Patents

Literature

97results about How to "Solve static problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive run board and manufacturing method thereof

InactiveCN102309835ASolve static problemsAvoid adsorptionSynthetic resin layered productsWood layered productsMethyl ethyl ketone peroxideEngineering

The invention discloses a conductive run board and a manufacturing method thereof. No static electricity is generated even if a running belt and the run board mutually rub, so that the conductive run board is safe and reliable to operate. The conductive run board is characterized in that the substrate surface of the run board is covered with a conductive layer. The formula of the conductive run board comprises the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 15-30 parts of graphite, 0.3-1.2 parts of cobalt promoting agent and 0.5-2 parts of methyl ethyl ketone peroxide. The manufacturing method of the conductive run board comprises the following steps: according to the above formula components, mixing the graphite into the unsaturated polyester resin; dispersing by a three-roll grinder; adding the cobalt promoting agent to evenly mix; then adding the methyl ethyl ketone peroxide to evenly mix; coating on the substrate surface of the run board; and curing at normal temperature.

Owner:吴小凤

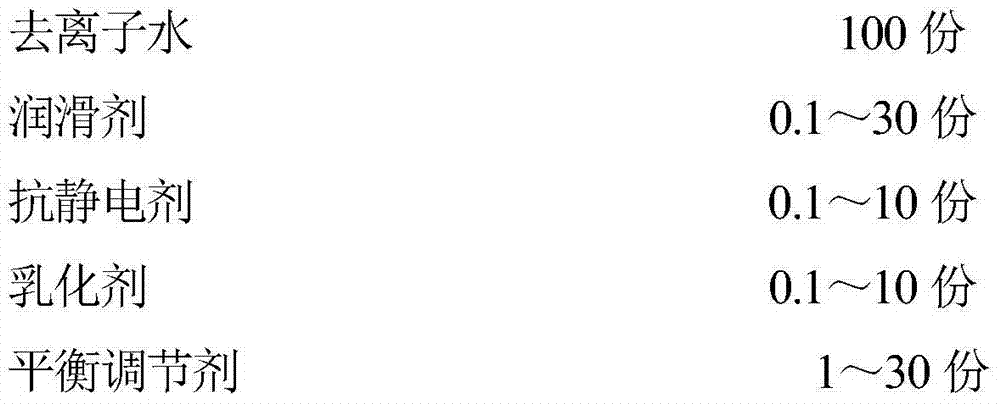

General grade pitch-based carbon fiber spinning oil

InactiveCN103757899AAvoid stickingTensile strength has no effectCarbon fibresIsolation effectAntistatic agent

The invention discloses general grade pitch-based carbon fiber spinning oil. The oil is prepared by mixing deionized water, a lubricating agent, an antistatic agent, an emulsifying agent and a balance regulator in a stirring state. The general grade pitch-based carbon fiber spinning oil has the beneficial effects that the viscosity of the oil is 2-20mPa.s and the light transmittance is 80-98%; the oil has an antistatic effect when sprayed onto fiber surfaces, ensures cohesive forces between fiber monofilaments, achieves a fiber packing effect and prevents fiber adhesion; oil films formed on the fiber surfaces not only protect the monofilament surfaces from being damaged in spinning but also have the same adhesion prevention and isolation effects in the non-melting and carbonizing processes, so that the problems of easiness in adhesion, static electricity, wear and the like in the general grade pitch-based carbon fiber preparation process can be solved; test results indicate that the contact angles between the general grade pitch-based carbon fiber spinning oil and the fiber surfaces are 0-5 degrees, the oil can be well coated on the fiber surfaces, and the fiber strength retention rate is 95-100%, so that the oil basically has no impact on the tensile strength of fibers.

Owner:SHAANXI NORMAL UNIV

Environment-friendly antistatic polypropylene plastic inspection well material restored and modified by waste polypropylene molecular chain and preparation method for environment-friendly antistatic polypropylene plastic inspection well material

The invention discloses an environment-friendly antistatic polypropylene plastic inspection well material restored and modified by a waste polypropylene molecular chain and a preparation method for the environment-friendly antistatic polypropylene plastic inspection well material. The environment-friendly antistatic polypropylene plastic inspection well material consists of the following components in percentage by weight: 36.4-76.2% of waste polypropylene, 3-6% of a molecular chain restoration agent, 2-5% of antistatic master batch, 5-15% of a flexibilizer, 10-30% of minerals, 3-5% of a compatilizer, 0.2-0.6% of an antioxidant, 0.2-0.4% of a light stabilizer and 0.4-1.6% of a lubricant. The environment-friendly antistatic polypropylene plastic inspection well material has the advantage that the polypropylene plastic inspection well material which is excellent in mechanical performance, cold resistance, heat resistance and antistatic effect is prepared by adopting the components of waste polypropylene, the molecular chain restoration agent, the antistatic master batch, the flexibilizer, the minerals, the compatilizer and the like; the waste polypropylene plastic can be greatly recycled because of the preparation of the material, the environmental pollution because of the waste polypropylene plastic and the resource waste are effectively solved, and an electrostatic problem generated in mounting and transporting processes of the plastic inspection well is completely solved, so that the safety of the plastic inspection well in engineering operation is greatly improved.

Owner:雷刚

Polypropylene film packaging material and preparation method thereof

The invention discloses a polypropylene film packaging material and a preparation method thereof. The polypropylene film packaging material is composed of the following components by weight: 75-90 parts of polypropylene, 20-30 parts of maleic anhydride grafted polypropylene, 10-25 parts of calcium stearate, 10-19 parts of polyethylene glycol, 5-18 parts of cyclodextrin and 0.05-1.5 parts of graphene. The polypropylene film packaging material prepared by the method has good adhesion with ink, can meet requirements of various automatic packaging production lines, and reduces occurrence possibility of static electricity.

