Manufacturing device and manufacturing method for supportless polarized separation grid at microwave band

A polarization separation and microwave band technology, applied to electrical components, antennas, etc., can solve the problems of complex manufacturing system construction and debugging, low cost performance in small and medium batch production, and complicated maintenance and maintenance, and achieve low production costs, simplified production processes, Produce cheap effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

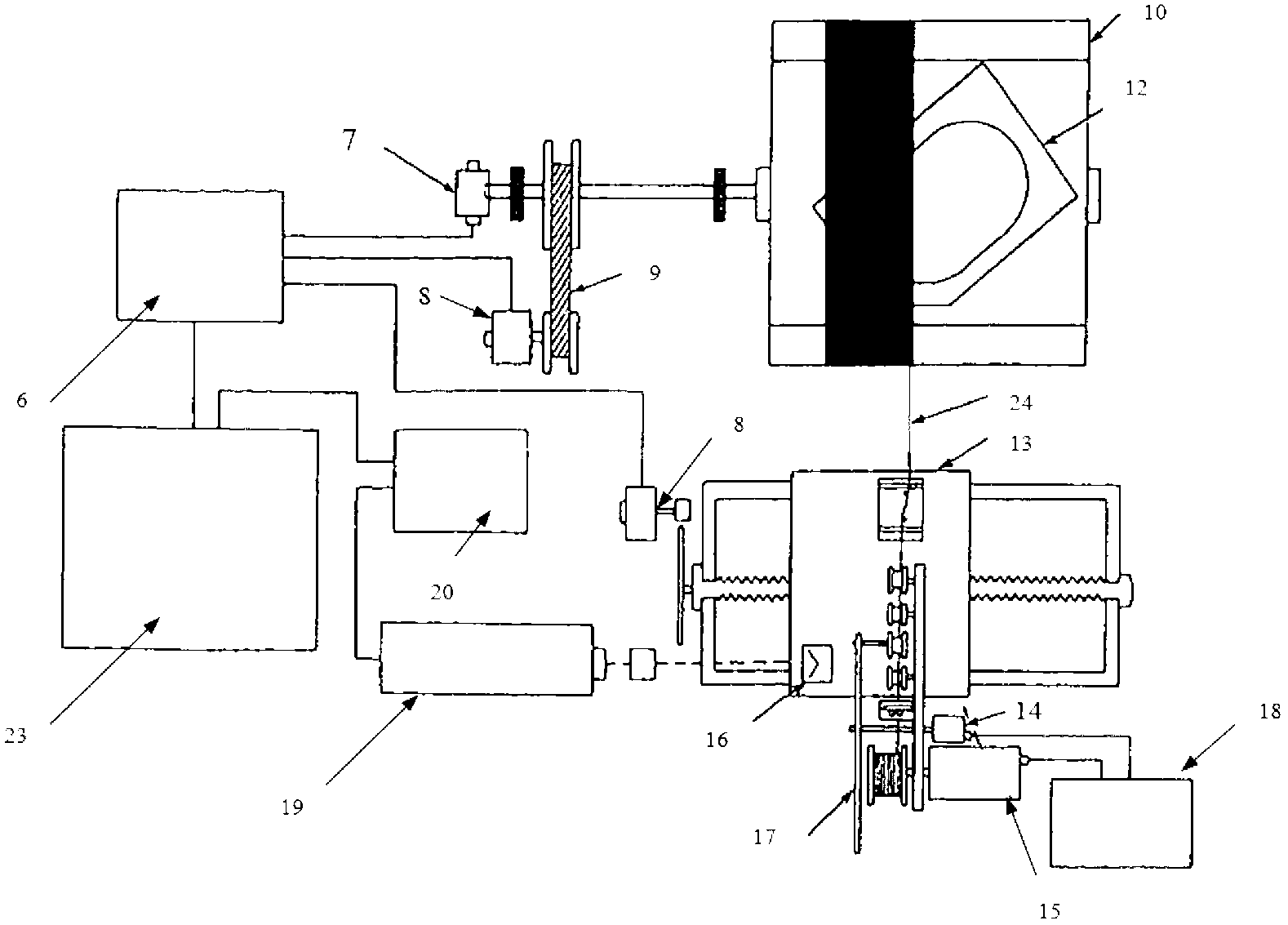

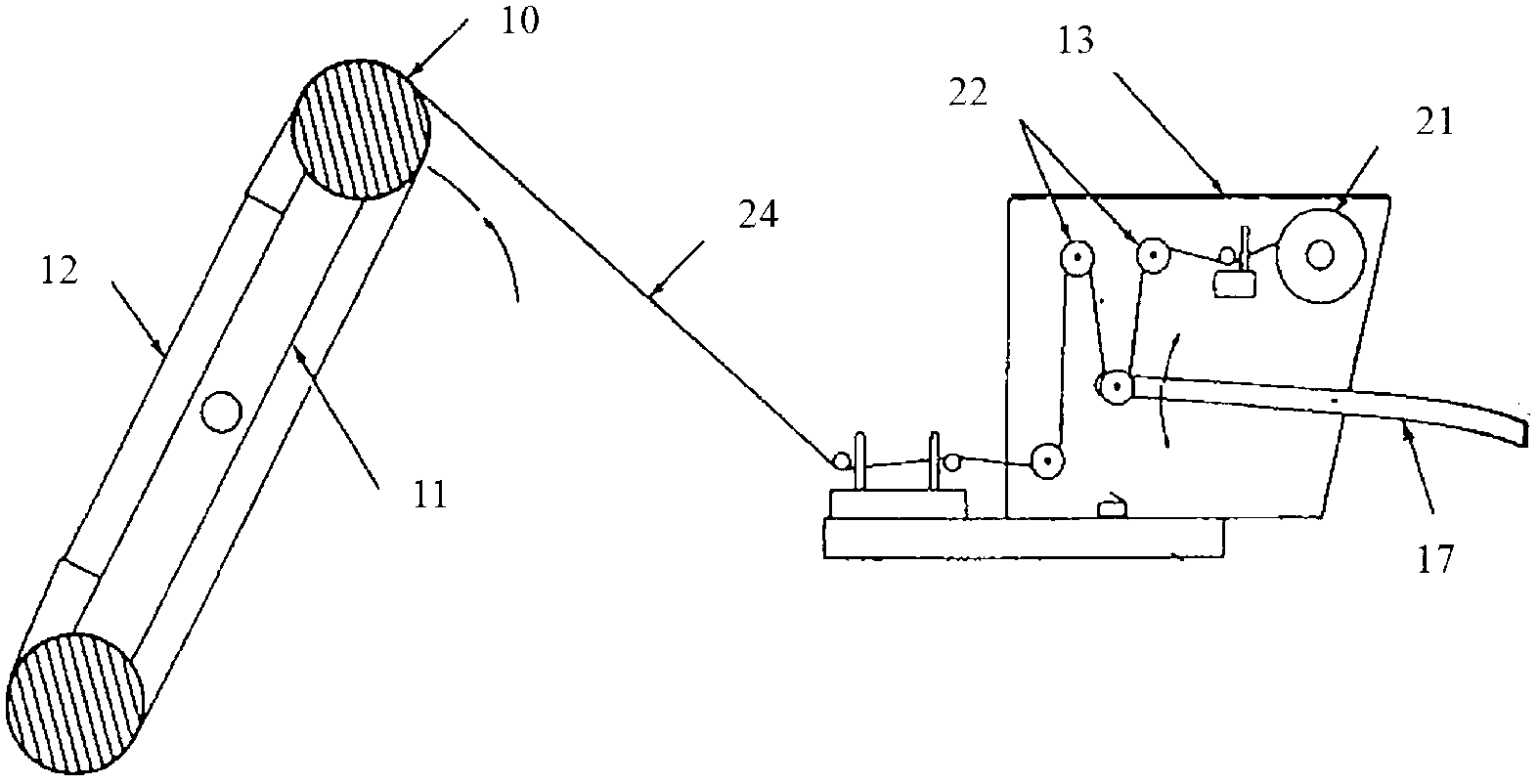

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and realized through the following technical solutions.

