Fermentation tank of dry red winew ith press function and fruit seed discharge during fermentation process

A technology for dry red wine and fermentation tanks, applied in the field of dry red wine fermentation tanks, which can solve problems such as wine taste astringent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

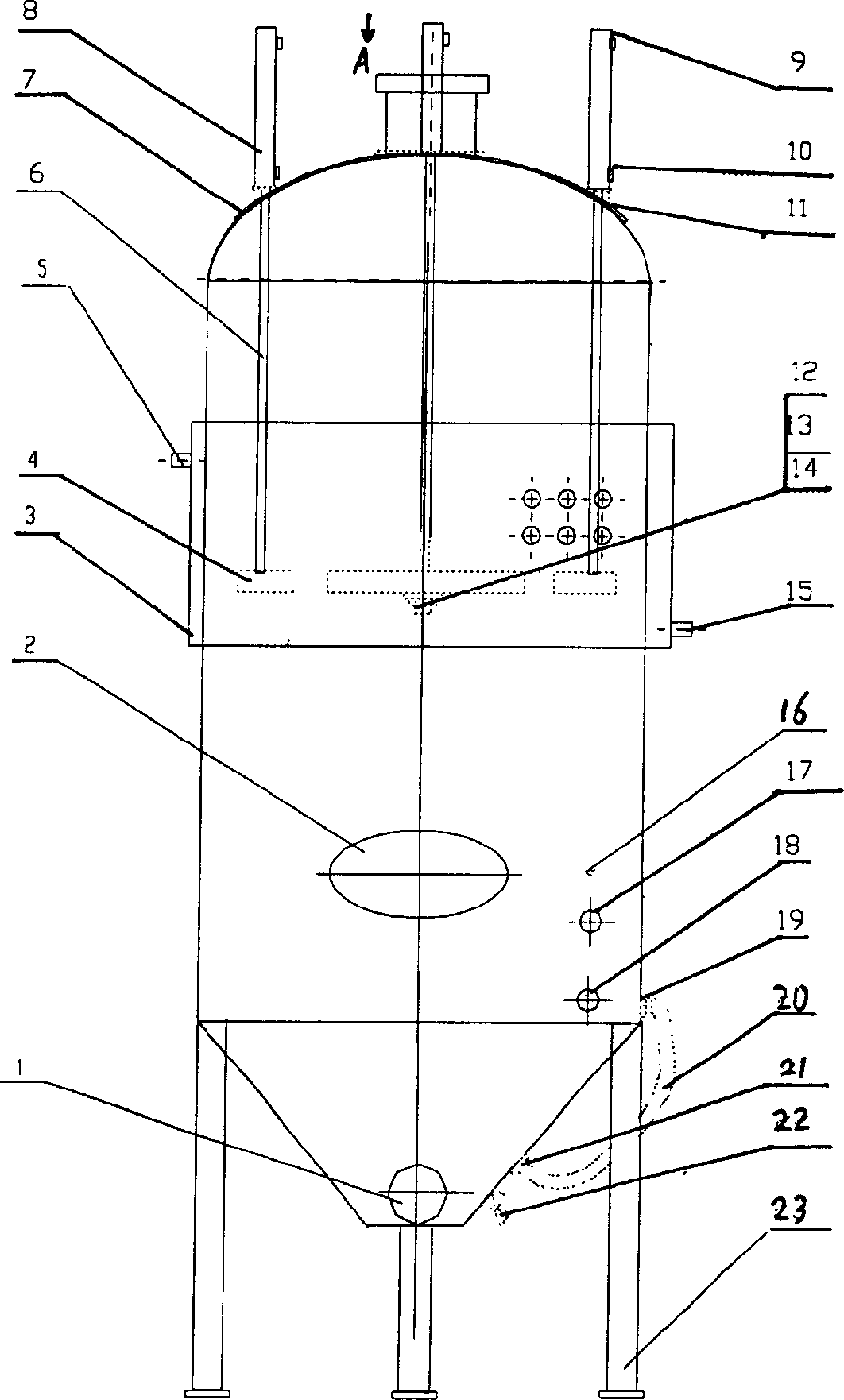

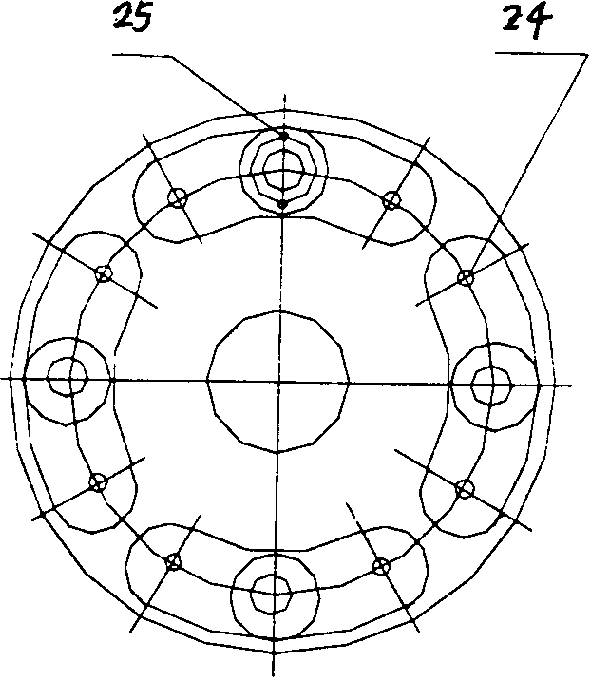

[0023] see figure 1 , figure 2 The difference between the present invention and the general fermenter lies in that four skin pressing cap mechanisms are designed and installed on the entire circumference of the head of the fermenter, and a special seed discharge mechanism is provided on the cone bottom of the tank. 1. Cap pressing mechanism: A crescent-shaped groove is opened on the head of the tank, and the cap pressing mechanism is installed on the crescent-shaped groove on the head through a detachable connection, and the cap pressing mechanism can press the leather cap. After the fermentation season, the capping mechanism can be removed, and the crescent-shaped groove can be resealed with a gasket 11 and a cover plate, and the fermentation tank can still be used as a wine storage tank. The cap pressing mechanism is mainly composed of a piston, a cylinder block 8, a cover plate 7 and a pressing plate 4, etc. A crescent-shaped groove is opened on the head of the fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com