Owner:SUZHOU SHENGBAIWEI PACKAGE EQUIP

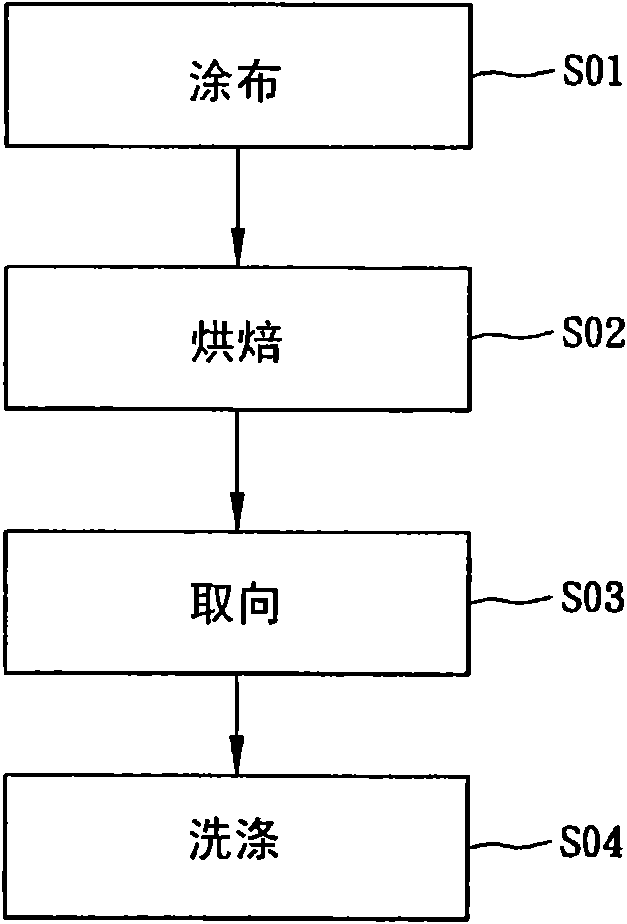

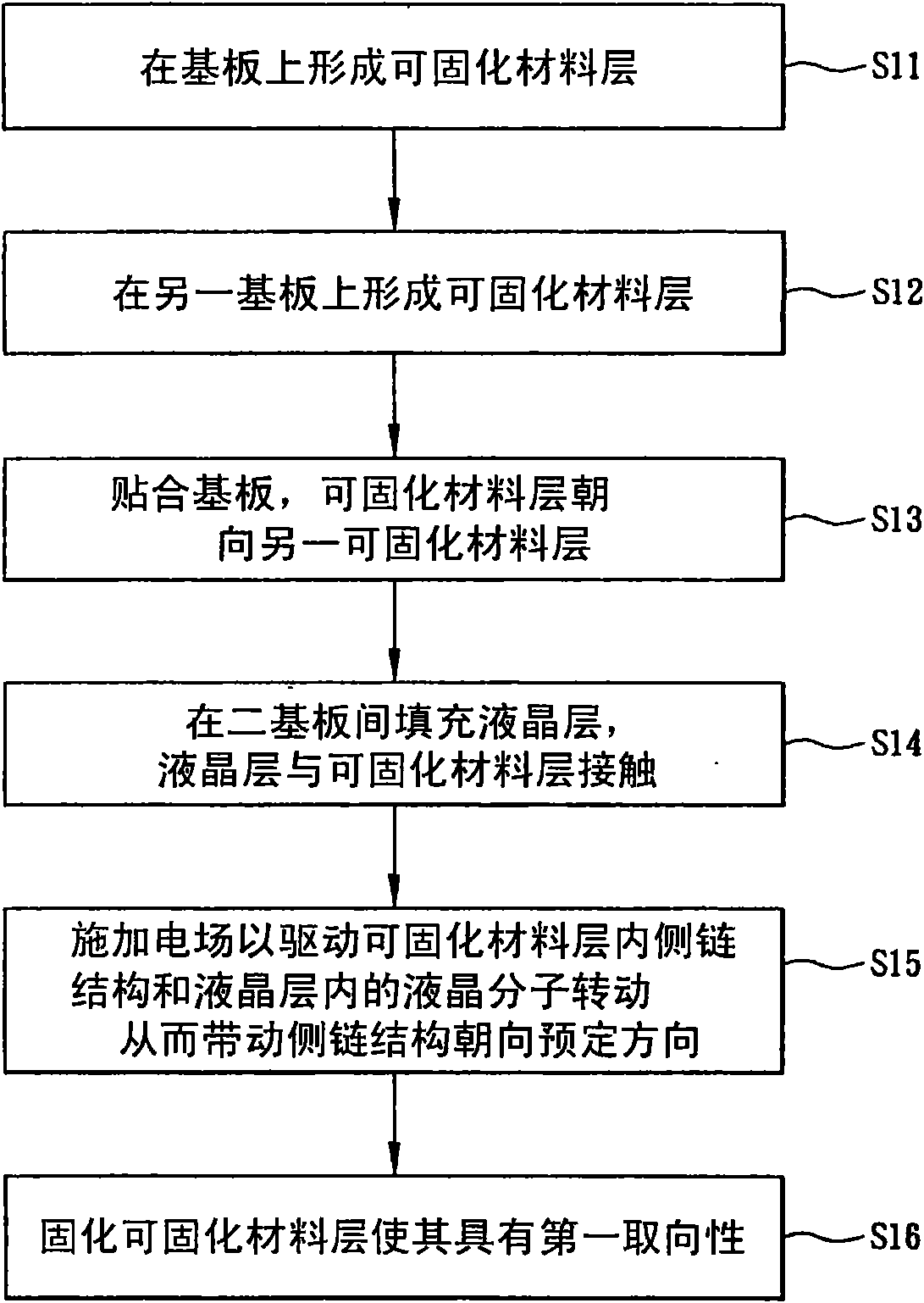

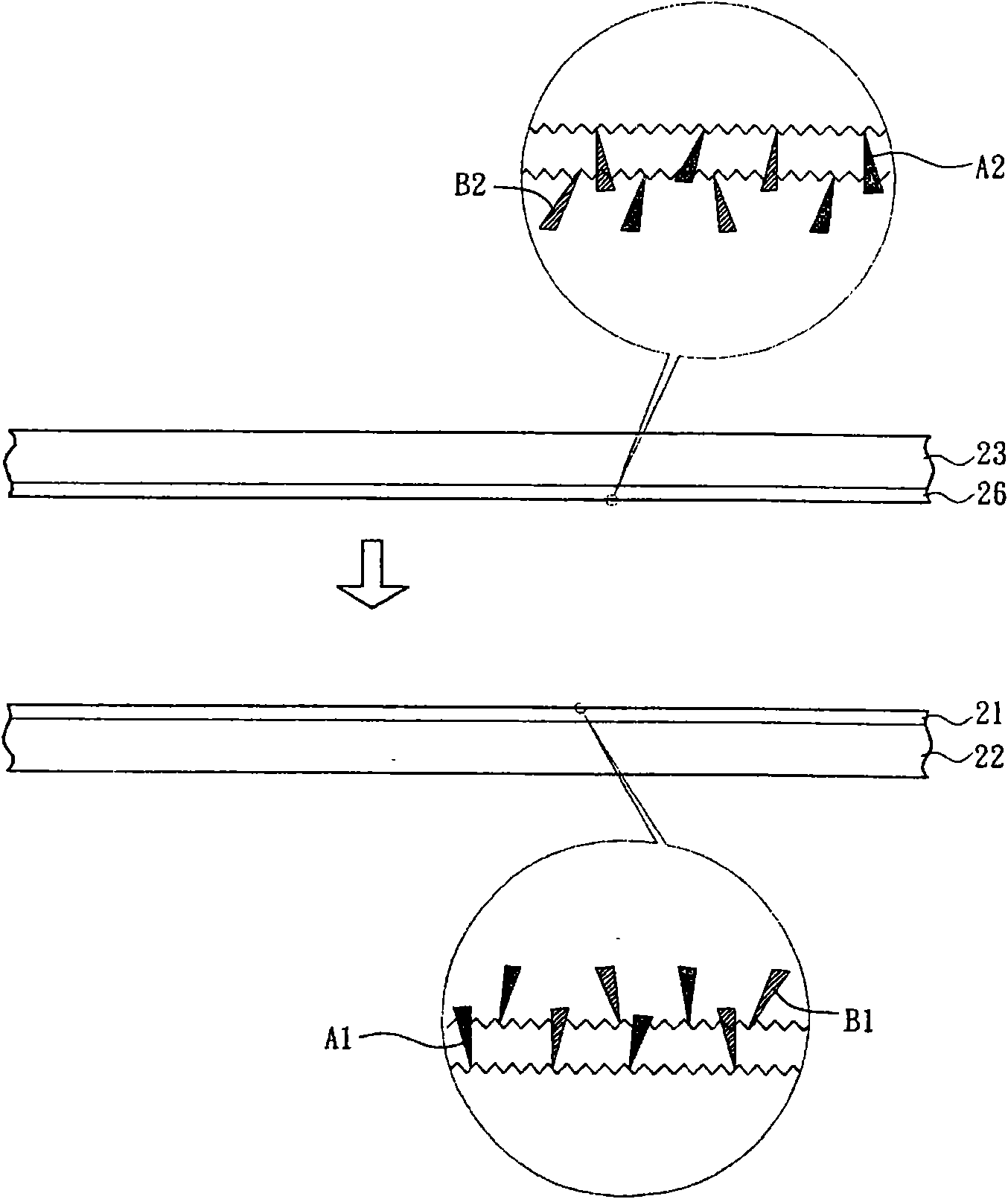

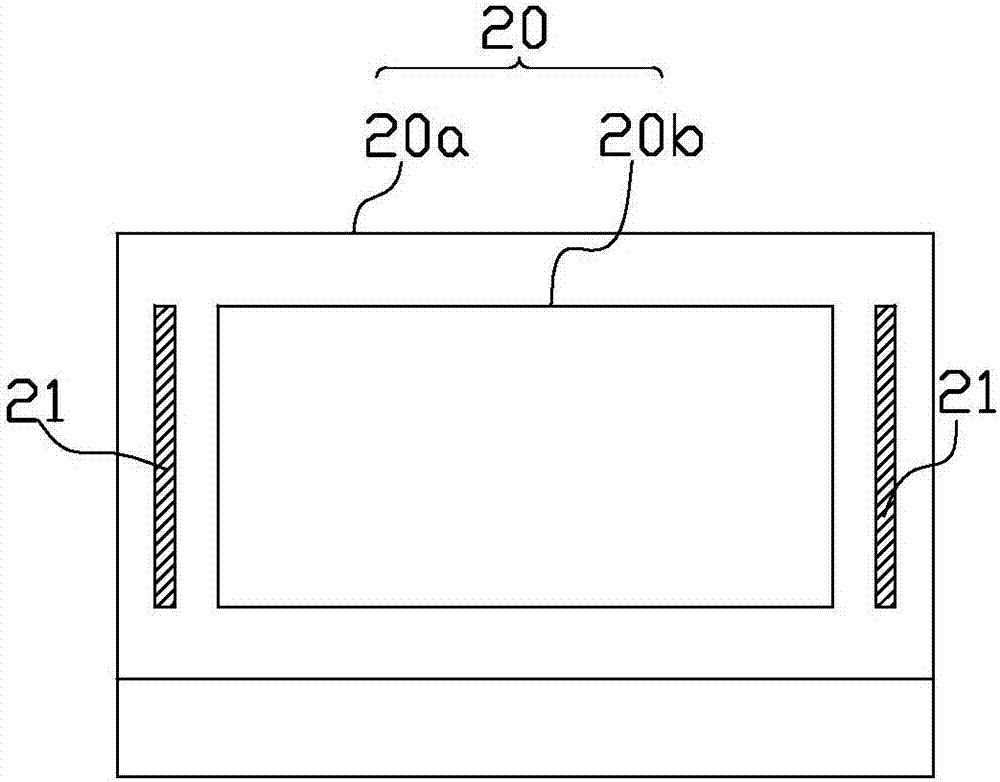

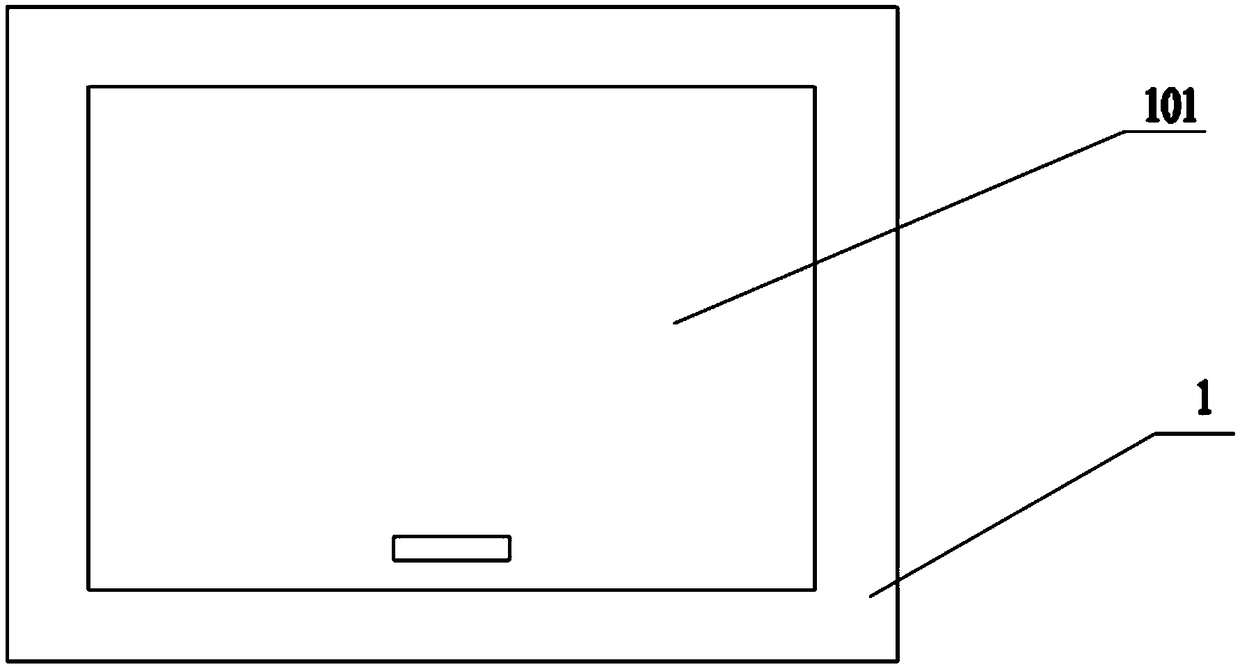

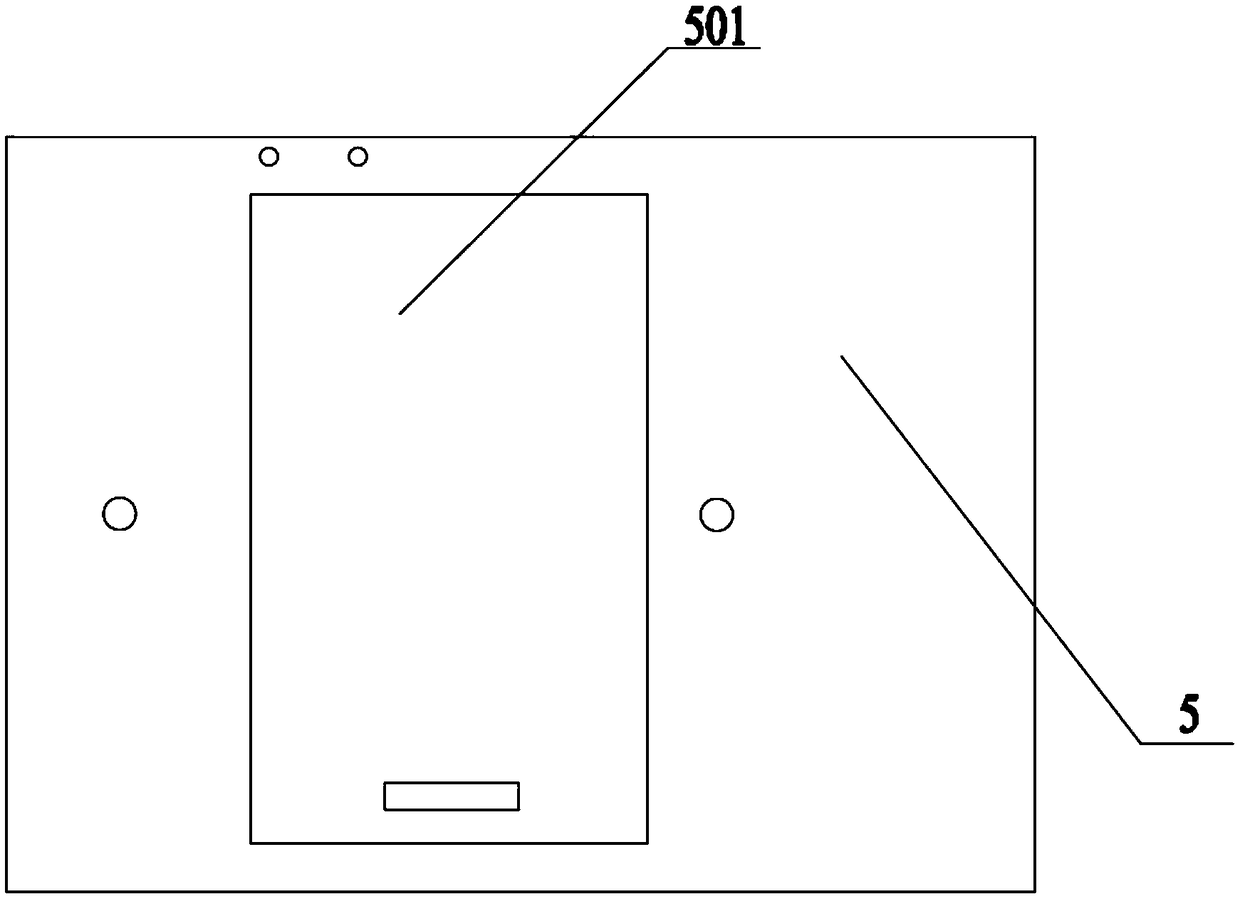

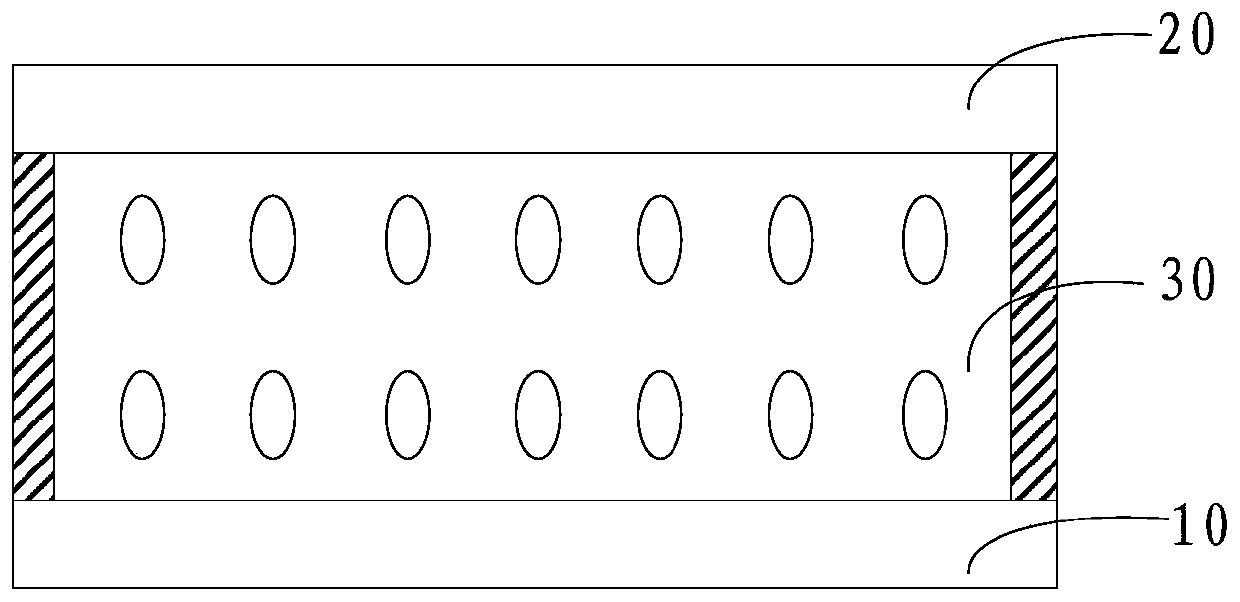

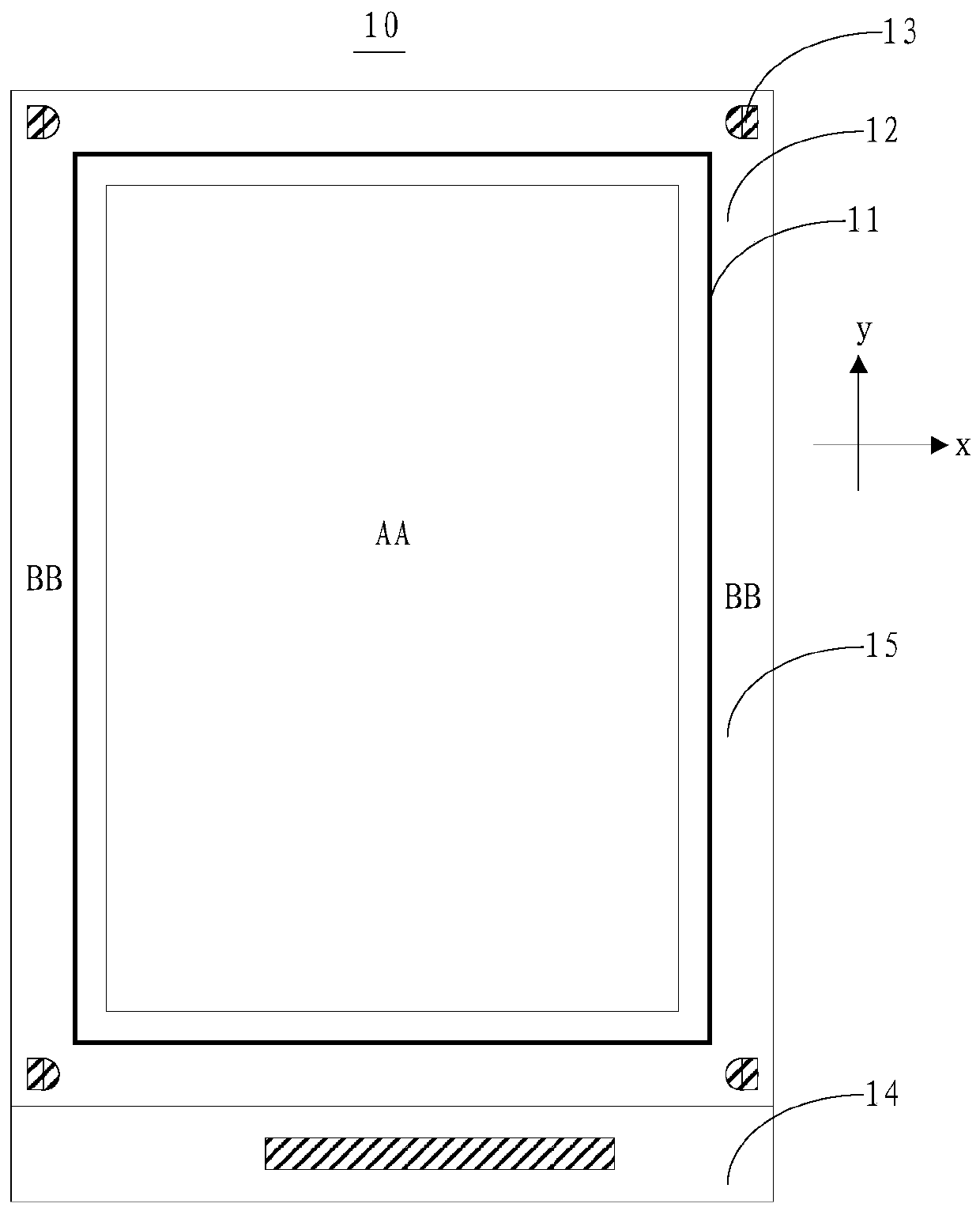

Manufacturing method of oriented film and LCD panel

The invention discloses a manufacturing method of an oriented film, comprising: forming a solidifiable material layer with a side chain on a first substrate; sticking a first substrate and a second substrate to cause the solidifiable material layer to face the second substrate; filling a liquid crystal layer between the first substrate and the second substrate to ensure that the liquid crystal layer can be contacted with the solidifiable material layer; applying an electric field to cause the side chain to face a preset direction; solidifying the solidifiable material layer to cause the side chain to be in crosslinking and be solidified, and ensuring that the solidifiable material layer has liquid crystal orientation. The manufacturing method of an LCD panel comprises: forming a first UV-curing material layer with a first side chain on the first substrate; forming a second UV-curing material layer with a second side chain on the second substrate; sticking the first substrate and the second substrate to cause the first UV-curing material layer to face the second UV-curing material layer; filling the liquid crystal layer between the first substrate and the second substrate; causing the liquid crystal layer to contact with the first UV-curing material layer and the second UV-curing material layer; applying a first electric field to cause the first side chain to face the first preset direction; and photocuring the first UV-curing material layer to cause the UV-curing material layer to have the first orientation.

Owner:INNOLUX CORP

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

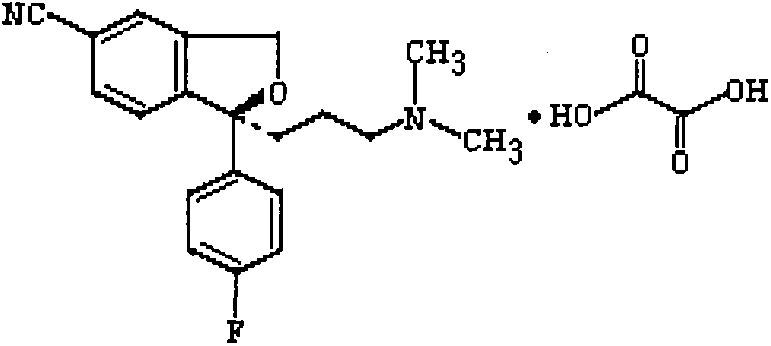

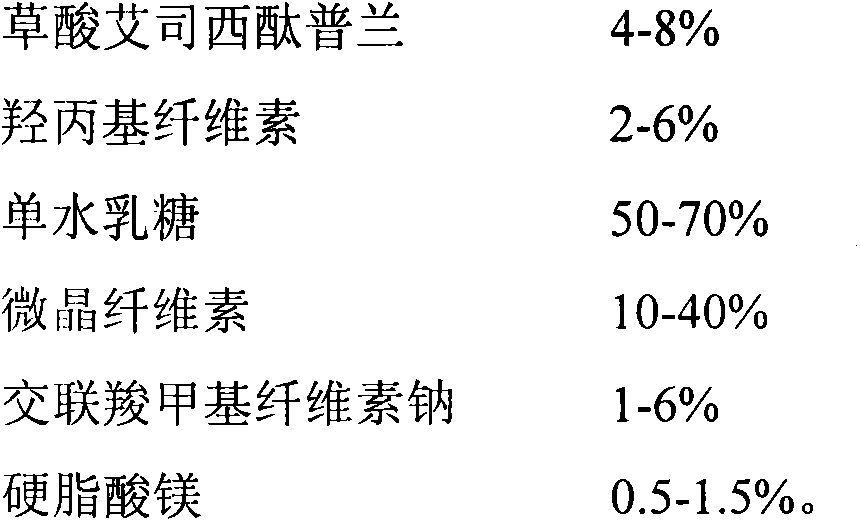

Tablet containing escitalopram oxalate and preparation method thereof

ActiveCN104523638ASolve Content Uniformity ProblemsSolve the sticking problemOrganic active ingredientsPharmaceutical non-active ingredientsAdhesiveChemistry

The invention discloses a tablet containing escitalopram oxalate and a preparation method thereof. According to the invention, the tablet containing escitalopram oxalate uses hydroxy propyl cellulose as an adhesive and uses escitalopram oxalate with median particle size less than or equal to 20mum, and the prepared tablet containing escitalopram oxalate has the advantages of beautiful appearance and stable quality. The invention also provides the preparation method of oral tablet, and has the advantages of simple process and adaptability of commercialized production.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

Attapulgite clay/polyanion/polystyrene composite particle and preparation method thereof

InactiveCN105504337ASolve static problemsIncrease the reactive surface areaOther chemical processesWater/sewage treatment by ion-exchangeMicrospherePolystyrene spheres

The invention discloses an attapulgite clay / polyanion / polystyrene composite particle and a preparation method thereof. Polystyrene microspheres are used as a carrier, the polyanion modified by the attapulgite clay covers the surface of the polystyrene microsphere to obtain a core-shell structure of the polyanion-polystyrene microsphere, and then the composite particle integrating the conductivity and the heavy metal ion adsorbability is prepared. The prepared composite particle is high in heavy metal ion adsorbability, the application effect of the polystyrene microspheres in the field of water purification can be enhanced, and the water purification effect is remarkable; and meanwhile, the surface of the composite particle has conductivity, so that the problems of fire potential danger caused by the static electricity during the transportation and pre-processing process of the ordinary polystyrene microspheres can be solved, and the attapulgite clay / polyanion / polystyrene composite particle is safer when used as a building insulated material and a packing material.

