Suspended garbage channel for building construction

A construction and suspension technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of easy blockage and inconvenient garbage transportation in garbage channels, and achieve the effect of convenient collection, easy transportation and processing, and reduced falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

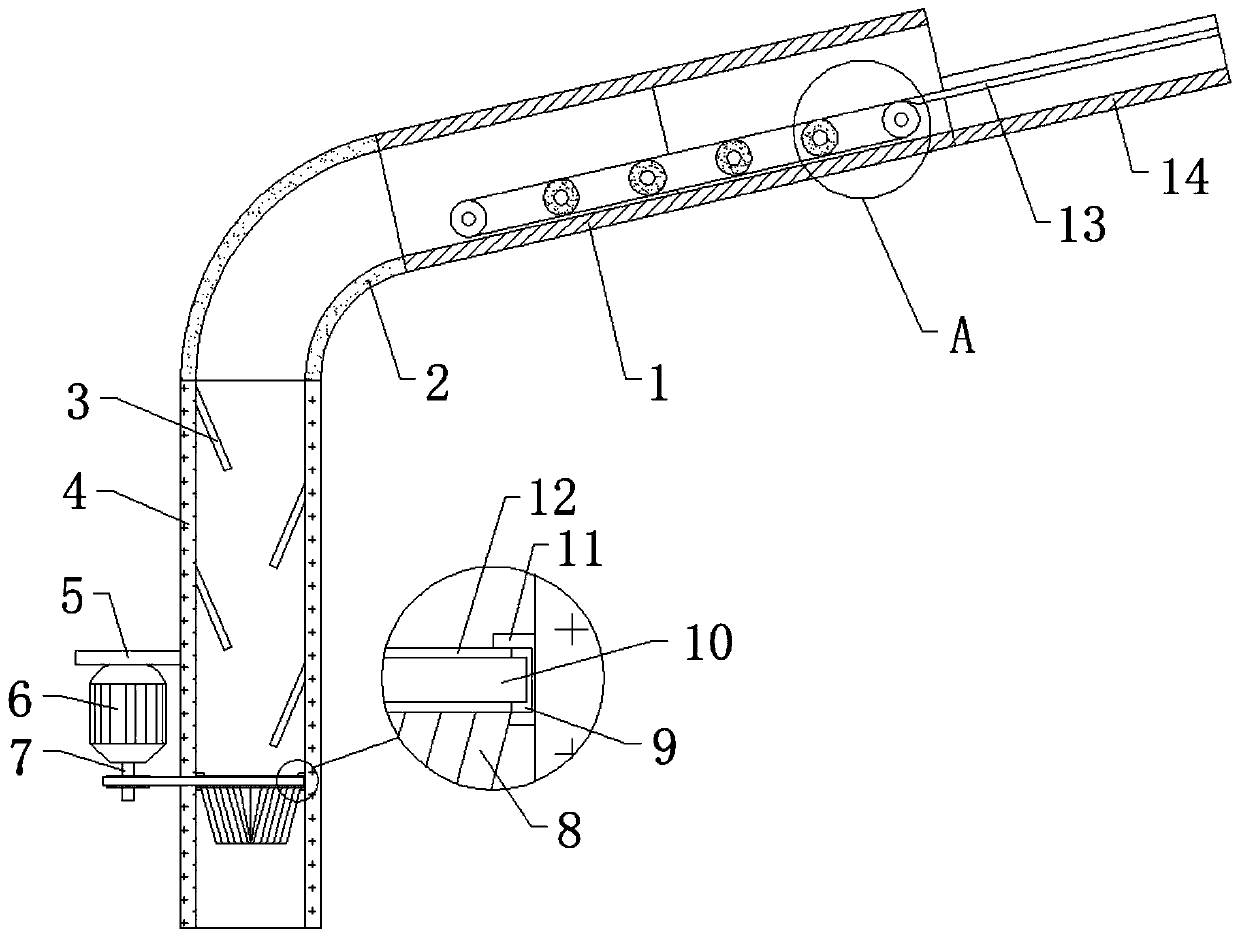

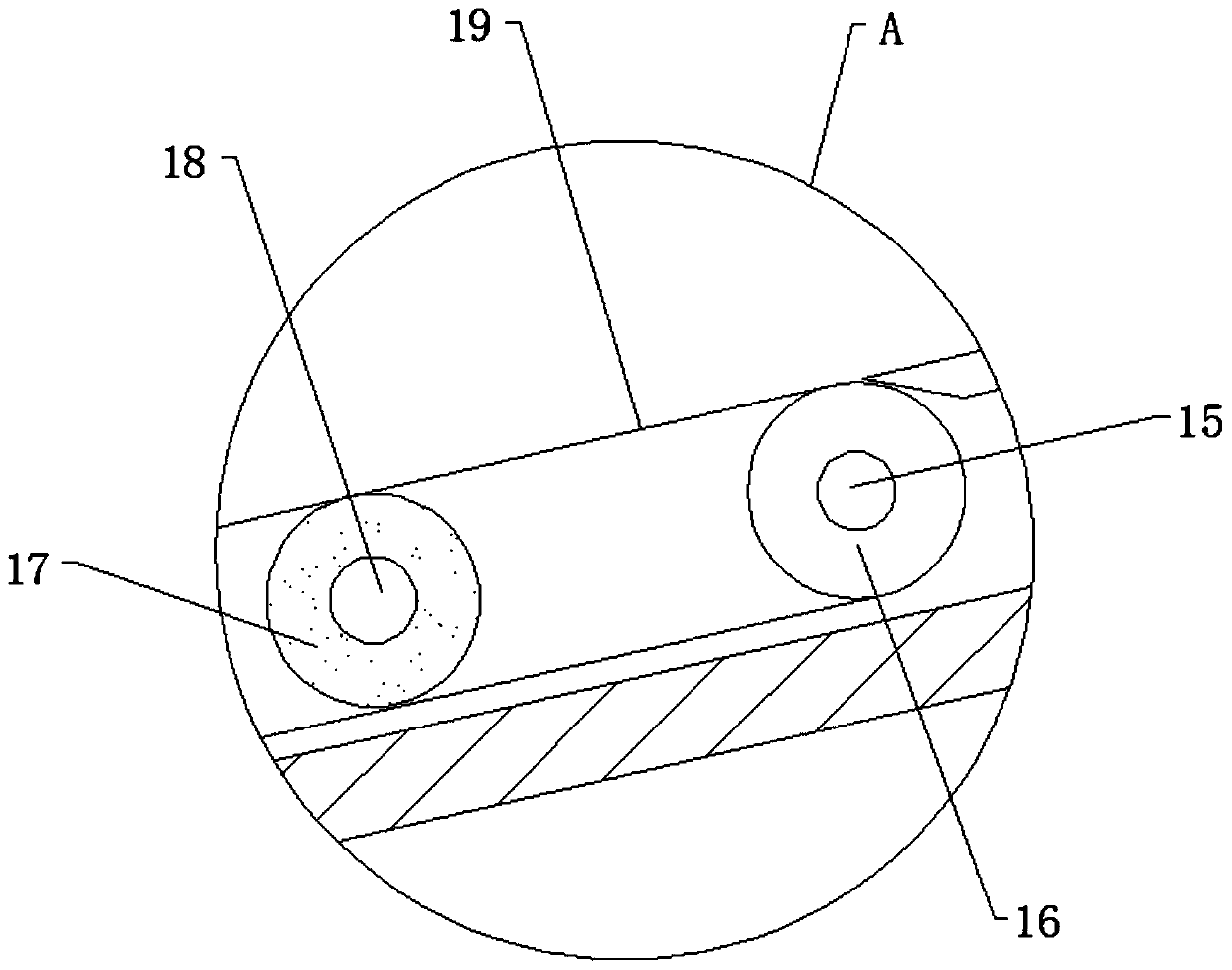

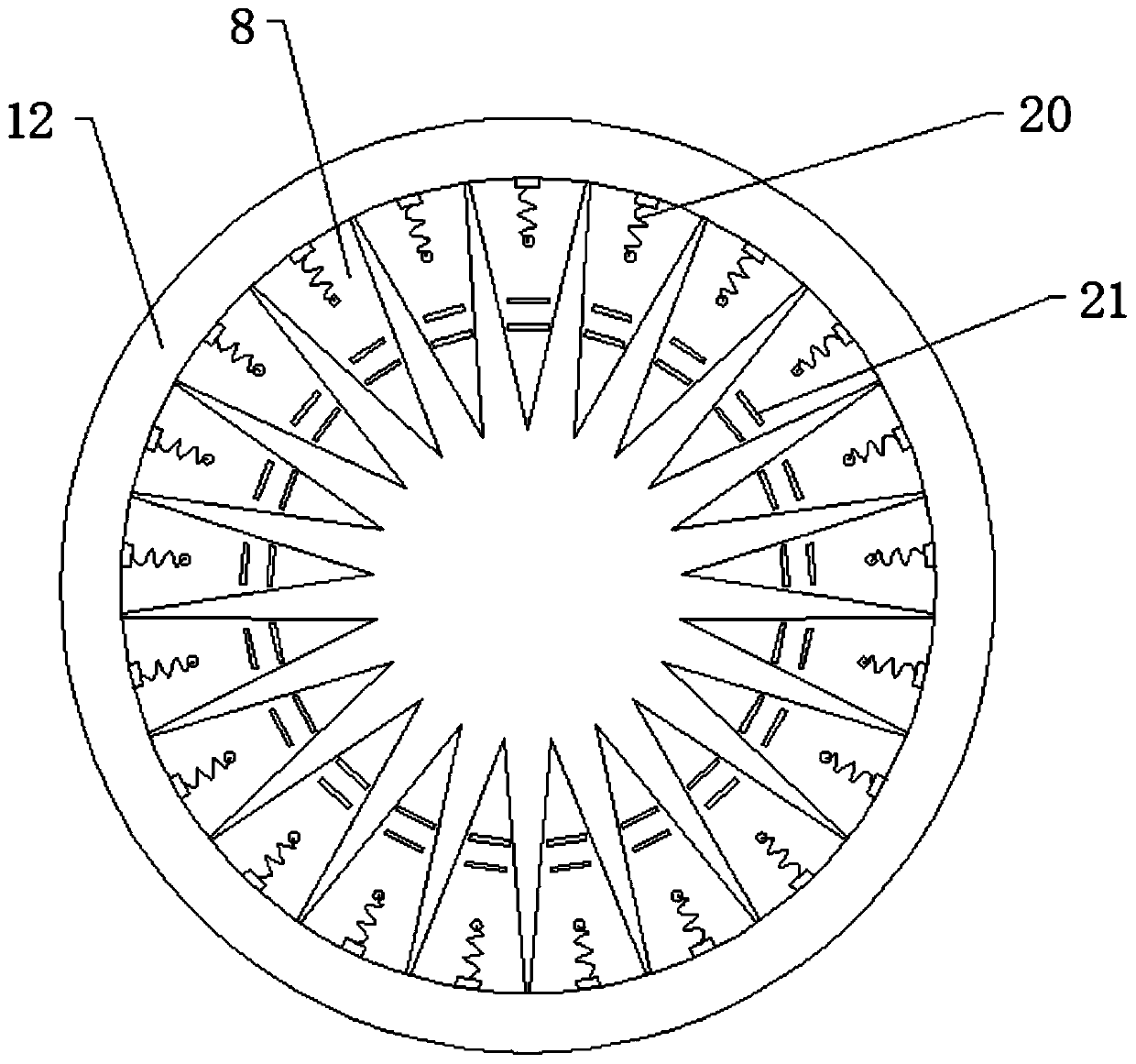

[0027] refer to Figure 1-5 , a suspension type garbage channel for building construction, comprising a first feeding pipe 1, an elbow 2 and a second feeding pipe 4, one end of the elbow 2 is inserted into one end of the first feeding pipe 1, and the elbow 2 The other end of the first feed pipe 1 is inserted into one end of the second feed pipe 4, and the end of the first feed pipe 1 far away from the elbow 2 is welded with a feed trough 14, and a material guide plate 13 is welded on the inner wall of one side of the feed chute 14. The inner wall of the feeding pipe 1 is provided with a conveying mechanism, the surface of the conveying mechanism and the surface of the material guide plate 13 are on the same straight line, and both sides of the inner wall of the second feeding pipe 4 are fixedly connected with rubber plates 3 which are alternately distributed. Alternately distributed rubber plates 3 can buffer the blanking. Both sides of the inner wall of the second feeding pip...

Embodiment 2

[0036] refer to Image 6 , a suspended garbage channel for building construction. Compared with Embodiment 1, this embodiment also includes a hook 24 and a storage bag 25. The two hooks 24 are fixed on the inner walls of both sides of the second feeding pipe 4 by bolts. At the bottom position, the storage bag 25 is hung on the inner walls of the two hooks 24 .

[0037] During use, the hook 24 in the bottom second feed pipe 4 is hung with a storage bag 25, which can be used to collect the construction waste that is discharged down, so that it can be directly consigned in the later stage, and the construction waste is more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com