Method for producing anti-corrosion pattern in production of printed circuit board

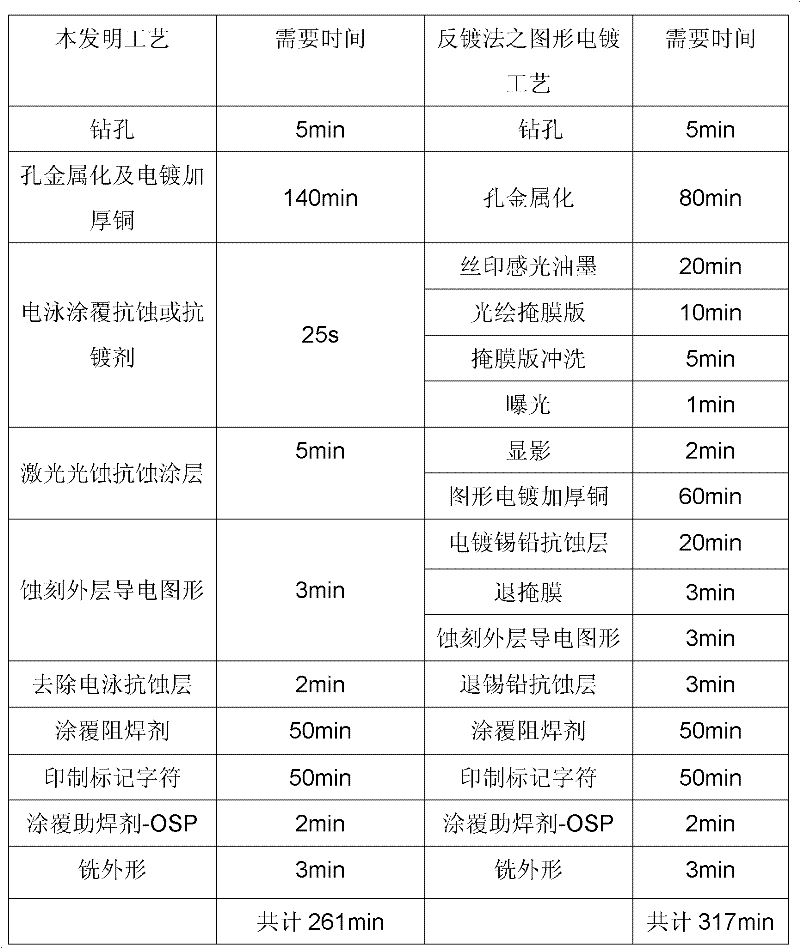

A technology for printing circuit boards and resist patterns, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve the problems of complex production process, high cost, affecting product accuracy, etc., to improve production flexibility, improve efficiency, The effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with an implementation example. The following implementation examples are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following examples.

[0064] A method for manufacturing a printed circuit board using electrophoretic coating resist and laser direct formation of resist patterns, the steps of which are:

[0065] 1. Drilling: Use a DCT-M620 drilling and milling machine to drill the circuit board substrate, and the spindle speed of the drilling machine is 60000r / min. The operation steps are as follows:

[0066] (1) Place the cut copper clad laminate on the vacuum adsorption table of the drilling and milling machine, and fix it with tape around it;

[0067] (2) Import the drilling data, and configure the drilling tool according to the data requirements for the aperture;

[0068] (3) Drill holes on the copper clad laminate according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com