Owner:WUHAN UNIV OF TECH

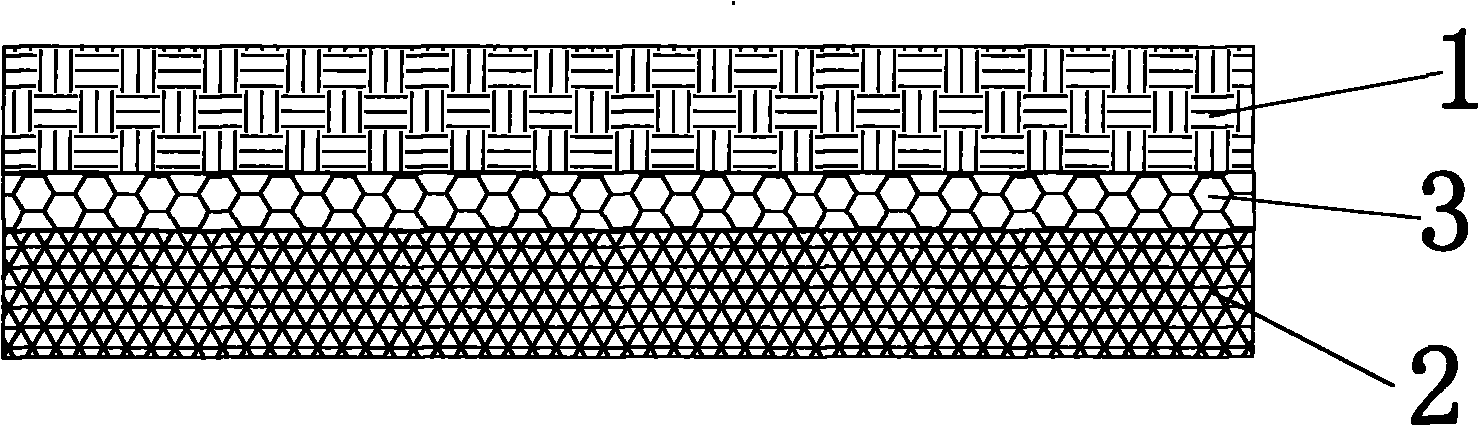

Anti-static down feather composite fabric

InactiveCN102090738AGood windproofImprove waterproof performanceSynthetic resin layered productsProtective garmentEngineeringCold resistance

The invention discloses an anti-static down feather composite fabric. The fabric comprises a fabric layer and a down feather layer, wherein an anti-static layer is arranged between the fabric layer and the down feather layer. The anti-static down feather composite fabric has simple structure and characteristics of good wind resistance, water resistance, corrosion resistance, prominent cold resistance, wear resistance and tearing and pulling resistance, can prevent the surface of the down feather fabric from adhering to dust and is especially suitable for producing down feather clothing, thus solving the problem that people suffer from static when wearing the down feather coats in winter.

Owner:WUJIANG YUANMING PRINTING FACTORY

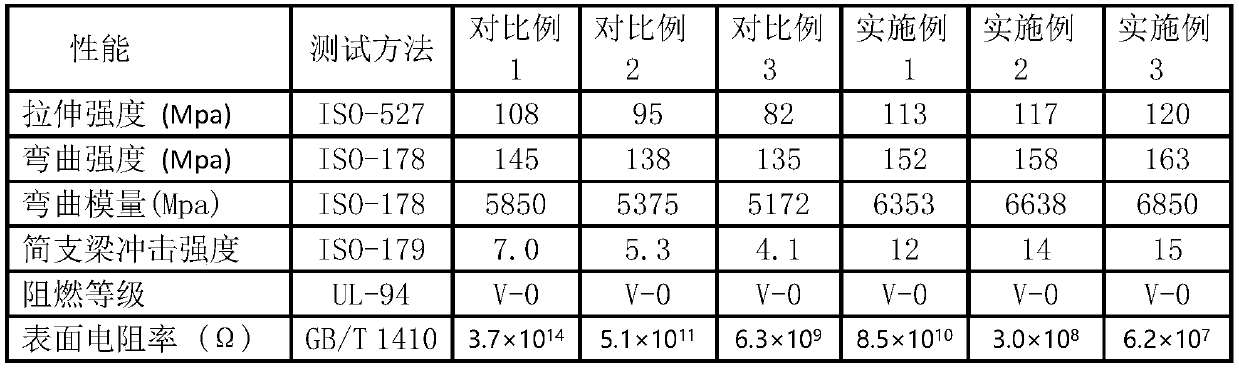

Flame-retardant antistatic reinforced nylon composite material and preparation method thereof

The invention discloses a flame-retardant antistatic reinforced nylon composite material. The composite material is characterized by comprising the following raw materials in parts by weight: 60-90 parts of nylon, 5-15 parts of glass fibers, 3-10 parts of carbon fibers, 0.5-10 parts of carbon nano tubes, 10-15 parts of red phosphorus, 0.3-2 parts of borate alkyl amine, 0-1.5 parts of a lubricant and 0.3-3 parts of a composite additive. The invention also discloses a preparation method of the flame-retardant antistatic reinforced nylon composite material. The composite material not only has excellent flame retardance and high mechanical strength, but also has an excellent antistatic performance, and can be used for manufacturing conveying rollers, which are applied to the fields of coal mines and the like.

Owner:苏州禾润昌新材料有限公司

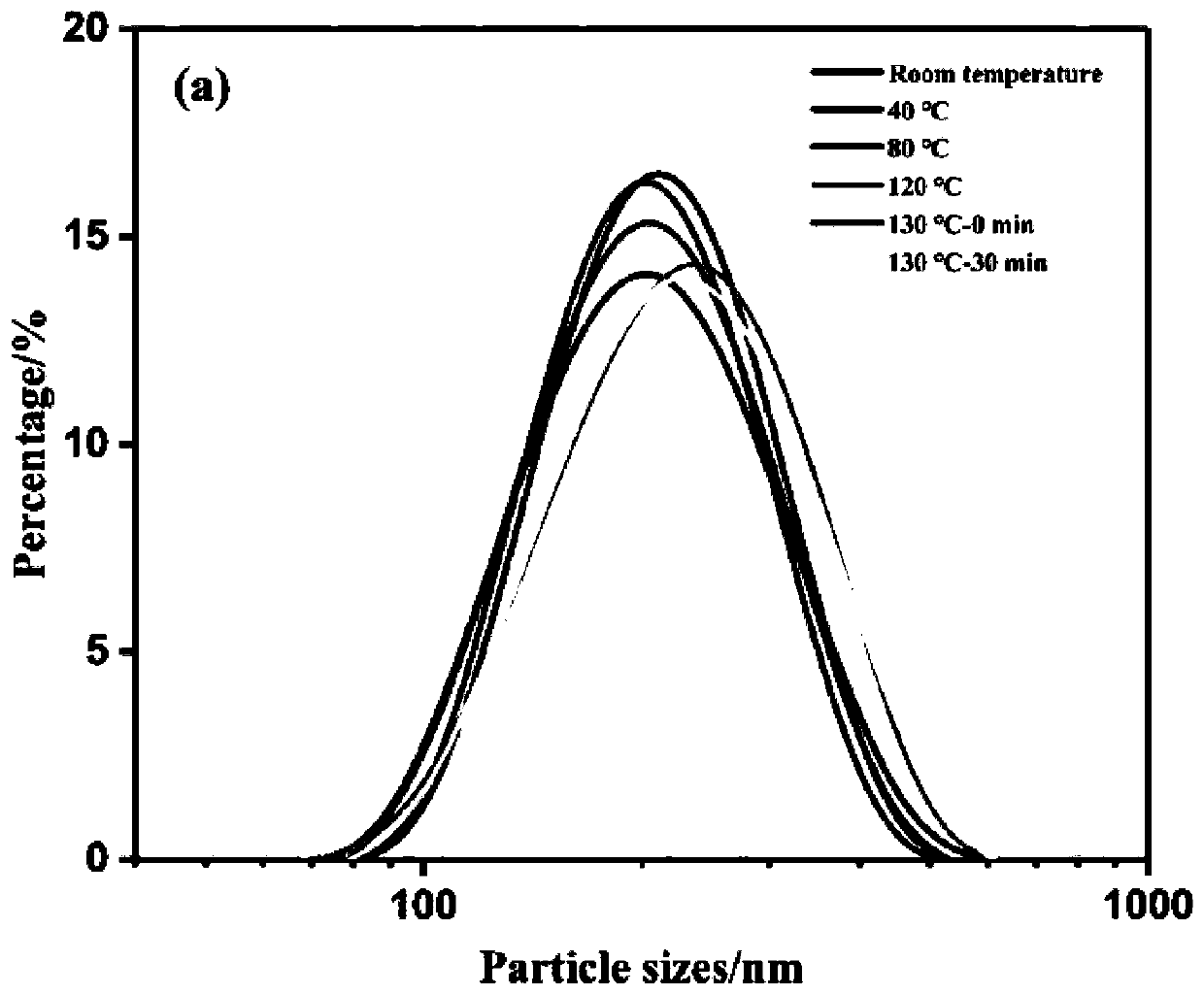

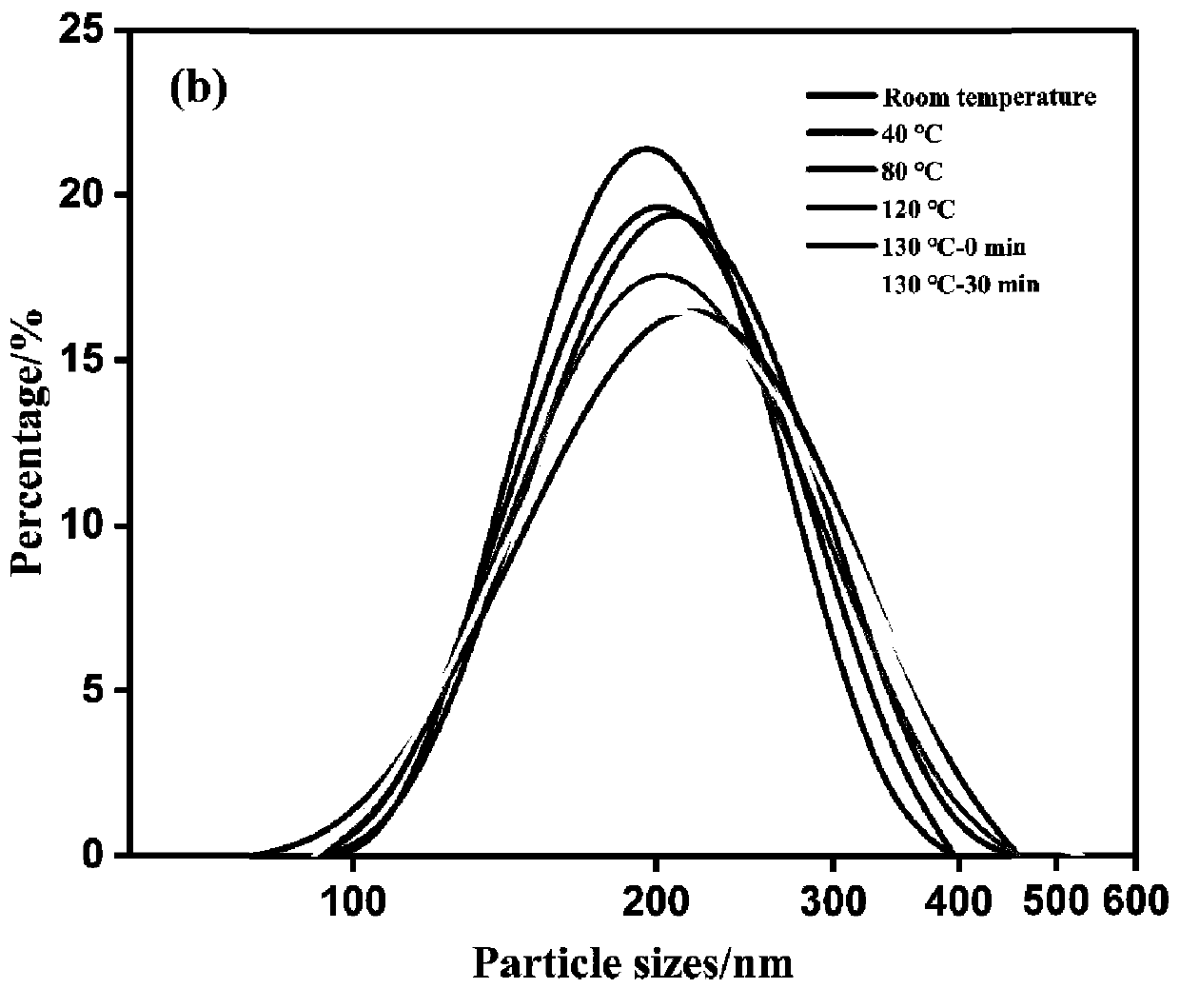

Preparation method of liquid-state nano disperse dye modified by graphene and graphene derivatives

PendingCN110195358AImprove dispersion stabilitySmall particle sizeFibre typesDyeing processDisperse dyeAfter treatment

The invention discloses a preparation method of a liquid-state nano disperse dye modified by graphene and graphene derivatives. A disperse dye filter cake and the graphene or the graphene derivativesare mixed, wherein the graphene derivatives comprise a graphene oxide and a reduced graphene oxide; the mixture is ground to obtain the liquid-state nano disperse dye modified by the graphene and thegraphene derivatives. A high-temperature high-pressure one-bath dyeing method is adopted for dyeing a terylene fabric, and reduction of the graphene oxide can be achieved in the reduction cleaning process. The fabric is endowed with the color performance by the disperse dye and endowed with the functionality by the reduced graphene oxide, dyeing and finishing are completed through a one-step method, the fabric is endowed with the colors and functionality, the after-treatment technology is omitted, the reduction time of the reduced graphene oxide is shortened, and the liquid-state nano dispersedye has great application potential in the field of textiles.

