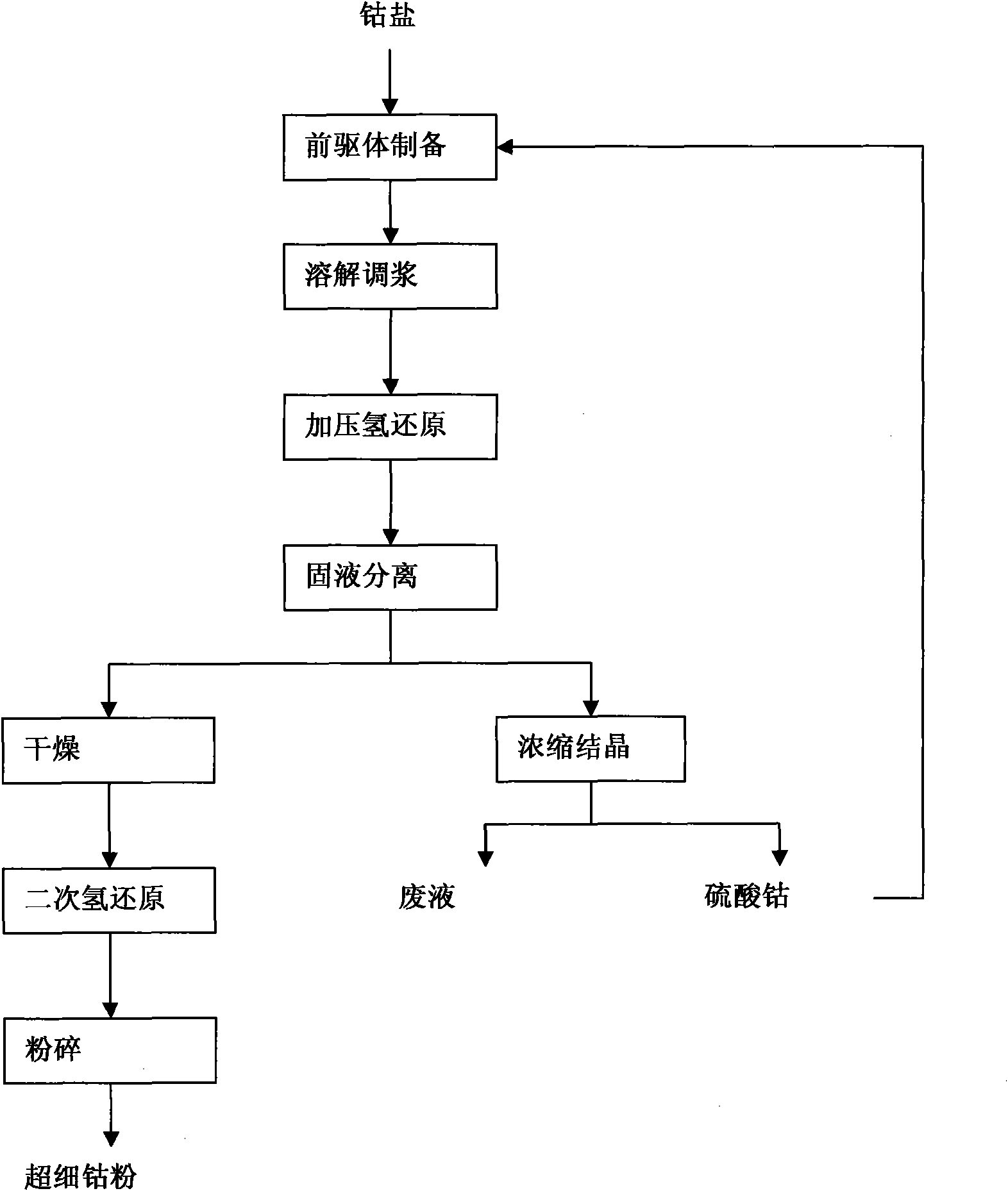

Method for preparing superfine cobalt powder in close-packed hexagonal structure or face-centered cubic structure by hydrogen reduction

A technology of ultra-fine cobalt powder and close-packed hexagonal, applied in the field of metal powder material preparation, can solve the problems of high equipment requirements, large operational hidden dangers, difficult industrialization implementation, etc., and achieves mild reaction conditions, low equipment requirements, and low operation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

