Ammonia-water mixed working medium thermodynamic cycle system for low-grade thermal power generation

A thermodynamic cycle system and mixed working medium technology, which is applied in the direction of machines/engines, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of high condensation back pressure of mixed steam, many links in the distillation subsystem, negative economic impact, etc. problems, to achieve the effect of improving thermal efficiency, high cycle efficiency, and small exergy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

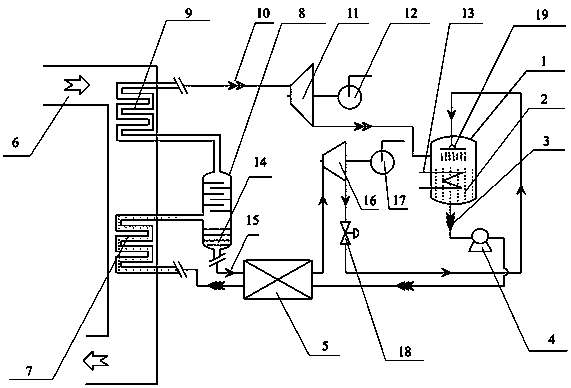

[0015] Such as figure 1 As shown, a thermal circulation system of ammonia-water mixed working medium for low-grade thermal power generation, which includes absorption condenser 1, ammonia-rich solution pipeline 3, solution pump 4, regenerator 5, heat source fluid flow channel 6, evaporation 7, gas-liquid separator 8, superheater 9, ammonia water mixed steam pipeline 10, steam turbine 11, main generator 12, cooling water heat exchanger 13, absorption liquid pipeline 15, water turbine 16, auxiliary generator 17, back The pressure regulating valve 18 and the absorption liquid sprayer 19 are interconnected as follows: the steam outlet of the steam turbine 11 is connected with the steam inlet of the absorption condenser 1 through pipelines, and the low-pressure ammonia-water mixed steam (exhausted steam) after doing work enters the absorption Condenser 1; a cooling water heat exchanger 13 is arranged inside the absorption condenser 1, and an absorption liquid sprayer 19 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com