System and method for wet flue gas desulfurization and oxidation monitoring in cooperation with sulfur mixing and blending combustion of thermal power plant

A wet flue gas desulfurization and thermal power plant technology, applied in combustion methods, controlled combustion, combustion equipment, etc., can solve the problem that mixed sulfur and mixed combustion cannot meet the system safety, economy and environmental protection at the same time, no oxidation control, oxidation Air volume regulation, centralized shared air distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

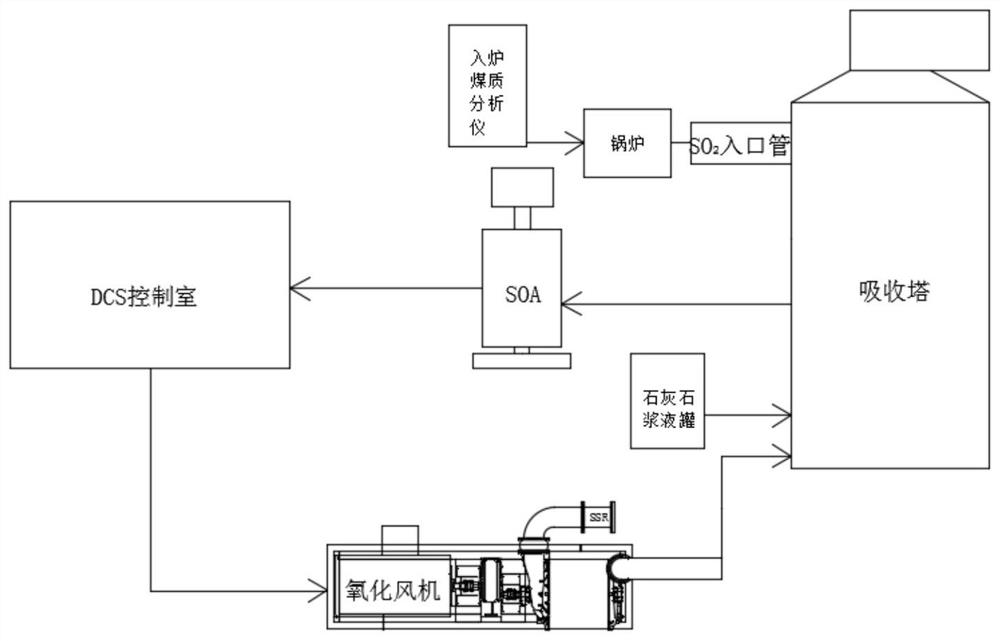

[0054] A wet-process flue gas desulfurization oxidation monitoring system coordinated with a thermal power plant mixed sulfur blending combustion system, including an absorption tower for desulfurization reaction, and also includes:

[0055] SO 2 The inlet pipe is arranged on the outside of the absorption tower, and the upper end side of the absorption tower is provided with SO 2 export, the SO 2 The outlet is equipped with detection equipment to detect SO 2 Carry out concentration detection;

[0056] Boiler, arranged upstream of the absorption tower, the flue gas channel of the boiler is connected with the SO 2 The inlet pipe is connected, and the flue gas channel is connected with the SO 2 A boiler denitrification device and an electrostatic precipitator are installed between the inlet pipes; they are used for destocking and dust removal; the upstream of the boiler is equipped with a furnace coal quality analyzer;

[0057] The slurry oxidation analyzer, i.e. SOA, is arr...

Embodiment 2

[0087] As an option, see Figure 10-12 , a wet-process flue gas desulfurization and oxidation monitoring system in cooperation with thermal power plants, the slurry oxidation analyzer includes a box body 116, and a liquid collector 104 is arranged inside the box body 116, in order to discharge the slurry in the liquid collector 104 , The bottom of the liquid collector 104 is provided with a sewage pipe 115, and the sewage pipe 115 extends into the outside of the box body 116. In order to prevent the slurry from leaking, a liquid baffle 105 is provided below the liquid collector 104; 103, the outside of the bottom of the sampler 103 is provided with a placement table 109, the lower end of the placement table 109 is provided with a lifting frame 108, the upper end of the box body 116 is provided with a seal 101, and the upper end of the seal 101 is provided with an analyzer body 113, The measurement signal of the analyzer body 113 is input into the DCS control room. In order to ...

