A kind of ethanol extraction method

An ethanol extraction and leaching technology, which is applied in the field of ethanol extraction, can solve problems such as unsatisfactory grinding effect, potential safety hazards of the pulverizer, and insufficient grinding, and achieve the effects of fast and convenient leaching, reduced physical labor, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

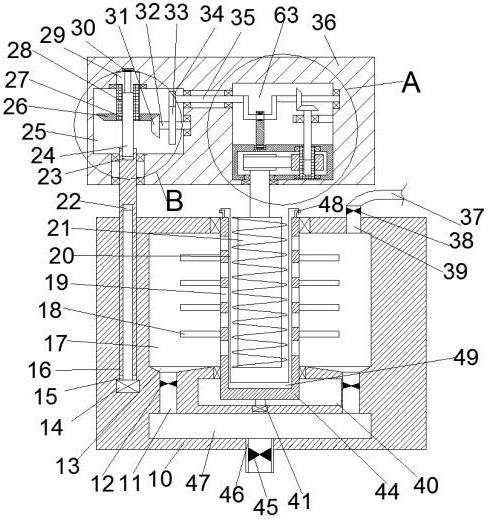

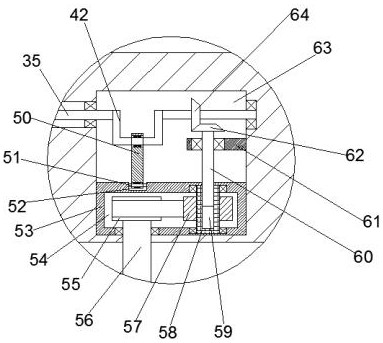

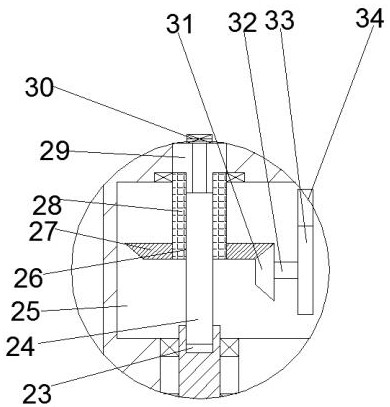

[0012] Bonded below Figure 1-3 The present invention will be described in detail, which is convenient, and now, the orientation of the following statement is as follows: The upper and lower directions of the upper and lower directions said below figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0013] Refer Figure 1-3 , A ethanol extraction method according to an embodiment of the present invention, comprising a body 10 having a function chamber 17 in which a cavity 17 is disposed in a feed tube 39, and the feed tube. The feed valve 38 is provided in the 39 end wall, and the feed tube 39 is coupled to the feed port 37 located outside, and the lower end wall in which the lower end wall is in communication with an annular leakage chamber 13, the leak cavity 13 The lower end wall communication is provided with the left and right symmetrical lumen 11, and the connecting cavity 11 end wall is provided with a lumen valve 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com