Owner:JIANGNAN UNIV

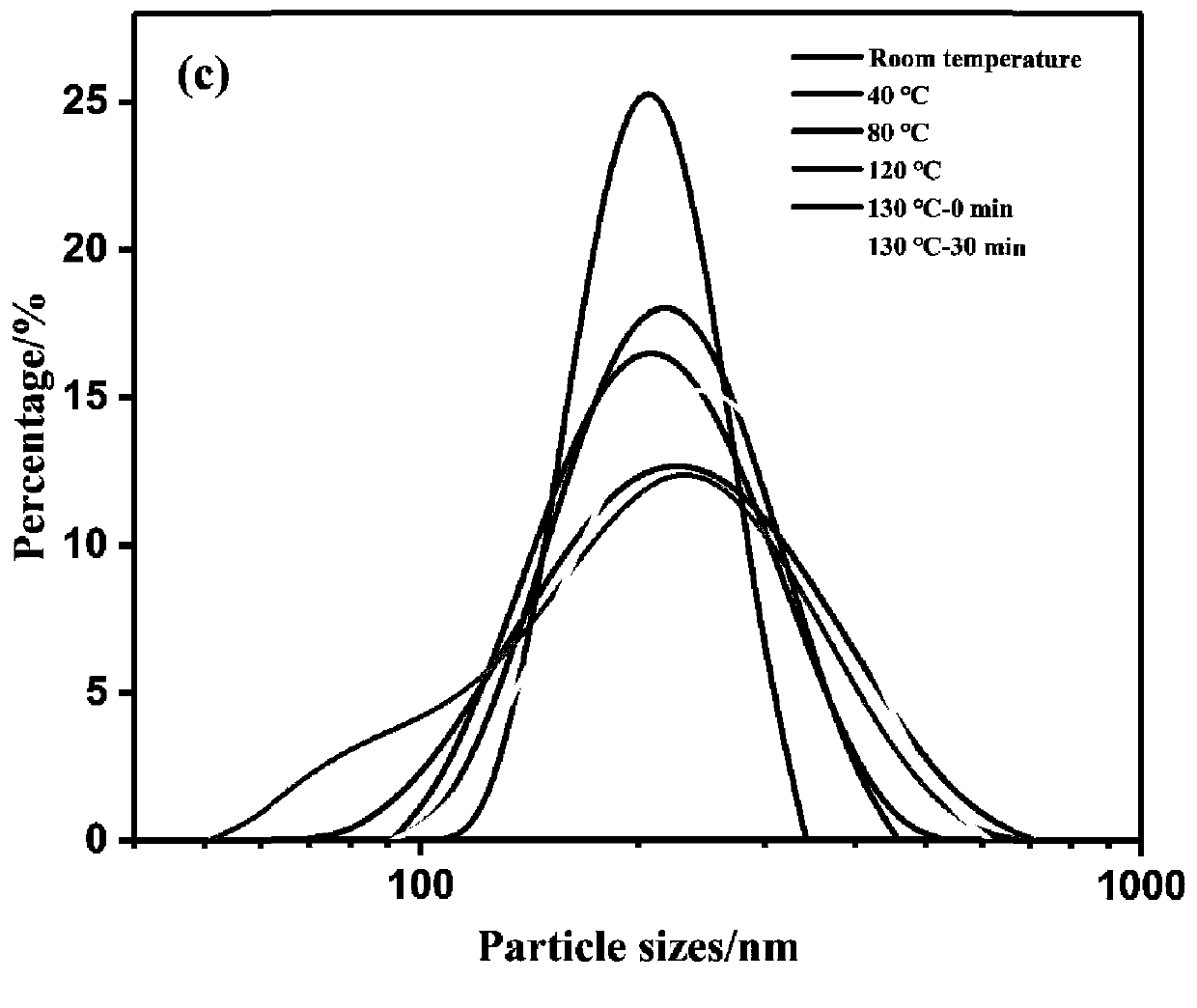

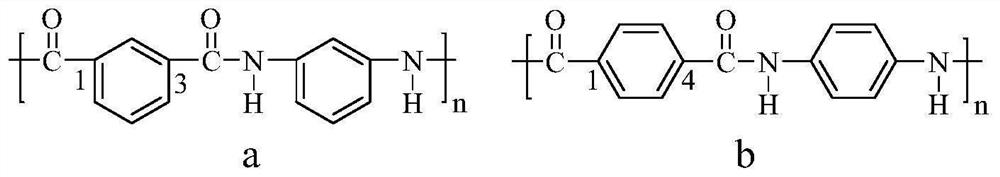

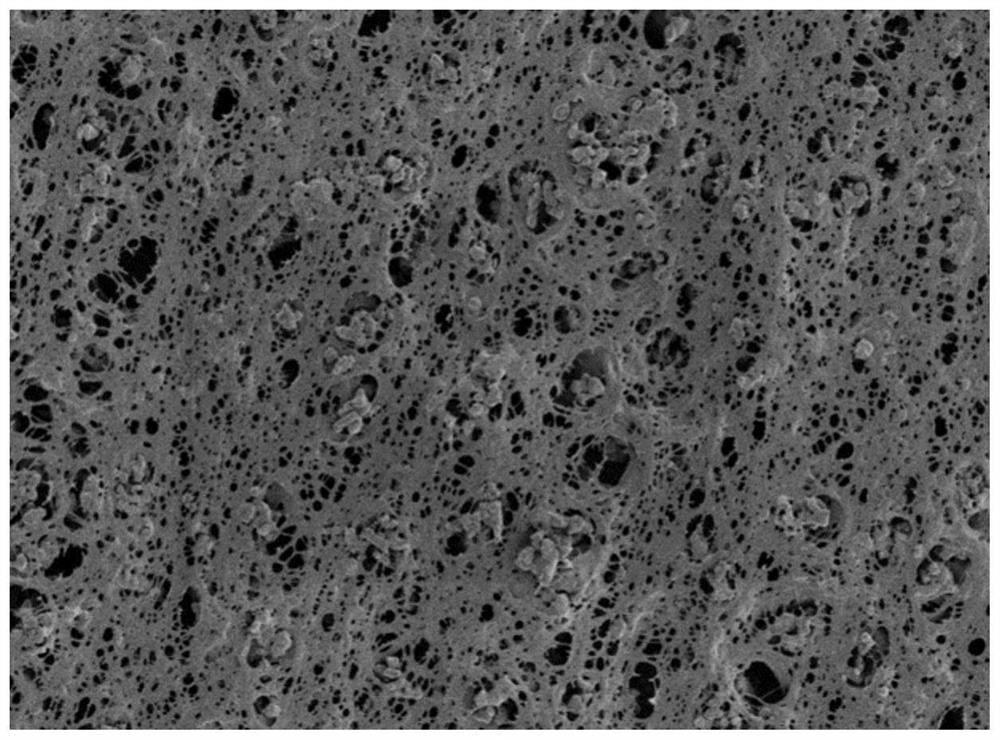

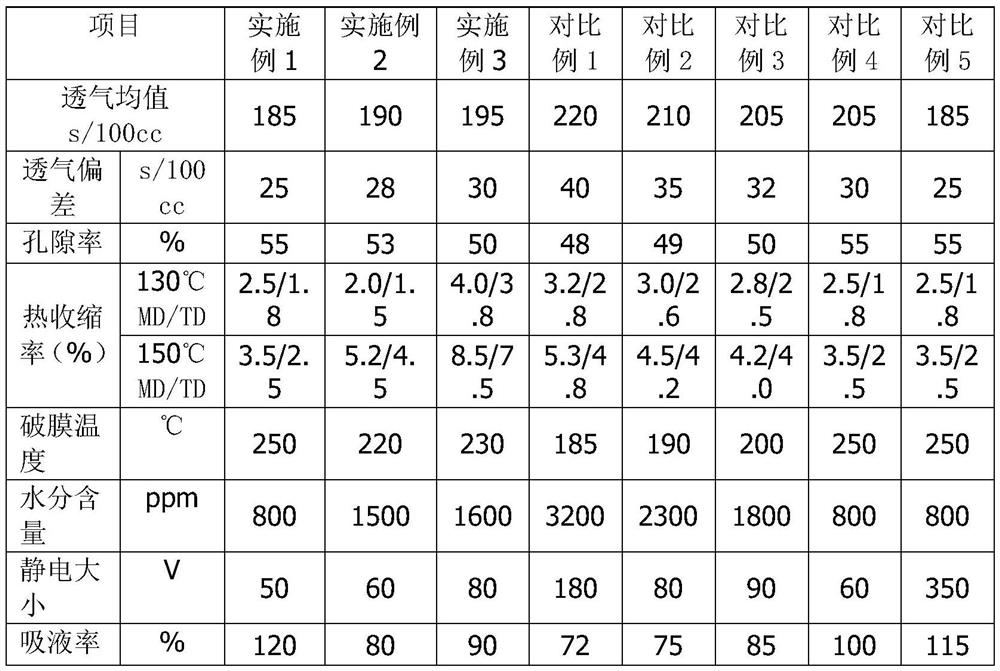

Modified composite heat-resistant lithium ion battery diaphragm and preparation method thereof

InactiveCN112216928AImprove electrochemical performanceImprove mechanical propertiesSecondary cellsNanotechnologyHeat resistanceLithium-ion battery

The invention belongs to the field of high polymer materials, and discloses a preparation method of a modified composite heat-resistant lithium ion battery diaphragm, which comprises the following steps: A, modifying aramid fibers; B, modifying an inorganic nano material; C, mixing the modified aramid fiber slurry and the modified inorganic nano slurry with a solvent in proportion to prepare organic-inorganic mixed modified slurry; and D, coating a base membrane with the organic-inorganic mixed modified slurry, and carrying out moisture solidification, washing, solvent removal and drying to obtain the modified composite heat-resistant lithium ion battery diaphragm. The problems of insufficient heat resistance, high moisture, large static electricity and the like of an existing aramid fibercoating diaphragm are solved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

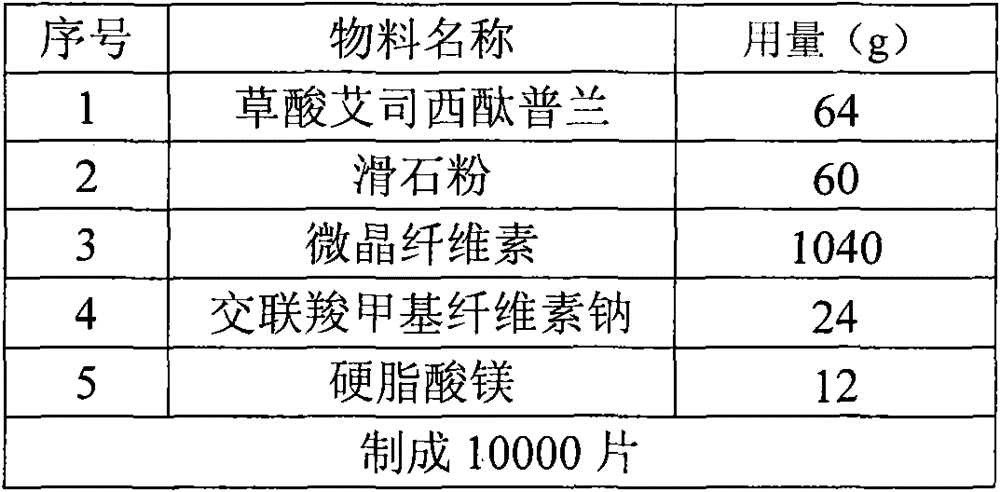

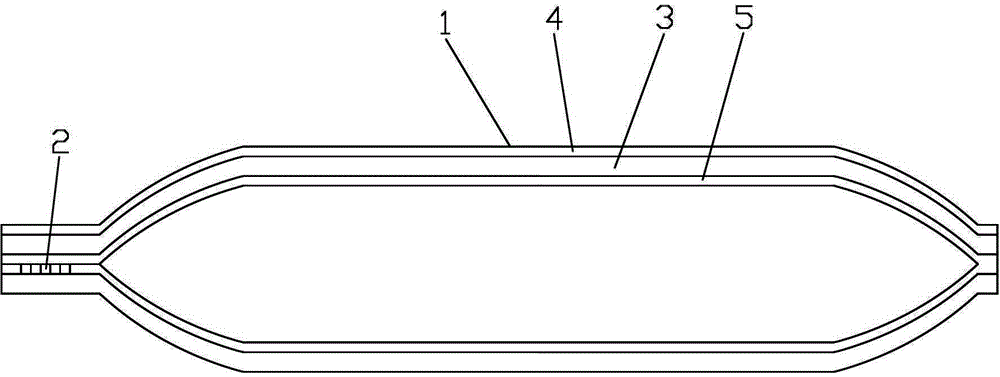

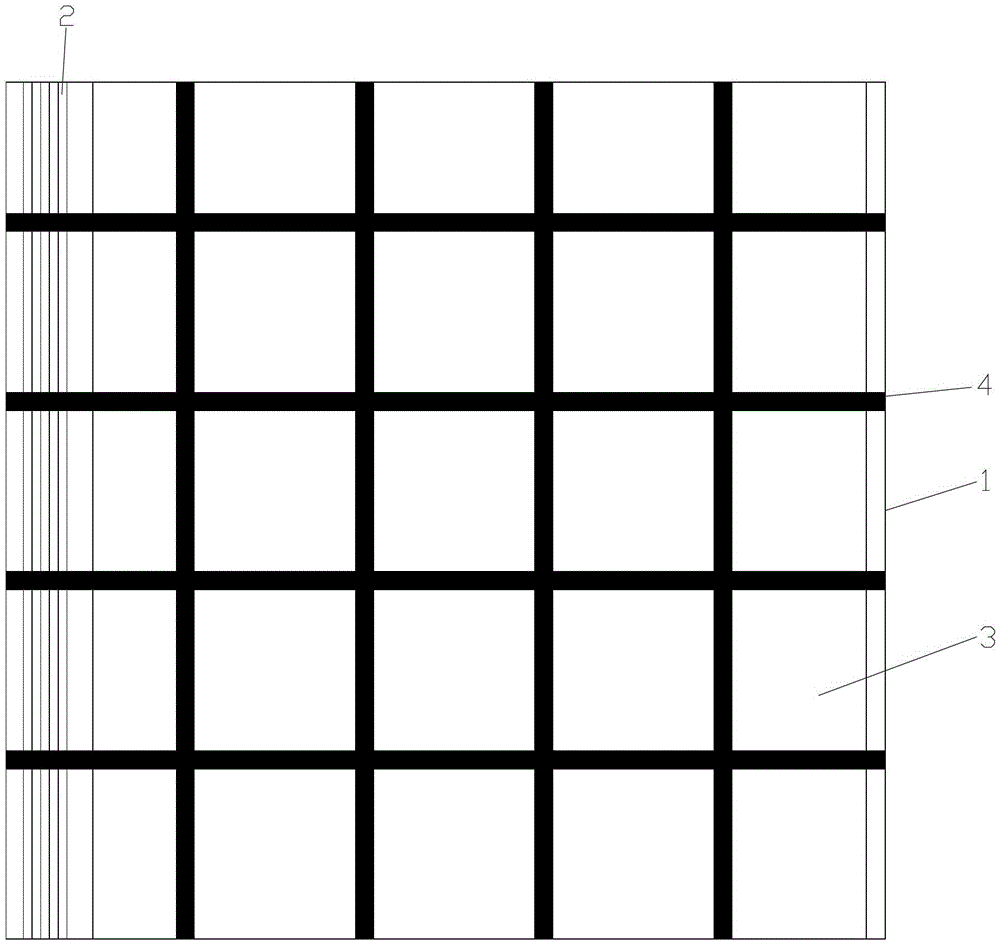

Air bag material for stratospheric airship and preparation method thereof

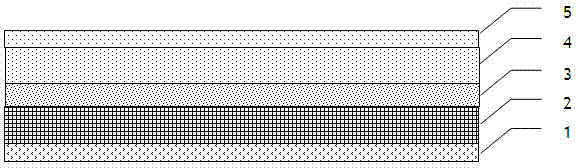

ActiveCN104760371AImprove anti-static performanceAvoid electrostatic damageLamination ancillary operationsSynthetic resin layered productsEngineeringPolymer thin films

The invention relates to an antistatic air bag material for a stratospheric airship and a preparation method thereof. The air bag material is prepared by arranging an antistatic layer at one side of a supporting layer and successively arranging a bonding layer, a gas blocking layer and an antistatic layer at the other side of the supporting layer, wherein the antistatic layer arranged on the surface of the supporting layer is a film containing a polythiophene-based conductive polymer and having a thickness of 0.4 to 2.3 [mu]m, the gas blocking layer is a polymer film, and the antistatic layer arranged on the surface of the gas blocking layer is a film containing a polythiophene-based conductive polymer and having a thickness of 0.05 to 0.8 [mu]m. According to the invention, the air bag material has substantially improved antistatic performance without influence on surface density and physical and mechanical properties of the air bag material; the antistatic performance of the material in the processes of assembly and usage is improved; static damage in the processes of assembly and usage of the air bag material is effectively avoided; and safety of the stratospheric airship in the process of usage is guaranteed.

