Preparation method of liquid-state nano disperse dye modified by graphene and graphene derivatives

A nano-dispersed and disperse dye technology, applied in the direction of dyeing method, fiber type, textile and papermaking, etc., can solve the problems of complex operation process, and achieve the effect of controllable process, short process and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Determination of the solid content of disperse dyes: take a certain amount of disperse dye filter cakes in a watch glass or a beaker, dry them in an oven, weigh the mass, and calculate their solid content;

[0029] (2) raw material preparation: take a certain amount of disperse dye filter cake and graphene, the mass ratio of the two is 1:1, then add auxiliary agents such as dispersant, defoamer, used dispersant is sodium lignosulfonate, The addition amount is 1:1 with the mass ratio of graphene and its derivatives, and the defoamer is GP type polyether defoamer, and the addition amount is 1% of the total amount.

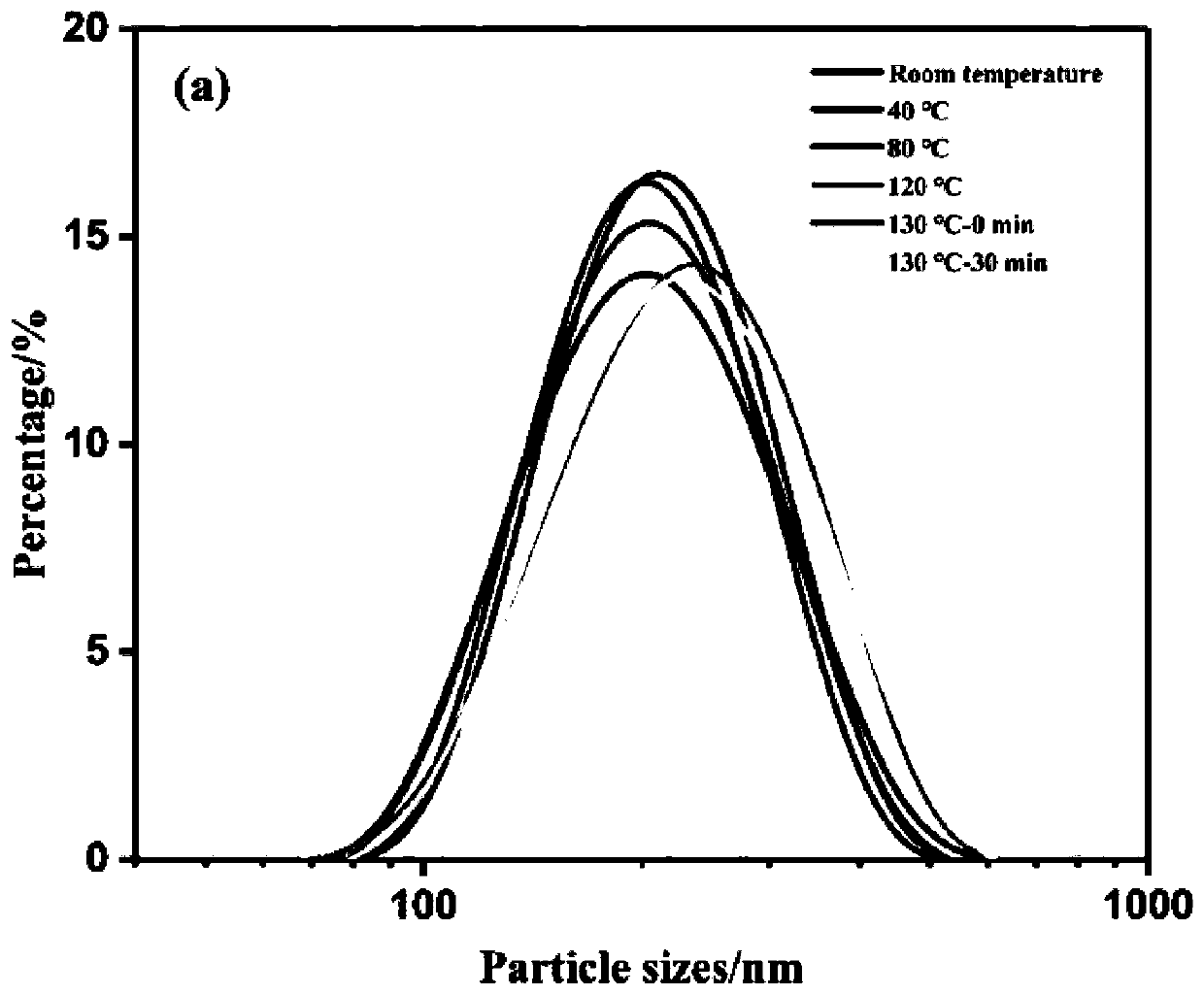

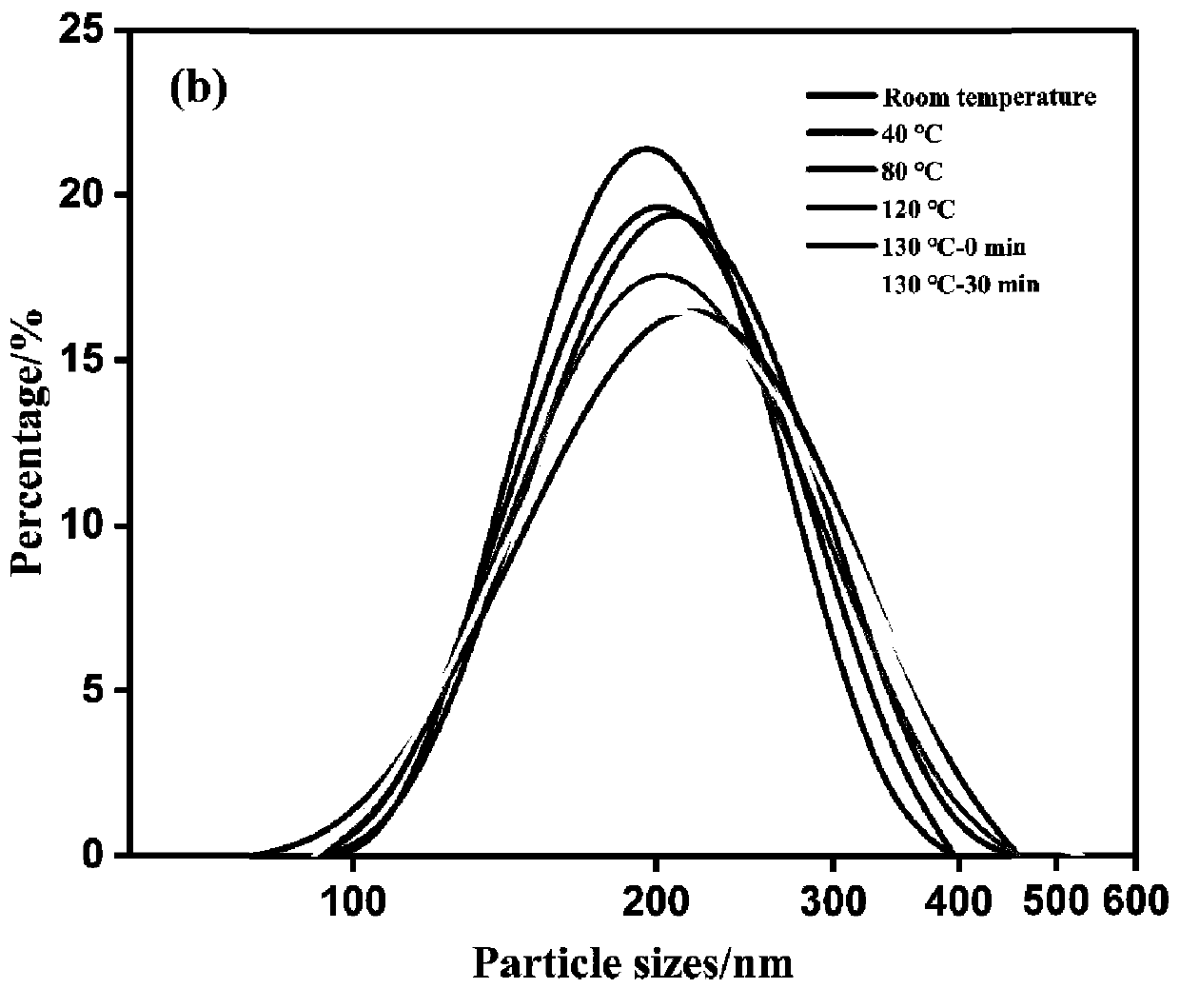

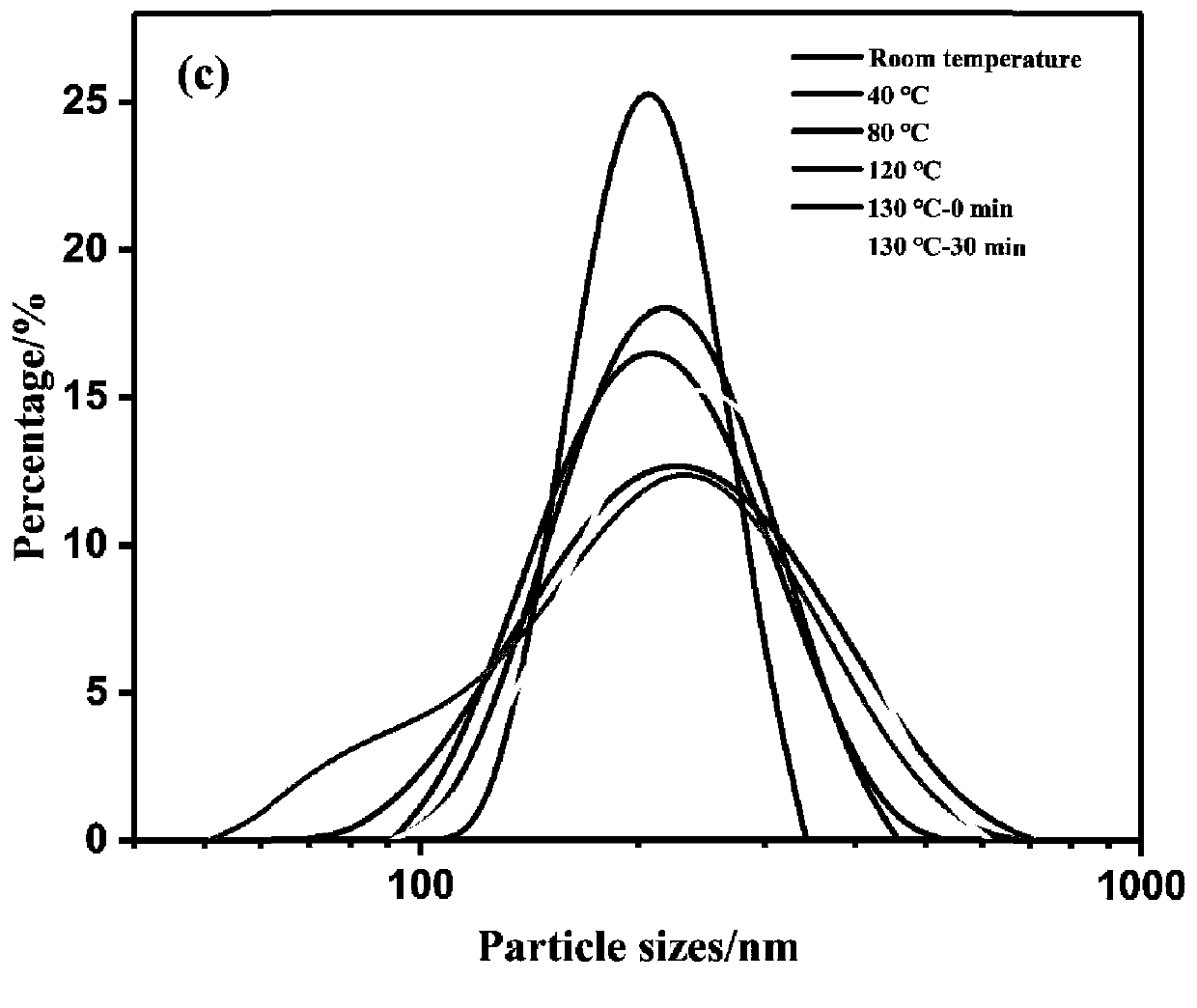

