Welding method and welding device for implementing welding method

A welding method and welding speed technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of setting pads and narrow space on the back, so as to improve the quality of welding seams and reduce the number of welding layers and welding passes , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

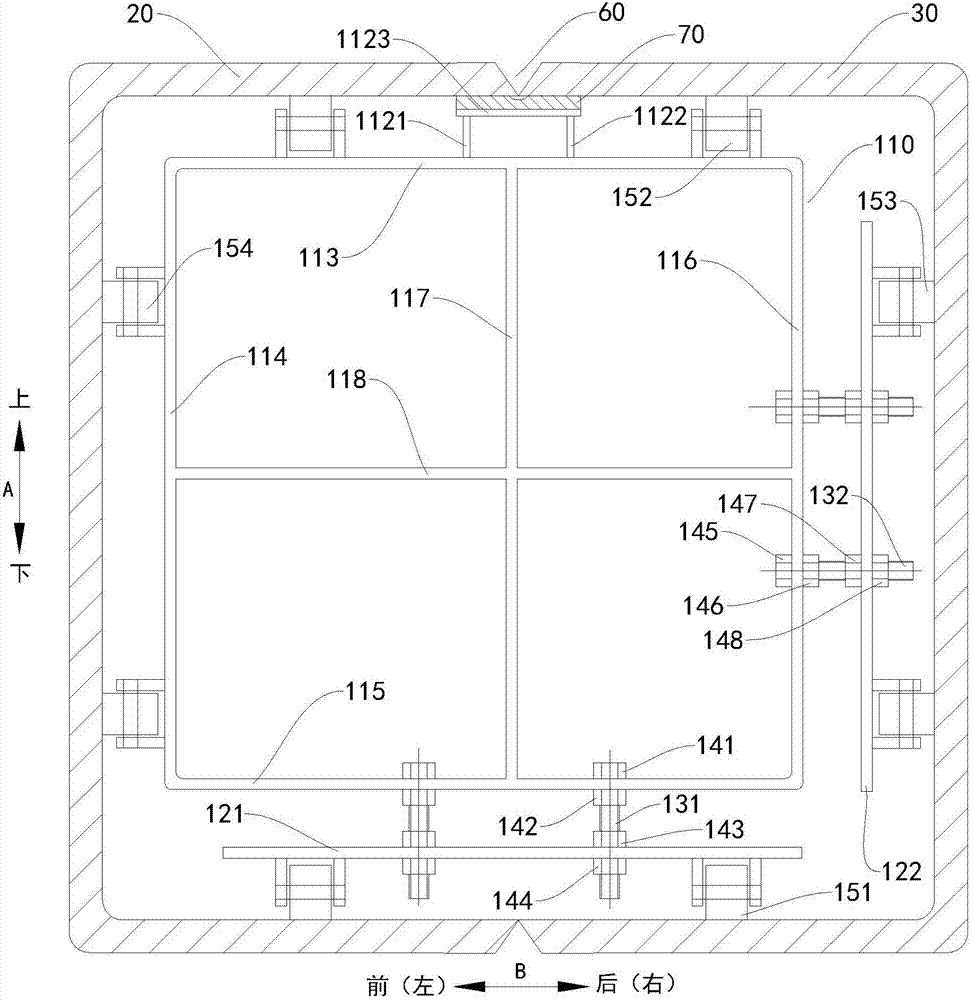

[0033] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

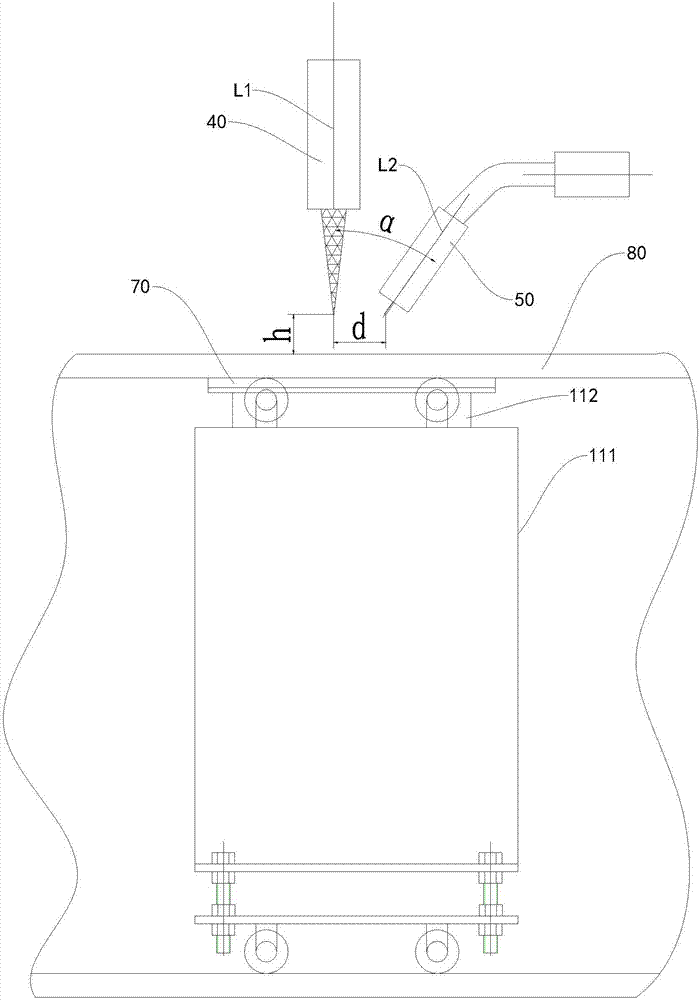

[0034] A welding method according to an embodiment of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 