Owner:CHINA LUCKY FILM CORP

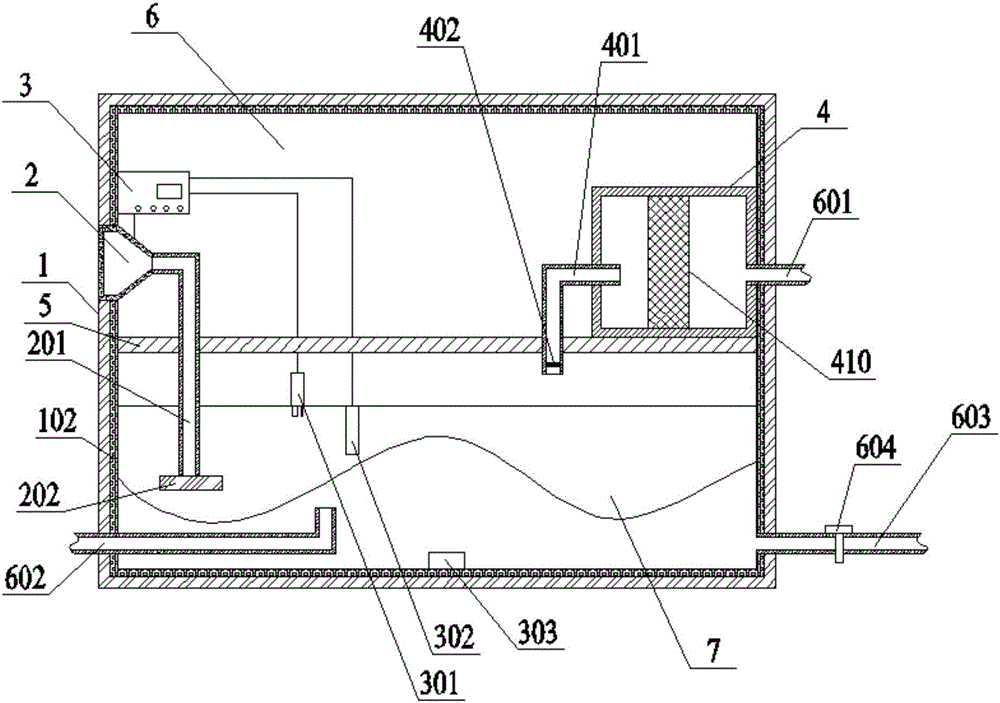

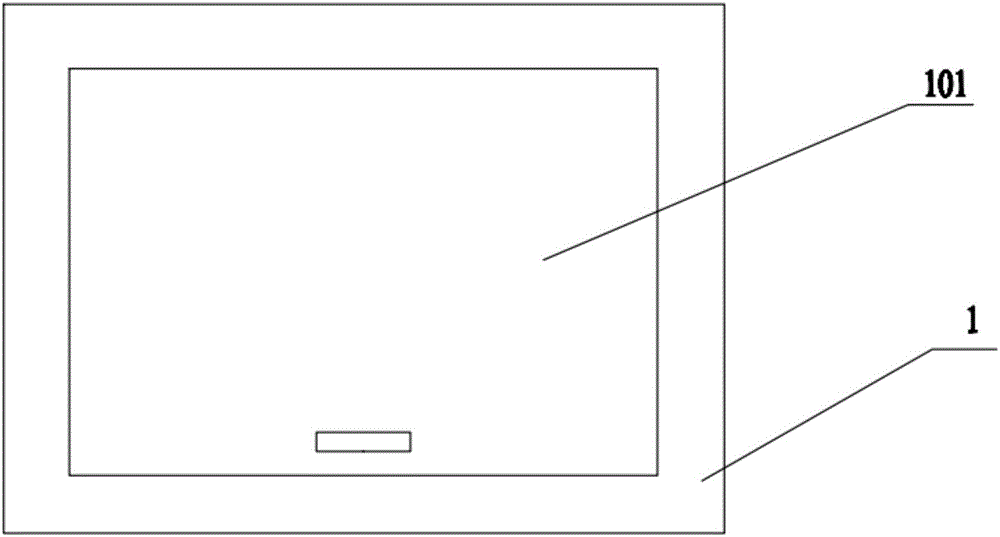

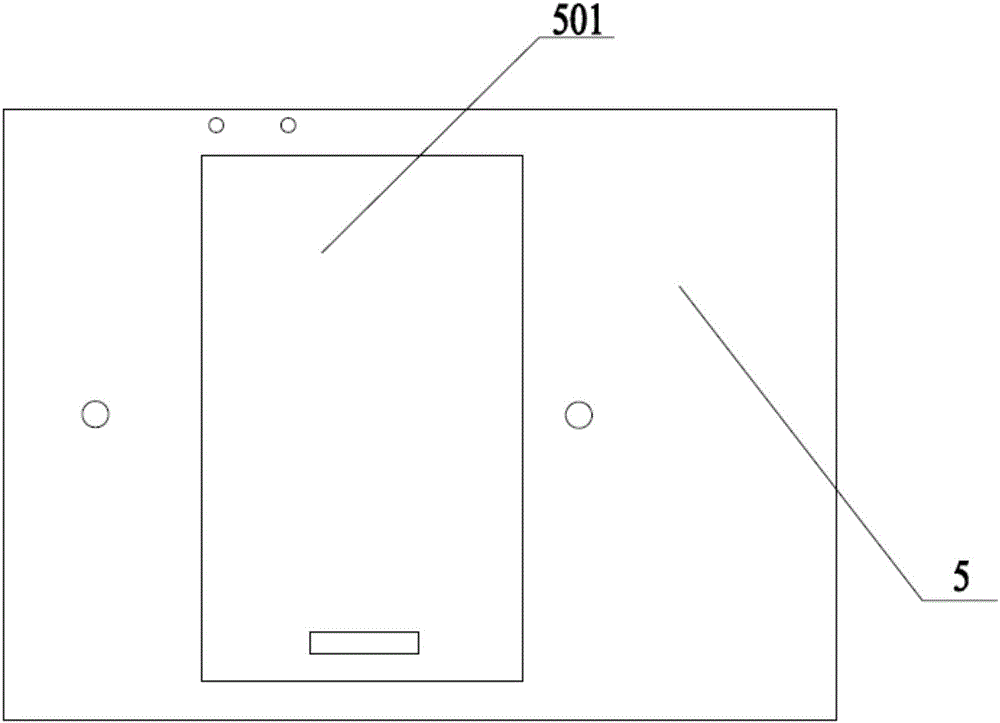

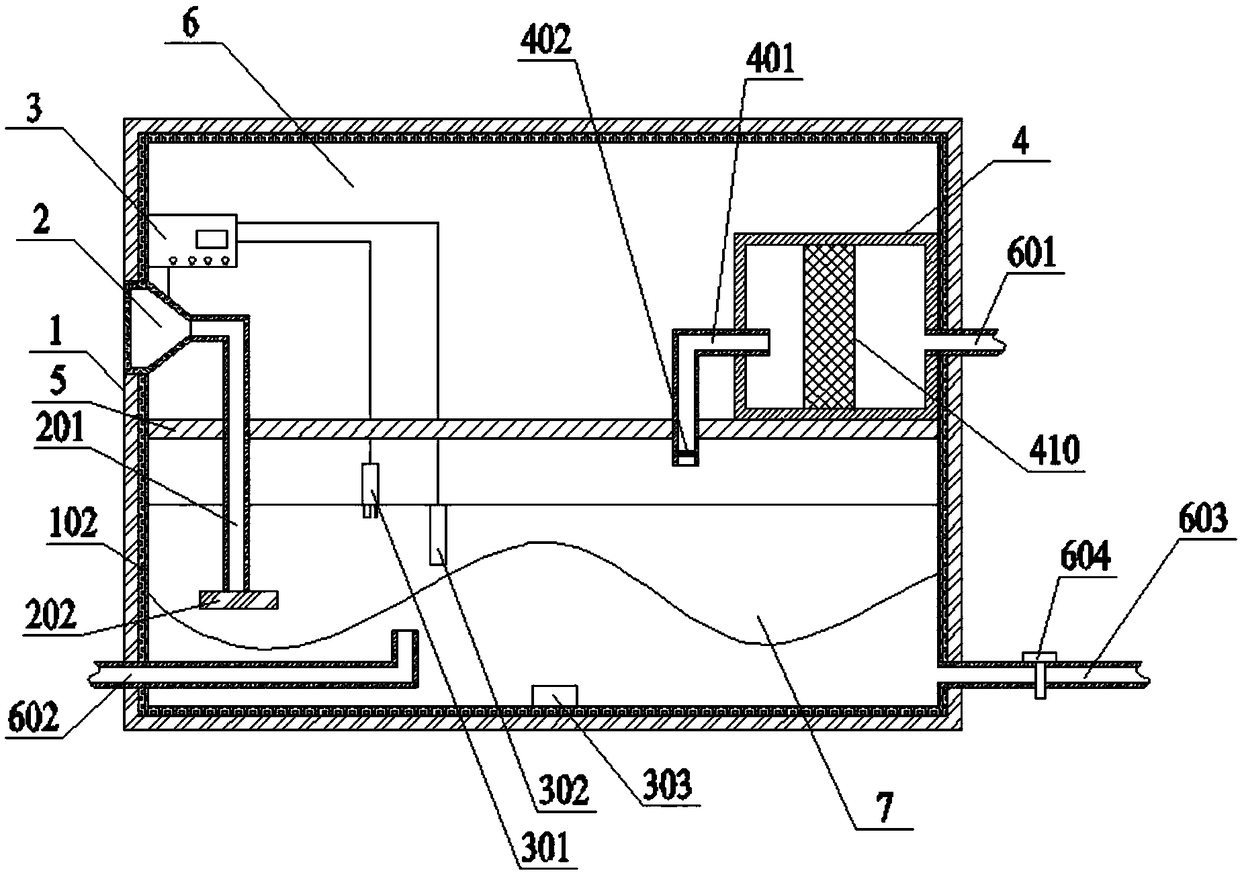

Water filtering and dust absorbing device for flour mills

ActiveCN106621626AEfficient removalReduce risk of deflagrationHuman health protectionGas treatmentDust explosionEngineering

The invention relates to the field of air purification of workshops, and especially relates to a water filtering and dust absorbing device for flour mills. The water filtering and dust absorbing device comprises a shell, a blower fan, a controller, and a filter box. The device has the advantages that dusts can be effectively removed; air leakage will not happen, the dedusting efficiency is high; the electrostatic problem in the prior art is avoided, the happening rate of dust explosion is reduced; the occupied space is small, and the device is easy to install and maintain.

Owner:徐州天骋智能科技有限公司

Distributed feedback injection amplification semiconductor laser

InactiveCN101237121AGuaranteed stabilityReduce line widthLaser detailsLaser optical resonator constructionPhotovoltaic detectorsGaussian beam

The invention discloses a distributed feedback injection amplifying semiconductor laser, consisting of a main laser, a first light isolator, a taper laser amplifier, a second light isolator, a tiny light exploring laser power stabilization system and a laser shaping system, wherein, the main laser adopts a distributed feedback semiconductor laser tube, the collimated laser beam is injected into a taper laser amplifying chip passing through the first light isolator, the amplified laser adopts the beam splitting technique passing through the second light isolator, an electrophotonic detector detects the fluctuation of power of the amplified laser, the error signal is sent to a current control interface of the taper laser amplifier through a feedback circuit, the power stability of the laser is outputted after the error signal is amplified by a reverse feedback mechanism, the light outputs the collimated Gaussian beam through the laser shaping system. The distributed feedback injection amplifying semiconductor laser has compact structure, convenient adjustment, wide and narrow laser rays, high power, good stability and strong practicability.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

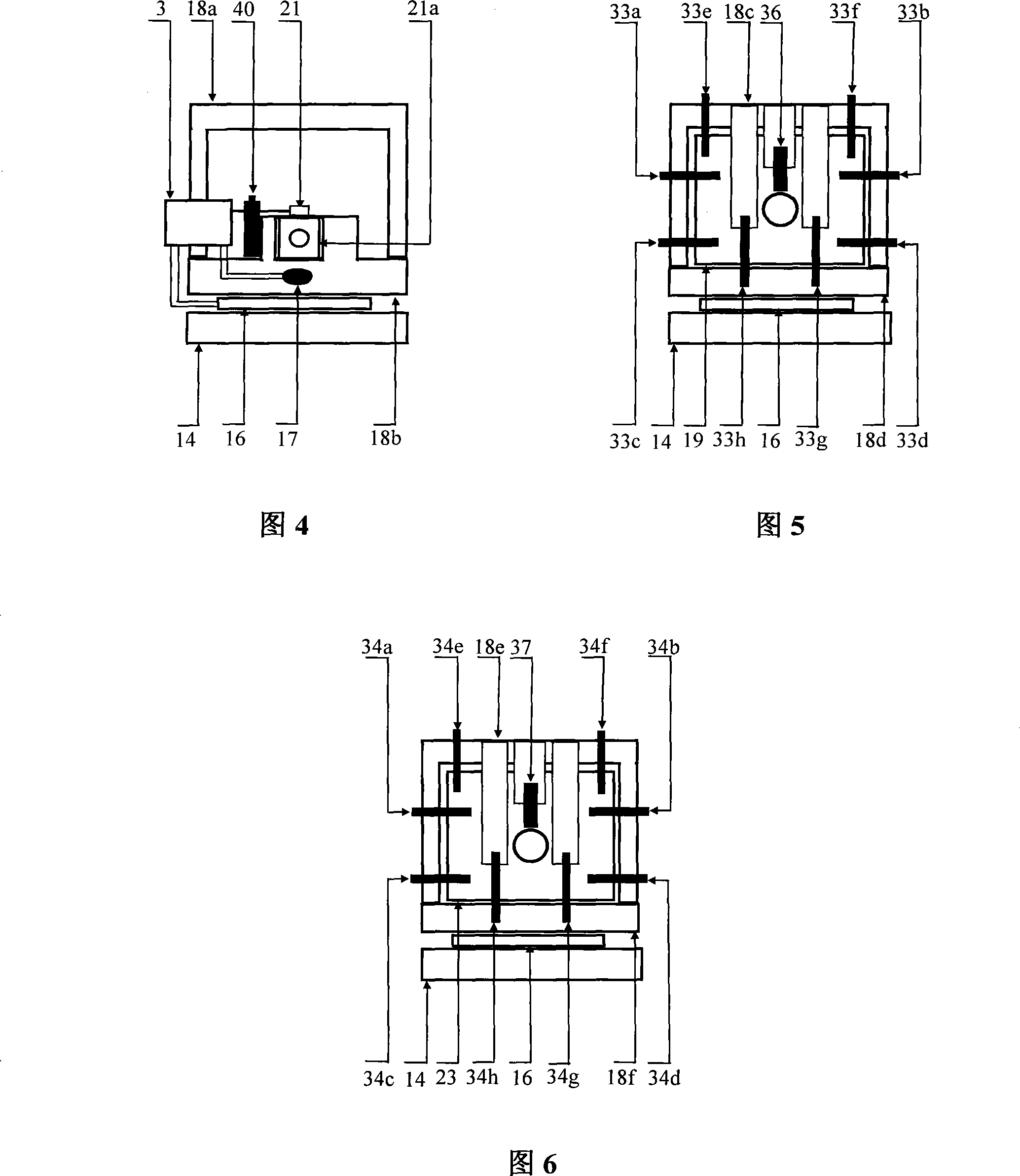

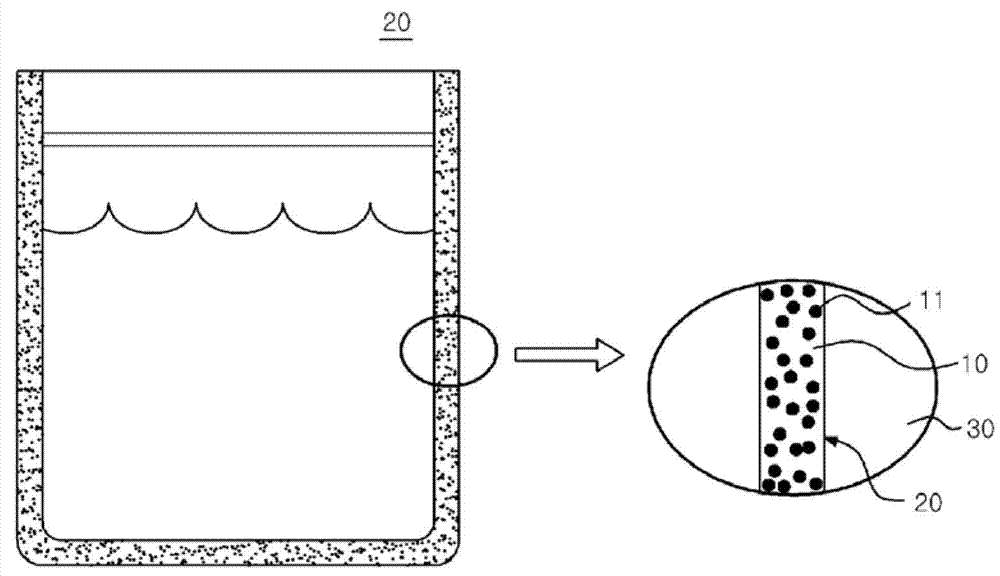

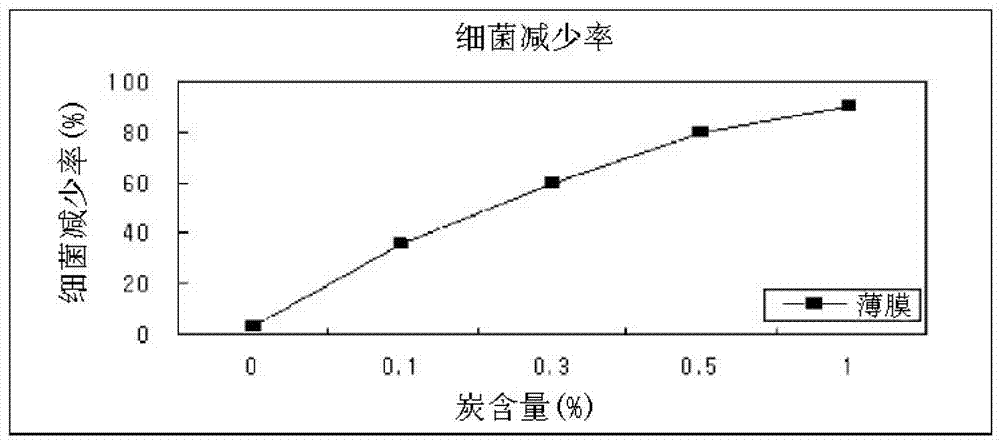

Charcoal-containing plastic packing material and method for manufacturing same

The present invention relates to a charcoal-containing plastic packing material and to a method for manufacturing same. The present invention provides a plastic packing material which resolves the problems caused by the immiscibility of charcoal and resin, such as deficiencies in mechanical properties, an aggregation phenomenon, foreign body sensation, defective forms, and poor quality, and which not only exhibits high-level general qualities, but which also, as a result of containing charcoal, has functional properties such as suppressing putrefactive bacteria, absorbing polluted particles and smells, radiating far-infrared rays and anions, and preventing the generation of static electricity. Also, the present invention provides a method for manufacturing a plastic packing material, in which the particle size, the amount used for resin, and the particle size uniformity of charcoal powder to be mixed with resin are adjusted in accordance with the thickness of the plastic packing material to be formed.

Owner:KOREA COMPOSITE RES

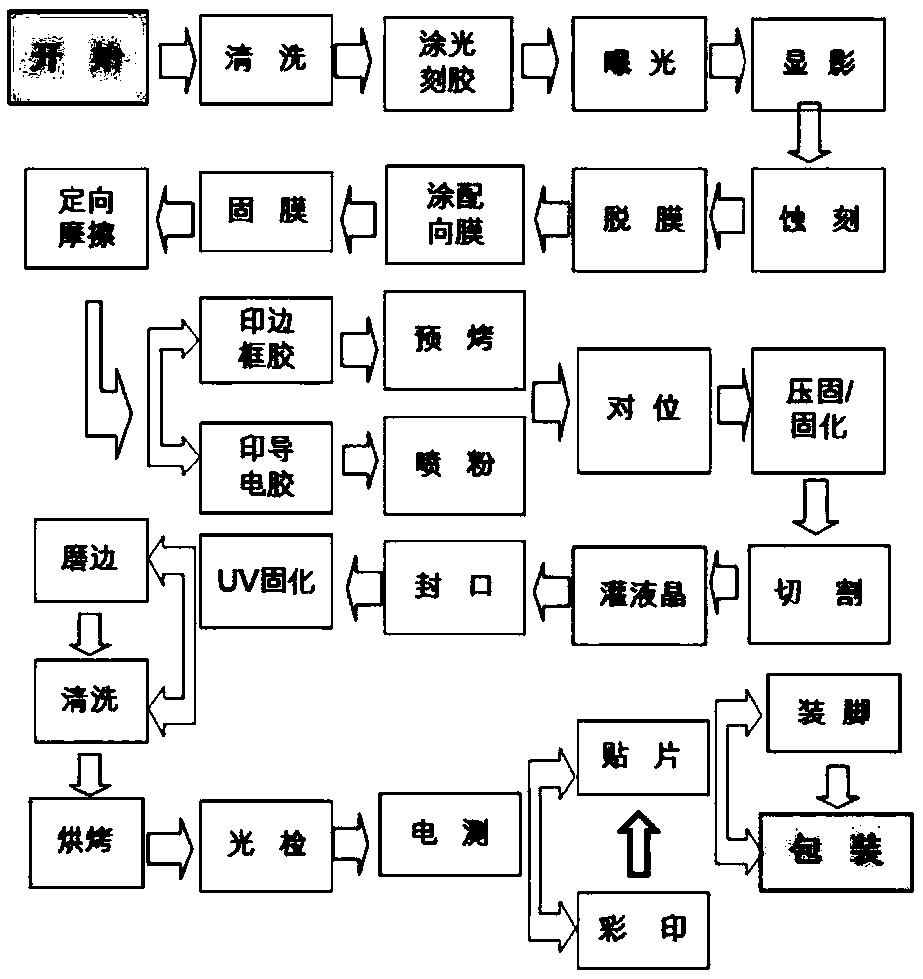

LCD technique

InactiveCN108761863AAddressing inhomogeneitySolve static problemsNon-linear opticsScreen printingEngineering

The invention relates to the technical field of LCD production, and particularly discloses an LCD technique. The technique comprises the steps of S1, preprocessing: cleaning for the first time, photoresist spreading, exposure, developing, hardbaking, etching, demolding and cleaning for the second time are sequentially conducted after raw material inspection is conducted to obtain an ITO glass substrate; S2, orientation layer spreading and PI curing: orientation layer spreading and powder spraying are completed before curing is conducted, and curing is conducted to obtained the cured ITO glasssubstrate; S3, post processing: PI rubbing, silk screening, heat pressing, cutting, granulating, liquid crystal filling and sealing are sequentially conducted on the cured ITO glass substrate, and theinitial production of an LCD display screen is completed after cleaning is conducted; S4, finished product processing: detecting, outer screen printing and patching are conducted on the initially produced LCD display screen, and the LCD display screen is finally packaged and put into a warehouse.

