Preparation method and application of bifunctional perovskite type oxide oxygen electrode catalyst

A perovskite type and oxide technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of resource shortage, high price, single catalytic performance of noble metal catalysts, etc., and achieve low price, improved catalytic performance, excellent dual Effect of functional electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

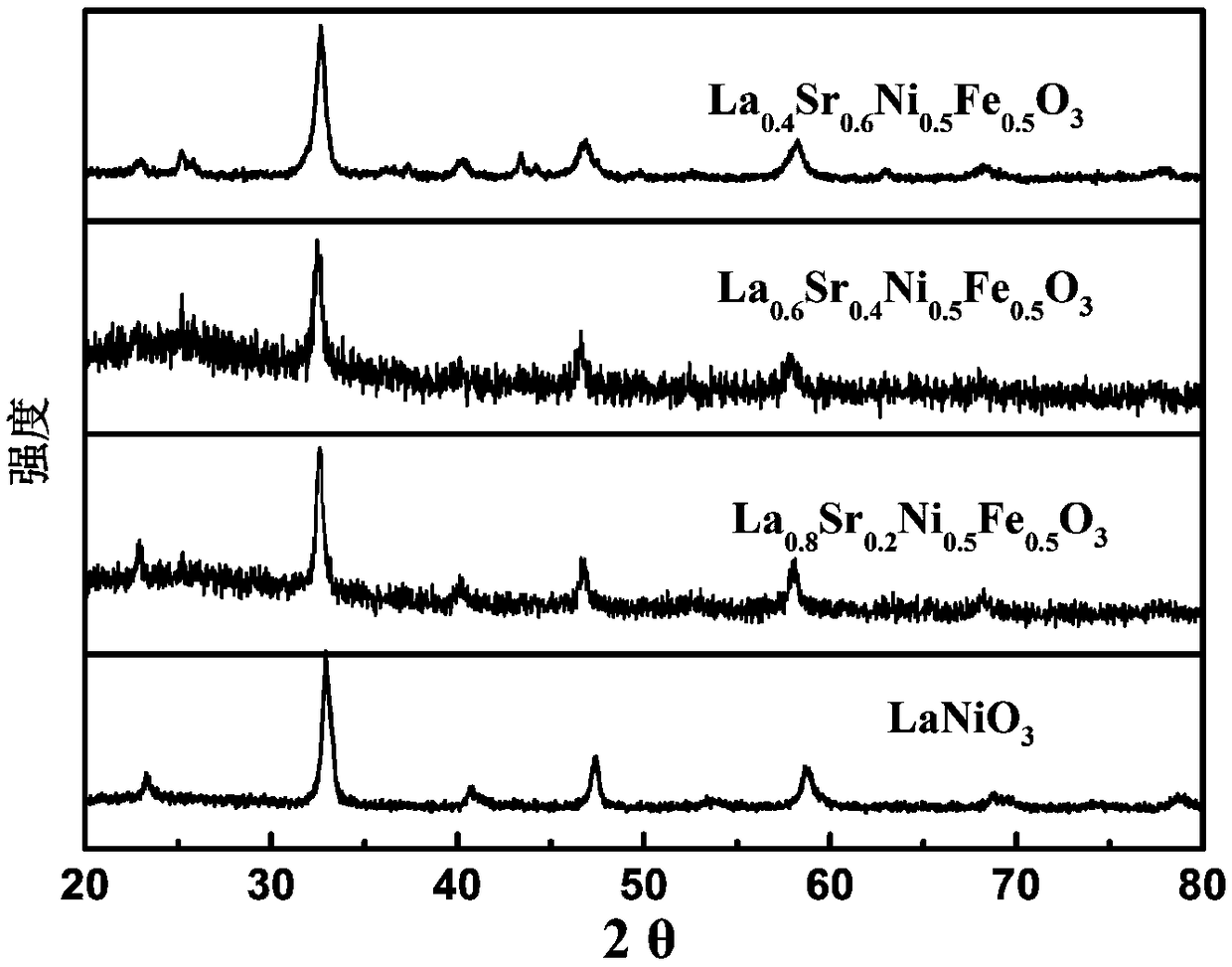

[0034] The perovskite-type bifunctional oxygen electrode catalyst in this example is prepared according to the following steps:

