A method and device for removing oil from a horizontal air flotation coupled corrugated plate

A corrugated plate, horizontal technology, applied in grease/oily substance/float removal devices, separation methods, flotation water/sewage treatment, etc., can solve the problems of slow separation speed, poor treatment effect, and high energy consumption, to prevent The effect of sediment blocking, fast separation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

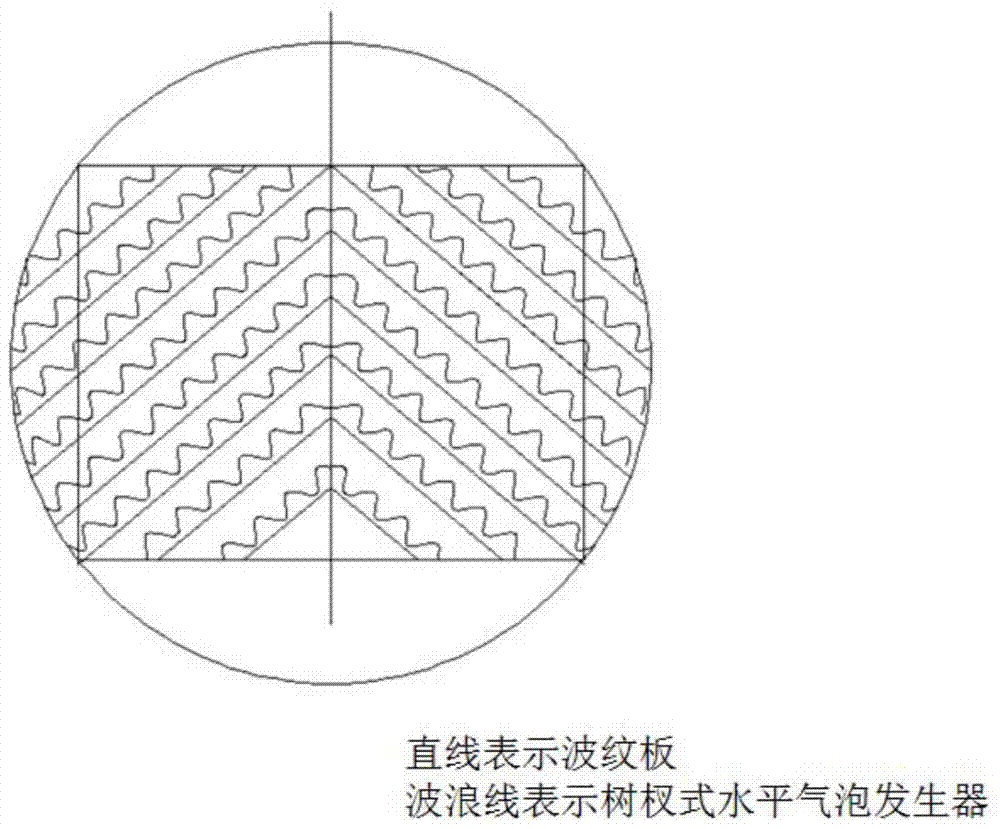

[0037] Such as Figure 5 As shown, the device of this embodiment includes a housing, a material inlet 1 placed at the left end of the housing, along the material inlet 1 to the right, successively provided with a baffle 2 that is not connected to each other, a tree branch type horizontal bubble generator 3, a symmetrical Type perforated corrugated coalescing plate 4, oil separator 5, air bag 6 and boundary gauge 7;

[0038] The air bag 6 is on the upper part of the housing;

[0039] There is a purified water outlet 10 at the lower part of the shell between the symmetrical perforated corrugated coalescing plate 4 and the oil separator 5, and an oil outlet 8 is provided at the lower part of the shell on the right side of the oil separator 5;

[0040] The height of the oil separator 5 is 60-70% of the diameter of the casing.

[0041] A mud outlet 12 is provided at the lower part of the housing between the baffle plate 2 and the tree branch type horizontal bubble generator 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com