Injection mold of micro-molded dumbbell product

A dumbbell-shaped and micro-molding technology is applied in the field of forming molds, which can solve the problems of single production mode, low work efficiency, low adaptability, etc., and achieve the effects of reducing production costs, improving work efficiency, and improving production flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

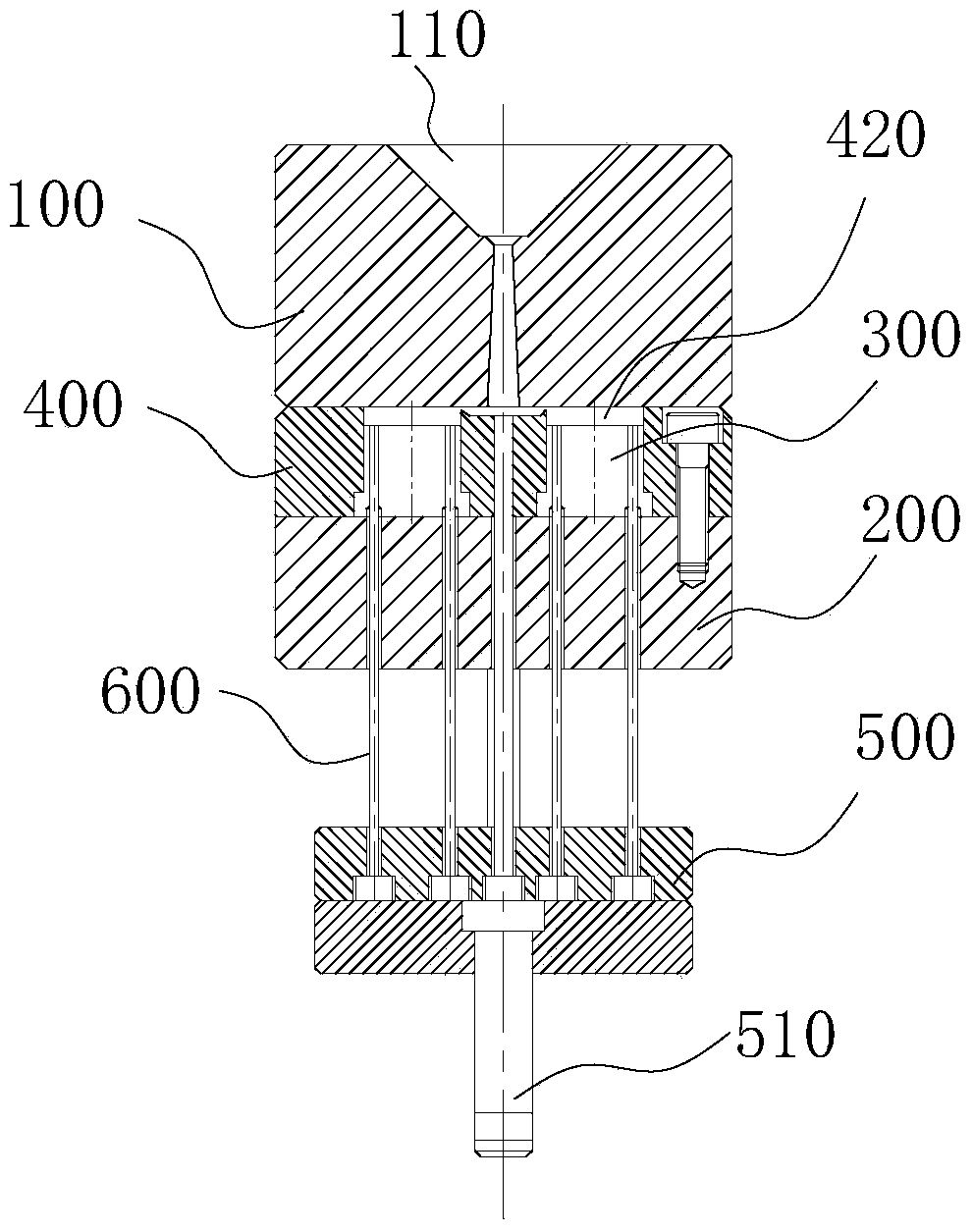

[0056] The injection mold of the micro-formed dumbbell-shaped product provided by the invention and the injection molding machine are used for injection molding of the dumbbell-shaped tensile part.