Embodiment 3

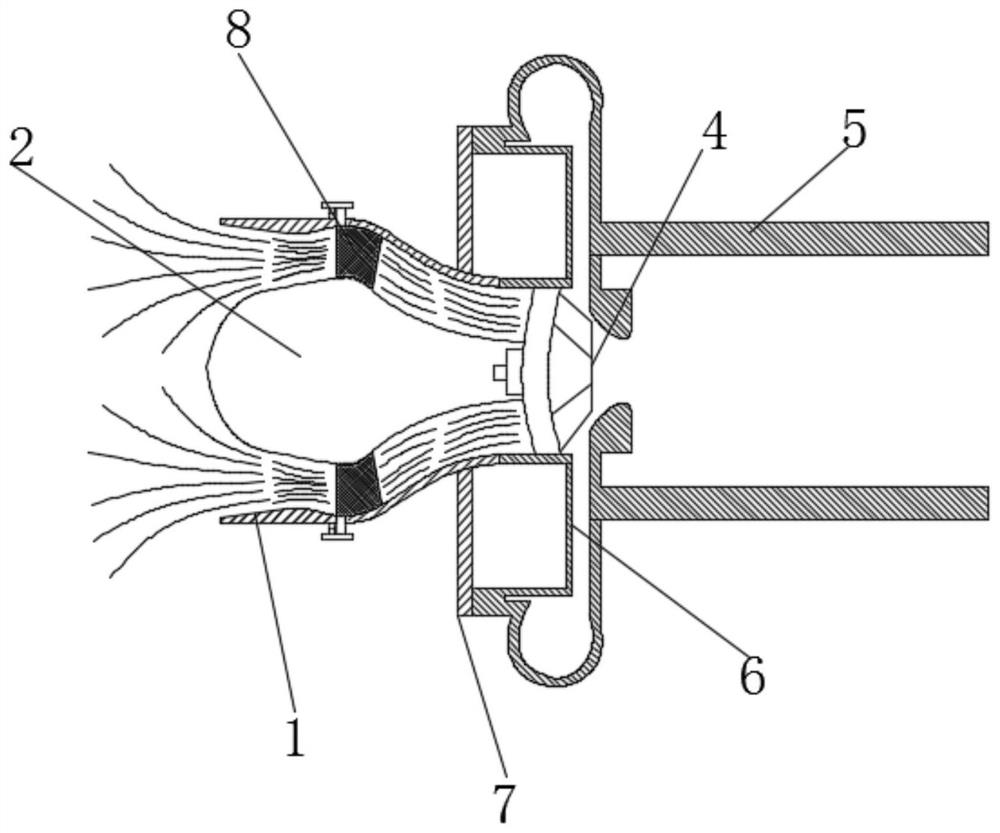

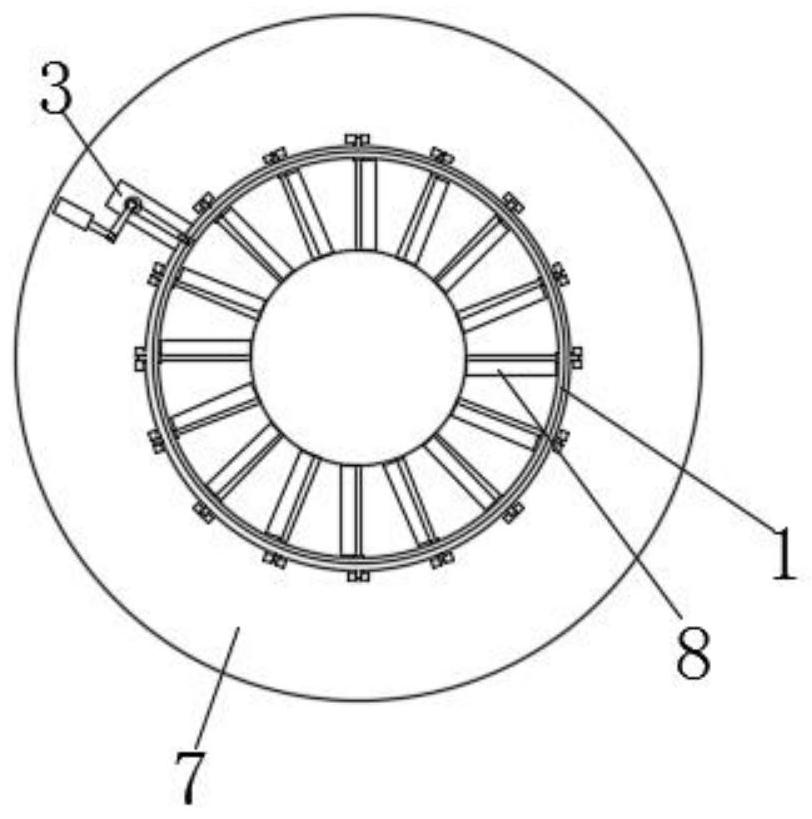

[0092] As an option, see Figure 2-9, a wet-process flue gas desulfurization oxidation monitoring system in cooperation with thermal power plants, the oxidation sub-machine includes a fan body, a fan impeller 4 is arranged inside the fan body 6, and a fan volute 5 is arranged on one side of the fan body 6, and the oxidation The air inlet of the fan is provided with an adjustment device, that is, SSR. The adjustment device includes a fixed plate 7 fixed to the oxidation fan. One side of the fixed plate 7 is provided with an air intake shell 1, and the inside of the air intake shell 1 is provided with a fairing 2. The fairing 2 is set in a spherical shape on one side and a long cylinder on the other side, which can well adjust the turbulent flow before the air enters the fan, reduce unnecessary mechanical wear and energy loss, and make the fan more efficient; The air intake housing 1 and the fairing 2 form a unique air intake channel, so that the air can be turned reasonably, cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com