Display panel and display device

A technology for display panels and display substrates, used in instruments, nonlinear optics, optics, etc., can solve problems such as frame sealant corrosion, pollution, and poor circuit corrosion, and achieve the effect of ensuring product yield and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

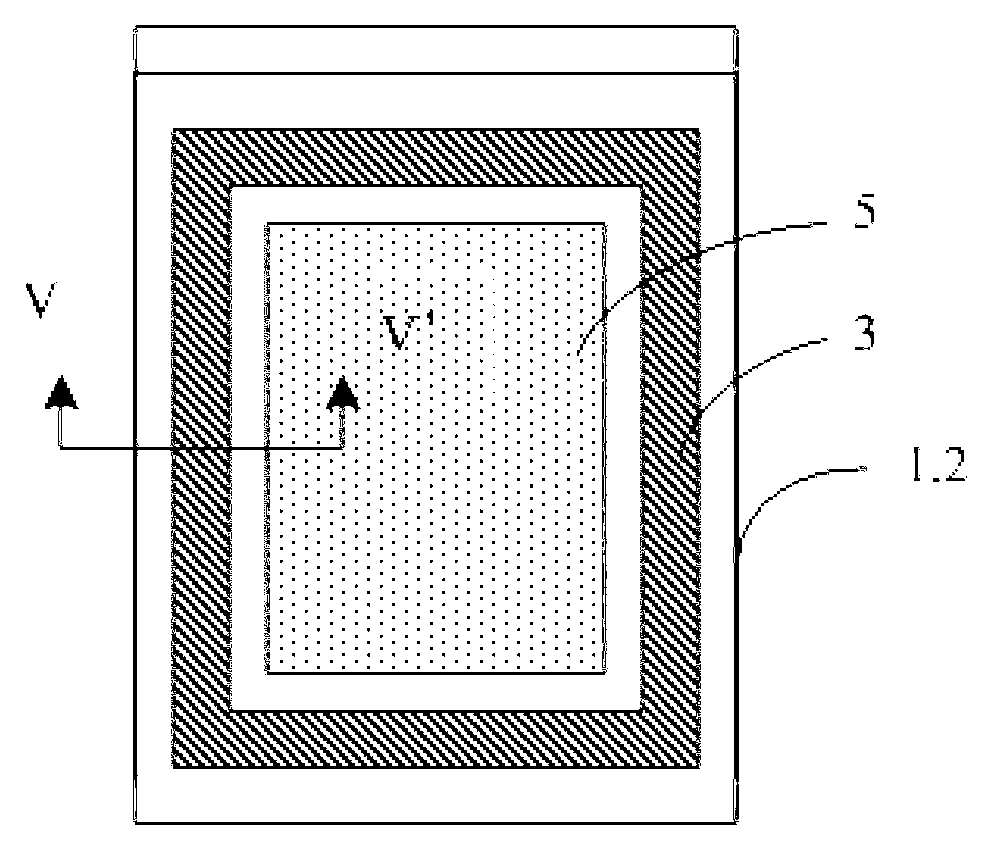

[0035] In this embodiment, the display panel includes a display area and a non-display area surrounding the display area, the non-display area is provided with a sealant, the sealant surrounds the display area, and the non-display area An isolation frame is also arranged in the display area, and the isolation frame is arranged on the outside of the sealant and surrounds the sealant, so that the sealant is completely isolated from the outside world.

