A method for preparing acid and alkali-resistant nano Hastelloy coatings by magnetron sputtering and vacuum heat treatment

A technology of vacuum heat treatment and Hastelloy, applied in metal material coating process, coating, sputtering and other directions, can solve the influence of high cost factors of strong acid and alkali resistance of C-276 Hastelloy, and high preparation cost The problem is to improve the acid and alkali corrosion resistance, the effect is obvious, and the process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

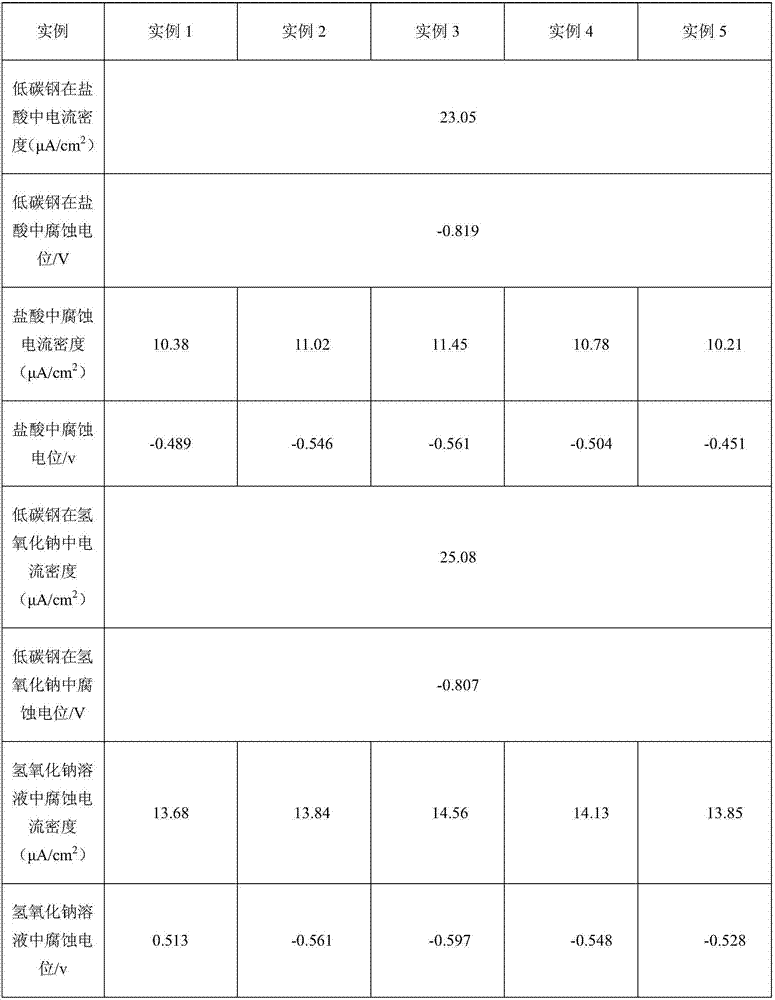

Embodiment 1

[0027] The commercially available C-276 Hastelloy alloy was used as the target, and the Q235 low-carbon steel was ultrasonically cleaned with acetone, ethanol and deionized water, blown with high-pressure nitrogen and placed on the substrate holder in the deposition chamber. The distance from the substrate to the target is about 7 cm. The background vacuum before deposition is better than 8×10 -5 Pa, the working pressure during the deposition process is 0.1Pa, N 2 The flow rate is 20mL / min (standard state). The C-276 Hastelloy target is controlled by a medium-frequency pulse power supply with a fixed power of 350W and a frequency of 80kHz. In order to improve the uniformity of the sample, the speed of the sample stage is 14r / min. In order to improve the film quality, 20min pre-sputtering is required to clean the target surface before sputtering. During the deposition process, a medium-frequency pulse bias of -90V was applied to the substrate, the substrate temperature was c...

Embodiment 2

[0030] The commercially available C-276 Hastelloy alloy was used as the target, and the Q235 low-carbon steel was ultrasonically cleaned with acetone, ethanol and deionized water, blown with high-pressure nitrogen and placed on the substrate holder in the deposition chamber. The distance from the substrate to the target is about 7 cm. The background vacuum before deposition is better than 8×10 -5 Pa, the working pressure during the deposition process is 0.1Pa, N 2 The flow rate is 20mL / min (standard state). The C-276 Hastelloy target is controlled by a medium-frequency pulse power supply with a fixed power of 350W and a frequency of 80kHz. In order to improve the uniformity of the sample, the speed of the sample stage is 14r / min. In order to improve the film quality, 20min pre-sputtering is required to clean the target surface before sputtering. During the deposition process, a medium-frequency pulse bias of -90V was applied to the substrate, the substrate temperature was c...

Embodiment 3

[0033] The commercially available C-276 Hastelloy alloy was used as the target, and the Q235 low-carbon steel was ultrasonically cleaned with acetone, ethanol and deionized water, blown with high-pressure nitrogen and placed on the substrate holder in the deposition chamber. The distance from the substrate to the target is about 7 cm. The background vacuum before deposition is better than 8×10 -5 Pa, the working pressure during the deposition process is 0.1Pa, N 2The flow rate is 20mL / min (standard state). The C-276 Hastelloy target is controlled by a medium-frequency pulse power supply with a fixed power of 350W and a frequency of 80kHz. In order to improve the uniformity of the sample, the speed of the sample stage is 14r / min. In order to improve the film quality, 20min pre-sputtering is required to clean the target surface before sputtering. During the deposition process, a medium-frequency pulse bias of -90V was applied to the substrate, the substrate temperature was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com