Owner:株洲晶彩电子科技有限公司

Anti-static garment

InactiveCN104544617APromote escapeImprove anti-static performanceProtective garmentCarbon fibersMetal foil

The invention provides an anti-static garment, and belongs to the field of garment manufacturing. The invention provides the anti-static garment with the advantages of low cost and good anti-static performance. The anti-static garment is mainly characterized in that in the fabric manufacturing process, anti-static fiber or anti-static synthetic fiber made of conducting materials is separately or uniformly mixed, or the anti-static fiber or anti-static synthetic fiber are mixed and interwoven. The conducting fiber is made of one or several materials from metal-based composite materials, high-polymer-based composite materials, resin-based composite materials or rubber-based composite materials. The conducting fiber is made of raw materials such as ceramic-based composite materials or carbon black, metal powder, metal foils, metal fiber or carbon fiber. The anti-static garment can be applicable to various fabrics, further, any garments can be prepared, the popularization performance is high, meanwhile, the garment resistance is low, and a good anti-static effect is realized.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

Flame-retardant and antistatic knitted fabric and manufacturing method thereof

PendingCN107761236ASolve static problemsImprove visibilityWeft knittingSynthetic resin layered productsPolyesterYarn

The invention provides a flame-retardant and antistatic knitted fabric and a manufacturing method thereof. The flame-retardant and antistatic knitted fabric comprises a surface layer and an inner layer; the surface layer is formed by weaving 100 percent of polyester yarns with a count being 100 D; and the inner layer is formed by weaving blended yarns of 60 percent of acrylonitrile-vinylidene chloride copolymer fibers, 27 percent of flame-retardant viscose fibers, 10 percent of para-aramid fibers and 3 percent of transparent conductive fibers, wherein a count of the blended yarns is 30 S. Themanufacturing method of the flame-retardant and antistatic knitted fabric comprises the following steps of 1, dyeing the yarns of the surface layer; 2, performing weaving, feeding the yarns of the surface layer and the yarns of the inner layer onto a working needle of a knitting machine, enabling the yarns to be sequentially curved to form rings, performing mutual penetrating and sleeving, and suturing the surface layer and the inner layer with connection lines at the same time, wherein suture lines are the yarns of the inner layer; and 3, washing the fabric, and treating and setting the fabric with a softening agent to finish manufacturing of the fabric. The flame-retardant and antistatic knitted fabric enables the flame retardancy, the antistatic property, high visibility, comfortable hand feeling and perfect appearance of the fabric to be unified and combined.

Owner:营口俊安防护服装有限公司 +1

Preparation method of antistatic composite fabric

The present invention discloses a preparation method of an antistatic composite fabric. The method is characterized by comprising the following steps of 1, preparing conductive fibers; 2, cleaning theobtained antistatic fibers with warm water, and drying the antistatic fibers until the water content is below 10%; 3, knitting blended yarns of the antistatic fibers and cotton fibers in different proportions on a knitting machine to form knitted grey cloth; 4, sequentially performing a bleaching process, a dyeing process, an antibacterial process and a setting process on the knitted grey cloth to obtain the antistatic knitted fabric. According to the method, the fibers are combined with antistatic modification liquid, a hydrophilic soft finishing agent and absolute ethanol and are blended with the cotton fibers, and the blended yarns are subjected to bleaching, dyeing, antibacterial treatment and setting, so that the fabric has the excellent antistatic performance, the problem that the knitted composite fabric generates static electricity in the prior art and the problem of relatively difficult antistatic care of the fabric are effectively solved, the fabric is soft in hand feeling,comfortable and breathable, the skin affinity of the composite fabric is improved, and the use comfort is improved.

Owner:宁波太平鸟潮服饰营销有限公司

Packaging bag

The invention discloses a packaging bag. A bag body is formed by folding one piece of packaging material and carrying out double-sided heat sealing; a bag mouth of the bag body is sealed by a sealing port; the packaging material comprises a transparent substrate; conductive ink is printed on the outer layer of the transparent substrate; and the inner layer of the transparent substrate is coated with antistatic liquid. According to the packaging bag disclosed by the invention, due to existence of the transparent substrate, the packaging bag has better transparency; the conductive ink is printed on the outer layer of the transparent substrate, so that the packaging bag has good conductivity; and moreover, the inner layer of the transparent substrate is coated with the antistatic liquid, so that the packaging bag has good antistatic performance.

Owner:SUZHOU STAR NEW MATERIAL

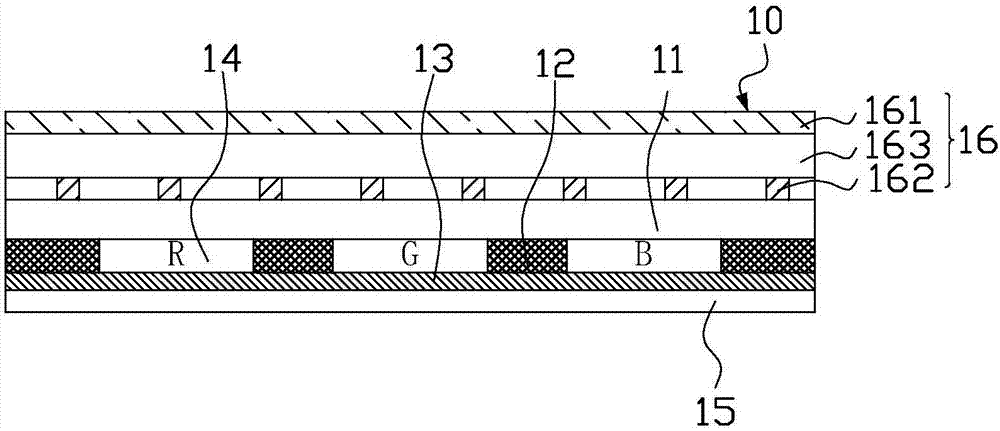

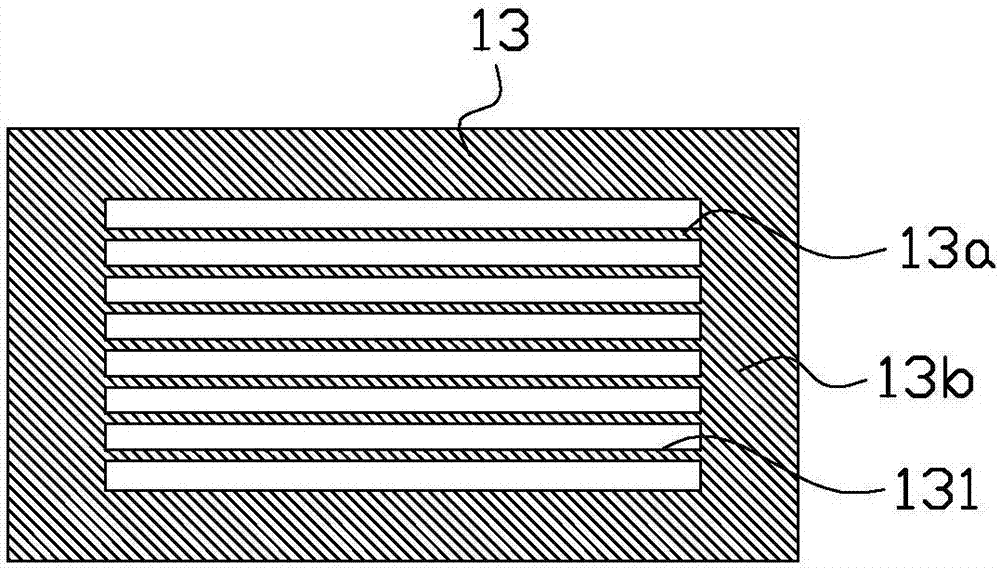

Color film substrate and liquid crystal display panel

The invention provides a color film substrate and a liquid crystal display panel. The color film substrate comprises a lining, and the inner side of the lining is provided with a black matrix and a color resistor layer. The outer side of the lining is provided with a touch sensing circuit, the inner side of the lining is provided with a conductive layer which comprises a first conductive portion and a second conductive portion, the first conductive portion and the second conductive portion cover a display area and a non-display area respectively and connected into a whole, and the first conductive portion is in a hollowed-out structure while the second conductive portion is in a planar structure. The color film substrate has advantages that the problem of static electricity caused by lack of an ITO (indium tin oxide) protective layer on the outer side of an existing color film substrate is solved effectively, and problems of high noise and signal interference in joint use of the color film substrate and the touch sensing circuit can be solved as well.

Owner:KUSN INFOVISION OPTOELECTRONICS

A water filter dust suction device for flour mill

ActiveCN106621626BEfficient removalReduce risk of deflagrationHuman health protectionGas treatmentWater filterDust explosion

Owner:徐州天骋智能科技有限公司

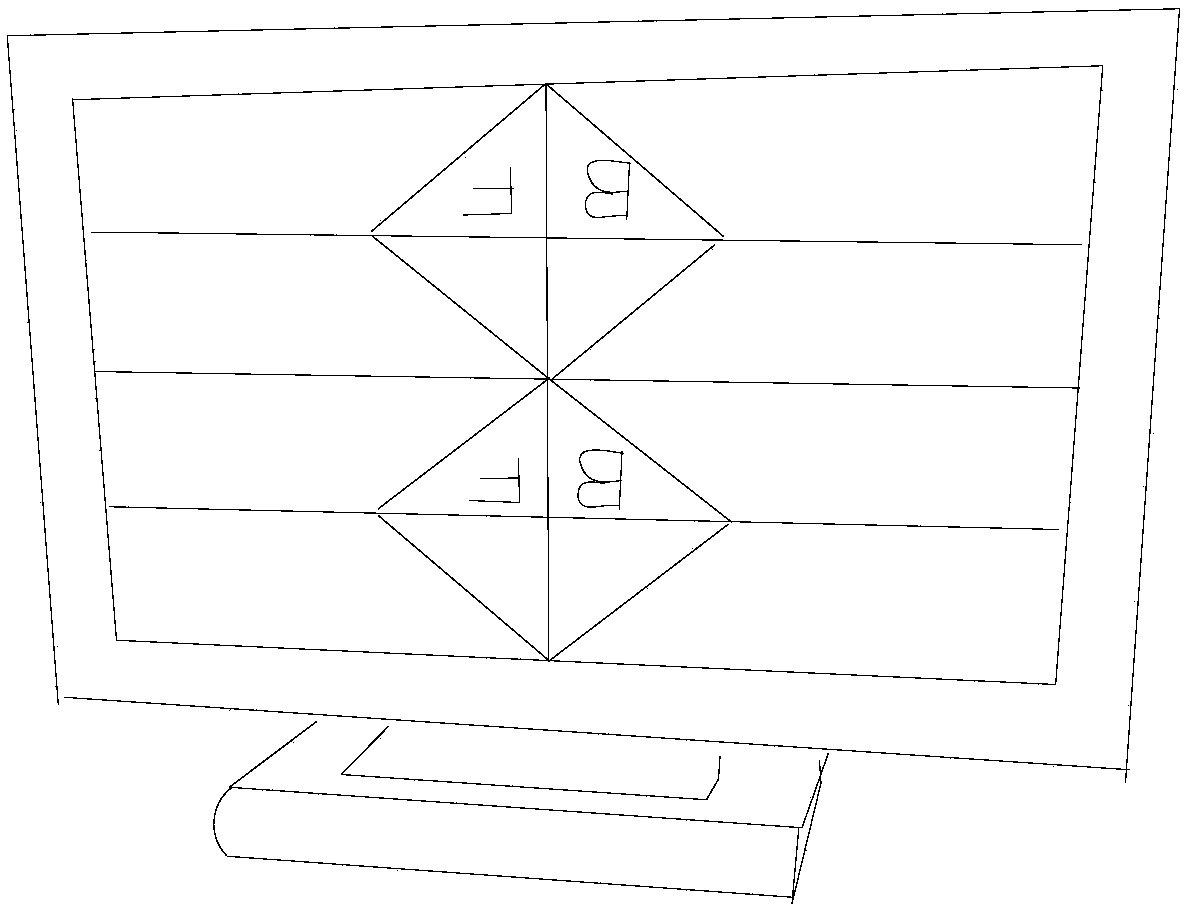

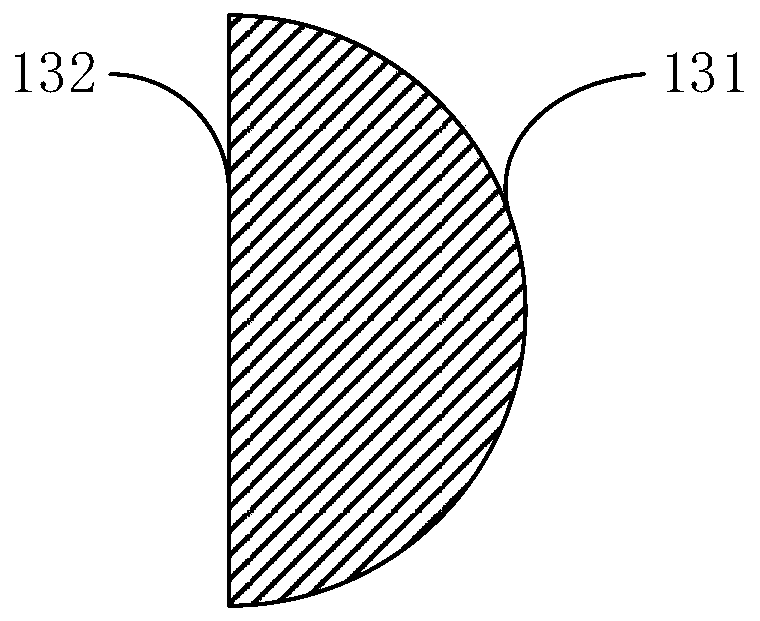

Array substrate and display panel

ActiveCN110333615AAvoid prone to static electricity problemsSolve static problemsNon-linear opticsComputer scienceStatic electricity

The invention discloses an array substrate and a display panel. The array substrate comprises a rectangular routing area and a non-routing area surrounding the routing area; at least one cutting precision mark is arranged in the non-routing area corresponding to the corner of the non-routing area, and the cutting precision mark and the routing area are arranged at intervals; and the edge of the cutting precision mark close to the routing area is a curve edge. According to the invention, the cutting precision mark with low static electricity generation probability can be provided, so that the requirement of actual production of the display panel is met.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Preparation method of graphene antistatic plastic

The invention discloses a preparation method of graphene antistatic plastic. The graphene antistatic plastic comprises graphene antistatic plastic, and the graphene antistatic plastic is prepared fromgraphene, resin, an antistatic agent, a stabilizer, a plasticizer, a lubricant, a dispersing agent, a flame retardant, a coupling agent and an antioxidant, wherein the graphene antistatic plastic comprises the following components in parts by weight: 80-100 parts of the resin, 3-6 parts of the graphene, 0.3-3 parts of the antistatic agent, 2-5 parts of the stabilizer, 1-3 parts of the plasticizer, 0.5-4 parts of the lubricant, 3-8 parts of the dispersing agent, 4-10 parts of the flame retardant, 0.2-2 parts of the coupling agent and 0.6-2 parts of the antioxidant. According to the preparationmethod of the graphene antistatic plastic, by arranging the combination of the graphene and the antistatic agent, the graphene has relatively high conductivity, and the antistatic agent endows the surface of the high polymer material with certain lubricity, reduces the friction coefficient and inhibits and reduces the generation of electrostatic charges.