and figure 2 As shown, the welding method according to the embodiment of the present invention includes the following steps:

[0035] Position the first workpiece 20 and the second workpiece 30 to be welded so that the surface to be welded is in a horizontal welding position;

[0036] providing a pad 70 to the back of the surfaces to be welded of the first workpiece 20 and the second workpiece 30;

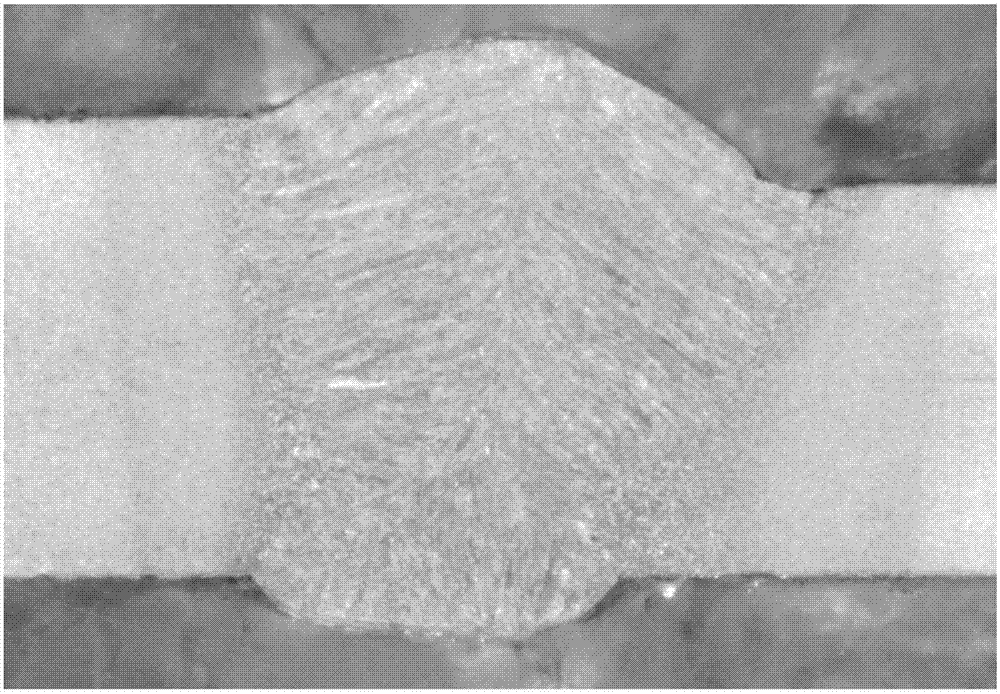

[0037] A front heat source 40 and a rear heat source 50 are provided to form welds on the surfaces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com