Method for recycling zinc from zinc leaching slag cleaning solution

A technology of zinc leaching residue and washing liquid is applied in the field of wet processing technology of zinc ore, which can solve the problems of reducing metal recovery rate, wasting resources, increasing operation technology, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

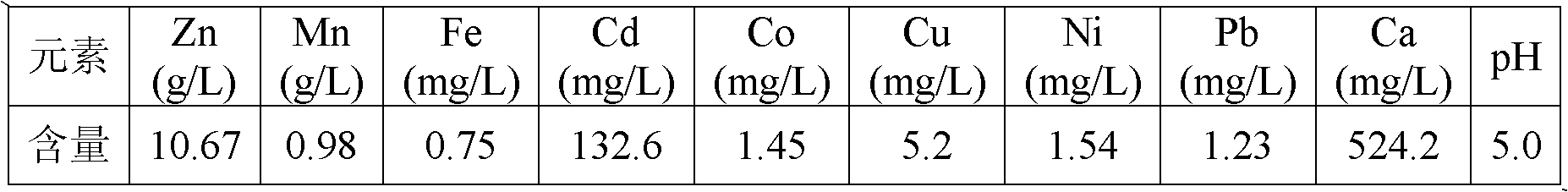

[0025] Use zinc oxide ore leaching slag containing 5% zinc. After filtering, it does not need to be dried, and it is directly washed with water. The Zn content in the solution after washing is about 10g / L, and the pH value is 4.5-5.2. The residual zinc in the slag after washing with water 1.2%, the resulting washing water composition is listed in the following table:

[0026]

[0027] Since the cadmium content in the washing water is relatively high, and it will also be partially extracted into the organic phase during the extraction process, which will eventually affect the quality of the electrodeposited zinc, therefore, cadmium removal must be carried out first. The removal of cadmium is replaced by zinc powder. When the amount of zinc powder is 1.5 to 2 times the theoretical replacement amount, the cadmium content is controlled to ≤50mg / L.

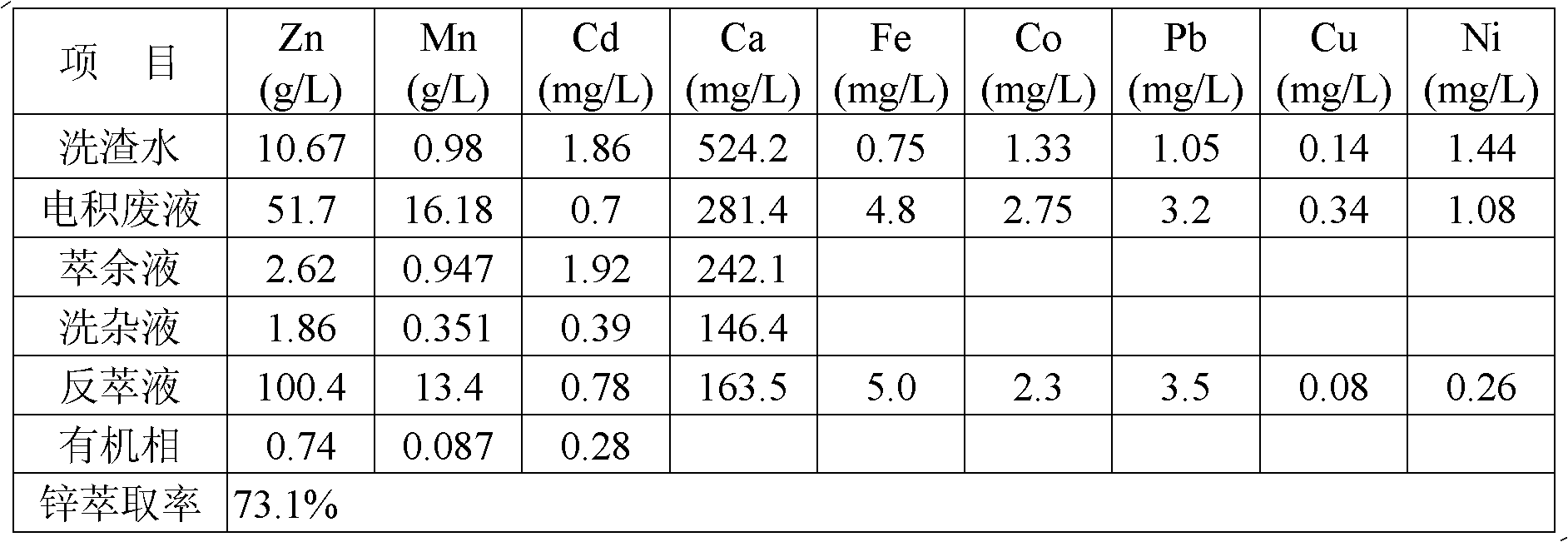

[0028] After removing cadmium, the liquid is extracted, using P 204 , that is, di-2-ethylhexylphosphoric acid is used as the extr...

example 2

[0032] The zinc oxide ore leaching slag containing 5% zinc is directly washed with dilute acid, and the Zn content in the washed solution is controlled to be about 10.8g / L, and the pH value is 2.0. with P 204 As an extractant, use 260# kerosene as a diluent, and the organic phase contains P 204 It is 30% extracted organic liquid, according to the extraction ratio of organic to aqueous phase is 1.2 / 1, three-stage countercurrent extraction is performed, mixed for 1 minute, the temperature is between 20 ° C and 30 ° C, and the mixed phase is clarified and separated for 2 minutes , to obtain a solution containing 15g / L of zinc in the loaded organic phase. There is no impurity removal and purification work before stripping, and the liquid after stripping is not directly used for electrowinning, but is incorporated into the liquid production section of zinc hydrometallurgy for neutral leaching, and neutral leachate is produced, which is carried out together Purify and remove impur...

example 3

[0034] The zinc oxide ore leaching slag containing 6% zinc is directly washed with washing water, and the Zn content in the washed solution is controlled to be about 15.0 g / L, and the pH value is 3.5-5.2. with P 204 As an extractant, use 260# kerosene as a diluent, and the organic phase contains P 204 It is 40% extracted organic liquid, according to the extraction ratio of organic to aqueous phase is 4 / 1, three-stage countercurrent extraction is carried out, mixed for 1 minute, the temperature is between 10°C and 40°C, and the mixed phase is clarified and separated for 2 minutes , to obtain a solution containing 15 g / L of zinc in the loaded organic phase. The loaded organic phase was washed in two stages (the washing solution contained 6g / L of zinc and 3g / L of sulfuric acid), and finally back-extracted, and the waste electrolyte was used for back-extraction, Zn=50g / L, and a certain amount of concentrated sulfuric acid was added to make the solution The concentration of sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com