Deasphalting device and method

A deasphalting, columnar electrode technology, applied in the treatment of hydrocarbon oil, through electro/magnetic refining, petroleum industry, etc., can solve the problems of low separation efficiency, asphaltene backmixing, fluctuation of process conditions, etc., to achieve high removal efficiency, The effect of reducing backmixing and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

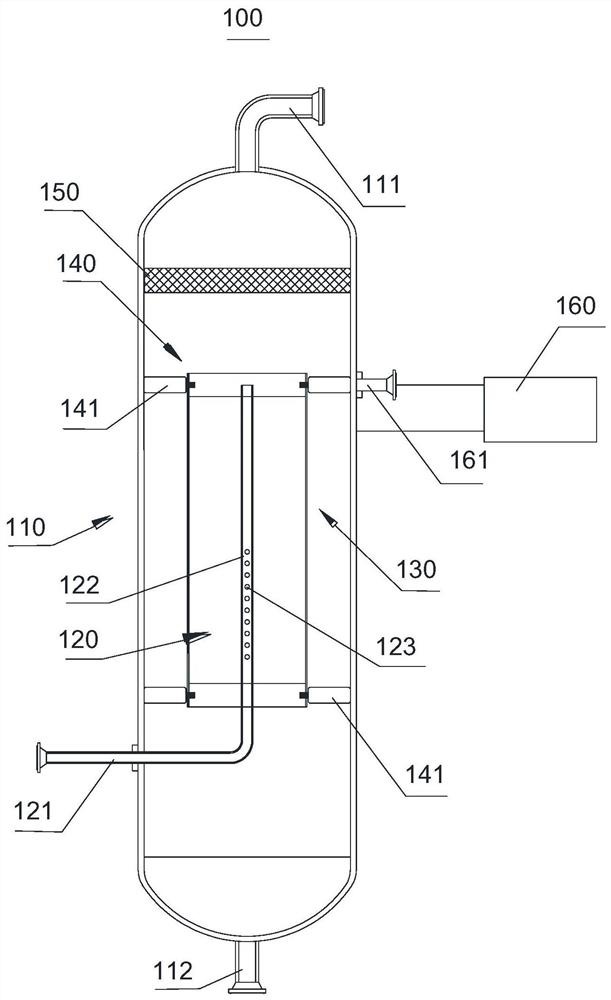

[0080] Choose a crude oil with an asphaltenes content of 2%. Crude oil and n-pentane are mixed at a mass ratio of 1:1.5 to form a homogeneous mixture, then heated to 150° C., and passed into the deasphalting device 100 through the conveying section 121 of the feed distributor 120 . The residence time of the mixture in the deasphalting unit 100 was 15 minutes. The applied electric field strength is 1500V / cm.

Embodiment 2

[0082] A residuum was selected with an asphaltenes content of 17%. The residual oil and n-heptane are mixed at a mass ratio of 1:2 to form a homogeneous mixture, then heated to 150° C., and passed into the deasphalting device 100 through the conveying section 121 of the feed distributor 120 . The residence time of the mixture in the deasphalting unit 100 was 15 minutes. The applied electric field strength is 1500V / cm.

experiment example

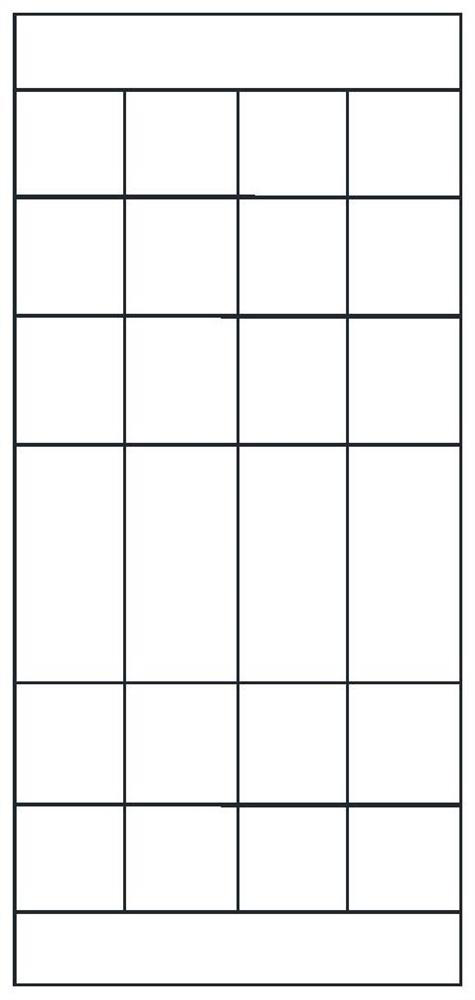

[0088] The content of asphaltenes in the deasphalted oil obtained by the methods provided in Examples 1 and 2 and Comparative Examples 1 and 2 was detected. Record the results in the table below.

[0089] Table 1 Asphaltene content in deasphalted oil of each experimental group

[0090] experiment Asphaltene content in deasphalted oil (%) Example 1 0.05 Example 2 0.1 Comparative example 1 1 Comparative example 2 5.2

[0091] It can be seen from the above table that the embodiment provided by the application has a better effect on removing asphalt than the comparative example, and the asphaltene content in the obtained deasphalted oil is lower. After applying an electric field, the deasphalting of the raw oil can be improved. Efficiency, remove more than 90% of asphaltenes in raw oil.

[0092] In summary, the device provided by this application, by setting the discharge section of the distributor in the hollow cylindrical electrode, enab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com