Patents

Literature

45results about How to "Play antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

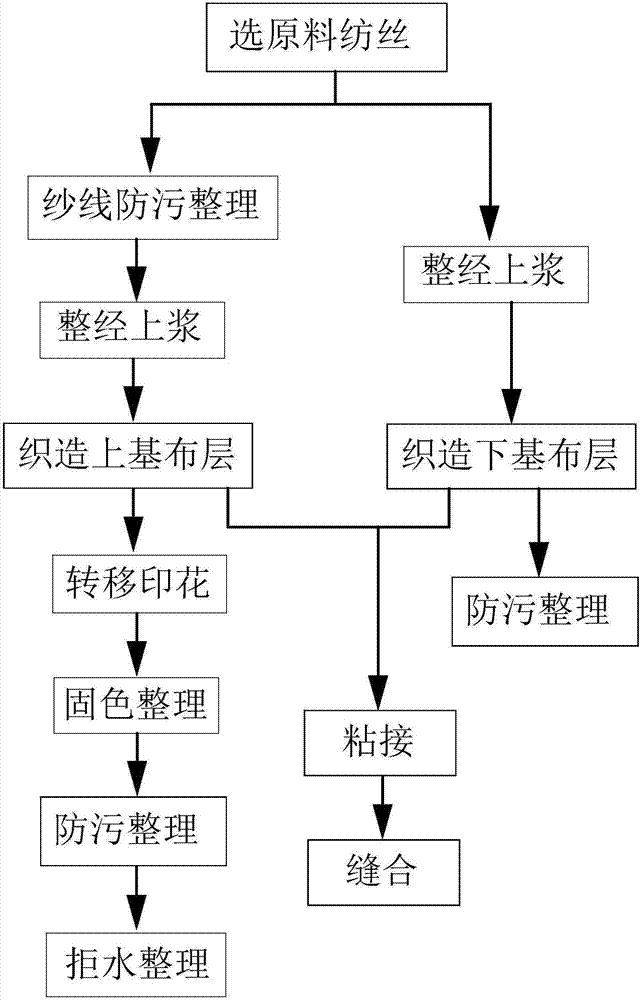

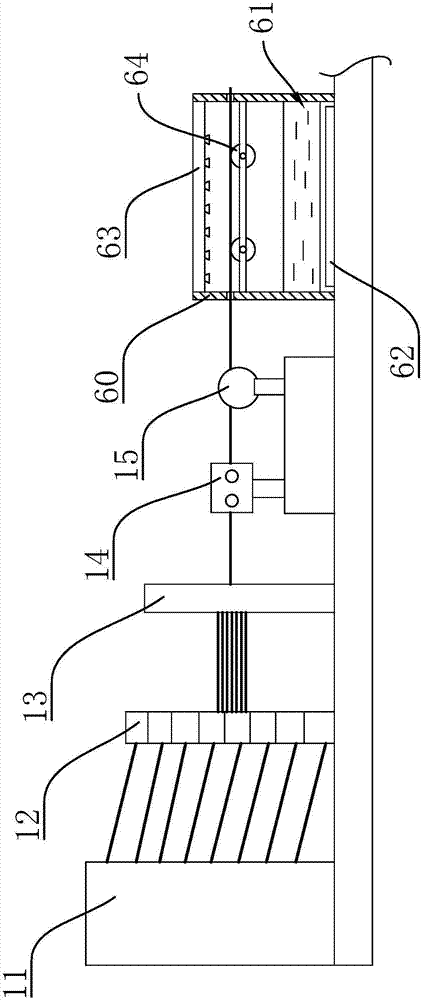

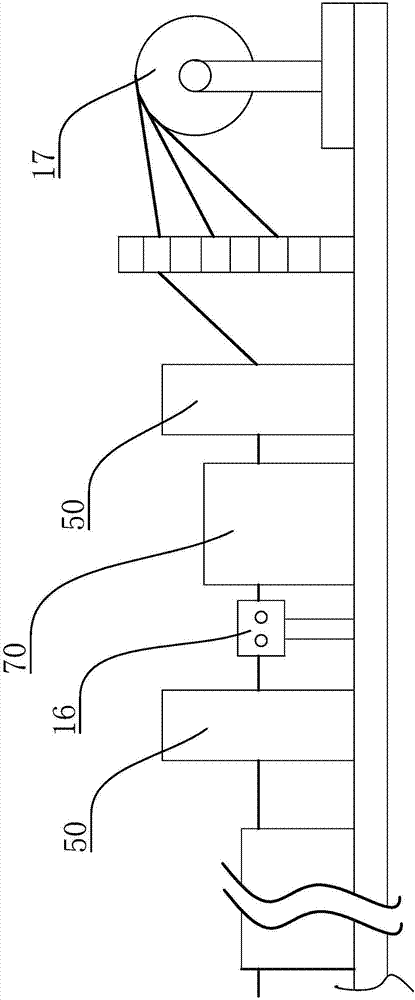

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

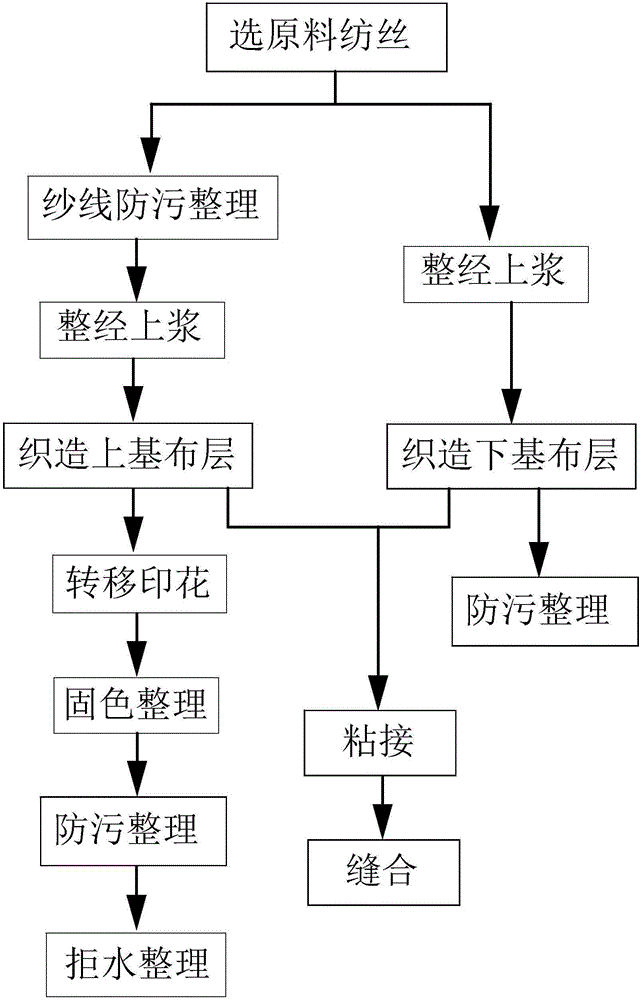

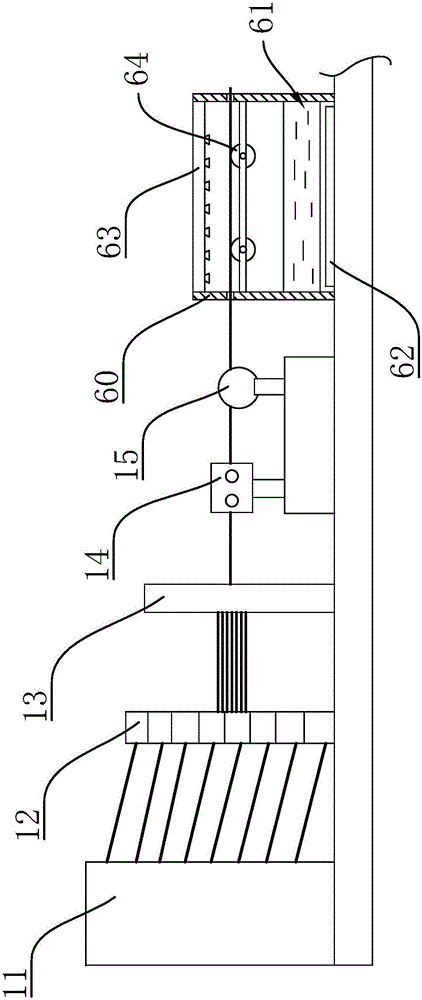

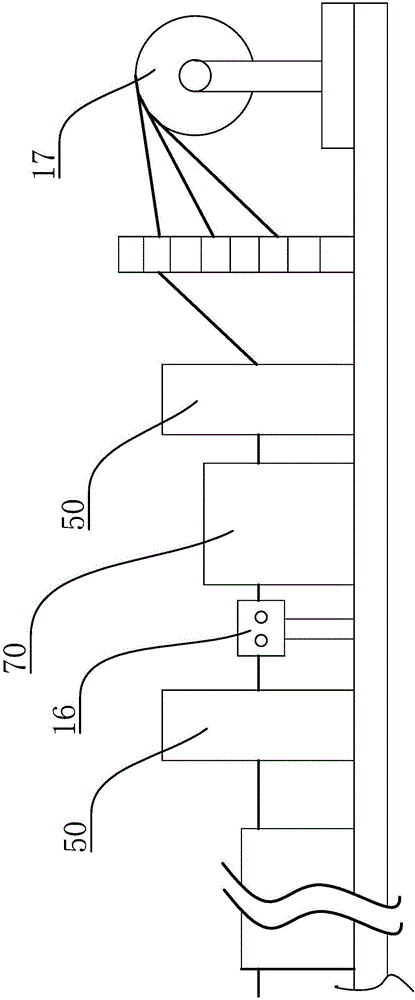

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

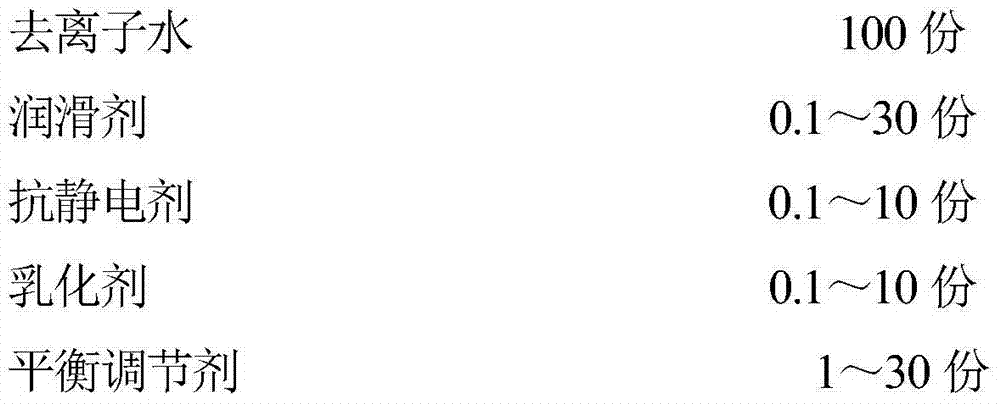

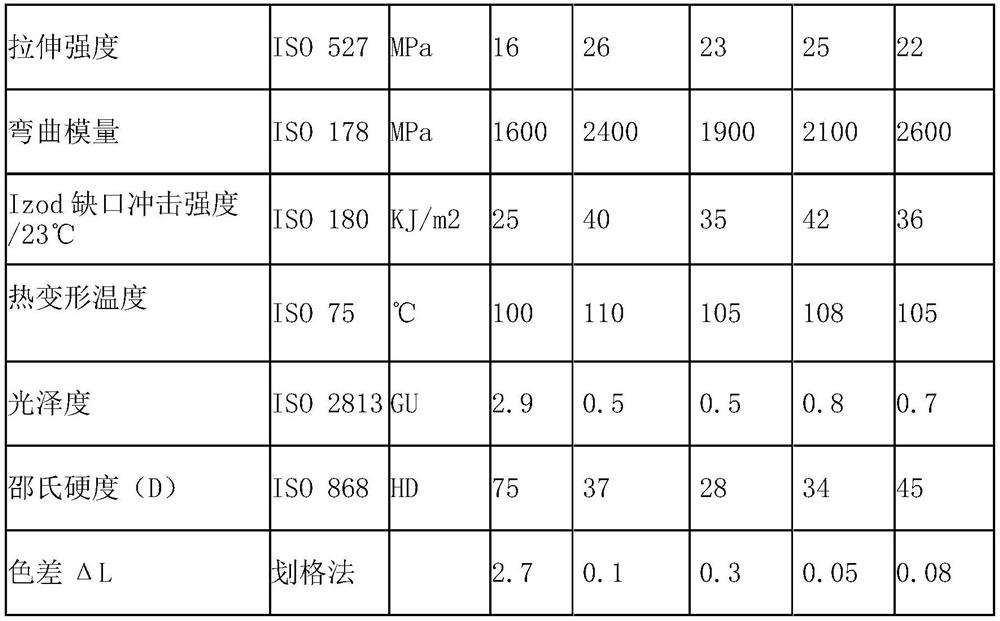

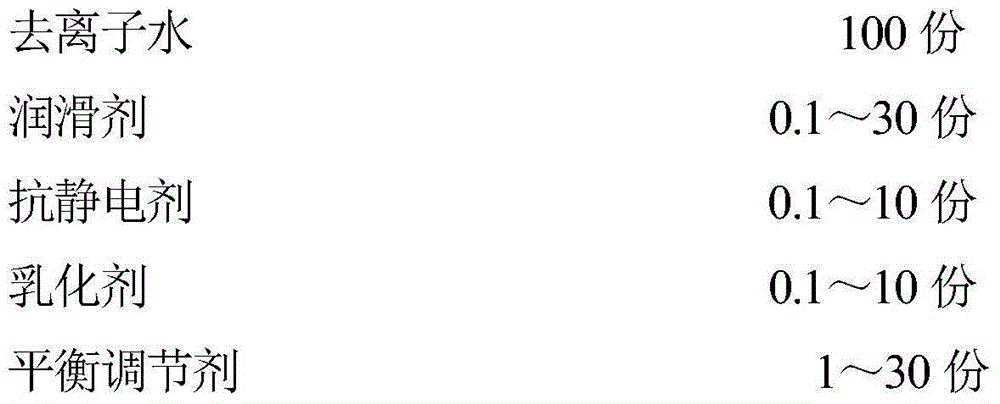

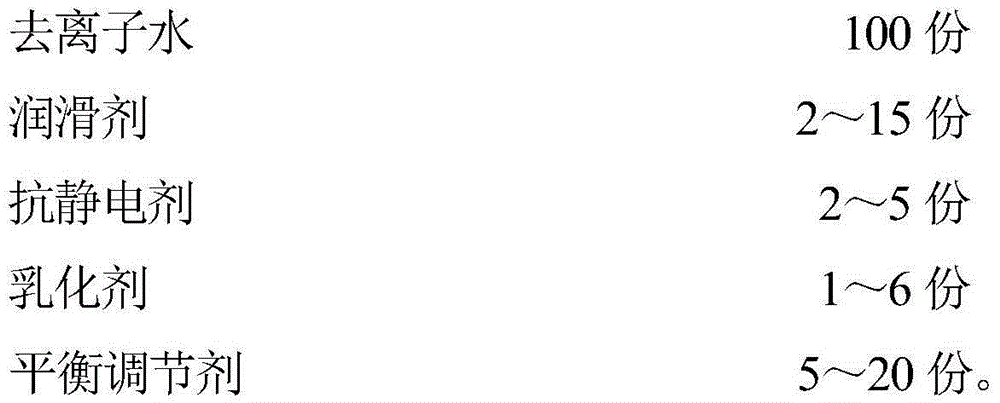

General grade pitch-based carbon fiber spinning oil

InactiveCN103757899AAvoid stickingTensile strength has no effectCarbon fibresIsolation effectAntistatic agent

The invention discloses general grade pitch-based carbon fiber spinning oil. The oil is prepared by mixing deionized water, a lubricating agent, an antistatic agent, an emulsifying agent and a balance regulator in a stirring state. The general grade pitch-based carbon fiber spinning oil has the beneficial effects that the viscosity of the oil is 2-20mPa.s and the light transmittance is 80-98%; the oil has an antistatic effect when sprayed onto fiber surfaces, ensures cohesive forces between fiber monofilaments, achieves a fiber packing effect and prevents fiber adhesion; oil films formed on the fiber surfaces not only protect the monofilament surfaces from being damaged in spinning but also have the same adhesion prevention and isolation effects in the non-melting and carbonizing processes, so that the problems of easiness in adhesion, static electricity, wear and the like in the general grade pitch-based carbon fiber preparation process can be solved; test results indicate that the contact angles between the general grade pitch-based carbon fiber spinning oil and the fiber surfaces are 0-5 degrees, the oil can be well coated on the fiber surfaces, and the fiber strength retention rate is 95-100%, so that the oil basically has no impact on the tensile strength of fibers.

