomposition reaction, the three components cooperate with each other to achieve a synergistic effect, the high-barium scheelite can be well decomposed, the decomposition rate is high, the leaching rate of the tungsten is high, the energy consumption is low, and the cost is low.

Owner:JIANGXI UNIV OF SCI & TECH

Black rice wine and preparation method thereof

ActiveCN107988011AFatty acid value risesReduce churnAlcoholic beverage preparationRefrigerationFatty acid

The invention provides black rice wine and a preparation method of the black rice wine. The method comprises the steps of taking coarse black glutinous rice as a raw material, separating chaff powderfrom refined rice for separate treatment in a rice milling procedure, performing refrigeration, jet milling and degreasing to process into degreased superfine chaff powder, performing soaking, microwave irradiation, mixing, beating, steaming and fermentation on the refined rice to form initial rice wine, adding the degreased superfine chaff powder into the initial rice wine, and performing ageingby the action of a fruit body of a mature abalone mushroom to form the black rice wine. Anthocyanin is mainly concentrated in the chaff powder, and not exposed to a high-temperature environment, and the loss of anthocyanin is effectively reduced. The chaff powder is degreased; the refined rice soaked in water is subjected to the microwave irradiation, so that a lipolytic enzyme is destroyed; the rise of a fatty acid value in the refined rice is avoided; the chaff powder and the refined rice are treated separately to avoid acidification in an ageing or fermentation process; and the quality damage of the black rice wine is avoided.

Owner:孝感麻糖米酒有限责任公司

Method for phosphorite processing and calcium and magnesium production

ActiveCN106315529APromote decompositionFully leachedAmmonium carbonates/bicarbonatesMagnesium nitratesEcological environmentPhosphorite

The invention relates to a method for phosphorite processing and calcium and magnesium production. According to the method, mined phosphorite is subjected to calcinations, and slaking is performed, and then, magnesium is thoroughly separated from crude phosphorite by using a two-step-leaching treatment mode, so that the loss of phosphorus pentoxide is effectively avoided while the quality of the phosphorite is improved; waste liquid and exhaust gas resulted from a process are recovered, and a treated solvent is regenerated; in addition, calcium and magnesium products are prepared from a filtrate obtained after high-quality phosphorite is obtained, so that calcium and magnesium are effectively recycled, the emission of the waste liquid and the exhaust gas and the accumulation of tailings are avoided, and the improvement on ecological environment is facilitated.