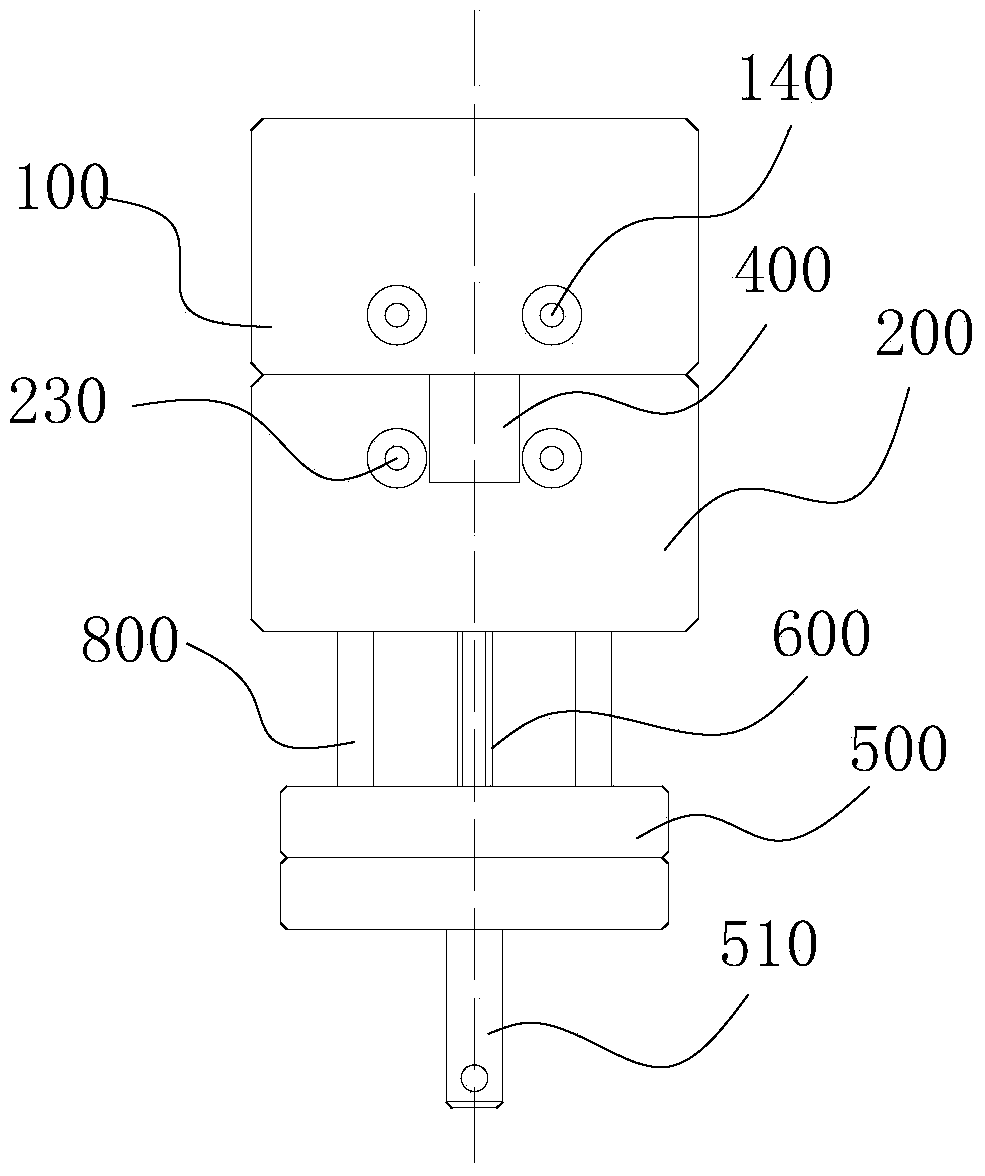

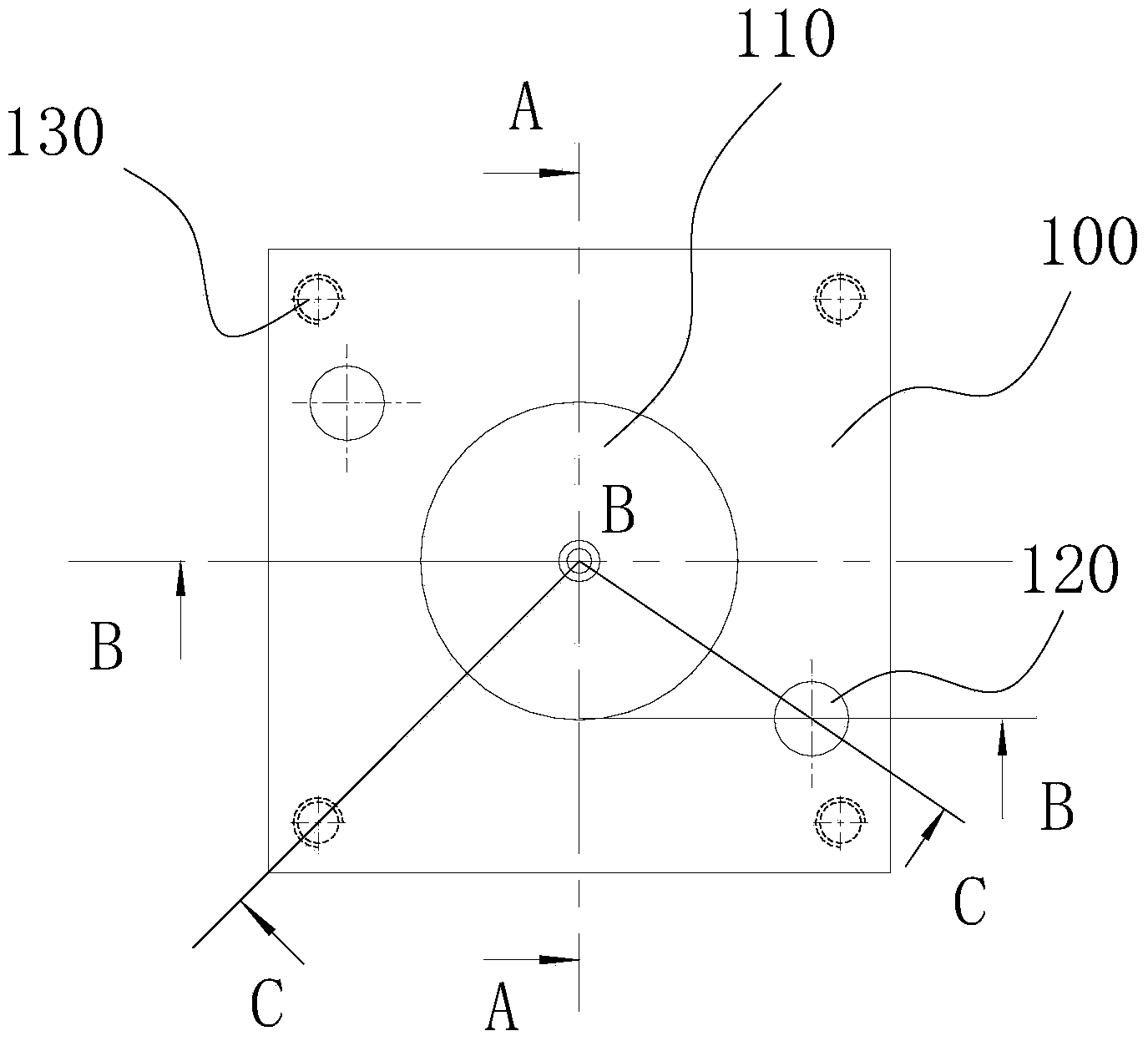

[0057] Such as figure 1 As shown, the overall profile of the injection mold of the micromolded dumbbell-shaped product is 75mm×75mm, that is, the upper surfaces of the movable mold 200 and the fixed mold 100 are both square.

[0058] Such as Figure 2-8 As shown, the injection mold of micro-molded dumbbell-shaped products includes: fixed mold 100, moving mold 200, molding insert 300 and insert 400;

[0059] The fixed mold 100 is provided with a first guide hole 120, a gate 110 and a main channel 111 communicating with the gate 110; the movable mold 200 is provided with a mounting groove 210 and a second guide hole 220; the fixed mold The upper surface of the 100 is provided with a mounting hole 130 .

[0060] The fixed mold 100 is located above the movable mold 200, the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com