Scheelite decomposing agent and method for extracting tungsten from scheelite through same

A technology of scheelite and decomposing agent, applied in the direction of improving process efficiency, etc., can solve the problems of low tungsten leaching rate, high cost, high energy consumption, etc., and achieve the effects of low cost, inhibition of hydrolysis, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

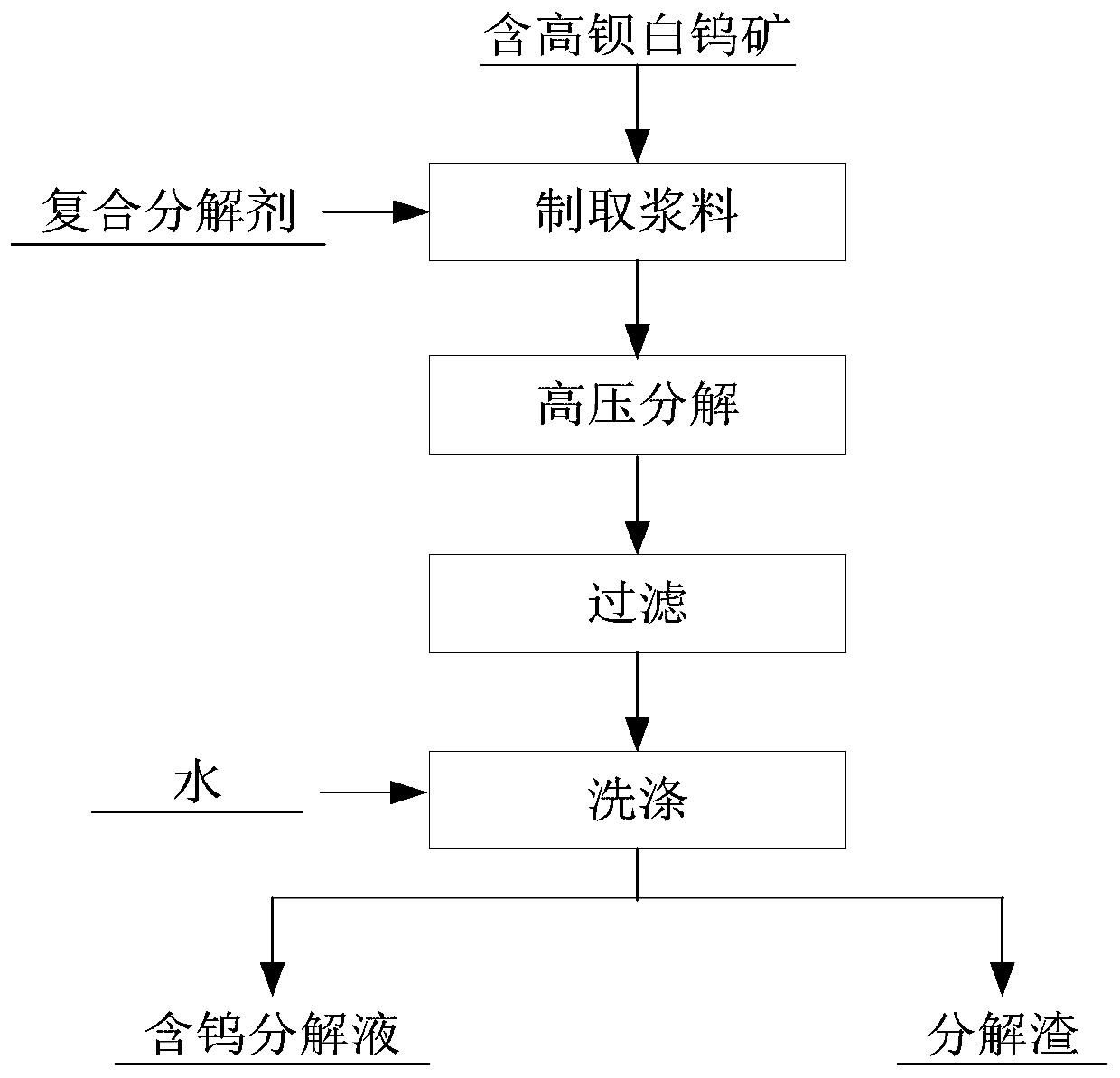

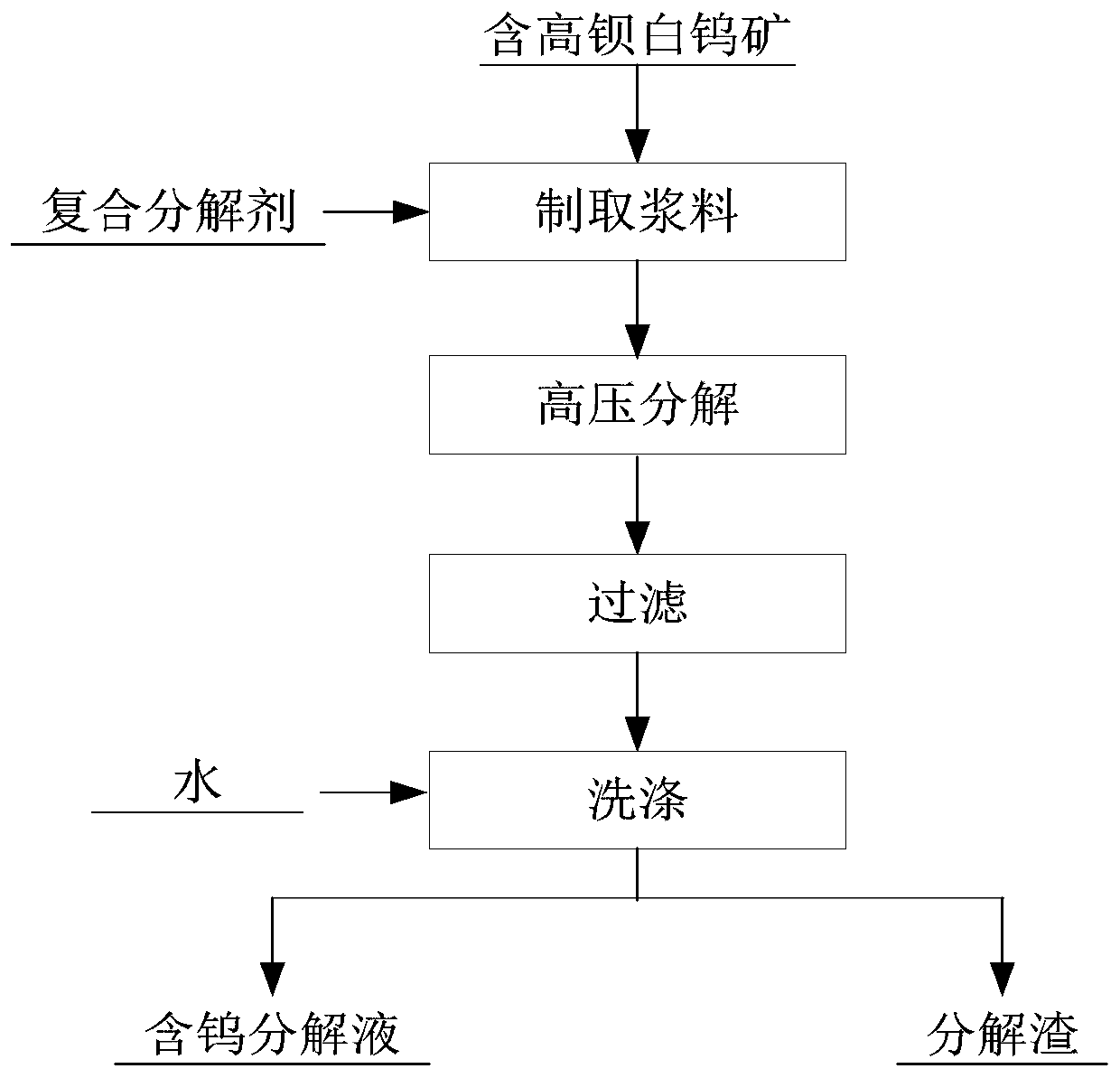

Image

Examples

Embodiment 1

[0034] The high-barium scheelite used in this example was tested for its initial WO according to the standards GB / T 14352.1-2010 and GB / T 6730 respectively. 3 and Ba content, the test result is WO 3 31.2%, Ba 2.56%.

[0035] This embodiment provides a scheelite decomposer, which includes sodium nitrate, sodium hydroxide and sodium carbonate, and the mass ratio of sodium nitrate, sodium hydroxide and sodium carbonate is 1:4:40.

[0036] This implementation also provides a method for extracting tungsten from scheelite, comprising,

[0037] S1. Prepare the above scheelite decomposing agent into an aqueous solution with a mass fraction of 15wt%, weigh 100g of scheelite, add it to the autoclave, and add 300mL (liquid-solid ratio: 3:1) decomposing agent aqueous solution to it to prepare into slurry.

[0038] S2. Decompose the slurry obtained in S1 under the conditions of stirring, pressurizing and heating. The stirring speed is 60r / min, the pressure is 1.6MPa, the temperature is...

Embodiment 2

[0042] The high-barium scheelite used in this example was tested for its initial WO according to the standards GB / T 14352.1-2010 and GB / T 6730 respectively. 3 and Ba content, the test result is WO 3 29.35%, Ba 1.67%.

