Method for producing crude cobalt hydroxide from cobalt-containing low-copper raffinate industrially

A cobalt hydroxide and raffinate technology, applied in the field of hydrometallurgy, can solve the problems of low primary recovery rate of products, high unit consumption of auxiliary materials, low cobalt content, etc. The effect of quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

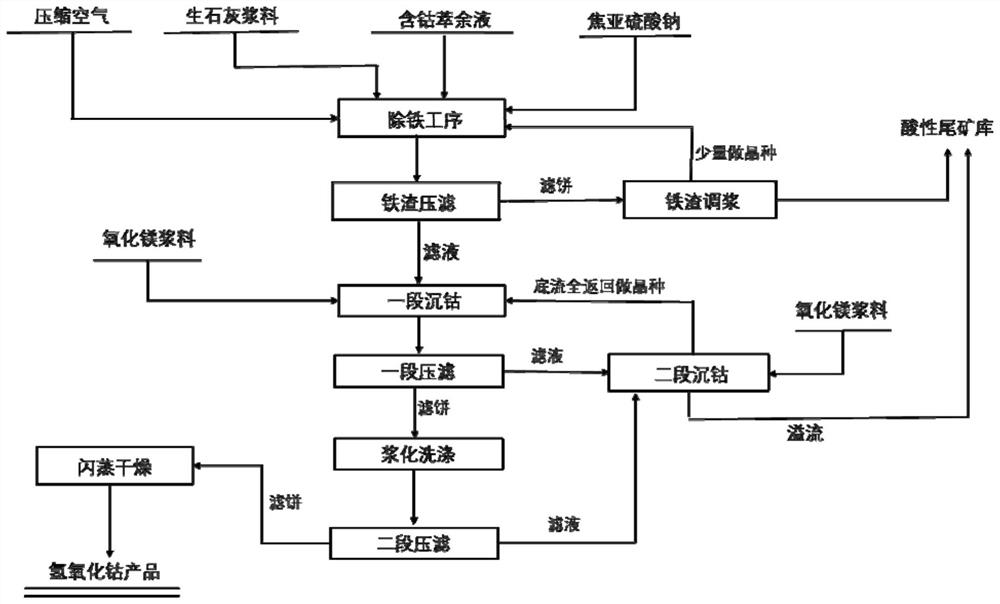

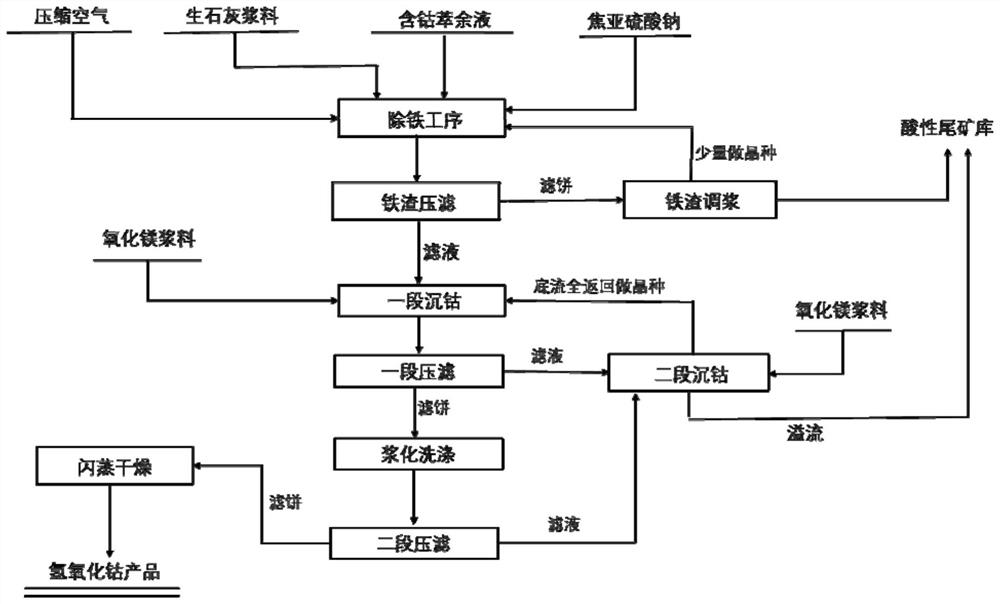

Image

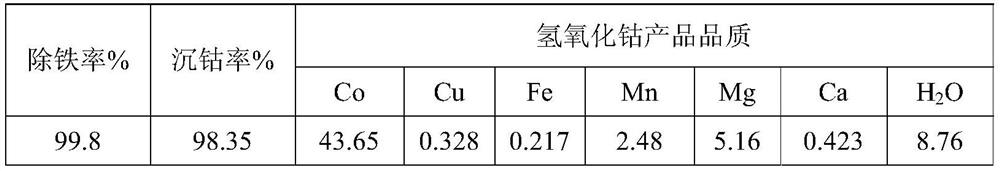

Examples

Embodiment 1

[0018] The components of the cobalt-containing low-copper raffinate used in this example are Co: 3.12g / L, Cu: 0.315g / L, Mn: 1.12g / L, Fe: 1.235g / L, Ca: 0.6g / L, H 2 SO 4 :22.1g / L

[0019] Iron removal process: the cobalt-containing and low-copper raffinate is 180m 3 The speed of / h is passed into the No. 1 tank for iron removal, and the reaction feed liquid is sequentially flowed from the No. 1 tank of the first section of cobalt sinking to the No. 6 tank by using the height difference of the tank; it is respectively passed into the No. 1, 2, 3 and 4 tanks For quicklime slurry with a mass concentration of 17.6%, control and adjust the pH of each tank to 2.5 to 4.5, and the pH at the end point to be 5.0; respectively feed sodium pyrosulfite solutions with a mass concentration of 18% into iron removal tanks 1, 2, and 3; 30L / min of compressed air is fed into No. 1 to No. 6 tanks, and the oxidation-reduction potential of each tank is controlled to be about 420mv; the reaction time...

Embodiment 2

[0028] The components of the cobalt-containing and low-copper raffinate used in this example are Co: 2.82g / L, Cu: 0.217g / L, Mn: 1.14g / L, Fe: 1.435g / L, Ca: 0.5g / L, H 2 SO 4 :23.5g / L

[0029] Iron removal process: the cobalt-containing and low-copper raffinate is 190m 3 The speed of / h is passed into the No. 1 tank for iron removal, and the reaction feed liquid is sequentially flowed from the No. 1 tank of the first section of cobalt sinking to the No. 6 tank by using the height difference of the tank; it is respectively passed into the No. 1, 2, 3 and 4 tanks For quicklime slurry with a mass concentration of 15%, control and adjust the pH of each tank to 2.5 to 4.0, and the pH at the end point to 4.5; feed sodium metabisulfite solutions with a mass concentration of 18% into iron removal tanks 1, 2, and 3 respectively; 45L / min of compressed air is fed into No. 1 to No. 6 tanks, and the oxidation-reduction potential of each tank is controlled to be about 460mv; the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com