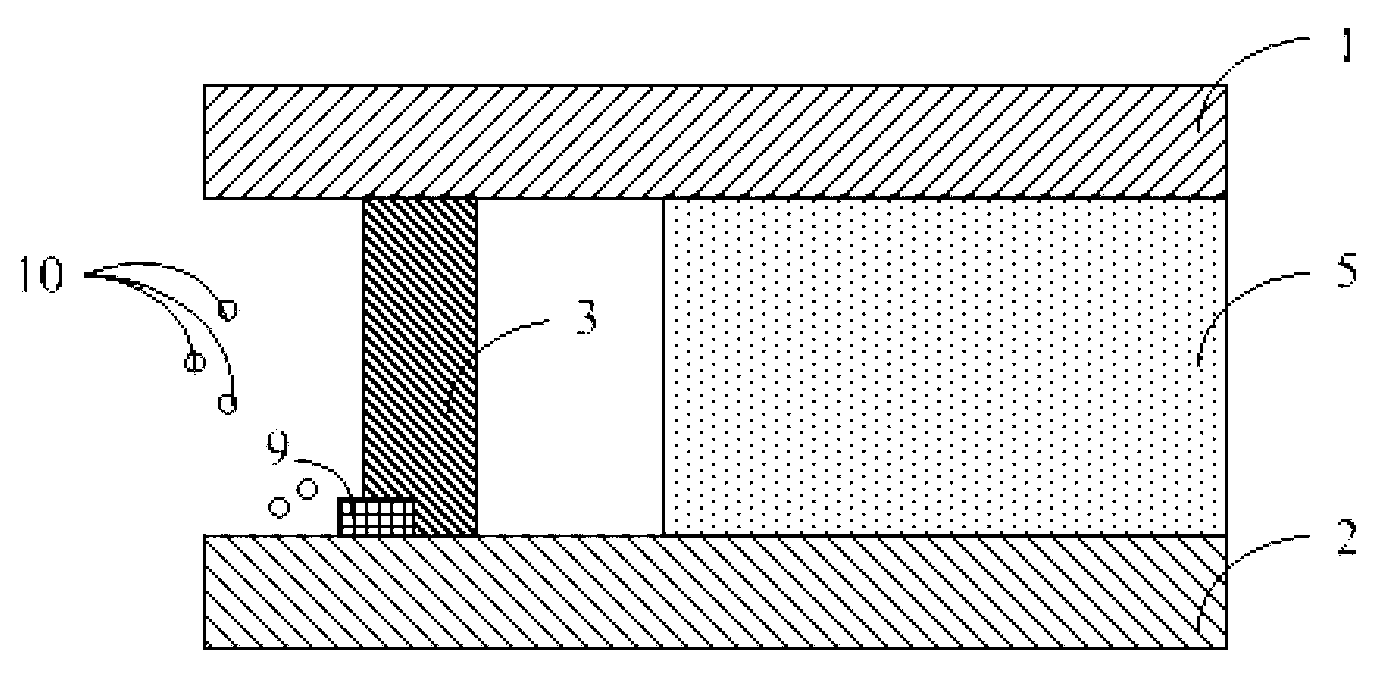

[0036] Wherein, the display panel includes a first display substrate and a second display substrate oppositely arranged, and the sealant is disposed on the outer edge of the first display substrate and the second display substrate corresponding to the display area. position, the isolation frame is disposed outside the sealant, and the isolation frame is airtightly connected to the first display substrate and the second display substrate respectively.

[0037] In this example, if Figure 5 , 6 or 8, the isolation frame includes a...

Embodiment 2

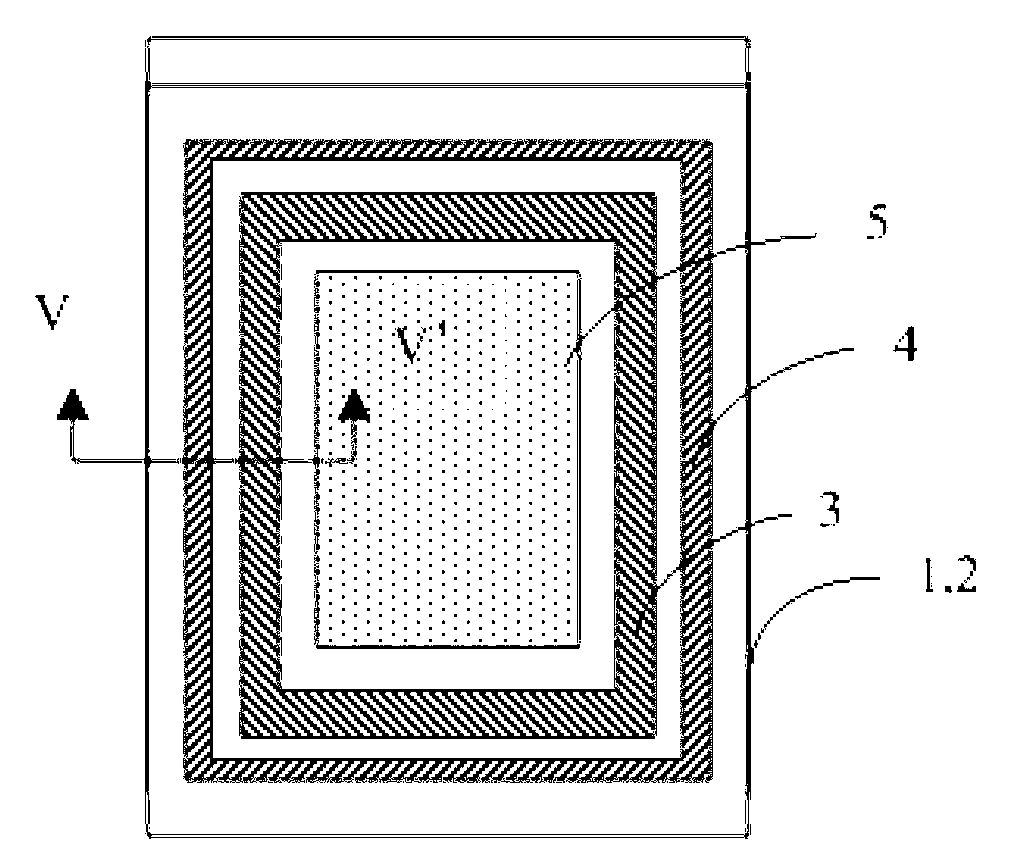

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, the isolation frame is made of multi-layer materials. That is, in this embodiment, at least one auxiliary layer capable of increasing the thickness of the first isolation part or the second isolation part is provided inside the first isolation part or the second isolation part, and the The auxiliary layer is made of metal material or insulating material.

[0054] The first display substrate is a color filter substrate, and a black matrix and a color filter layer are arranged on the region corresponding to the display area on the color filter substrate, columnar spacers are arranged on the color filter layer, and the color filter substrate The area corresponding to the non-display area on the top is provided with a first isolation part, the first isolation part is made of the same material as the color filter layer, its bottom end is set on the color filter substrate, its top end is set a...

Embodiment 3

[0059] The difference between this embodiment and Embodiments 1 and 2 is that the structure of the isolation frame in this embodiment is the same as that of the black matrix on the color filter substrate, the color filter layer and columnar spacers, and the thin film transistor on the array substrate in the prior art. The structures are not exactly the same.

[0060] In this embodiment, in the concave / convex or convex / concave matching structure of the first isolation part and the second isolation part in the isolation frame, the first isolation part or the second isolation part has more than two protrusions The second isolating portion or the first isolating portion has a lower concave portion matched with the raised portion, and the raised portion is in airtight contact with the lower concave portion.

[0061] Wherein, the top surfaces of the first isolation part and the second isolation part are in the shape of gears that cooperate with each other, that is, when the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com