Smoke-eliminating antifreezing agent for diesel oil

An antifreeze and smoke elimination technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems that consumers cannot use directly, the antifreeze effect is not ideal, and aviation kerosene is expensive, so as to improve the smoke elimination effect , prevent wax crystals from growing up, and easy to ignite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

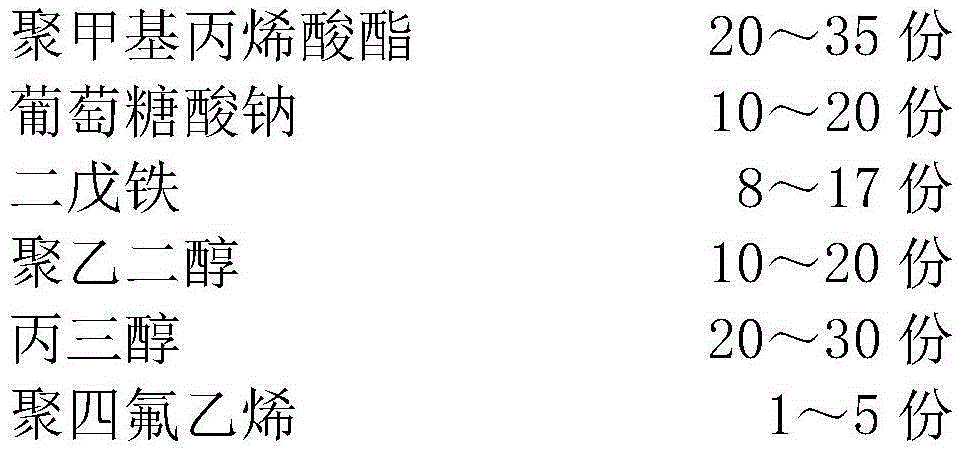

[0023] 1) Weigh the raw materials according to the following parts by weight:

[0024]

[0025] 2) Pump polymethacrylate, sodium gluconate, dipentyl iron, polyethylene glycol, glycerol, polytetrafluoroethylene and alkyl glycoside into the high shear mixing emulsifier in turn, heat up to 30 ° C, and react. 80min, you can get diesel smoke and antifreeze.

Embodiment 2

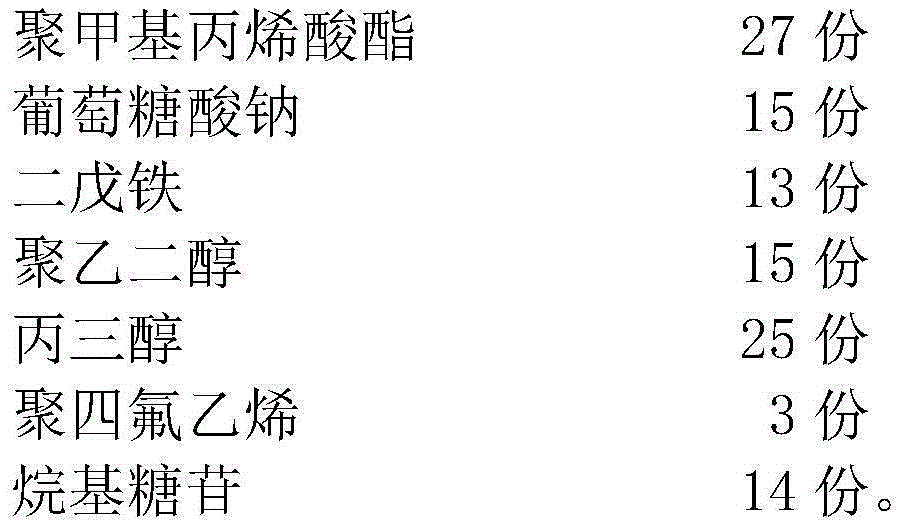

[0027] 1) Weigh the raw materials according to the following parts by weight:

[0028]

[0029]

[0030] 2) Pump the polymethacrylate, sodium gluconate, dipentyl iron, polyethylene glycol, glycerol, polytetrafluoroethylene and alkyl glycoside into the high shear mixing emulsifying machine in turn, heat up to 35 ° C, and react. 70min, you can get diesel smoke and antifreeze.

Embodiment 3

[0032] 1) Weigh the raw materials according to the following parts by weight:

[0033]

[0034] 2) Pump the polymethacrylate, sodium gluconate, dipentyl iron, polyethylene glycol, glycerol, polytetrafluoroethylene and alkyl glycoside into the high shear mixing emulsifier in turn, heat up to 40 ° C, and react. 75min, you can get diesel smoke and antifreeze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com