Owner:铜仁市万山区盛和矿业有限责任公司

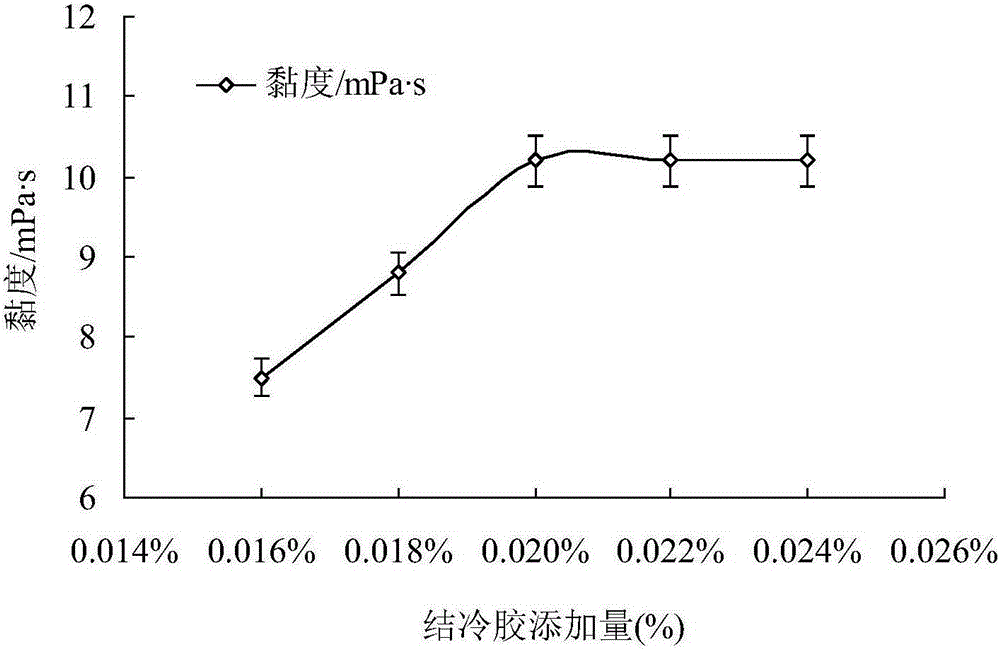

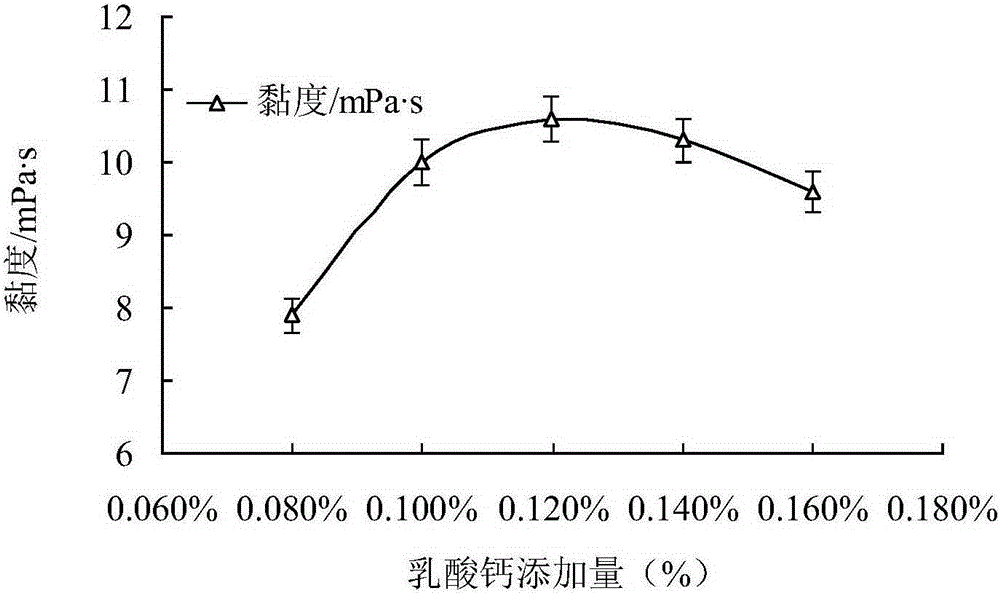

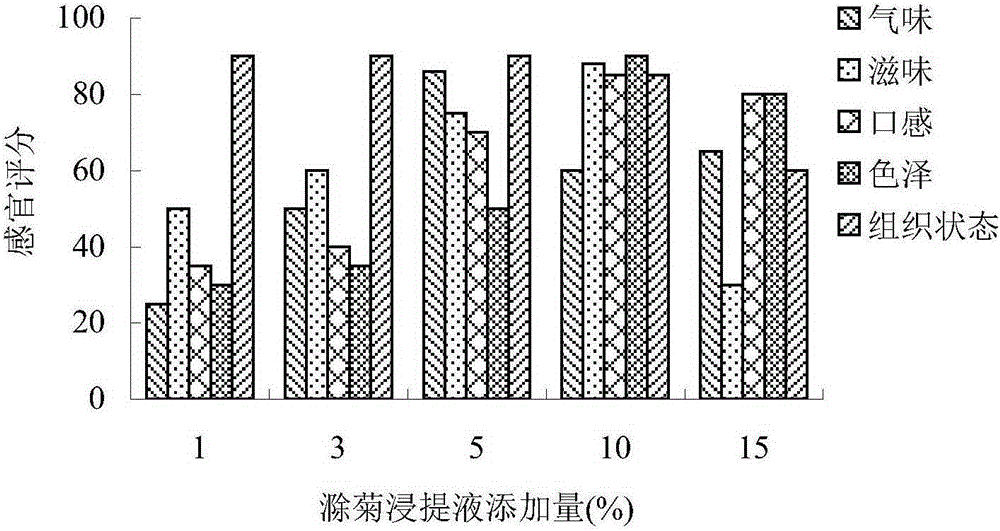

Chuzhou chrysanthemum petal suspension beverage containing galacto-oligosaccharides and preparation method thereof

ActiveCN105167092ASweet tasteImprove functionalityFood ingredient as clouding agentNatural extract food ingredientsAcute hyperglycaemiaAdditive ingredient

