Efficient kiwi fruit wine fermentation device capable of realizing total aroma recovery

A technology of kiwi fruit and fermentation equipment, which is applied in the field of high-efficiency fermentation equipment of kiwi fruit wine with full recovery of aroma, which can solve the problems of great influence on flavor, leakage of aroma, insufficient air (oxygen) blowing, etc., and achieve perfect and sufficient mixing of liquid flow , prevent deposition clogging, supplement automatic and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with accompanying drawing, the present invention is described in further detail.

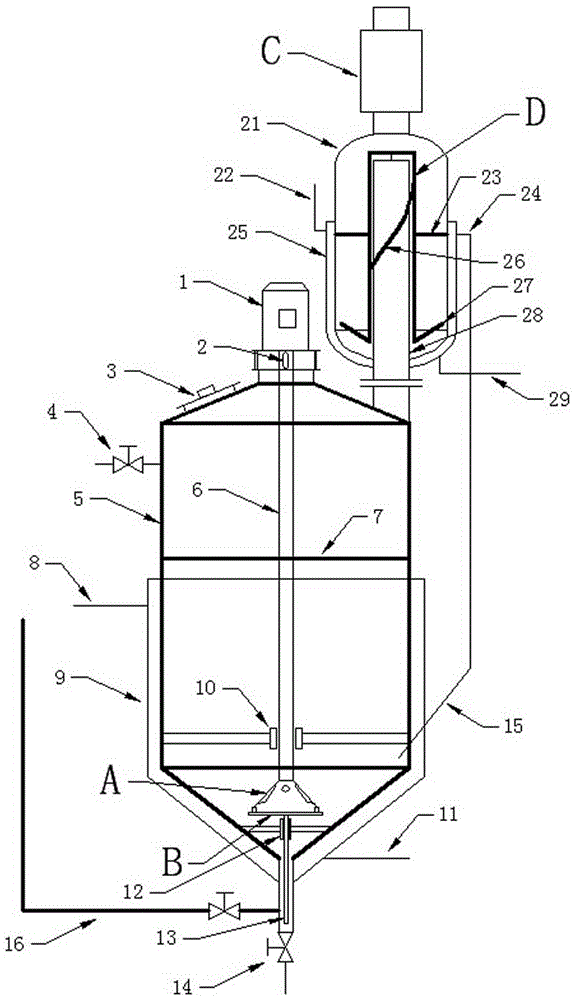

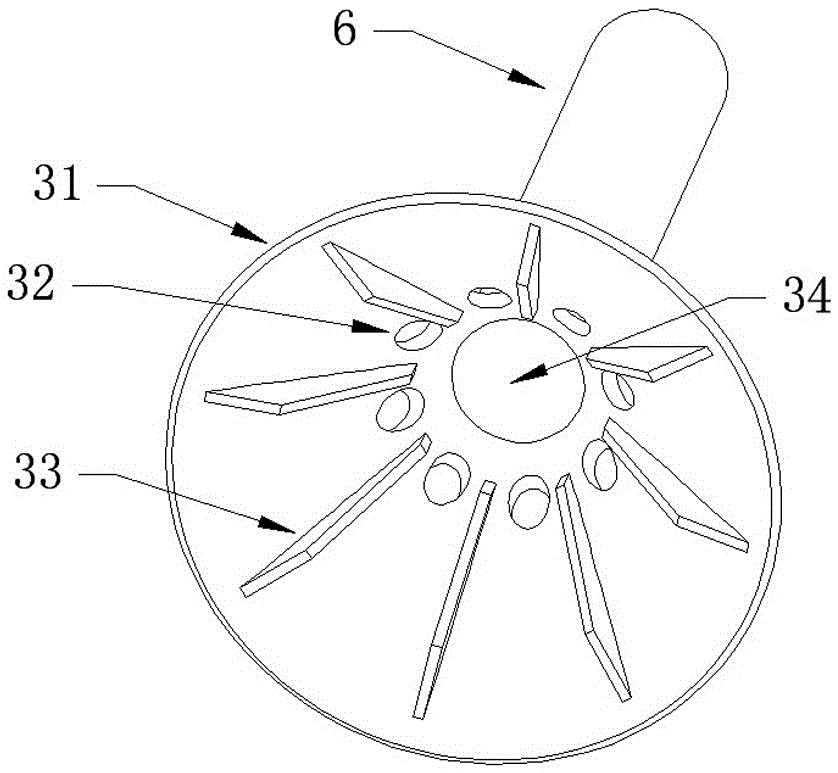

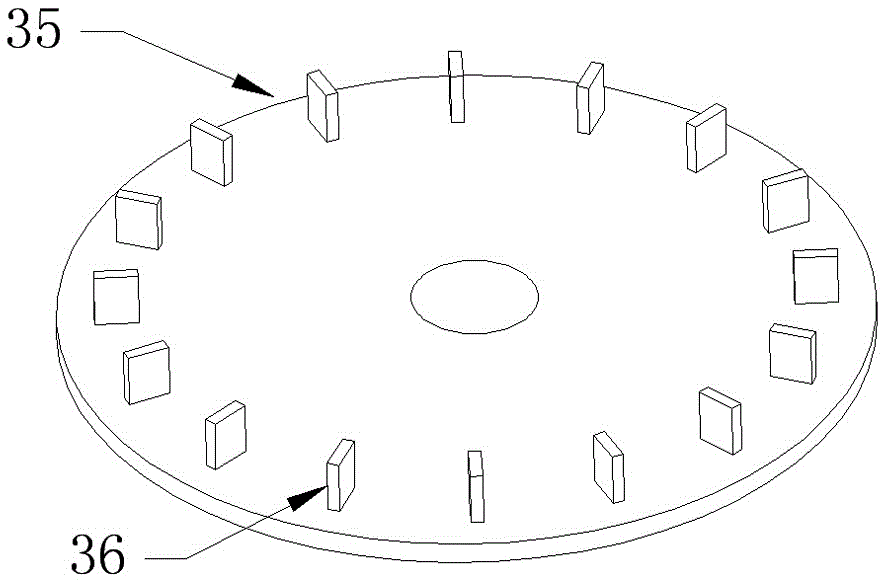

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The aroma full recovery type high-efficiency fermentation device for kiwi fruit wine shown includes a fermenter 5 and a tail gas purifier 21, the intermediate pipe 28 of the fermenter 5 and the tail gas purifier 21 is detachably connected by a flange, and the tail gas purifier 21 passes through an overflow pipe 24 And the liquid return inclined pipe 15 is connected back to the fermentation tank 5; the fermentation tank 5 is provided with a manhole 3, a liquid inlet valve 4 and a heating jacket 9, and the stirring motor 1 is inserted into the fermentation tank 5 after connecting the cone cover 31 through the hollow shaft 6, and the cone cover 31 is provided with vane 33 and liquid inlet hole 32, the air inlet 2 that shaft circumference is uniformly opened is arranged on the hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com