High-strength nitrogen-containing economical austenite stainless steel and manufacturing method thereof

A technology for austenitic stainless steel and its manufacturing method, which is applied in the field of high-strength nitrogen-containing economical austenitic stainless steel and its manufacturing field, which can solve problems such as unstable production and size limitations, and achieve small performance differences and good shape of the same plate , the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

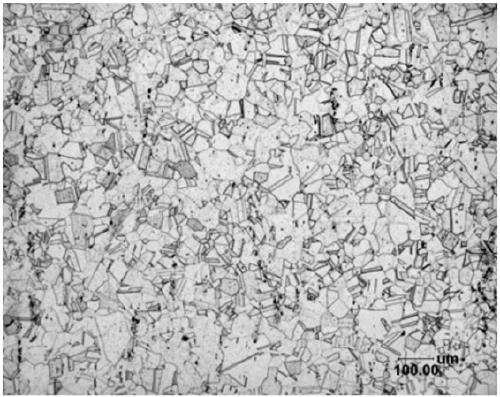

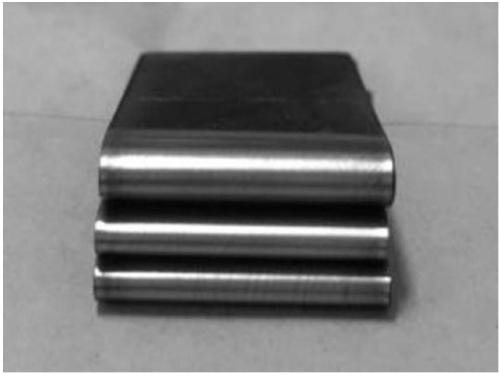

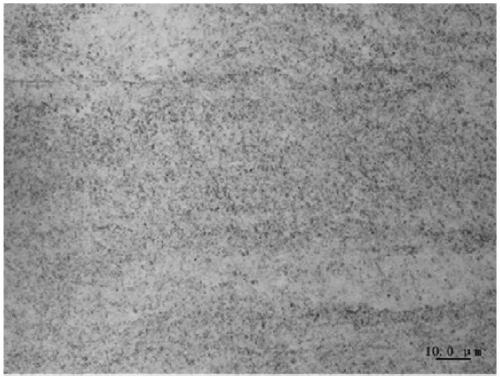

Embodiment 1

[0059] The composition of the steel is shown in Table 1. The two-step method of electric furnace and AOD is used for smelting. During the smelting process, the reduced Si content in the molten steel is controlled to be greater than 0.3%, and the actual analysis on site is 0.45%. The refining time of the LF station is not less than 40 minutes, and the actual time is 45 minutes. Argon blowing soft stirring time is not less than 10min, actually 12min. Ca treatment and B microalloying are carried out at the end of LF station. The molten steel is continuously cast to obtain a slab, and the slab is then subjected to hot rolling, hot annealing, pickling, first cold rolling, first soft annealing pickling, second cold rolling, second soft annealing pickling and smoothing to produce 2B surface state strip steel. Among them, the first cold rolling reduction is 55%, the first soft annealing temperature is 850°C, the first soft annealing time is 2min, the second cold rolling reduction is...

Embodiment 2

[0064] The steel composition is shown in Table 1. The two-step method of electric furnace and AOD is used for smelting. The control requirements of the smelting process are the same as in Example 1. The actual values of each main control point are: LF refining time 40 minutes, argon blowing soft stirring time 15 minutes. The molten steel undergoes continuous casting, hot rolling, hot rolling annealing and pickling, first cold rolling, first soft annealing pickling, second cold rolling, second soft annealing pickling, and smoothing to produce a high-strength nickel-saving austenitic alloy with a 2B surface state. One-time cold rolling reduction is 60%, the first soft annealing temperature is 800°C, the first soft annealing time is 3min, the second cold rolling reduction is 50%, and the second soft annealing temperature is 900°C, the second flexible annealing holding time is 3min. The mechanical performance test results of this embodiment are shown in Table 3.

[0065] GB / T 1...

Embodiment 3

[0068] The steel composition is shown in Table 1, and the two-step method of electric furnace and AOD is used for smelting. The control requirements of the smelting process are the same as in Example 1. The actual values of each main control point are: LF refining time is 40 minutes, and argon blowing soft stirring time is 15 minutes . The molten steel undergoes continuous casting, hot rolling, hot annealing and pickling, first cold rolling, first soft annealing pickling, second cold rolling, second soft annealing pickling, and smoothing to produce high-strength nickel-saving austenites with a 2B surface state. Body stainless steel strip. The first cold rolling reduction is 60%, the first soft annealing temperature is 850°C, the first soft annealing time is 3min, the second cold rolling reduction is 50%, the second soft annealing temperature is 900°C, the second soft annealing time 1.5min. The mechanical performance test results of this embodiment are shown in Table 3.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com