Method for recovering Cu, Cd, Ni, Co and Zn from copper-cadmium slag

A technology of copper cadmium slag and sponge cadmium, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of inseparability, sponge cadmium is easy to be oxidized or sulfated, etc., to improve quality, low production cost, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

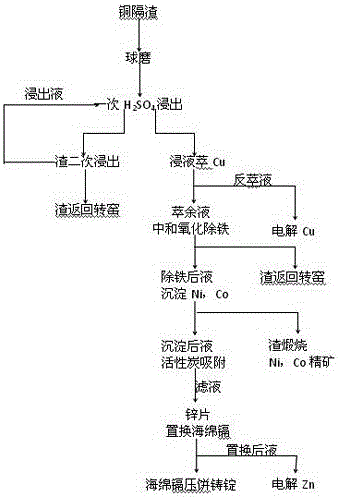

Image

Examples

Embodiment

[0029] Step 1, with H 2 SO 4 At 80~90℃, manganese ore powder 10% or H 2 o 2 5%, liquid / solid=3~4, leaching copper cadmium slag containing 0.57% Cu, 2.32% Cd, 0.19% Ni, 0.044% Co, 45.7% Zn. The leaching time is 2 hours; the pH value of the leaching end point is 2~3. Filter to obtain the leaching solution containing Cu 882mg / L, Cd6955mg / L, Ni366mg / L, Co140mg / L, Zn132g / L, and filter residue with 50g / L H 2 SO 4 , manganese ore powder 5%, at 80~90℃, liquid / solid=3 for the second leaching, the filtrate returns to the first leaching, the average filter residue rate is 6~7%, Cu0.039%, Cd0.19%, Ni0 .0053%, Co0.0023%, Zn4.1%.

[0030] Step 2, use the primary acid leaching solution of step 1 to extract Cu by Cp180, compared with / water=1.5~2, Cp180 30~40%, kerosene 60~70%, three-stage extraction, two-stage 250g / L H 2 SO 4 Stripping, primary 5%NH 4 HCO 3Wash and regenerate. The raffinate contains Cu 3mg / L, and the extraction rate is 99.6%. The back extraction liquid contains Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com