Owner:安徽聚科生物科技有限公司

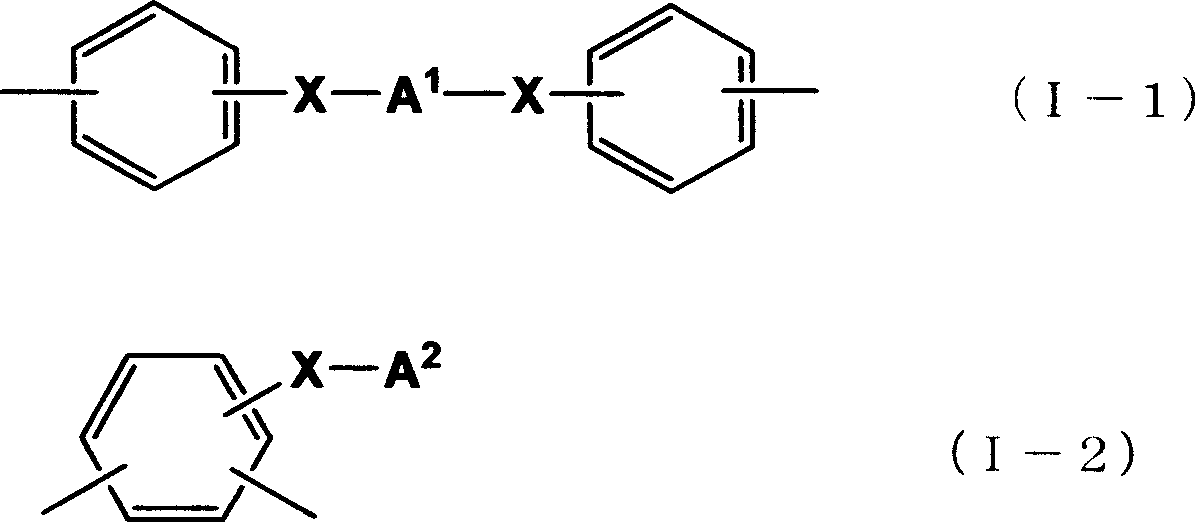

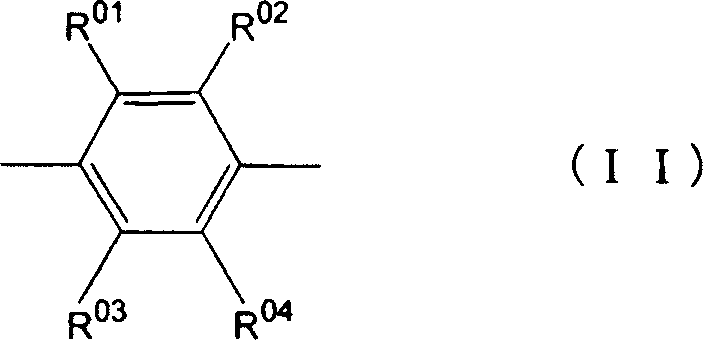

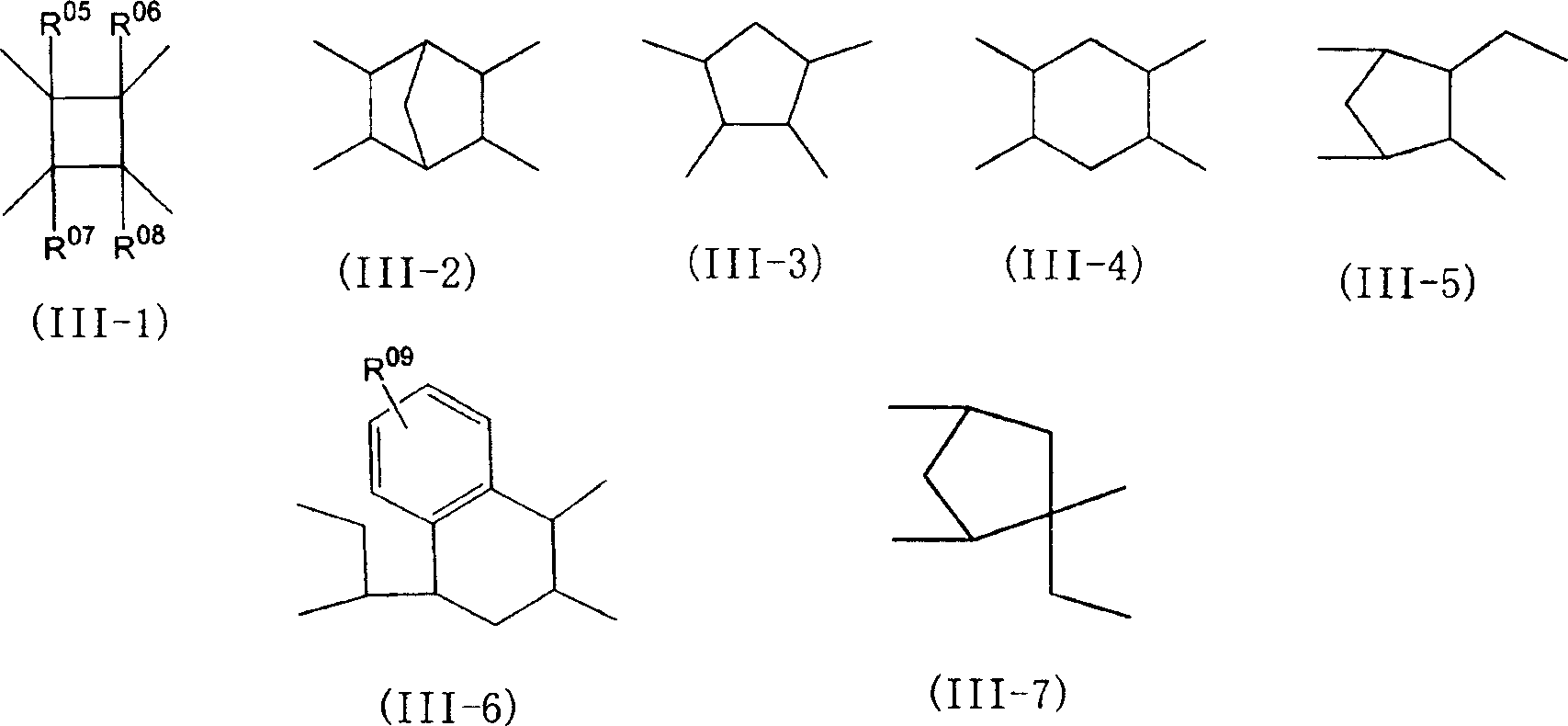

Vertical alignment-type liquid crystal aligning agent and vertical alignment-type liquid crystal display device

InactiveCN101017285AReduce afterimageImprove reliabilityLiquid crystal compositionsNon-linear opticsVertical alignmentAfterimage

The invention provides a vertical alignment-type liquid crystal alignment agent with good vertical alignment property and afterimage property. A vertical alignment-type liquid crystal alignment agent containing polyamide acid polymer and / or polyimide polymer has a volume resistivity of the film less than 1x1013 Omega.cm after the high-temperature roasting.

Owner:JSR CORPORATIOON

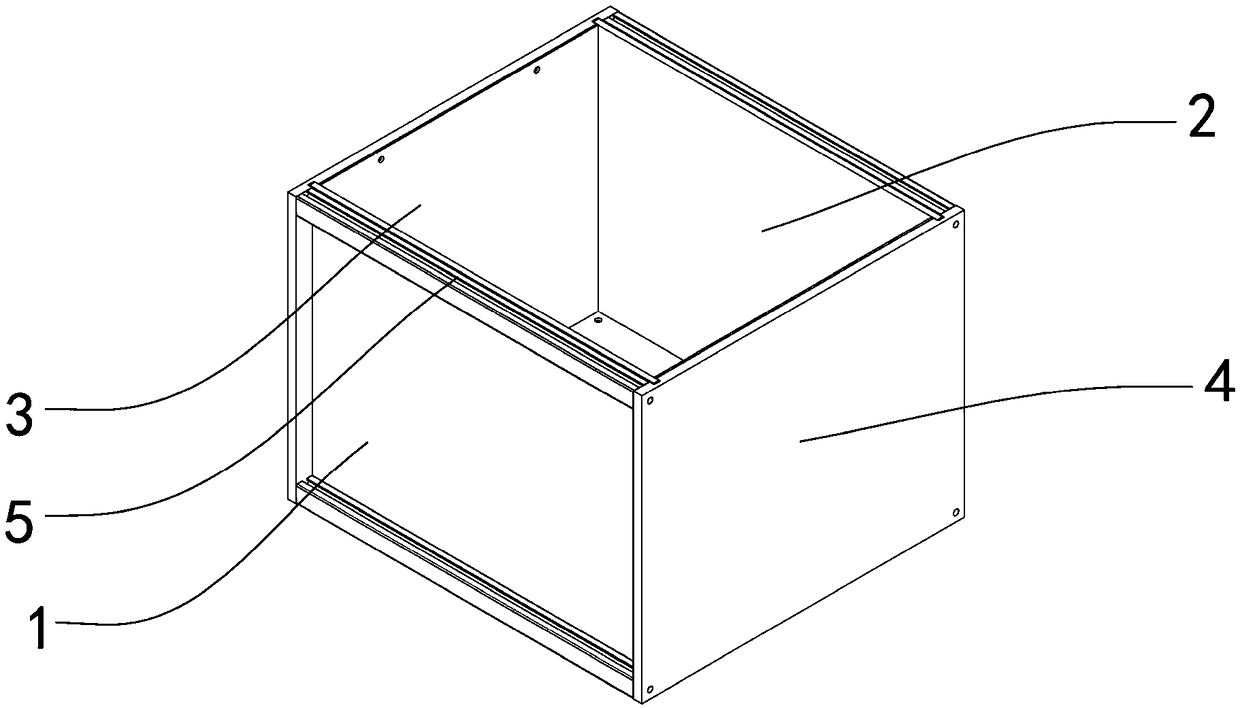

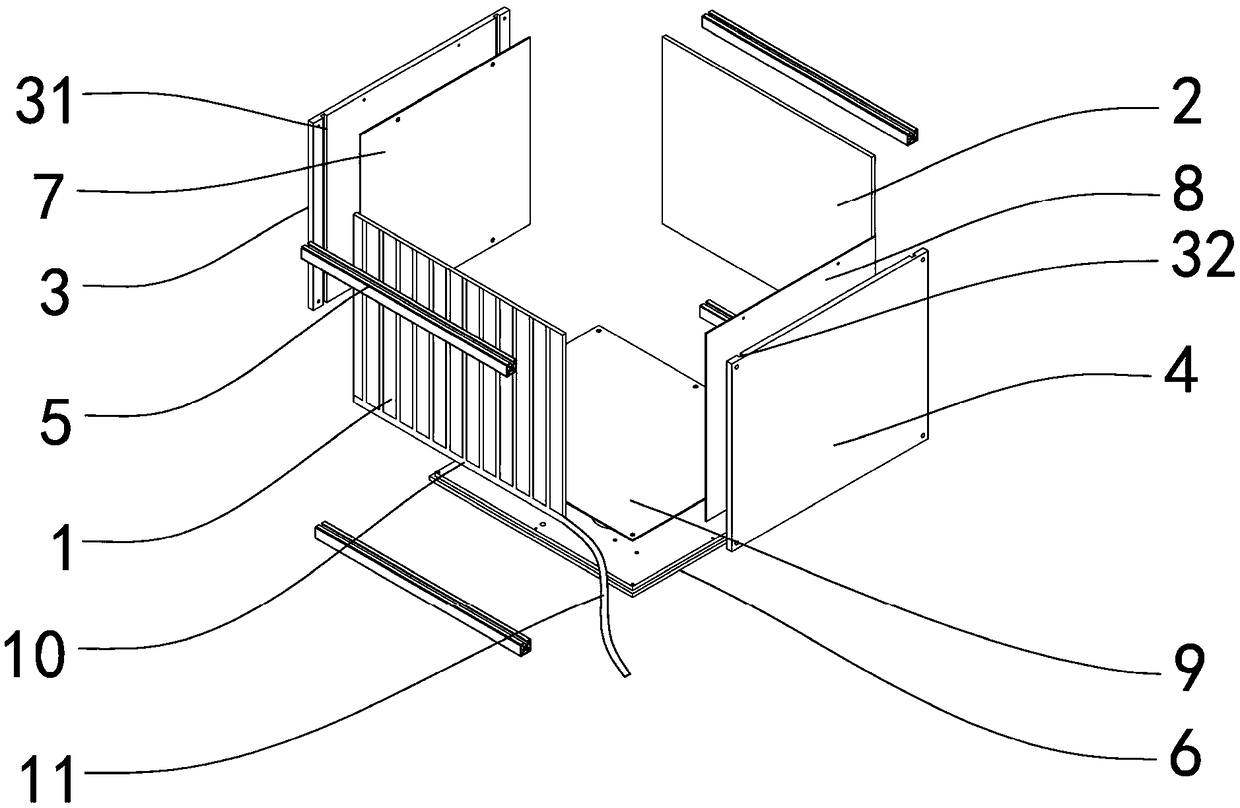

3D printer leakproof working cylinder

ActiveCN109049691AAvoid deformationAvoid corrosionManufacturing enclosuresAdditive manufacturing with solidsEngineeringUltimate tensile strength

The invention provides a 3D printer leakproof working cylinder. The 3D printer leakproof working cylinder comprises a first cylinder wall, a second cylinder wall, a first side plate, a second side plate, positioning rods and a piston plate; a rectangular channel structure is jointly defined by the first cylinder wall, the second cylinder wall, the first side plate and the second side plate; the first cylinder wall and the second cylinder wall are cooperatively connected through grooves in the first side plate and the second side plate; the first side plate and the second side plate are fastened and connected through the positioning rods; the piston plate slides in the rectangular channel; and the first cylinder wall and the second cylinder wall are made of glass or resin. The problems that3D printer working cylinders are insufficient in strength, and sand is prone to leaking are solved, the 3D printer leakproof working cylinder is convenient to dismount, mount and maintain and has good application prospects, on the basis of superior performance than original metal cutting machining, the cost is greatly reduced, the corrosion resistance is significantly improved, the especially inapplication of a large-sized piston cylinder blocks, the flatness of a whole board cannot be ensured by metal cutting machining easily, and the 3D printer leakproof working cylinder can be widely popularized in similar application.

