Aluminum alloy and heat treatment method thereof

A heat treatment method and aluminum alloy technology are applied in the field of aluminum alloy preparation to achieve the effects of reducing quenching residual stress, increasing room temperature tensile strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The aluminum alloy in this embodiment is an aluminum alloy product obtained by extrusion casting.

[0027] This embodiment proposes a heat treatment method for an aluminum alloy. In terms of mass percentage, the aluminum alloy includes the following components: 8% carbon steel fiber, 6.2% Mg, 1.0% Zn, 1% Cu, 0.12% Sc, Zr 0.13%, Y 0.16%, Si0.04%, Mn 0.07%, Er 0.02%, Ce 0.02%, impurity≦0.15%, the balance is Al;

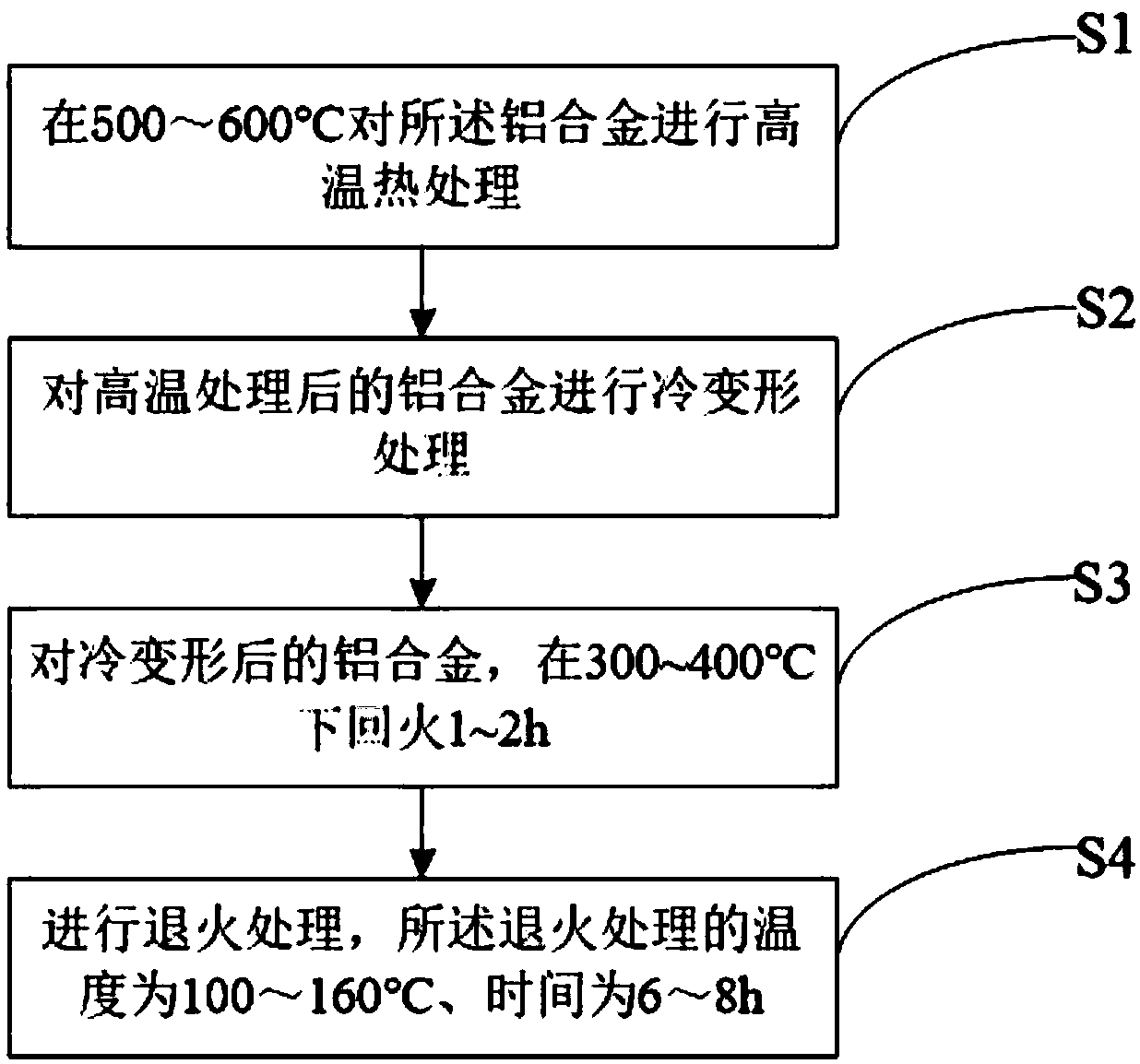

[0028] Described heat treatment step comprises:

[0029] S1. Perform high-temperature heat treatment on the aluminum alloy at 500° C. for 3 hours, and quench it with a PAG quenching solution after the high-temperature heat treatment to obtain a high-temperature-treated aluminum alloy; the PAG polymer content in the PAG quenching solution is 15 wt%, so The temperature of the PAG quenching liquid is 75°C, and the stirring rate of the PAG quenching liquid is 130r / s;

[0030] S2. Perform cold-drawing treatment on the aluminum alloy after the high-temperature treatm...

Embodiment 2

[0035] The aluminum alloy in this embodiment is an aluminum alloy product obtained by extrusion casting.

[0036] This embodiment proposes a heat treatment method for an aluminum alloy. In terms of mass percentage, the aluminum alloy includes the following components: 8% carbon steel fiber, 6.2% Mg, 1.0% Zn, 1% Cu, 0.12% Sc, Zr 0.13%, Y 0.16%, Si0.04%, Mn 0.07%, Er 0.02%, Ce 0.02%, impurity≦0.15%, the balance is Al;

[0037] Described heat treatment step comprises:

[0038] S1. Perform high-temperature heat treatment on the aluminum alloy at 600° C. for 3.5 hours, and quench with a PAG quenching solution after the high-temperature heat treatment to obtain a high-temperature-treated aluminum alloy; the content of the PAG polymer in the PAG quenching solution is 25 wt%, The temperature of the PAG quenching liquid is 60°C, and the stirring rate of the PAG quenching liquid is 130r / s;

[0039] S2. Perform cold-drawing treatment on the aluminum alloy after the high-temperature tre...

Embodiment 3

[0044] The aluminum alloy in this embodiment is an aluminum alloy product obtained by extrusion casting.

[0045] This embodiment proposes a heat treatment method for an aluminum alloy. In terms of mass percentage, the aluminum alloy includes the following components: 9% stainless steel fiber, 7.2% Mg, 1.5% Zn, 1.5% Cu, 0.15% Sc, Zr 0.18%, Y 0.18%, Si0.06%, Mn 0.06%, Er 0.01%, Ce 0.01%, impurity≦0.15%, the balance is Al;

[0046] Described heat treatment step comprises:

[0047] S1. Perform high-temperature heat treatment on the aluminum alloy at 550° C. for 4 hours, and quench it with a PAG quenching solution after the high-temperature heat treatment to obtain a high-temperature-treated aluminum alloy; the PAG polymer content in the PAG quenching solution is 45 wt%, so The temperature of the PAG quenching liquid is 70°C, and the stirring rate of the PAG quenching liquid is 130r / s;

[0048] S2. Perform cold-drawing treatment on the aluminum alloy after the high-temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com