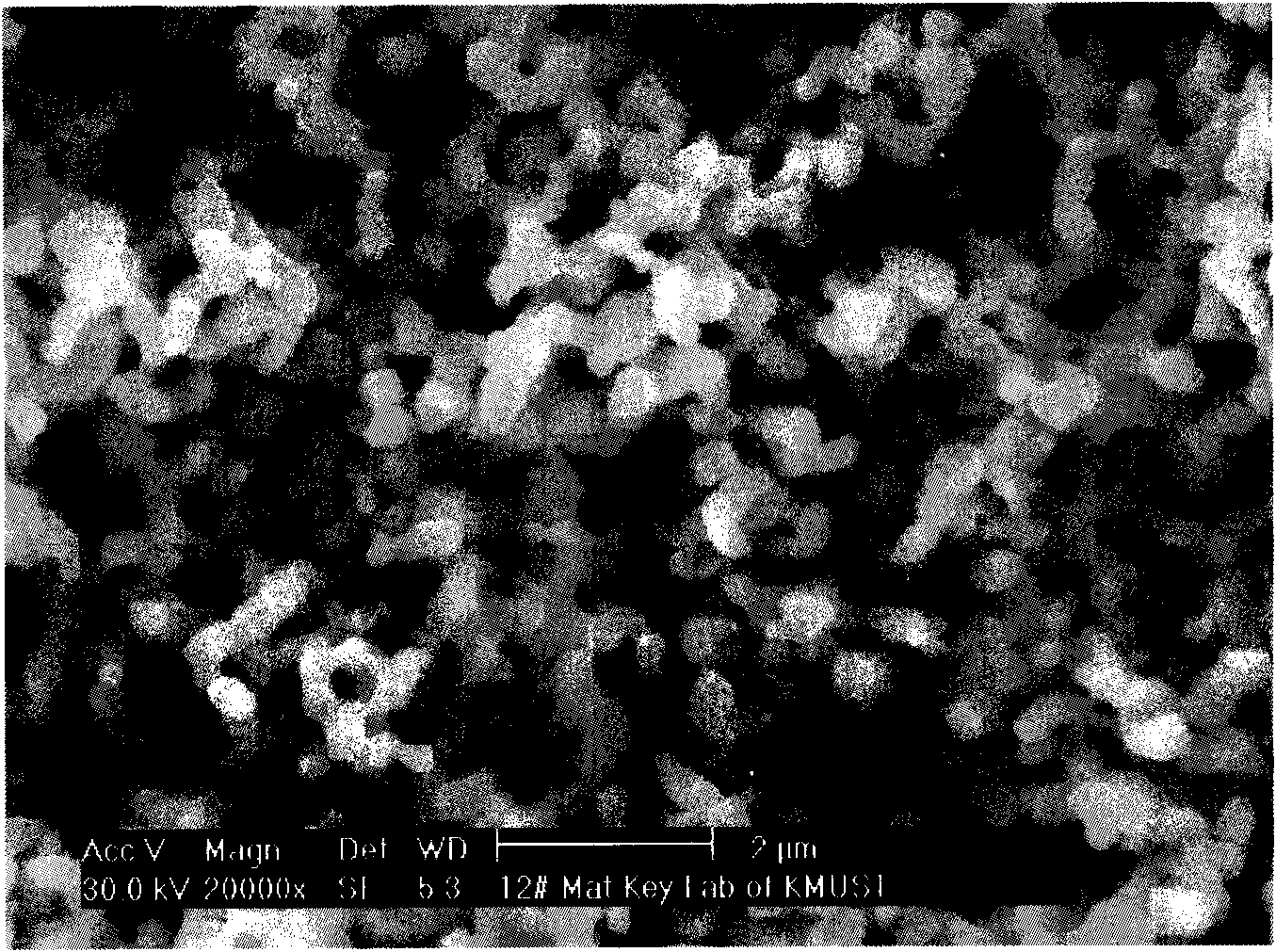

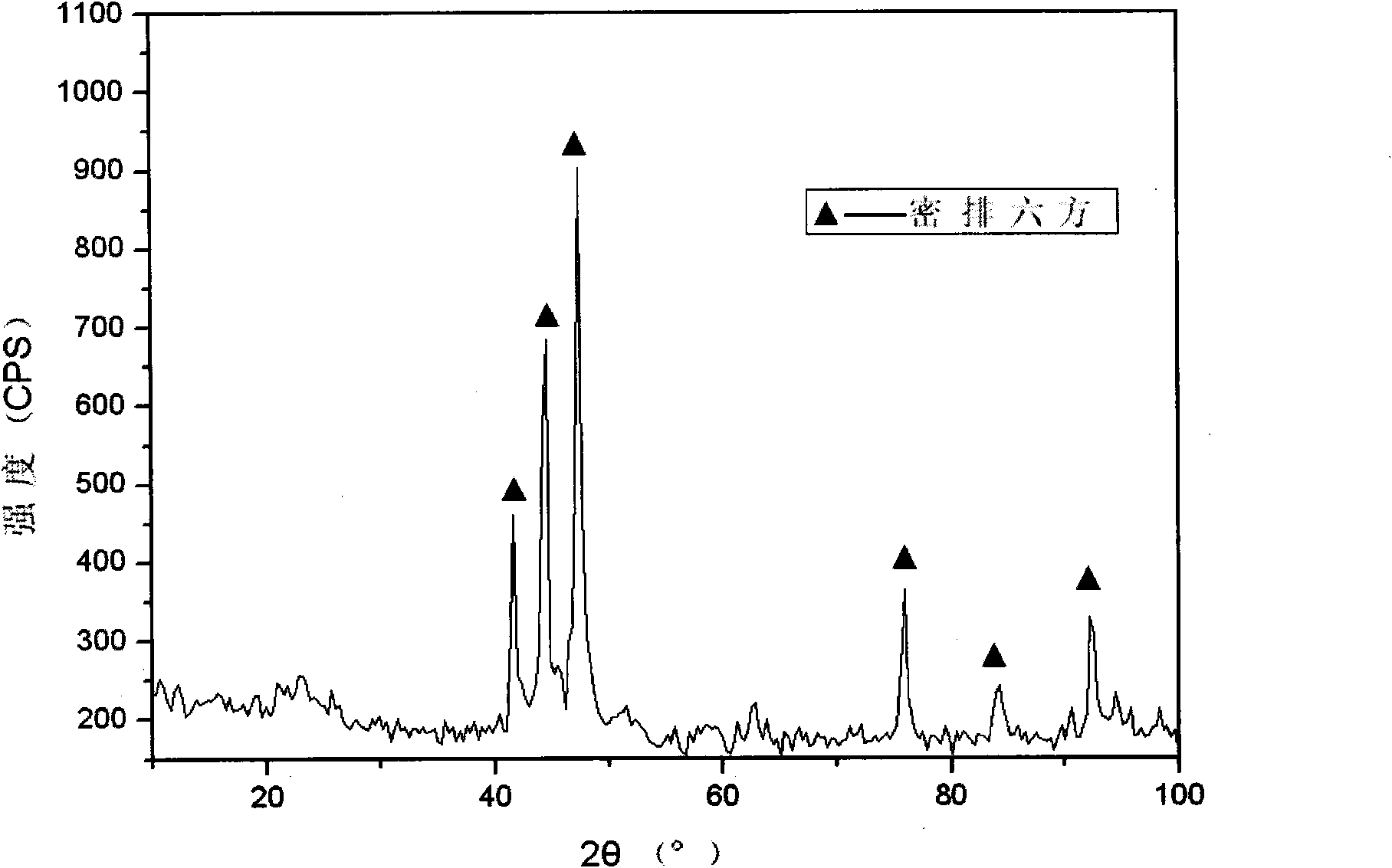

Embodiment 1

[0026] Cobalt sulfate heptahydrate was used as raw material and sodium hydroxide as precipitant to prepare superfine cobalt powder with single hexagonal close-packed structure. Add 200L of deionized water to the pre-reactor A, weigh 37.5kg of industrial pure sodium hydroxide, add it and stir to dissolve the sodium hydroxide; add 400L of deionized water to the pre-reactor B, weigh industrial pure heptahydrate sulfuric acid Cobalt 125kg, add wherein and fully stir to make cobalt sulfate dissolve; The lye in the pre-reactor A is pumped in the pre-reactor B, fully stirred to make it react completely, add the palladium chloride aqueous solution that configures (containing palladium chloride 12.5 g) 5L, stir evenly; pump the sediment water slurry reacted in the pre-reactor B into 3 Fill the reactor with nitrogen to discharge the air in the reactor, then empty it, fill it with hydrogen at 0.4MPa, heat it to 160°C and then fill it with hydrogen to keep the hydrogen partial pressure at...

Embodiment 2

[0028] Cobalt sulfate heptahydrate was used as raw material and sodium hydroxide as precipitant to prepare superfine cobalt powder with single face-centered cubic structure. Add 200L of deionized water to the pre-reactor A, weigh 37.5kg of industrial pure sodium hydroxide, add it and stir to dissolve the sodium hydroxide; add 400L of deionized water to the pre-reactor B, weigh industrial pure heptahydrate sulfuric acid Cobalt 125kg, add wherein and fully stir to make cobalt sulfate dissolve; The lye in the pre-reactor A is pumped in the pre-reactor B, fully stirred to make it react completely, add the palladium chloride aqueous solution (containing palladium chloride 20g )5L, stir evenly; pump the sediment water slurry reacted in the pre-reactor B into 3Fill the reactor with nitrogen to discharge the air in the reactor, then empty it, fill it with hydrogen at 0.4MPa, heat it to 150°C and then fill it with hydrogen to keep the hydrogen partial pressure at 0.9MPa, control the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com