Owner:武汉阿尔法激光有限公司

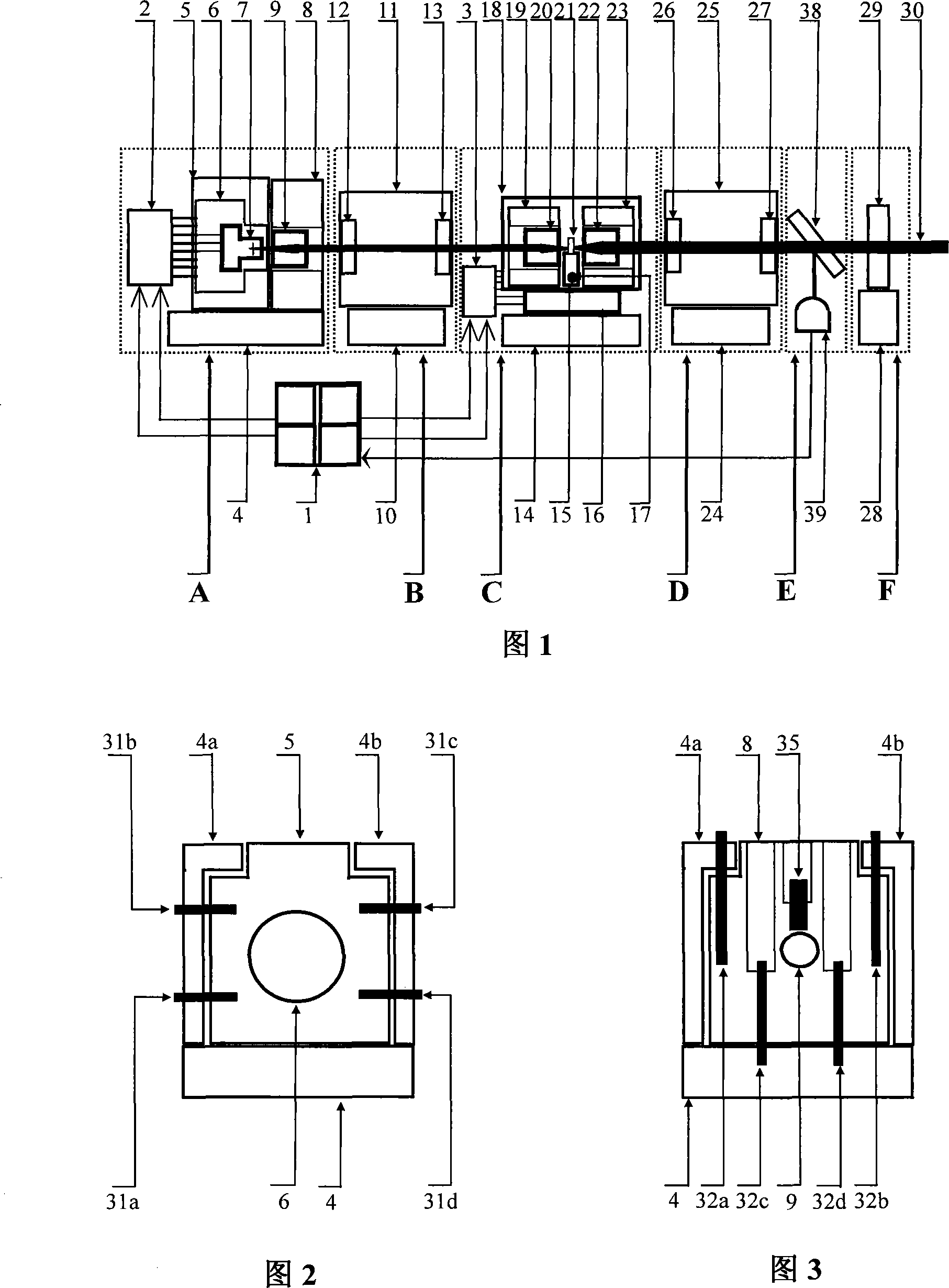

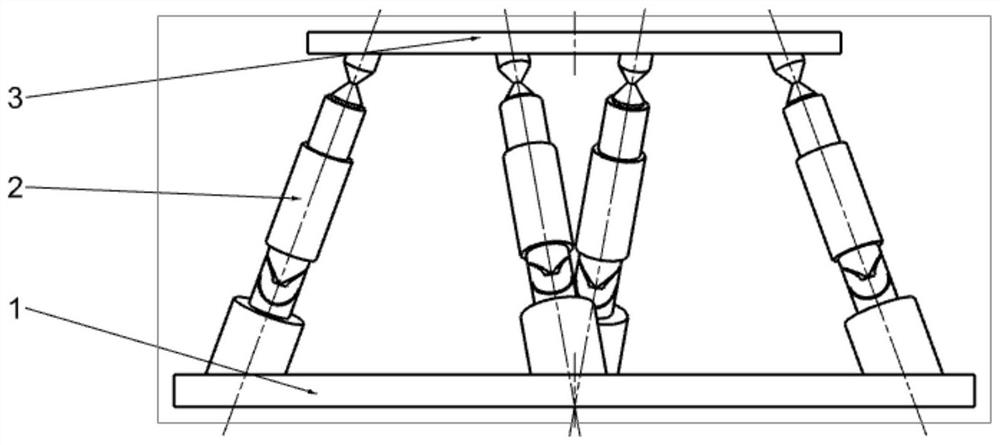

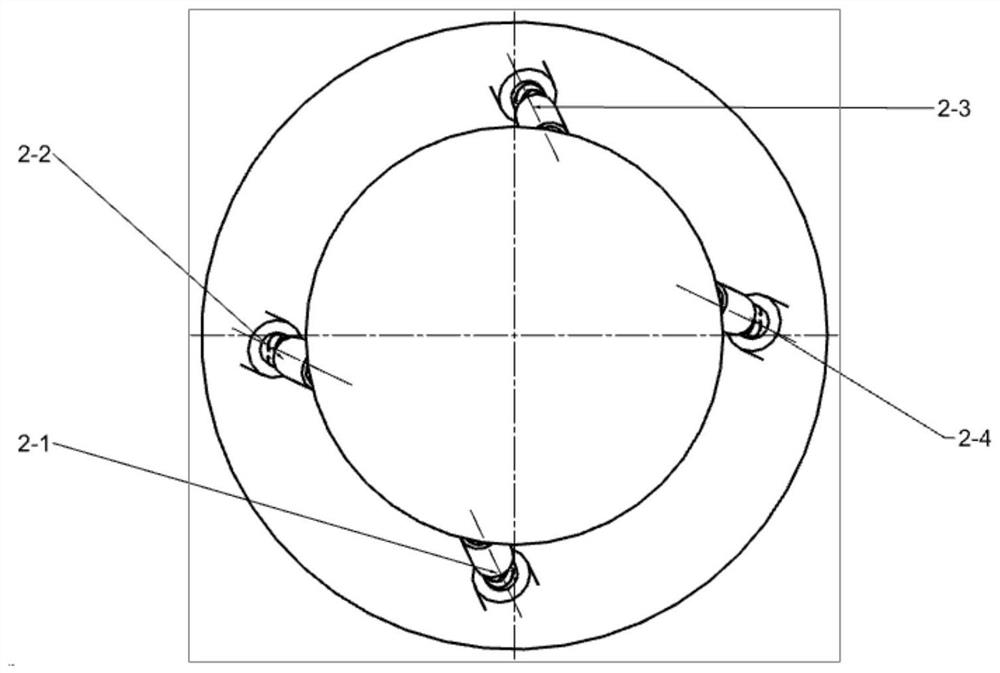

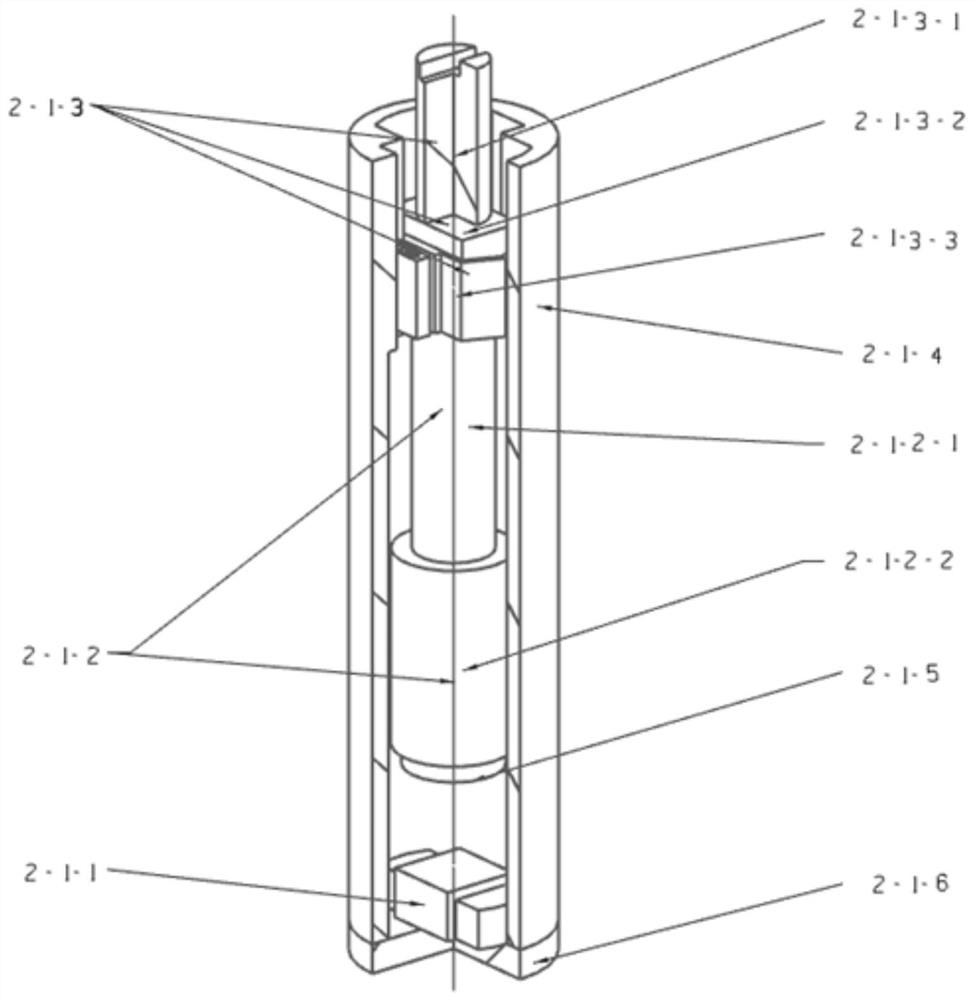

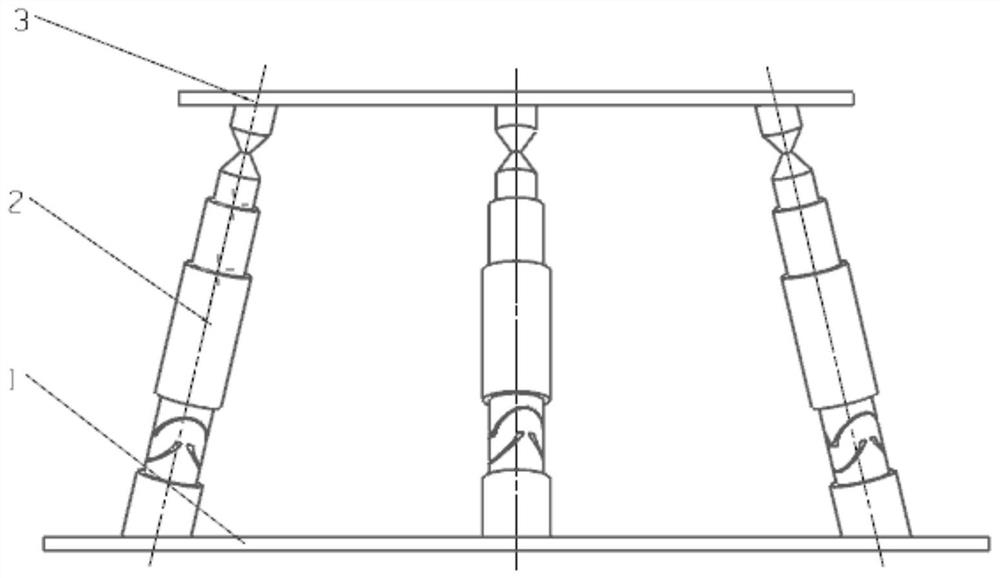

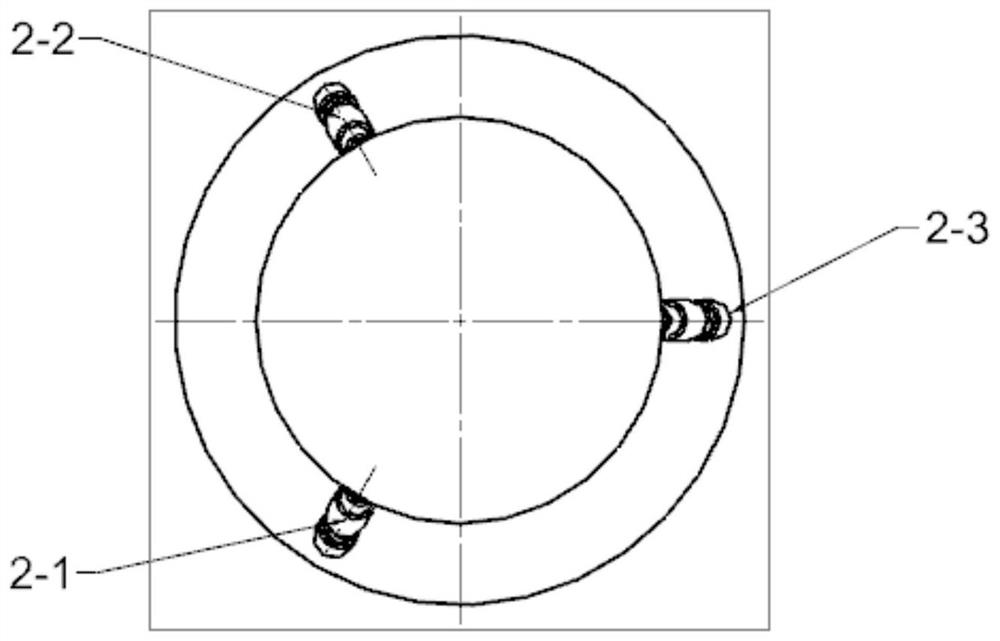

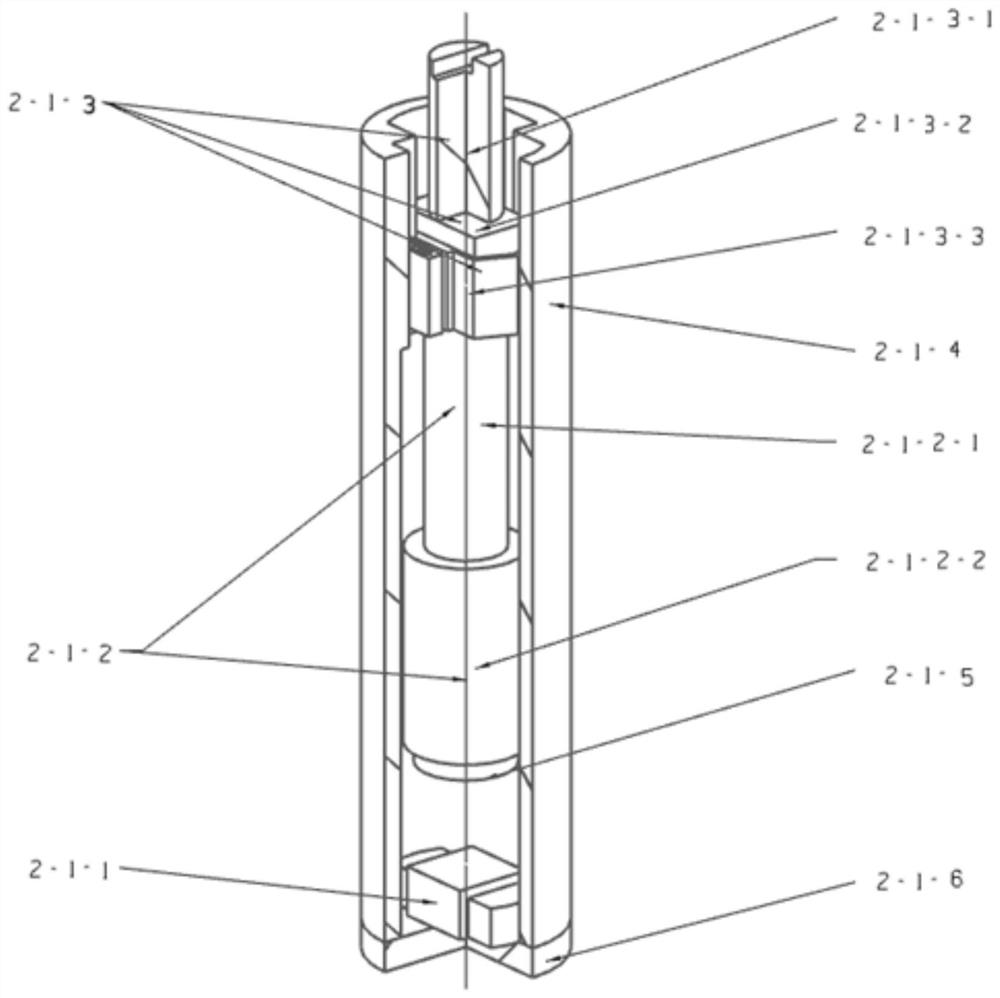

Multi-degree-of-freedom high-precision motion platform based on few-branch-chain mechanism

PendingCN112904519AReduce weightSolve static problemsPiezoelectric/electrostriction/magnetostriction machinesMountingsPiezoelectric actuatorsControl engineering

The invention discloses a multi-degree-of-freedom high-precision motion platform based on a few-branch-chain mechanism. The multi-degree-of-freedom high-precision motion platform comprises a static platform, four telescopic motion branch chains, a movable platform and four same piezoelectric inertial drivers. The static platform and the movable platform are connected through a flexible ball pair and a flexible hooke joint, and the motion branch chains are actuated by linear inertial piezoelectric actuators with a displacement sensing function. The actuator comprises a proportional linear Hall sensor, an actuating body, a motion unit, a cylindrical shell, a permanent magnet and a base. According to the four-degree-of-freedom platform, the flexible hinges are adopted to replace traditional kinematic pairs, the four-degree-of-freedom platform has the advantages of being easy to achieve equipment miniaturization, improving repeated positioning accuracy, being high in motion sensitivity and the like, meanwhile, the platform can reach a static stable state, and the problems of vibration and collision in the transportation process are solved. Large-stroke feeding motion of the platform is achieved through macro motion, and precise positioning is achieved by means of micro motion. And the platform is endowed with large-stroke and high-precision macro-micro motion capability.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Three-degree-of-freedom high-precision motion mechanism based on macro-micro motion mode

PendingCN112904551AReduce weightHigh repeat positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesShaftsKinematic pairEngineering

The invention discloses a three-degree-of-freedom high-precision motion mechanism based on a macro-micro motion mode. The three-degree-of-freedom high-precision motion mechanism comprises a static platform, three telescopic motion branch chains, a movable platform and three same piezoelectric inertial drivers. The static platform and the movable platform are connected through a flexible ball pair and a flexible hooke joint, and a linear inertia piezoelectric actuator with a displacement sensing function is adopted as the moving branch chain. The actuator comprises a proportional linear Hall sensor, an actuating body, a motion unit, a cylindrical shell, a permanent magnet and a base. According to the three-dimensional platform, the flexible hinges are adopted to replace traditional kinematic pairs, the three-dimensional platform has the advantages of being easy to achieve miniaturization of equipment, improving repeated positioning accuracy, being high in motion sensitivity and the like, meanwhile, the platform reaches a static stable state, and the problems of vibration and collision in the transportation process are solved. Large-stroke feeding motion of the platform is achieved through macro motion, and precise positioning is achieved by means of micro motion. According to the invention, the platform is endowed with large-stroke and high-precision macro-micro motion capability.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

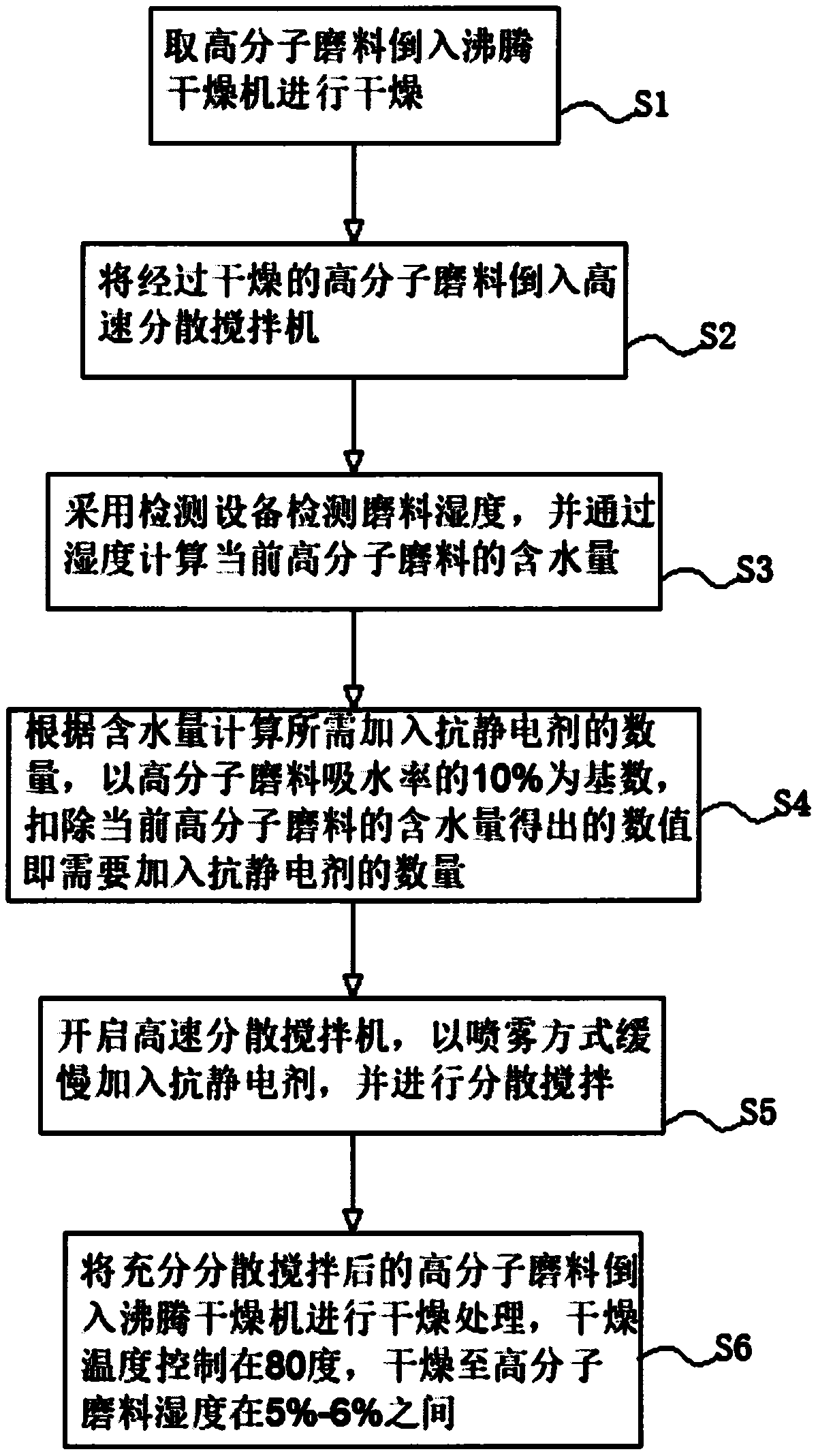

Synthesis method of polymer abrasive and antistatic agent

PendingCN111269697ASolve static problemsAvoid adsorptionOther chemical processesPolymer scienceSand blasting

The invention discloses a synthesis method of a polymer abrasive and an antistatic agent. The method comprises the following steps: taking and pouring a polymer abrasive into a boiling dryer, and drying; pouring the dried polymer abrasive into a high-speed dispersion stirrer, detecting the humidity of the abrasive by adopting detection equipment, calculating the water content of the current polymer abrasive according to the infrared humidity, calculating the quantity of an antistatic agent required to be added according to the water content, and deducting the water content of the current polymer abrasive by taking 10% of the water absorption rate of the polymer abrasive as a base number to obtain a numerical value, namely the quantity of the antistatic agents required to be added. The common phenomena of static electricity and sparks generated by friction in the sand blasting and grinding process of the polymer abrasive are solved, the problem of dust adsorption generated by static electricity after the sand blasting operation of the polymer abrasive is solved, and the dust explosion probability caused by static sparks is reduced.

Owner:LIANYUNGANG ZHONGYI AVIATION MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com