Owner:SHAANXI NORMAL UNIV

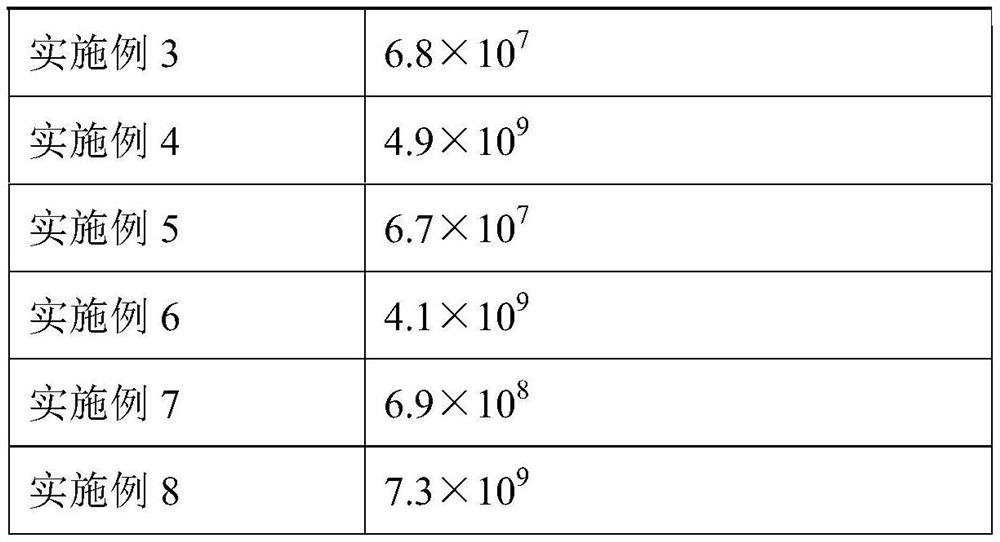

Antistatic halogen-free flame-retardation-reinforced PET (polyethylene glycol terephthalate) material and preparation method of same

ActiveCN102382431ADoes not affect mechanical and physical propertiesDoes not affect surface propertiesGlass fiberAntistatic agent

The invention discloses an antistatic halogen-free flame-retardation-reinforced PET (polyethylene glycol terephthalate) material containing the components in parts by weight as follows: 37.2-48.7 parts of PET resin, 10-26 parts of halogen-free flame retardant compound, 10-50 parts of glass fiber, 2-6 parts of composite antistatic agent, 0.5-8 parts of compatibilizer and 0.3-1.3 parts of processing additive. A preparation method of the PET material includes the steps as follows: (1) placing the composite antistatic agent, the compatibilizer and the processing additive in a high-speed mixing machine to dry mix for 2-4 minutes, wherein the revolving speed is 700-900 revolutions per minute; (2) placing the halogen-free flame retardant compound in the high-speed mixing machine to dry mix for 2-4 minutes, wherein the revolving speed is 600-800 revolutions per minute; and (3) adding the mixtures obtained from the step (1) and the step (2), the PET resin and the glass fiber in a double-screw extruder respectively through a feeder, and then conducting mixing, scattering, melt extrusion and granulation. The antistatic halogen-free flame-retardation-reinforced PET material has the advantagesof being excellent in antistatic effect and reinforced in flame retardation.