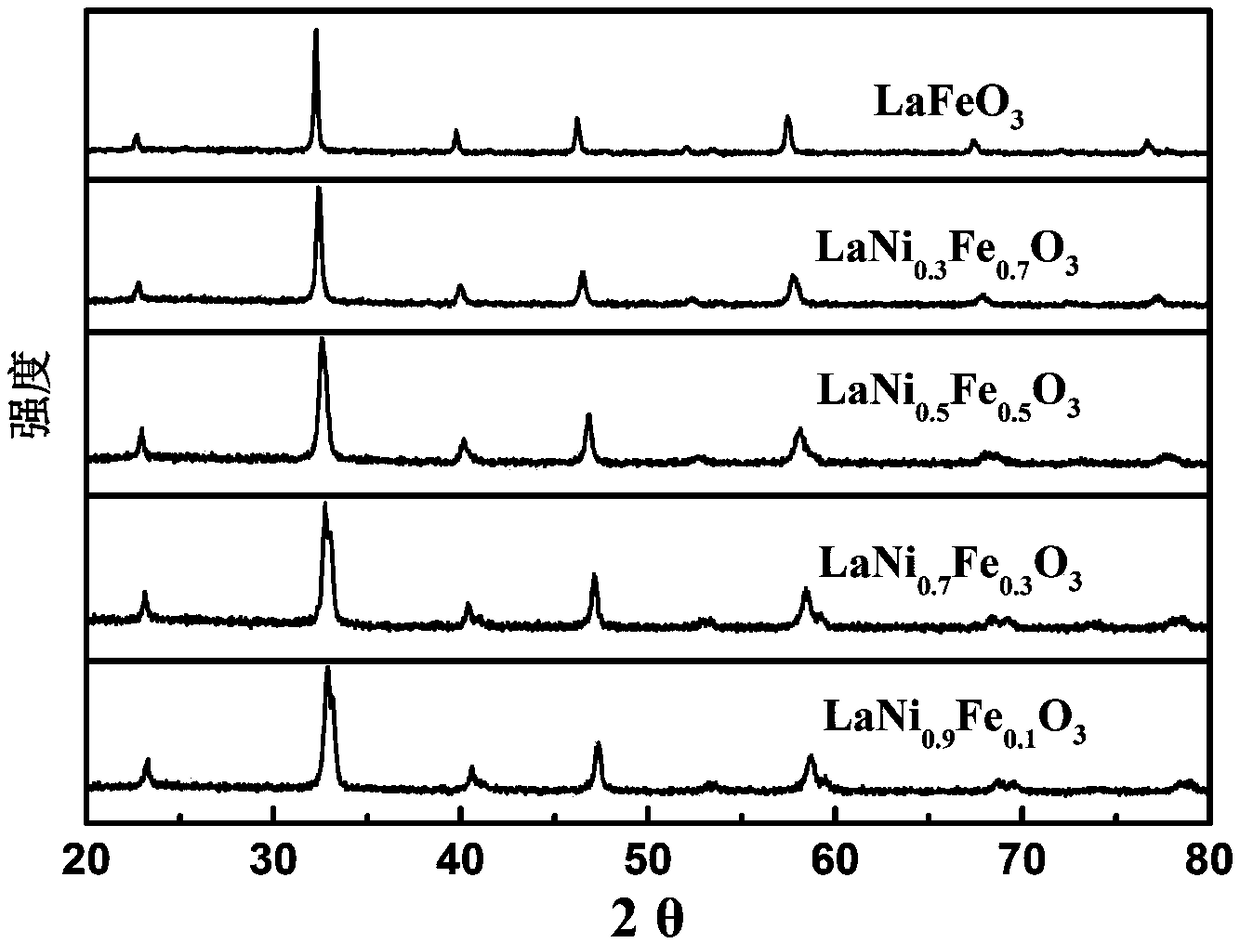

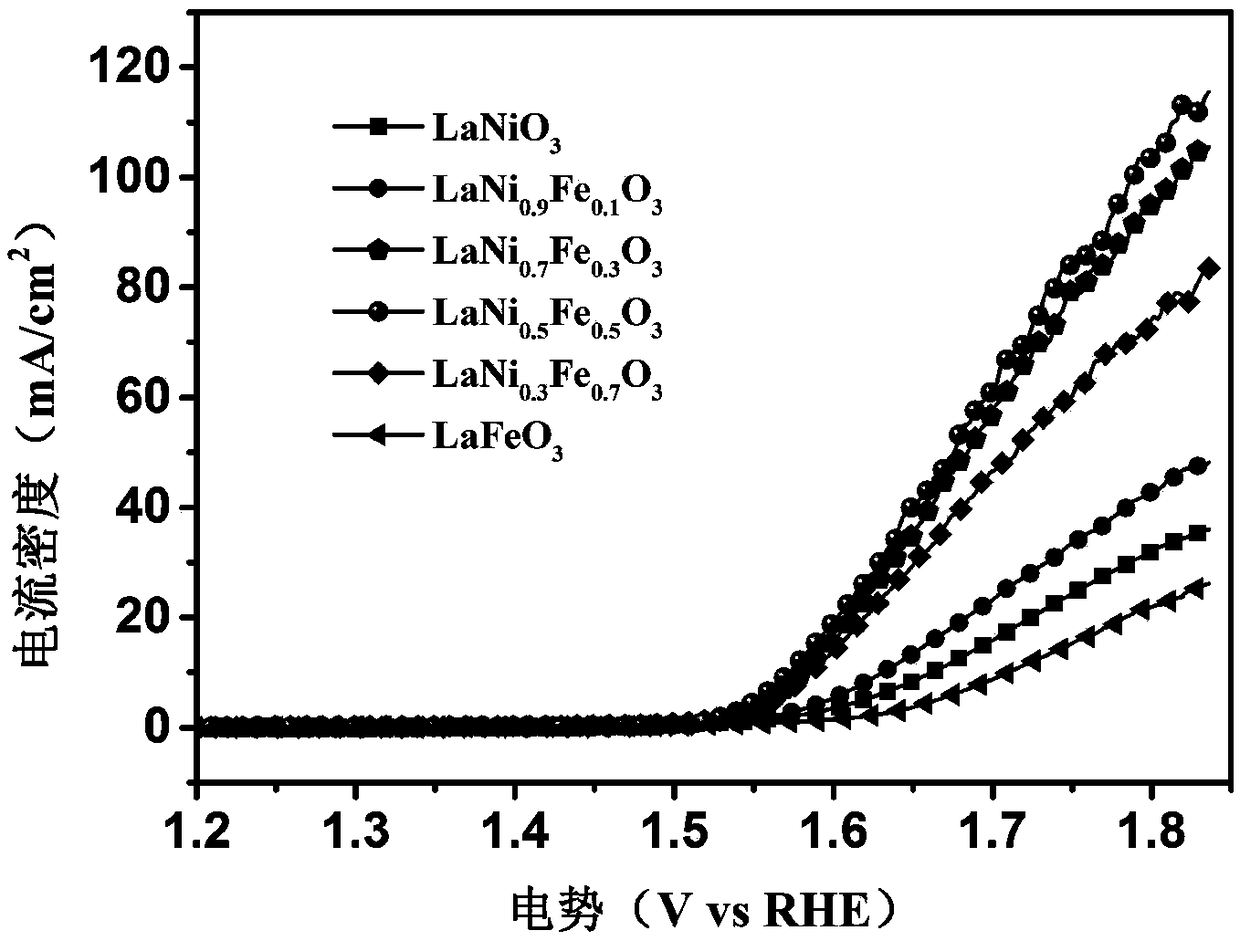

[0035] (1) Synthesis of La by sol-gel method 1-x Sr x Ni 1-y Fe y o 3 ;

[0036] a: Using deionized water as solvent, citric acid and ethylene glycol as complexing agent and thickener respectively, prepare a mixed solution of citric acid, ethylene glycol and soluble metal salt;

[0037] a1: Add 5ml deionized water and 0.6928g La(NO 3 ) 2 ·6H 2 O (ie 1.6mmol), get La (NO 3 ) 2 solution;

[0038] a2: Add 5ml deionized water and 0.29081gNi(NO 3 ) 2 ·6H 2 O, get Ni(NO 3 ) 2 Solution (1mmol Ni(NO 3 ) 2 ·6H 2 O);

[0039] a3: Add 5ml deionized water and 0.4040g Fe(NO 3 ) 3 9H 2 O (ie 1mmol Fe (NO 3 ) 3 9H 2 O), get Fe(NO 3 ) 3 solution;

[0040] a4: Add 5ml deionized water and 0.08465g Sr(NO 3 ) 2 4H 2 O (ie 0.4mmol Sr(NO 3 ) 2 4H 2 O,), get Sr (NO 3 ) 2 solution;

[0041] a5: Add 20ml of deionized water and 0.84056g o...

Embodiment 2

[0046] Embodiment 2: the La(NO of step a1 in embodiment 1 3 ) 2 ·6H 2 O is 2mmol, and its mass is 0.86604g; the Ni(NO 3 ) 2 ·6H 2 O is 1.4mmol, and its mass is 0.4071g; the Fe(NO 3 ) 3 9H 2 O is 0.6mmol, the quality is 0.2424g, without a4 step;

Embodiment 3

[0047] Embodiment 3: the La(NO of step a1 in embodiment 1 3 ) 2 ·6H 2 O is 2mmol, and its mass is 0.86604g; the Ni(NO 3 ) 2 ·6H 2 O is 1mmol, and its mass is 0.29081g; the Fe(NO 3 ) 3 9H 2 O is 1mmol, the quality is 0.404g, no a4 step;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com