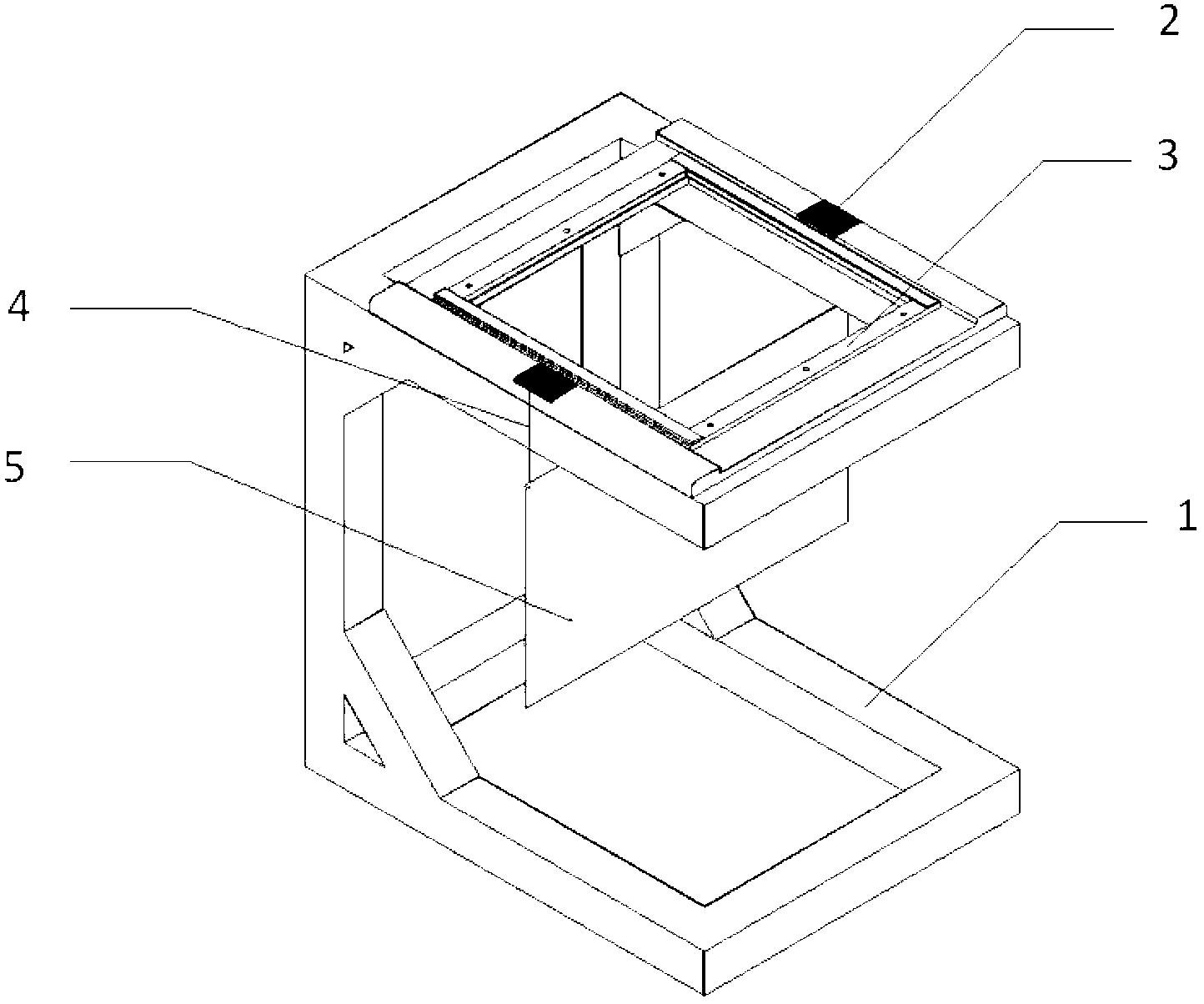

[0037] Such as figure 1 The structure of the microwave band unsupported polarization separation grid manufacturing device of the present invention is shown. The manufacturing device of the polarization separation grid includes: a bracket 1 and a grid frame 3 . Described support 1 is the support frame of whole device, and main function is to provide support for whole device, provides installation platform for mold 2;

[0038] The grid frame 3 is a support frame of the polarization separation grid, and the metal wire 4 of the polarization separation grid is fixed on the grid frame 3;

[0039] The polarization separation grid manufacturing device also includes a mold 2 and a tension weight 5. There is an installation interface between the mold 2 and the bracket 1, and grooves distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com