Owner:KINGFA SCI & TECH CO LTD +1

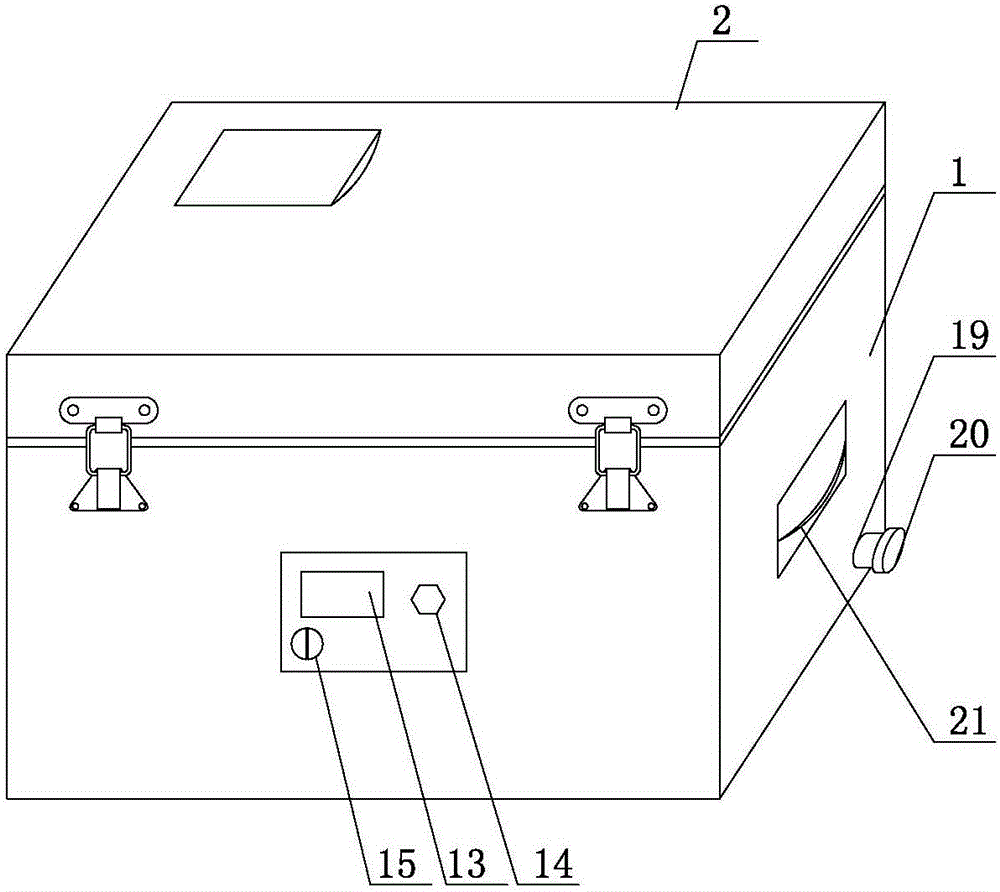

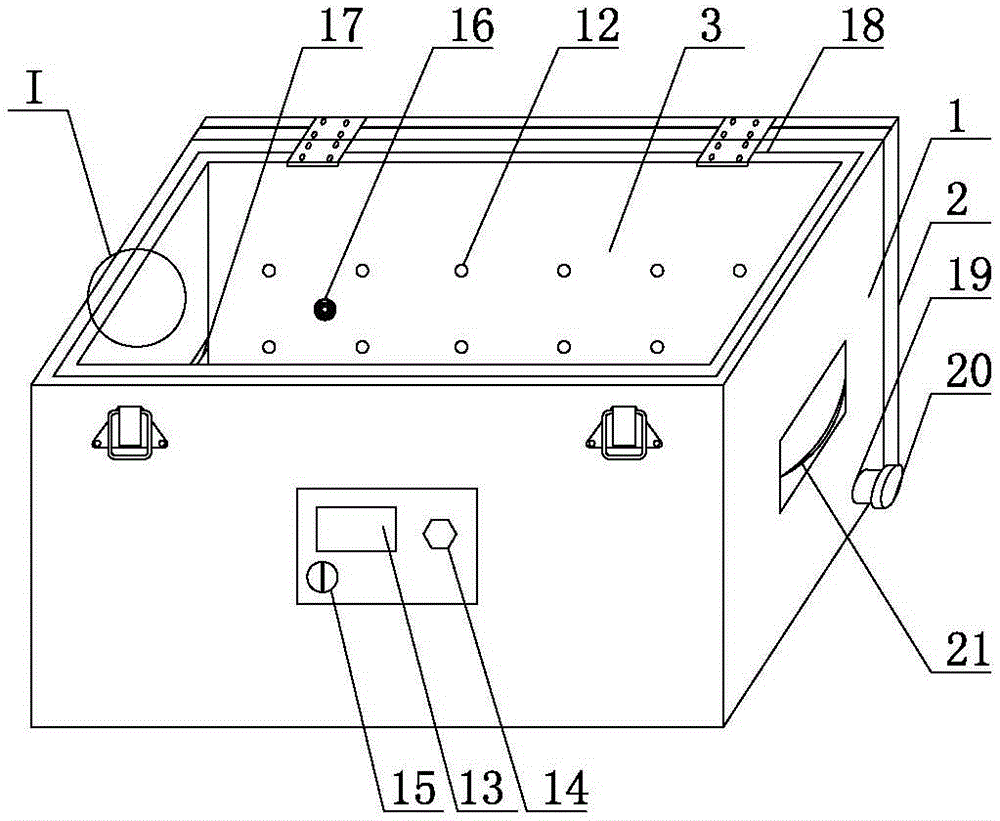

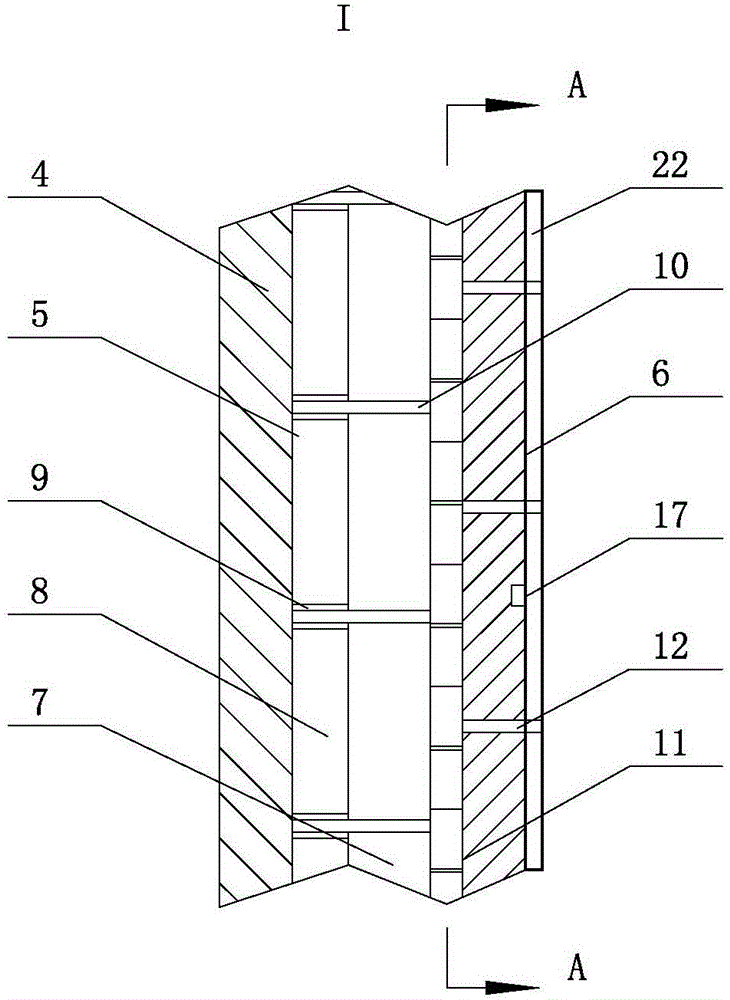

Intelligent temperature control early warning food security insulation box

ActiveCN104787484AHigh strengthReduce weightDomestic cooling apparatusLighting and heating apparatusTemperature controlThermal insulation

The invention discloses an intelligent temperature control early warning food security insulation box. The intelligent temperature control early warning food security insulation box comprises a box body, an upper cover and an insulation inner cavity formed by the box body and the upper cover; the box body and the upper cover are each sequentially provided with a shell, a vacuum thermal insulation layer and a cavity wall from exterior to interior; the inner side of the upper cover is provided with a pressing sheet, and the pressing sheet is connected with the upper cover through a spring; the longitudinal direction and the transverse direction of the inner wall of the box body are each provided with an elastic fixing belt, and therefore objects can be fixed in a cross traction mode after the object is well put into the box body. The intelligent temperature control early warning food security insulation box is used for solving the defects in the prior art, a detachable support air channel is arranged in the shell of the box body, the maintenance is facilitated, the air flow in the thermal insulation inner cavity is enhanced, and the thermal insulation effect of the objects is improved.