[0030] (3) Grinding process: Grinding the prepared raw materials in a high-speed dispersing machine for 4 hours at a high speed to obtain a functionally modified liquid nano-disperse dye with better dispersibility and stability, with a mass fraction of 20%;

[0031] (4) According to the dyeing concentration of disperse dyes 2% (o.m.f), the liquor ratio is ...

Embodiment 2

[0033] (1) Determination of the solid content of disperse dyes: take a certain amount of disperse dye filter cakes in a watch glass or a beaker, dry them in an oven, weigh the mass, and calculate their solid content;

[0034] (2) Raw material preparation: Weigh a certain amount of disperse dye filter cake and graphene oxide, the mass ratio of the two is 1:1.5, and then add dispersant, defoamer and other auxiliary agents, the dispersant used is sodium lignosulfonate , the addition amount is 1:1 with the mass ratio of graphene and its derivatives, and the defoamer is a GP polyether defoamer, and the addition amount is 1% of the total amount.

[0035] (3) Grinding process: Grinding the prepared raw materials in a high-speed dispersing machine for 4 hours at a high speed to obtain a functionally modified liquid nano-disperse dye with better dispersibility and stability, with a mass fraction of 20%;

[0036] (4) According to the dyeing concentration of disperse dyes of 2.5% (o.m.f)...

Embodiment 3

[0038] (1) Determination of the solid content of disperse dyes: take a certain amount of disperse dye filter cakes and place them in a watch glass or beaker, dry them in an oven, weigh the mass, and calculate their solid content.

[0039] (2) Raw material preparation: Weigh a certain amount of disperse dye filter cake and reduced graphene oxide, the mass ratio of the two is 1:2, and then add dispersant, defoamer and other auxiliary agents, the dispersant used is lignosulfonic acid Sodium, the addition amount is 1:1.5 with graphene and its derivatives mass ratio, and the defoamer is GP polyether defoamer, and the addition amount is 1.5% of the total amount.

[0040] (3) Grinding process: Grinding the prepared raw materials in a high-speed dispersing machine for 5 hours at a high speed to obtain a functionally modified liquid nano-disperse dye with better dispersibility and stability, with a mass fraction of 25%;

[0041] (4) According to the dyeing concentration of 3% (o.m.f) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com