The invention discloses a Chuzhou chrysanthemum petal suspension beverage containing galacto-oligosaccharides. A formula of the Chuzhou chrysanthemum petal suspension beverage comprises deionized water, Chuzhou chrysanthemum leaching solutions, Chuzhou chrysanthemum petals, the galacto-oligosaccharides, honey, citric acid and a suspension stabilizer; the suspension stabilizer is prepared from gellan gum, calcium lactate and sodium citrate; the Chuzhou chrysanthemum petals are in a suspension state in the liquid beverage. According to the Chuzhou chrysanthemum petal suspension beverage containing the galacto-oligosaccharides and a preparation method thereof, the compound functional beverage which has the advantages of being low in sugar, fresh and cool in mouthfeel, attractive in appearance and capable of clearing heat and loosening the bowels to relieve constipation is developed by taking the Chuzhou chrysanthemum petals, the galacto-oligosaccharides and the honey as the main raw materials and scientifically matching the three components for the problems that in existing varieties of beverages are generally high in sugar content, not beneficial for digestive system balance if the beverage is drunk for a long term and capable of inducing human health hazards such as hyperglycemia.

Owner:CHUZHOU UNIV

Preparation method of traditional Chinese medicine pellet

ActiveCN104224727AWith hypolipidemicImprove microcirculationOrganic active ingredientsPharmaceutical product form changeMoistureChinese drug

The invention relates to a traditional Chinese medicine pellet which is prepared from traditional Chinese medicine extractives or traditional Chinese medicine extracts and a base pellet according to the weight ratio of (1:5)-(5:1); and the traditional Chinese medicine pellet has the bulk density of 0.6-1.3g / ml, the specific surface area of 0.005-0.05m<2> / g and the particle size of 0.5-1.8mm. The invention also provides a preparation method of the pellet, so that the problems that traditional Chinese medicines or vegetable drugs easily absorb moisture and are unstable are solved; and the preparation method is simple, feasible and suitable for industrial production.

Owner:TIANJIN TASLY PHARMA CO LTD

Roasted Peking duck and preparation process thereof

InactiveCN105105188ACrispy tasteTender meatNatural extract food ingredientsFood ingredient functionsNutritive valuesWhole body

The invention discloses a preparation process of a roasted Peking duck. The preparation process is characterized by comprising the following steps: (1) preparing duck blank, namely, taking a live duck, killing the duck, dressing, removing viscera, cleaning, chopping off duck internal skeleton, cutting open the meat on the legs from the inner sides, and enabling the duck body to be in a plane; (2) blanching, namely, heating water to 85 DEG C to 95 DEG C, blanching the duck body for 3-5 minutes, and then taking out; (3) curing, namely, scattering powder on the duck body, and curing for 60-80 minutes; (4) applying skin finishing water to the duck in a spraying manner or a coating manner; (5) airing, namely, airing at 15-25 DEG C; (6) placing the duck in an oven for baking for 15 min; (7) brushing sauce, namely, taking the duck body with oil coming out due to baking, and coating the whole body with the sauce; (8) placing into the oven for baking for 15 minutes, so that the duck skin becomes orange red; and (9) taking out the baked duck body, and thus preparing the roasted Peking duck. The prepared roasted Peking duck has the distinct flavor, also has the improved nutritive value, and can improve the immunity.

Owner:张滨

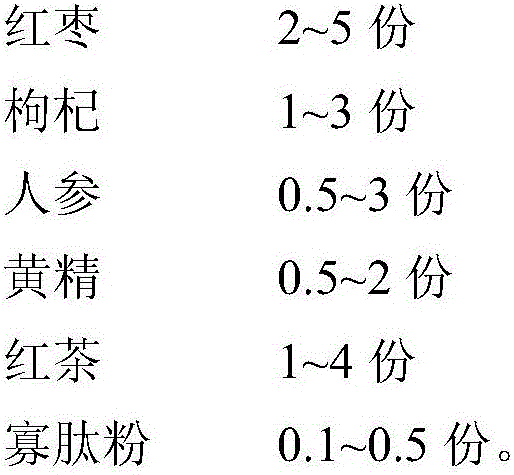

Winter health-preservation tea bag and preparation method thereof

InactiveCN106359712AEnhance immune functionRecovery functionNervous disorderPre-extraction tea treatmentBlack teaBody fluid