Owner:CHINA RAILWAYS CORPORATION

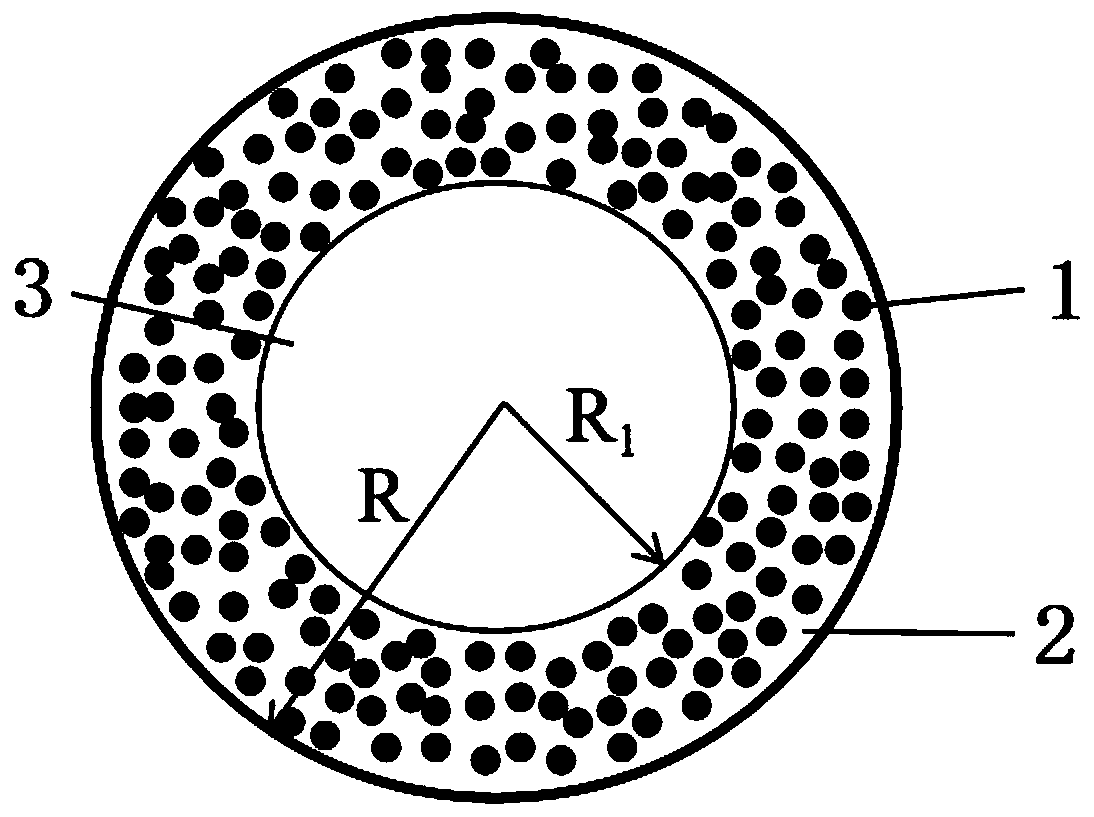

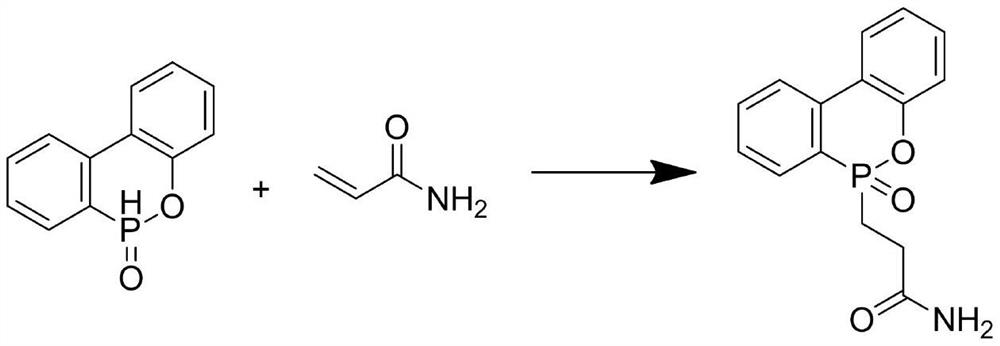

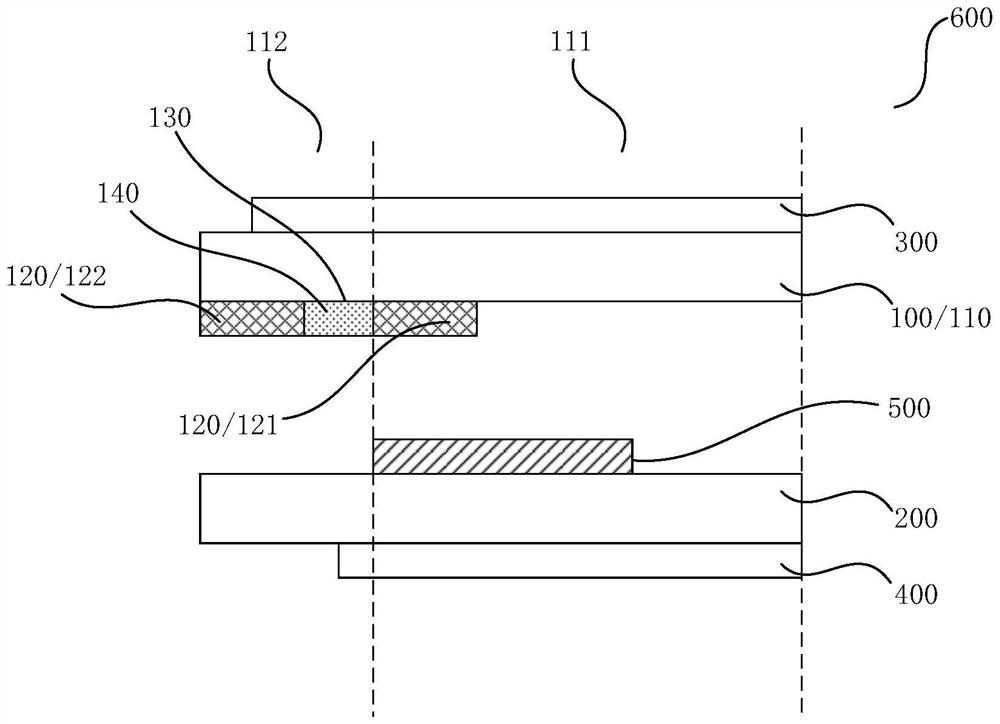

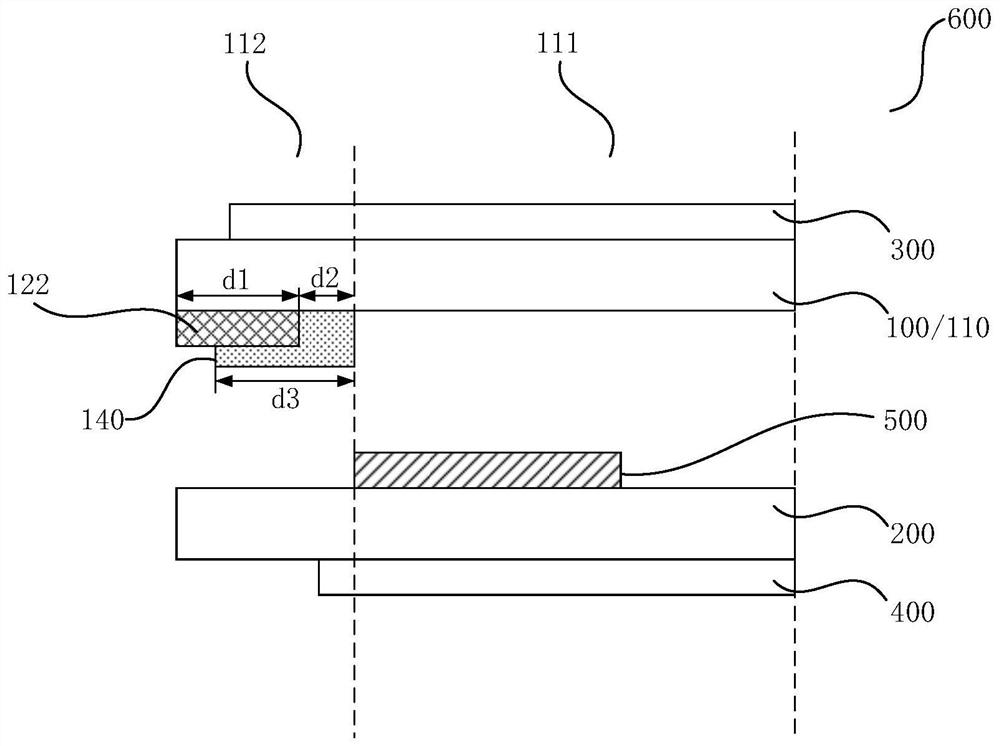

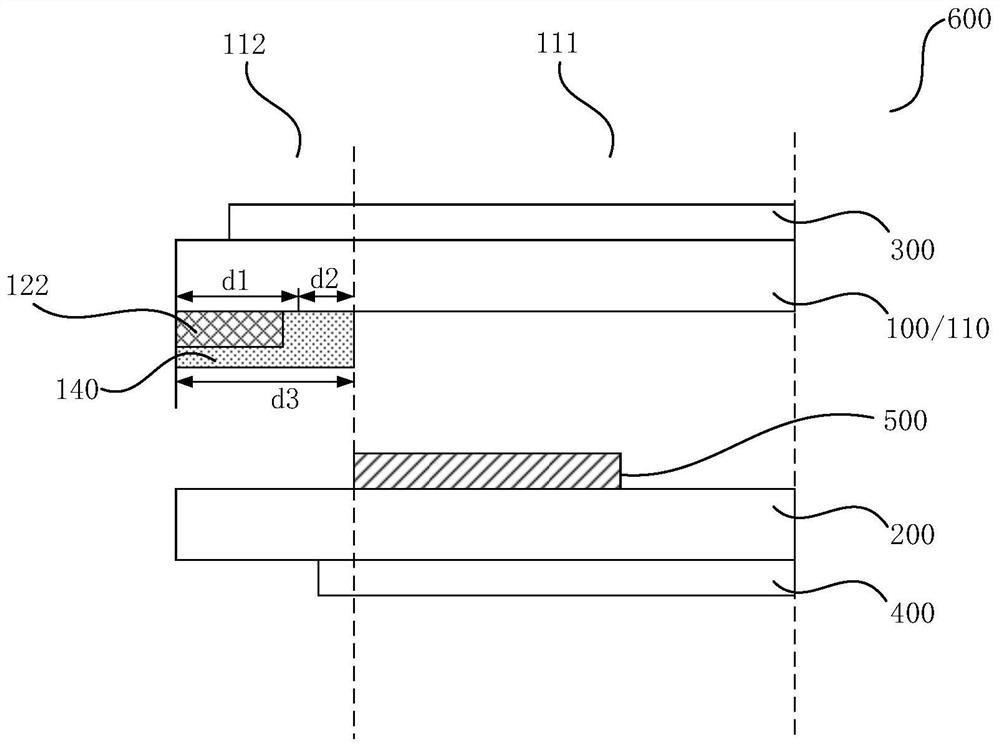

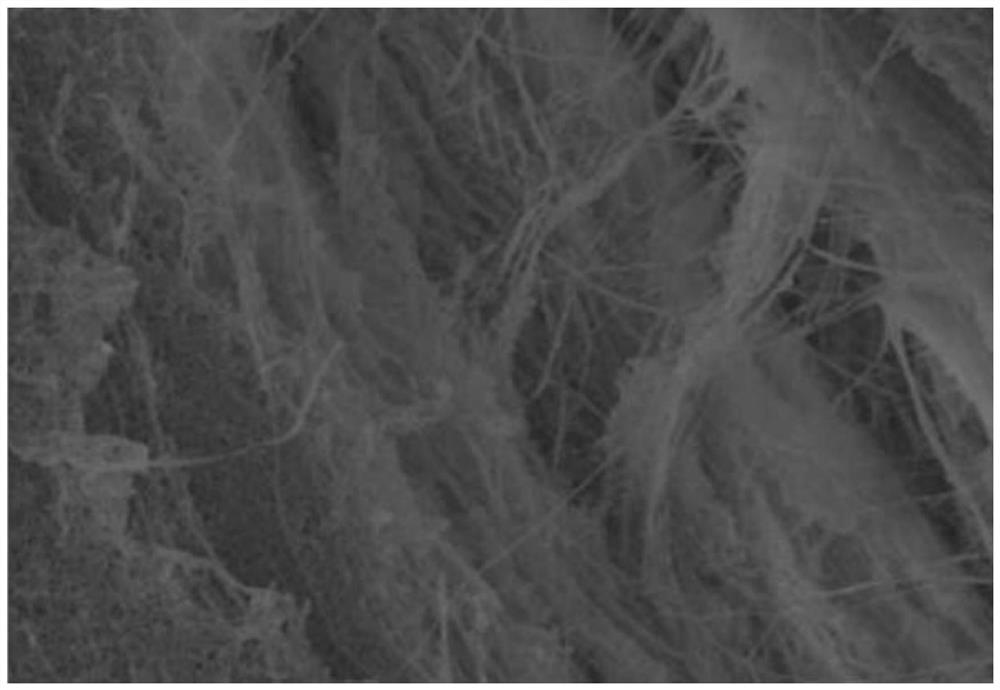

Polyacrylonitrile/carbon nanotube composite fibre, and preparation method and application thereof

ActiveCN111155201APlay antistatic effectImprove mechanical propertiesElectroconductive/antistatic filament manufactureFilament/thread formingPolymer scienceSingle fibre

