Preparation method of super-large particle hexanitrohexaazaisowurtzitane

A technology of hexanitrohexaazane and isowurtzitane is applied in the field of preparation of super-large particle hexanitrohexaazaisowurtzitane, and can solve the problems of low yield, poor morphology consistency, easy occurrence of twinning phenomenon and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

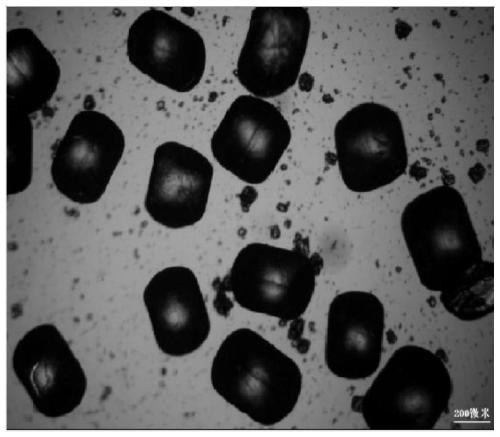

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing super-large particle hexanitrohexaazaisowurtzitane, comprising the following steps:

[0031] (1) dissolving a saturated amount of hexanitrohexaazaisowurtzitane in a recrystallization solvent to obtain a saturated solution of hexanitrohexaazaisowurtzitane;

[0032] (2) adding large particle hexanitrohexaazaisowurtzitane seed crystals to the saturated solution of hexanitrohexaazaisowurtzitane to obtain hexanitrohexaazaisowurtzitane suspension, the large The average particle size of the granular hexanitrohexaazaisowurtzitane seed crystals ranges from 250 to 300 μm;

[0033] (3) Adding a non-solvent to the hexanitrohexaazaisowurtzitane suspension in a natural feeding manner, after heat preservation, solid-liquid separation to obtain super-large particle hexaazaisowurtzitane, the The flow speed of the non-solvent is 20-40L / min, and the adding position of the non-solvent is located below the liquid level of the hexanitrohexaazais...

Embodiment 1

[0062] At room temperature, add 80 L of ethyl acetate into the dissolving machine, add 30 kg of raw material CL-20 under stirring, and after complete dissolution, filter to obtain a saturated solution of CL-20. Put the saturated solution into the crystallizer, control the temperature to 40°C, and the stirring rate to 150rpm, add 5kg of seed crystals with an average particle size of 150μm, stir for 10min, add 200L n-octane to the high level tank, and place the outlet below the liquid level of the saturated solution. Open the high-position tank bottom valve and add n-octane at a uniform speed for 5 minutes. After the addition, time and keep warm for 48 hours, filter, and dry to obtain large particles of hexanitrohexaazaisowurtzitane.

[0063] The screened hexanitrohexaazaisowurtzitane with an average particle size of 300 μm was used as the seed crystal; at room temperature, 80 L of ethyl acetate was added to the dissolving machine, and 30 kg of raw material CL-20 was added under ...

Embodiment 2

[0065] At room temperature, add 80L of acetone into the dissolving machine, add 30kg of raw material CL-20 under stirring, after completely dissolving, filter to obtain a saturated solution of CL-20. Add the saturated solution into the crystallizer, control the temperature at 40°C, and the stirring rate at 250rpm, add 5kg of seed crystals with an average particle size of 150μm, stir for 10min, add 200L of n-heptane to the head tank, and place the outlet below the liquid level of the saturated solution. Open the bottom valve of the high tank and add n-heptane at a uniform speed at one time, and the feeding time is 5 minutes. After the addition, time and keep warm for 48 hours, filter, and dry to obtain large particles of hexanitrohexaazaisowurtzitane.

[0066] The screened hexanitrohexaazaisowurtzitane with an average particle size of 300 μm was used as the seed crystal; at room temperature, 80 L of acetone was added into the dissolving machine, and 30 kg of raw material CL-20 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com