Boiling type radiator with high heat-conducting property

A boiling type, high thermal conductivity technology, applied in the direction of heat transfer modification, indirect heat exchangers, semiconductor devices, etc., can solve the problem of unsatisfactory heat dissipation effect, and achieve the effect of simple structure, large heat conduction, and high heat conduction and heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

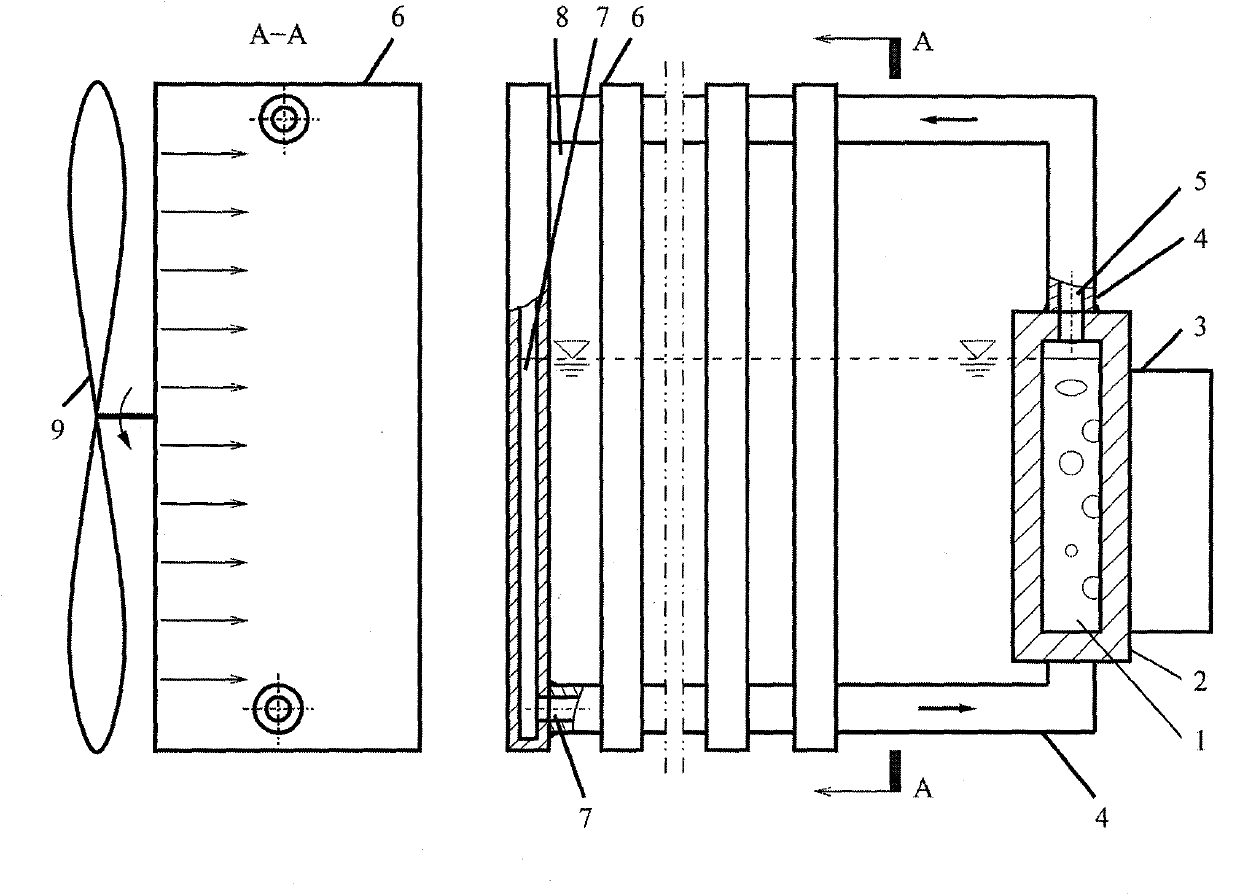

[0009] The embodiment of the heat sink of the present invention is described by taking a computer chip as an example. As shown in the figure, the working medium (1) absorbs the heat transmitted from the chip (3) in the boiling chamber (2) and boils to become a gas (5). The gas enters the condensation chamber (6) through the connecting pipe (4) and turns into a liquid (7) after releasing heat therein. The liquid gathers to the lower part of the condensation chamber due to gravity and flows into the boiling chamber through the connecting pipe. The released heat is taken away by the air (8) flowing through the outer surface of the condenser. Fan (9) is fixed on the condensing chamber for subsequent use.

[0010] It should be noted that the liquid level of the working medium should always exceed the upper limit of the chip surface in order to facilitate the heat dissipation of the entire chip surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com