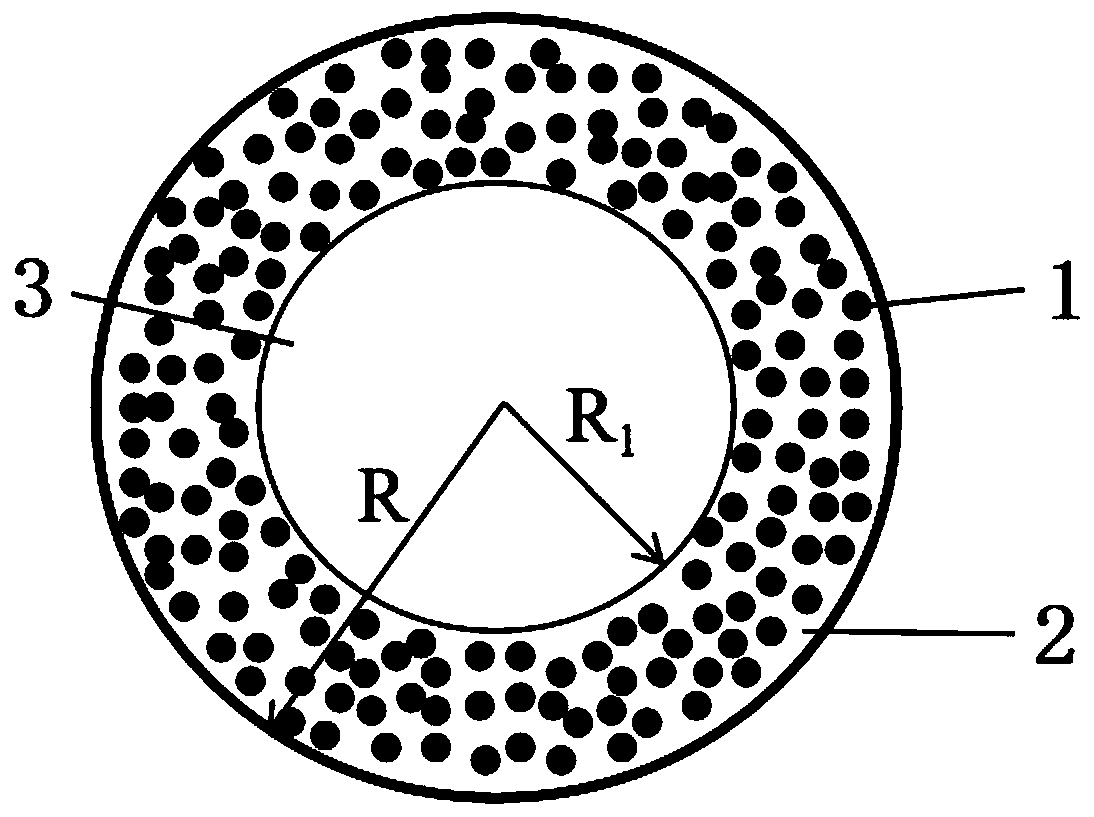

The invention discloses a polyacrylonitrile / carbon nanotube composite fibre, and a preparation method thereof. The composite fibre is a sheath-core two-layer coaxial structure, wherein a sheath layeris mainly composed of a polyacrylonitrile basal body and carbon nanotubes uniformly distributed in the basal body; the component of a core part is polyacrylonitrile; and the ratio of the semi-diameterof the composite fibre to the semi-diameter of the core part is (1.5-2):1. The preparation method comprises the steps of: preparing a sheath layer blended material and a core part blended material, which are blended uniformly, by adopting a mechanical stirring and blending method, and respectively extruding and granulating; and then, respectively performing melting and blending in a melt spinningmachine, after respectively performing extrusion and metering, correspondingly entering the same sheath-core spinning assembly to spin, and then, obtaining the composite fibre through corridor cooling, oiling, winding, secondary water bath drawing, ultrasonic washing and drying. The carbon nanotubes uniformly distributed in the sheath layer have the antistatic effect; but, the core part does notcontain a conducting material; therefore, the fibre can be used as the fibre for antistatic clothing; the preparation process is simple; the fibre structure is controllable; the cost is low; and furthermore, the method is suitable for production.

Owner:ZHENJIANG COLLEGE

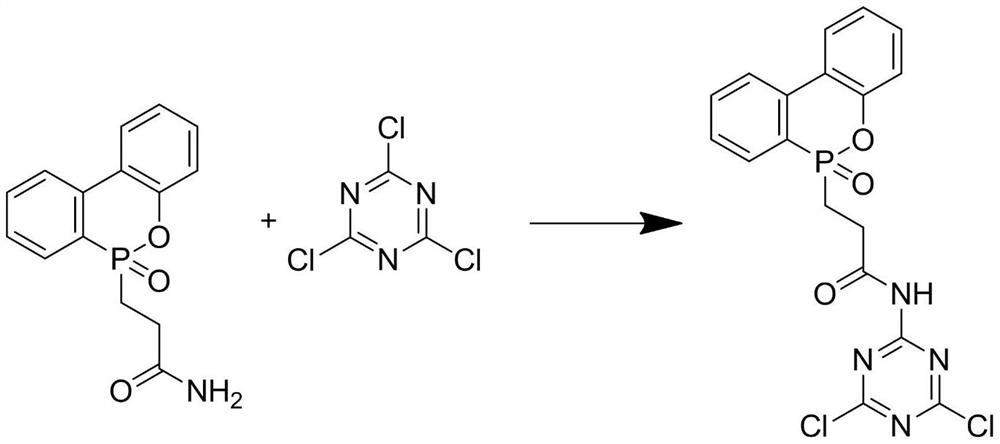

Preparation method of silicane functionalized graphene, antistatic organic silicon pressure sensitive adhesive and preparation method thereof

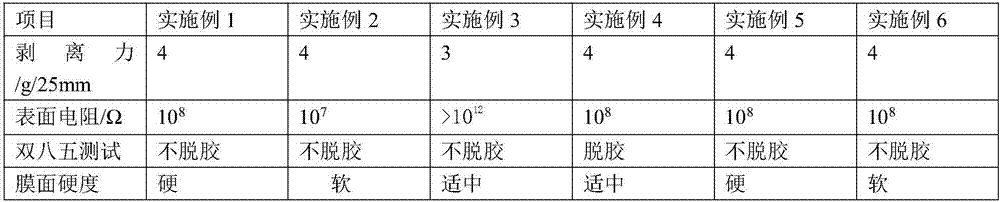

InactiveCN107541177ADoes not affect curabilityPlay antistatic effectNon-macromolecular adhesive additivesSilanesCvd graphene

The invention discloses a preparation method of silicane functionalized graphene, antistatic organic silicon pressure sensitive adhesive and a preparation method thereof. The technical problems are solved that existing graphene is unevenly dispersed in the organic silicon pressure sensitive adhesive and the surface of the organic silicon pressure sensitive adhesive after coating and forming has high static electricity so that hidden safety dangers can be brought to coating and production, the graphene oxide after silane is modified is used for giving antistatic performance to the pressure sensitive adhesive under the condition that the curing performance, coating technology and weather-proof performance of the pressure sensitive adhesive cannot be influenced, and the adverse effect causedby static electricity can be eliminated in the coating technology and the using process of formed products.

Owner:SHENZHEN KANGLIBANG TECH

Method for producing oil paint

ActiveCN104449025AWith weak magneticImprove antistatic performanceMagnetic paintsAnti-corrosive paintsAcrylic resinAdhesive

The invention discloses a method for producing an oil paint, and relates to the field of chemical processes. The method comprises the following steps: feeding, premixing, grinding, mixing a paint, introducing oxygen, filtering and the like, namely adding materials to a twin-cylinder high-speed disperser in opening mixing during feeding; firstly adding 1 / 5 of polyurethane acrylic resin to a first cylinder to render; adding a little of conductive carbon black, chlorinated paraffin, magnetic iron powder, zeolite powder and nickel powder, adding part of polyurethane acrylic resin at an interval of 1 minute, and completely adding the residual polyurethane acrylic resin for 3-4 times; adding a mixed solution of double distilled water, butanol, an organic silicone resin fluid and an isocyanate adhesive to a second cylinder, and carrying out hydrolytic crosslinking reaction; and adding nano powder, and carrying out catalytic reaction, mixing the materials which are processed in the first cylinder and the second cylinder at the ratio, thus various defects of the oil paint can be improved; resources can be reasonably distributed; and the method is economic and applicable.

Owner:丹阳恒安化学科技研究所有限公司

Nanometer self-cleaning film, preparation method thereof and lamp

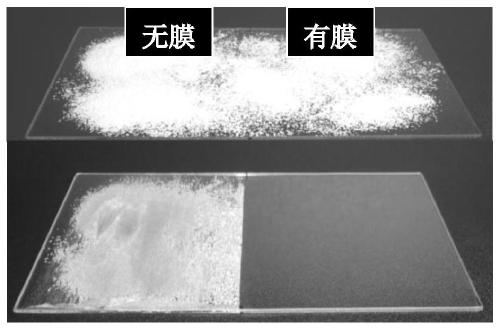

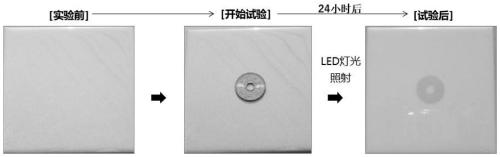

ActiveCN109762377AImprove practicalityImprove adhesionAntifouling/underwater paintsPaints with biocidesTectorial membraneOptoelectronics

The invention relates to a nanometer self-cleaning film, a preparation method thereof and a lamp. The technical problems of large thickness of protective films, waste of materials and complicated coating processes of existing self-cleaning lamps are mainly solved. According to the technical scheme, the nanometer self-cleaning film is composed of anA layer film and a B layer film, and the A layer film and the B layer filmare prepared from photocatalysis materials containing nanoscale TiO2 and SiO2. The preparation method includes the following steps: (1) the A layer film is prepared; and (2) the B layer film is prepared. The lamp prepared from the nanometer self-cleaning film comprises a light source, an aluminum foil shell, and an acrylic plate, and further comprises a reflection point, alampshade and the nanometer self-cleaning film composed of the A layer film and the B layer film arranged on the acrylic plate, the A layer film is arranged on the outer surface of the lampshade, andthe B layer film is arranged on the A layer film to form the nanometer self-cleaning film.