The invention belongs to the technical field of food production, and particularly relates to a winter health-preservation tea bag and a preparation method thereof. The winter health-preservation tea bag is prepared from 2-5 parts of red jujubes, 1-3 parts of Chinese wolfberry fruits, 0.5-3 parts of ginseng, 0.5-2 parts of rhizoma polygonati, 1-4 parts of black tea and 0.1-0.5 part of oligopeptide powder. A formula of the winter health-preservation tea bag is matched according to a four-season health-preservation principle and a winter health-preservation principle of traditional Chinese medicines, high-quality raw materials are preferably selected, the ginseng and the rhizoma polygonati are used for nourishing qi and the spleen, the red jujubes are used for nourishing blood, the Chinese wolfberry fruits are used for enriching yin and nourishing the kidney, the black tea is used for warming and tonifying the stomach, and besides, the oligopeptide powder is added, so that the immunity of organisms is enhanced, when people drinks the winter health-preservation tea bag for a long time, the effects of benefitting qi, eliminating fatigue, promoting production of body fluid, soothing nerves, and nourishing the kidney can be achieved, and the health-preservation health-care purposes are achieved.

Owner:南京苏新智慧社区服务有限公司

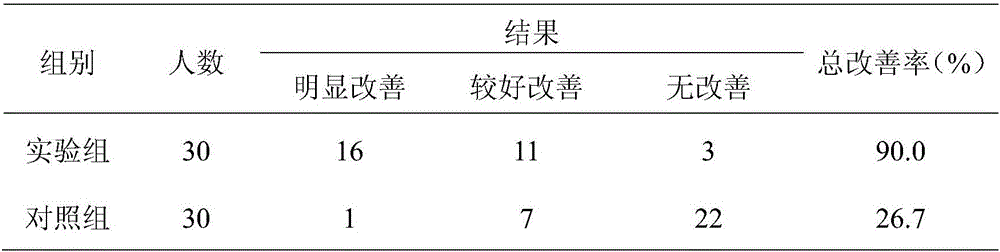

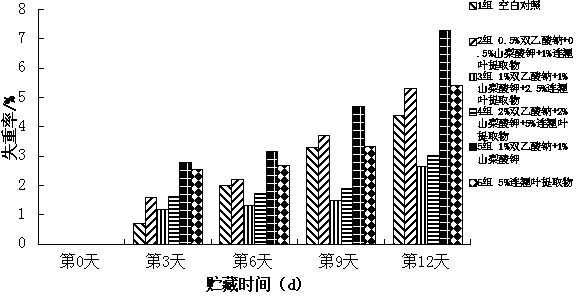

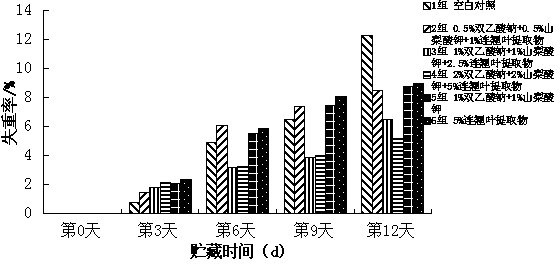

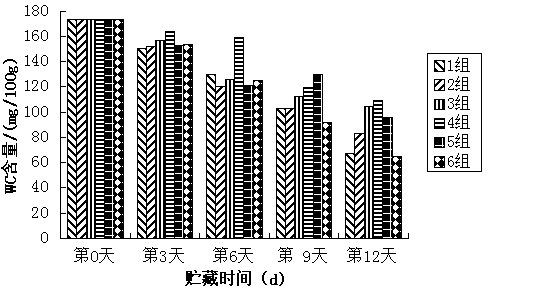

Vegetable fresh-keeping composition containing fructus forsythiae leaf extract and preparation method thereof

InactiveCN104106627AStrong fresh-keeping abilityGood synergyFruit and vegetables preservationBiotechnologyNatural product

The invention discloses a vegetable fresh-keeping composition containing fructus forsythiae leaf extract. The composition is prepared from the following raw materials by weight: 2.5 parts of the fructus forsythiae leaf extract, 1 part of sodium dehydroacetate and 1 part of potassium sorbate. A preparation method for the composition has the advantages of simple operation, mild process conditions, high separation efficiency, a high utilization rate of fructus forsythiae leaves, high purity and good quality of a finished product and capacity of meeting needs of industrial large-scale production. According to results of activity tests of the composition in assistant preservation and fresh-keeping of vegetable, the composition has substantial preservative and fresh-keeping capability and presents a strong fresh-keeping effect and an obvious synergistic effect compared with a natural preservative and a chemical preservative which are individually used. Since the composition is prepared by compounding the fructus forsythiae leaf extract which is used as a natural product and a chemical preservative, the composition provided by the invention has higher security and wide development and application prospects compared with artificially synthesized preservatives.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com