[0043] This embodiment provides a scheelite decomposing agent, which includes sodium nitrate, sodium hydroxide and sodium carbonate, and the mass ratio of sodium nitrate, sodium hydroxide and sodium carbonate is 1:3:30.

[0044] This implementation also provides a method for extracting tungsten from scheelite, comprising,

[0045] S1, the above scheelite decomposer is formulated into an aqueous solution with a mass fraction of 20wt%, weighs 100g of scheelite, puts it into an autoclave, and adds 450mL (liquid-solid ratio: 4.5:1) decomposer aqueous solution to it to prepare into slurry.

[0046] S2. Decompose the slurry obtained in S1 under the conditions of stirring, pressurizing and heating. The stirring speed is 90r / min, the pressure is 1.9MPa, the temperat...

Embodiment 3

[0050] The high-barium scheelite used in this example was tested for its initial WO according to the standards GB / T 14352.1-2010 and GB / T 6730 respectively. 3 and Ba content, the test result is WO 3 25.6%, Ba 2.83%.

[0051] This embodiment provides a scheelite decomposer, which includes sodium nitrate, sodium hydroxide and sodium carbonate, and the mass ratio of sodium nitrate, sodium hydroxide and sodium carbonate is 1:3.5:35.

[0052] This implementation also provides a method for extracting tungsten from scheelite, comprising,

[0053] S1, the above scheelite decomposer is formulated into an aqueous solution with a mass fraction of 10wt%, weighs 200g of scheelite, puts it into an autoclave, and adds 1200mL (liquid-solid ratio: 6:1) decomposer aqueous solution to it to prepare into slurry.

[0054] S2. Decompose the slurry obtained in S1 under the conditions of stirring, pressurizing and heating. The stirring speed is 120r / min, the pressure is 2.2MPa, the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com