Owner:SHANXI XINSIBEI TECH

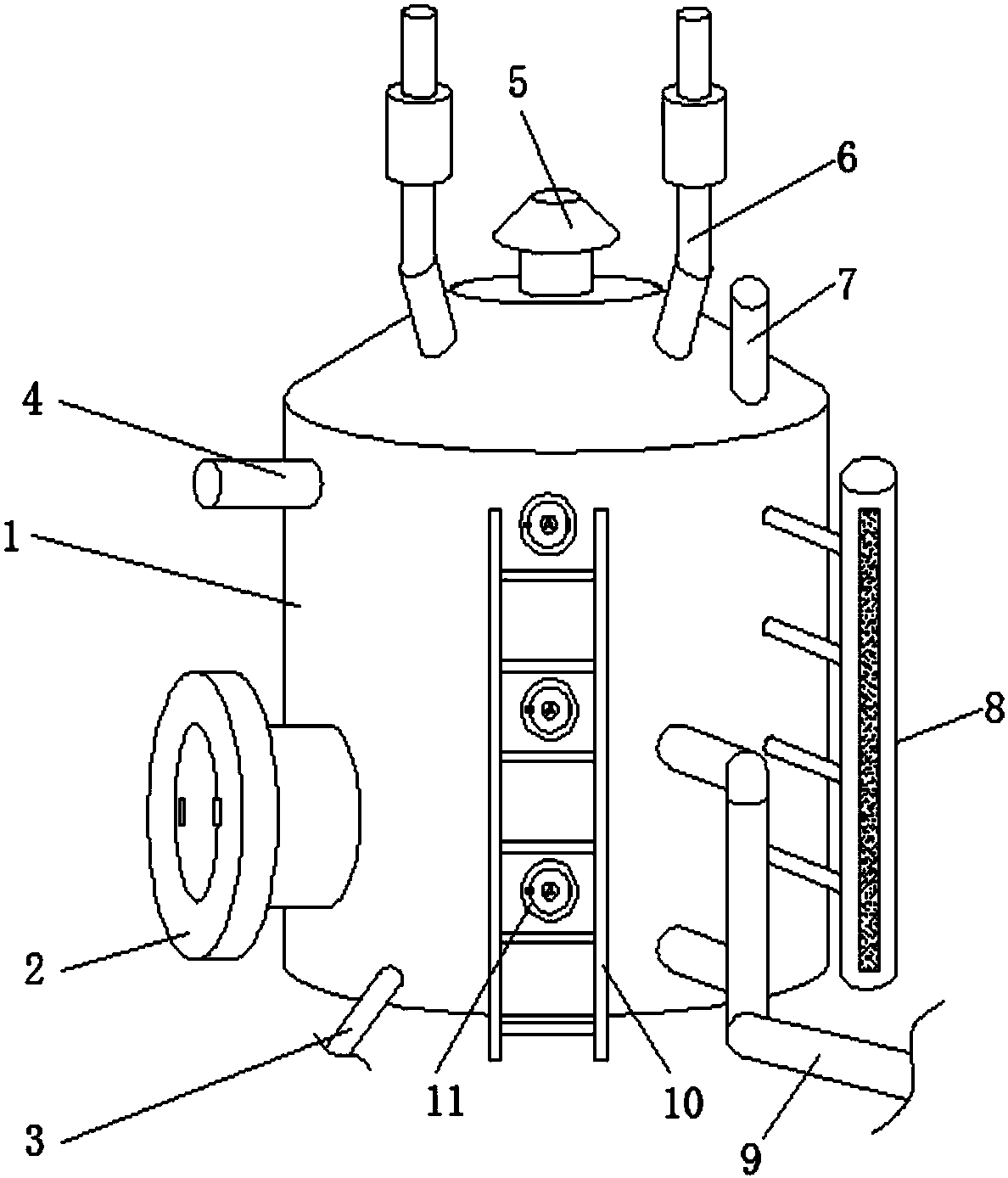

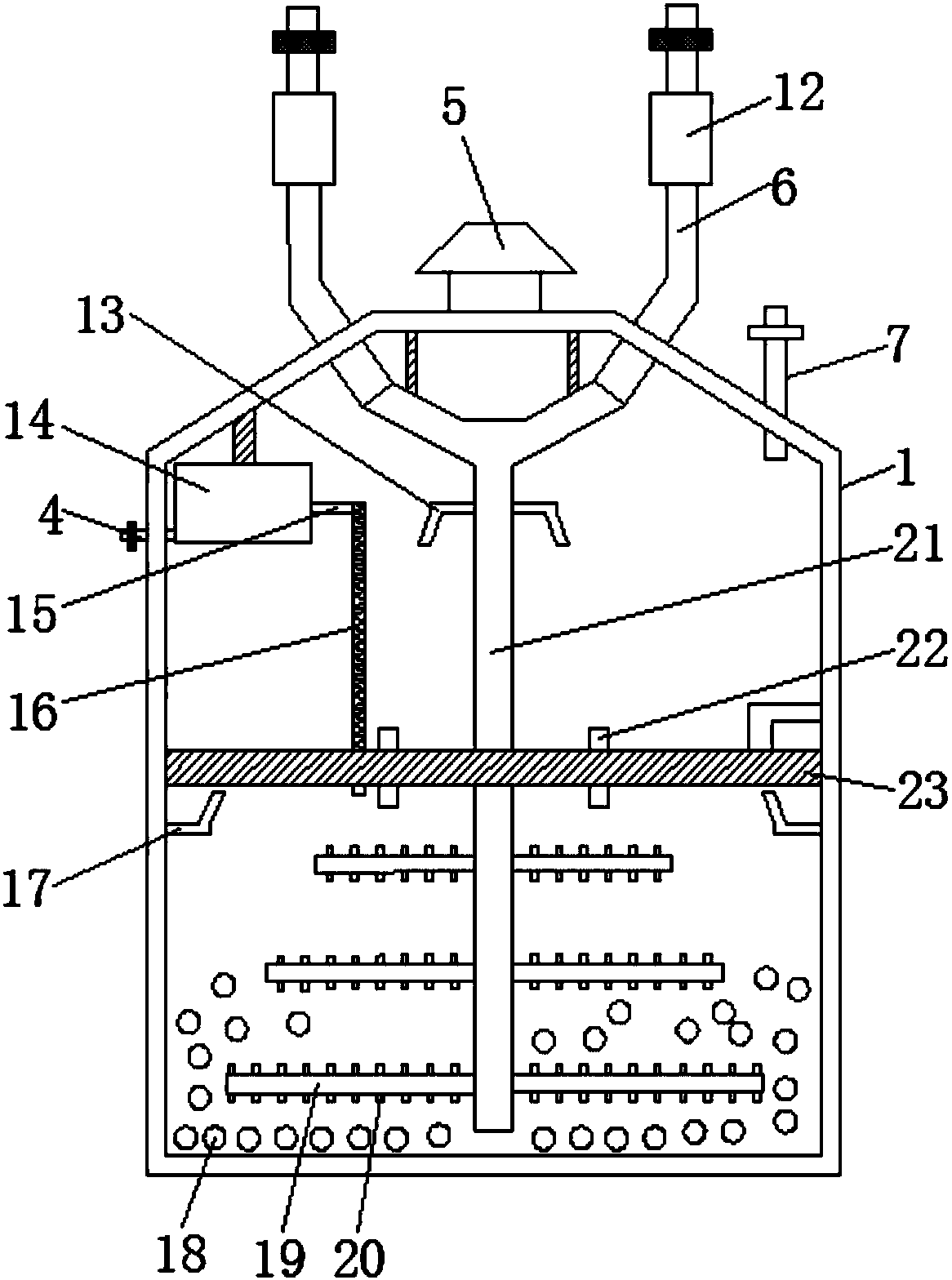

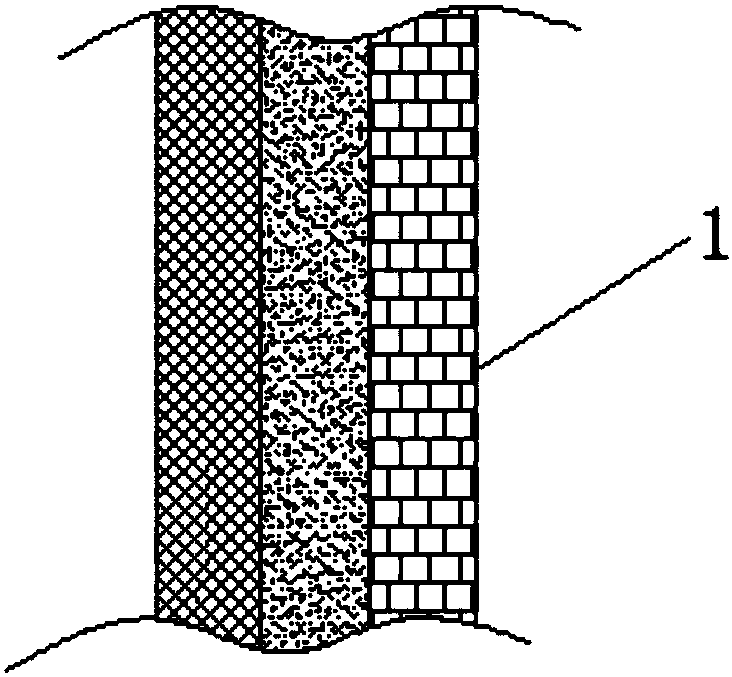

Efficient and durable storage container

InactiveCN109928103AReduce static electricityImprove securityLarge containersUnderwater structuresEngineeringLiquid storage tank

The invention discloses an efficient and durable storage container. The efficient and durable storage container has high quality and comprises a container, wherein a ceiling is horizontally arranged inside the container; the upper end of the interior of the container is connected to a mixed liquid storage tank through a bracing frame; a mixed liquid passage is arranged at one side of the mixed liquid storage tank; a joining passage is arranged at one side, far away from the mixed liquid passage, of the mixed liquid storage tank; a soft channel is arranged at one end, far away from the mixed liquid storage tank, of the joining passage; a transparent cover is arranged on the top end of the container; two entering liquid passages are symmetrically arranged at the upper end of the container; agas exchanging device is also inserted in the upper end of the container; and a temperature reducing instrument is arranged on each entering liquid passage. The efficient and durable storage container is practicable, stable, simple and convenient to operate, safe, efficient, and durable in use, can also treat internal liquid and has a high promotion value.

Owner:陕西海嵘工程项目管理有限公司

Polyethylene antistatic filling master batch and preparation method thereof

The invention discloses polyethylene antistatic filling master batch and a preparation method thereof. The filling master batch is prepared from the following raw materials in parts by weight: 14 to 20 parts of polyethylene, 80 to 90 parts of modified bentonite, 4 to 8 parts of polyethylene wax, 3 to 5 parts of ethylene-bis-stearamide, 2.5 to 2.8 parts of a phosphate coupling agent and 8 to 12 parts of carbon black. The preparation method comprises the following steps: (1) raising the temperature of a high-speed mixing machine to 180 DEG C to 200 DEG C, and keeping the temperature for 5min to10min; (2) adding the modified bentonite, the phosphate coupling agent and the carbon black, and stirring for 15min to 20min; continually stirring and cooling to 110 DEG C to 120 DEG C; (3) adding thepolyethylene wax and the ethylene-bis-stearamide and continually stirring for 1min to 2min; then adding the polyethylene, and mixing and stirring for 4min to 5min; discharging and cooling; (4) extruding and granulating a cooled material to obtain the polyethylene antistatic filling master batch. According to the polyethylene antistatic filling master batch and the preparation method thereof, disclosed by the invention, tetradecyl pyridinium bromide modified bentonite is adopted, and the compatibility between the modified bentonite and the polyethylene is improved, so that the prepared fillingmaster batch is easily dispersed in the polyethylene, and the mechanical property and the antistatic property of the polyethylene are improved.

Owner:贵州通汇塑料科技有限公司

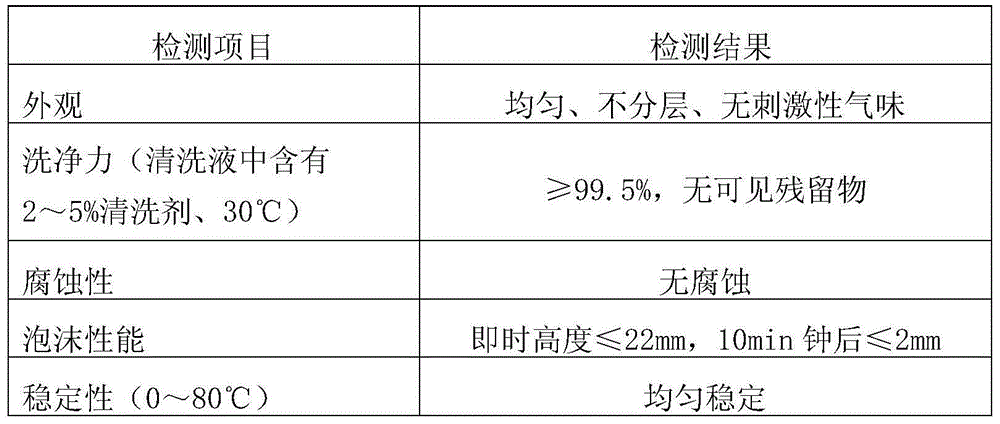

Mechanical part cleaning agent

InactiveCN104911623AImprove decontamination abilityGood decontamination effectCelluloseSodium metasilicate

The invention relates to a mechanical part cleaning agent, which comprises twelve fatty amine polyoxyethylene ethers, cocoanut fatty acid diethanolamide, dodecyl dimethyl betaine, dodecyl polyglucoside, sodium-cellulose propionate 4 (Na-CP4), sodium metasilicate, diethylenetriamine disodium, polyether-grafted polysiloxane, silicone emulsion, triethanolamine, sodium toluenesulfonate, fatty acid, perfluorocarbon surfactant, Hay fat sodium peptide, n-methyl-pyrrolidone and deionized water, which are 100 in part by weight. The mechanical part cleaning agent can not damage sensitive equipment and parts, is not easy to burn, and is high in cleaning rate.

Owner:程叶红

Anti-static PE corrugated pipe and preparation method thereof

The invention relates to an anti-static PE corrugated pipe. The anti-static PE corrugated pipe is characterized in that the anti-static PE corrugated pipe is prepared from the following materials in parts by weight: high-density polyethylene, low-density polyethylene, graphene, polymethylacrylic acid, carbitol acetate, aluminum powder, acetobutyryl cellulose, sodium dodecyl benzene sulfonate, triethanolamine, vinyltriacetoxysilane, gamma-glycidyl propyl trimethoxy silane, N,N-diphenyl p-phenylamine, tert-butyl peroxypivalate, cobalt stearate, polyvinyl chloride, N-methyl pyrrolidone, and alkylphenol polyoxyethylene. The PE corrugated pipe has the characteristics of strong crushing resistance, good anti-corrosion property, anti-static electricity, inflaming retarding and long service life.

Owner:安庆市悦发管业有限公司

Antistatic agent and preparation method thereof

ActiveCN112126127APlay antistatic effectReduce dependenceOrganic compound preparationAmino-hyroxy compound preparationPolymer scienceMonoglyceride

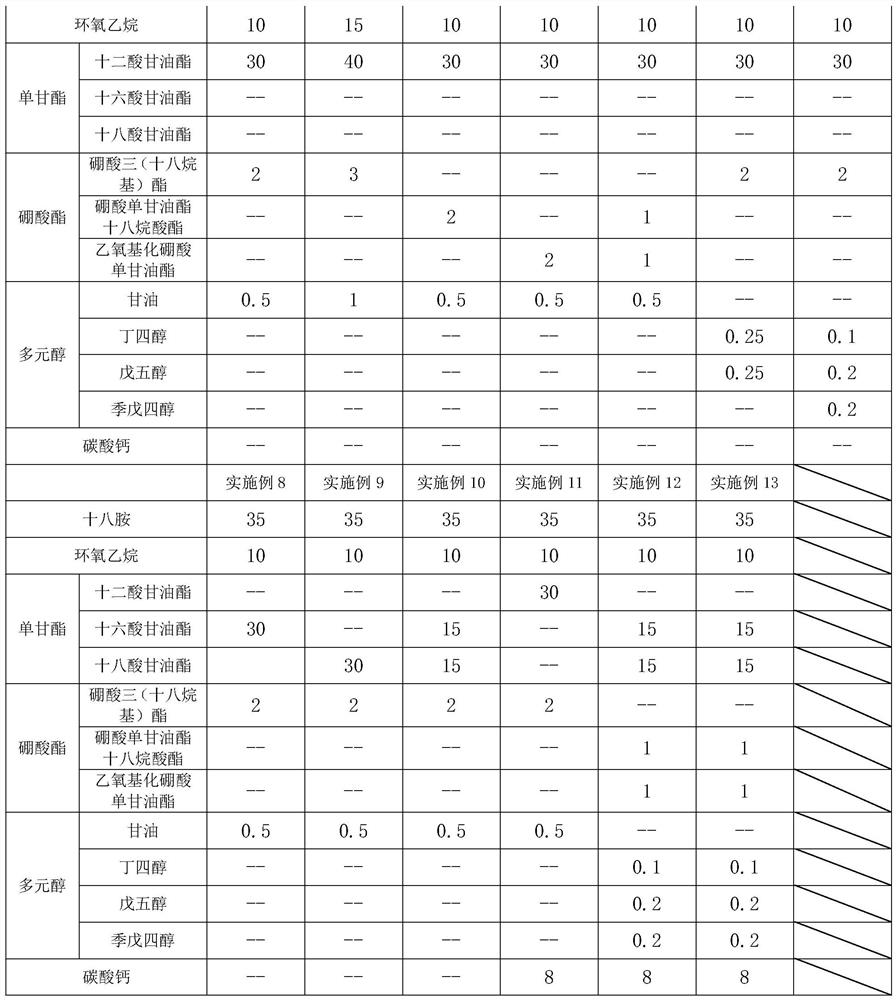

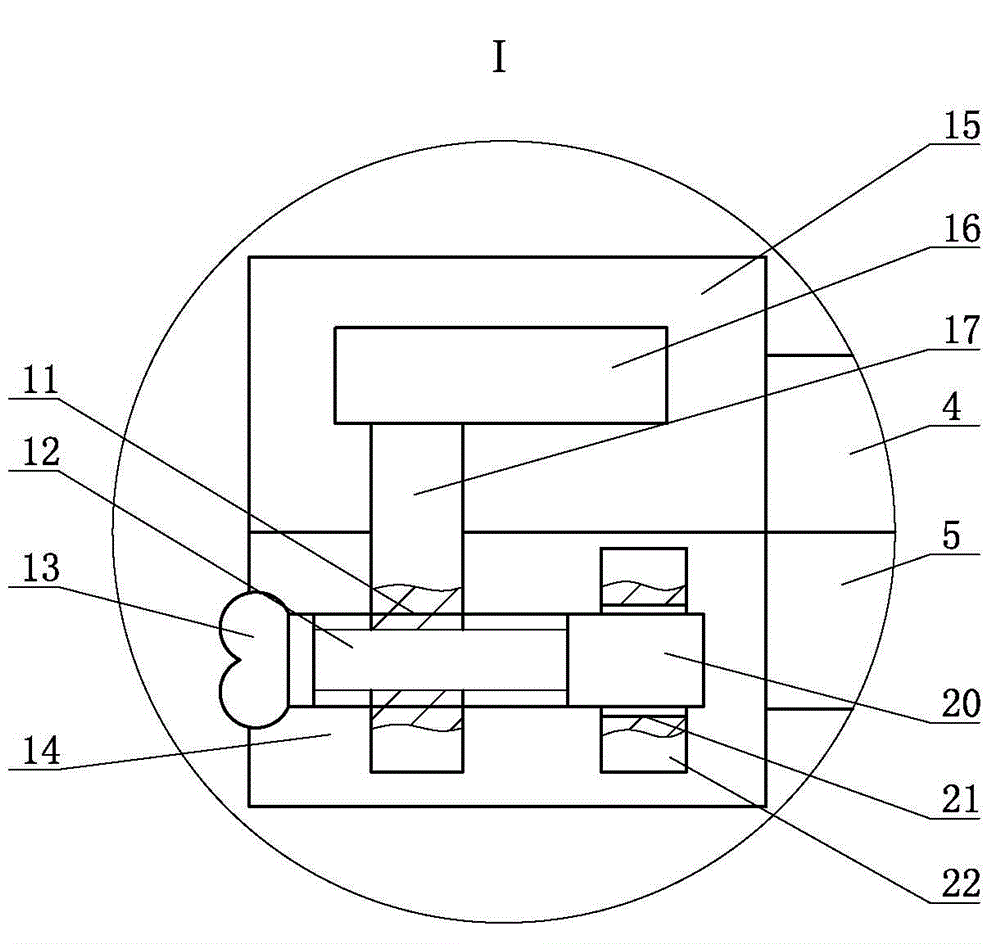

The invention relates to the technical field of plastic product additives, in particular to an antistatic agent and a preparation method thereof, and the antistatic agent is mainly prepared from the following raw materials in parts by mass: 35-45 parts of octadecylamine; 10-15 parts of ethylene oxide gas; 30-40 parts of monoglyceride; 2-3 parts of boric acid ester; and 0.5-1 part of a polyol. Thespecific preparation method comprises the following steps: S1, weighing the octadecylamine in parts by mass, heating and melting at the temperature of 70-75 DEG C, and feeding into a reaction kettle;s2, controlling the temperature of the reaction kettle to be 140-150 DEG C, introducing ethylene oxide gas into molten octadecylamine, and reacting for 1.5-2 hours; s3, adding the glycerol dodecanoate, the boric acid ester and the glycerol in parts by mass into the reaction kettle, and stirring for 1-1.5 hours at the temperature of 100-110 DEG C; and S4, cooling the reaction kettle to 80-85 DEG C,discharging while the reaction kettle is hot, and cooling to obtain the target antistatic agent. According to the antistatic agent prepared by the invention, after the antistatic agent is blended into a molded product, the antistatic agent has better antistatic capacity, and meanwhile, the influence of surface abrasion on the antistatic performance can be reduced.

Owner:杭州临安德昌静电科技有限公司

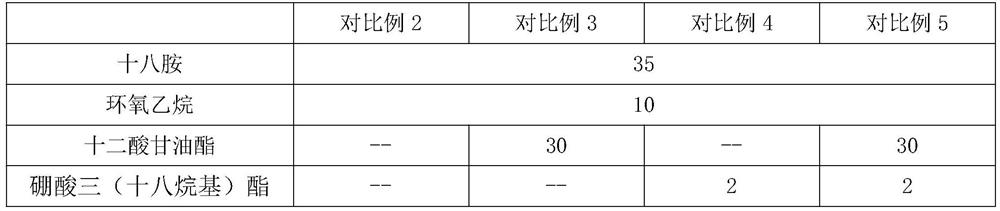

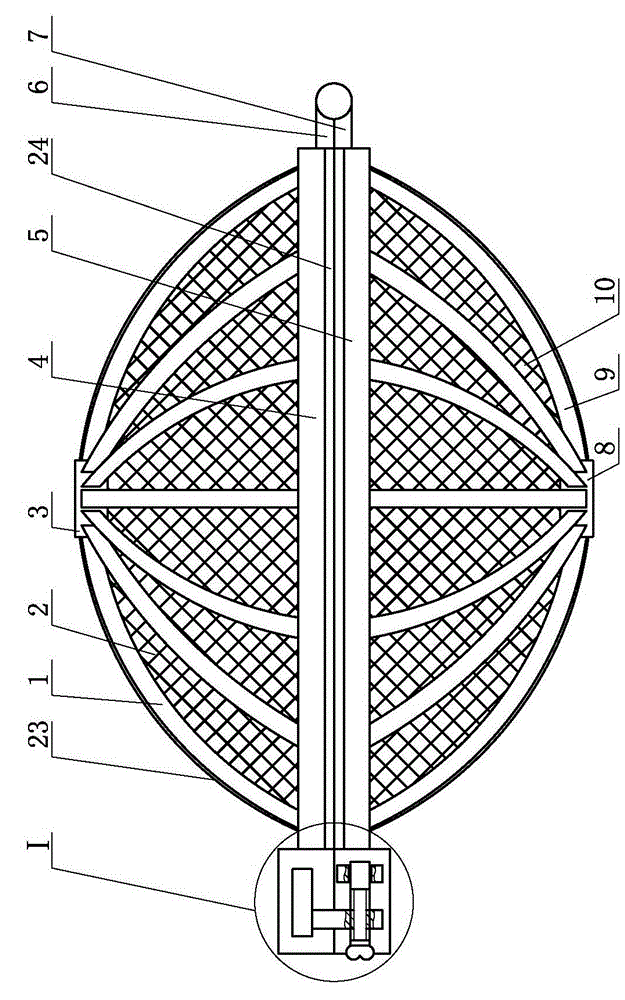

Charged foreign matter clearing unmanned aerial vehicle protection cover

The invention provides a charged foreign matter clearing unmanned aerial vehicle protection cover, which comprises a first connecting plate and a second connecting plate, wherein the end part of the first connecting plate and the end part of the second connecting plate are mutually hinged; one end of the first connecting plate is provided with a second fixing ring; the upper part of the second fixing ring is provided with an upper protection net; the upper protection net comprises a plurality of first arc-shaped rods, a copper wire layer and a first fixing ring. The first arc-shaped rods and the second arc-shaped rods are respectively made of carbon fiber, so that the first arc-shaped rods and the second arc-shaped rods can ensure the sufficient intensity of the charged foreign matter clearing unmanned aerial vehicle protection cover, and meanwhile, the weight of the charged foreign matter clearing unmanned aerial vehicle protection cover is reduced to the maximum degree. The first arc-shaped rods and the second arc-shaped rods can surround a rotor of a charged foreign matter clearing unmanned aerial vehicle for preventing foreign matters from falling on a vehicle body of the unmanned aerial vehicle and from being wound and collided with the rotor, and the influence on the normal work of the unmanned aerial vehicle is avoided.

Owner:STATE GRID CORP OF CHINA +1

High-flame-retardant antistatic yarn and processing method thereof

PendingCN112760982AThree-dimensional structureIncrease the degree of branchingElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolyesterYarn

Owner:JIESHOU TIANZHU TEXTILE MATERIAL

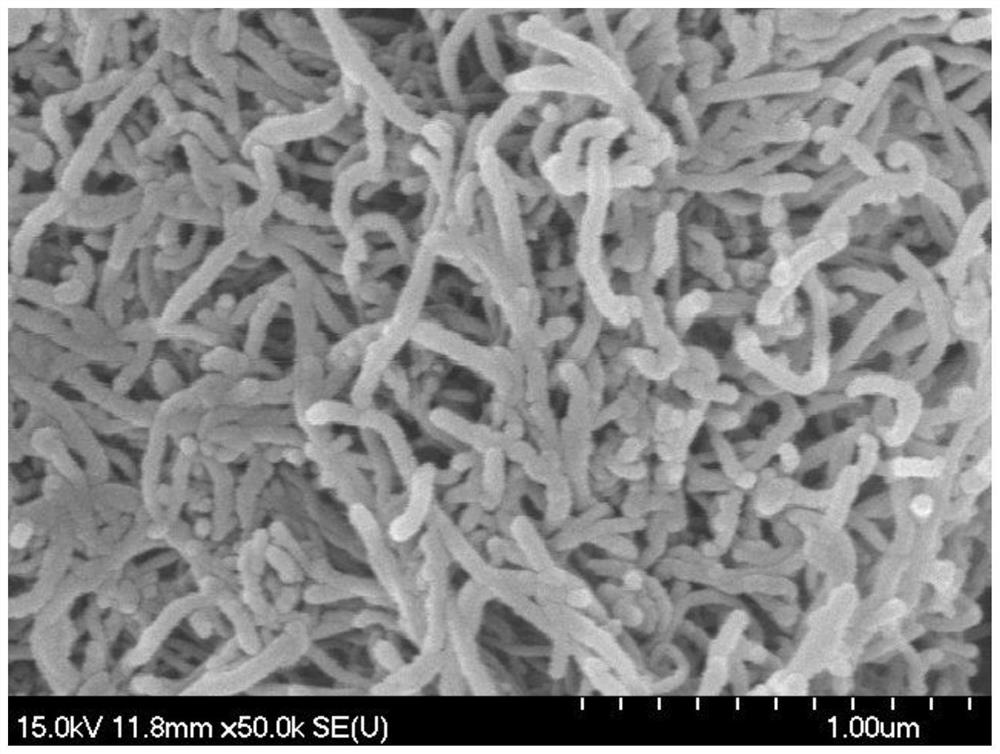

Antistatic organosilicon pressure-sensitive adhesive containing electron transport material and preparation of adhesive

ActiveCN112608689AFix incompatibilitiesDoes not affect curabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer sciencePtru catalyst

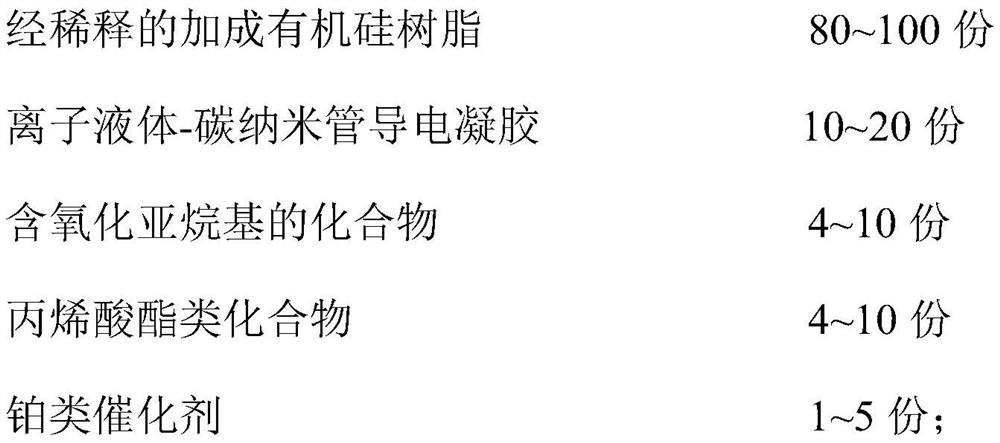

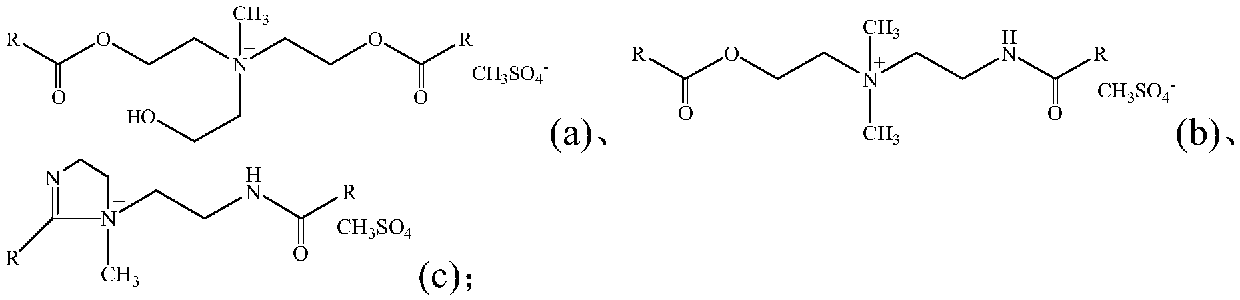

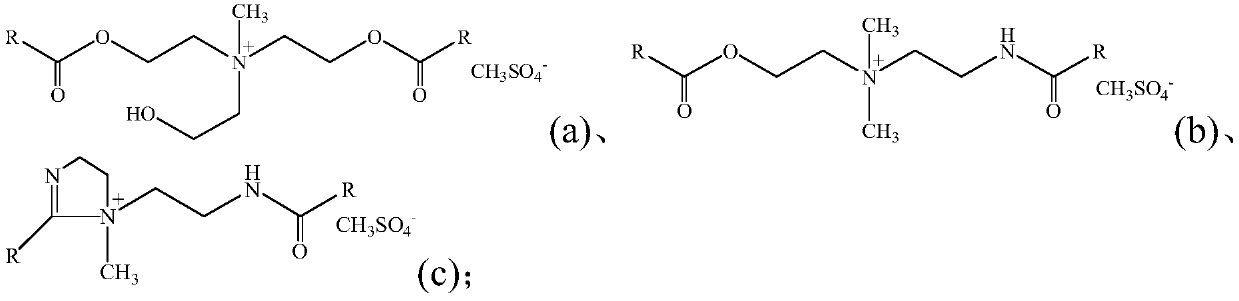

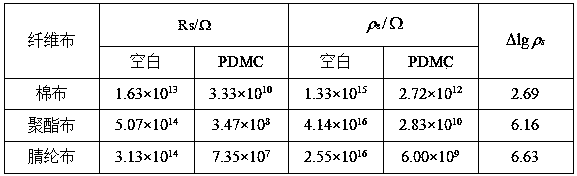

The invention provides an antistatic organic silicon pressure-sensitive adhesive containing an electron transport material and a preparation method of the antistatic organic silicon pressure-sensitive adhesive. The antistatic organosilicone pressure-sensitive adhesive is prepared from the following raw materials in parts by mass: 80-100 parts of diluted addition organosilicone resin, 10-20 parts of ionic liquid-carbon nanotube conductive gel, 4-10 parts of a compound containing alkylene oxide, 4-10 parts of an acrylate compound and 1-5 parts of a platinum catalyst. The carbon nano tube and ionic liquid mixed gel is used as an antistatic agent, the problem of incompatibility between the carbon nano tube and the pressure-sensitive adhesive is solved, the gel premixing method is applied, the dispersion effect is good, the gel can be stored for a long time, and the agglomeration phenomenon is avoided; and the antistatic effect can be achieved only by adding a small amount of the antistatic agent, and the curing property, the mechanical property and the optical property of a formed film are not influenced.

Owner:ZHEJIANG UNIV OF TECH

Antistatic biaxially-oriented polylactic acid film and preparation method thereof

The invention discloses an antistatic biaxially-oriented polylactic acid film and a preparation method thereof. The film is prepared from, by weight, 1-3.5% of an ester-based quaternary ammonium salt,and the balance of polylactic acid. The preparation method comprises the following steps: uniformly mixing the ester-based quaternary ammonium salt and part of polylactic acid, and carrying out extrusion granulation to obtain an antistatic master batch; and uniformly mixing the obtained antistatic master batch with the remaining polylactic acid, extruding, cooling, casting and biaxially stretching to obtain the antistatic biaxially-oriented polylactic acid film. The ester-based quaternary ammonium salt with a specific structure is selected as an antistatic agent to be applied to the PLA film,so that the elongation at break and glossiness of the obtained film are improved while the antistatic effect is achieved, the haze is reduced, and the optical performance of the obtained film is improved to a great extent.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

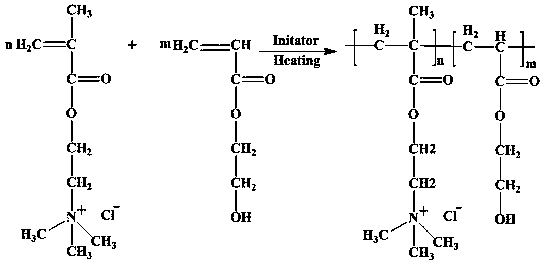

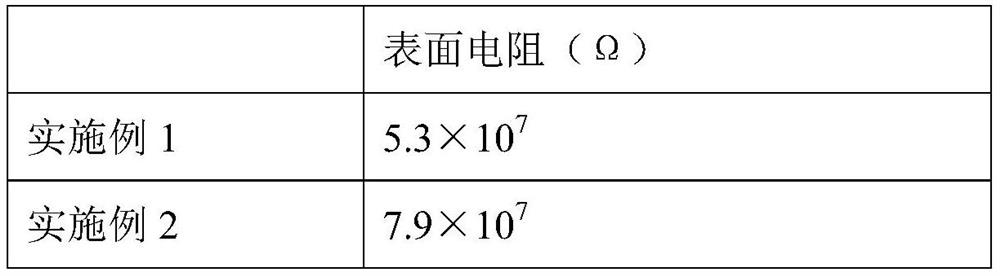

Polyquaternium antistatic agent and preparation method thereof

The invention discloses a polyquaternium antistatic agent and a preparation method thereof. The preparation method of the polyquaternium antistatic agent comprises the steps of weighing and adding methacryloyloxyethyl trimethyl ammonium chloride (DMC), hydroxyethyl acrylate (HEA), water, sodium hydrogen sulfite (NaHSO3) and ethylene diamine tetraacetic acid tetrasodium (Na4EDTA) into a reactor with a nitrogen atmosphere; weighing a reaction initiator potassium persulfate (KPS) to prepare an initiator solution, warming a reaction solution, uniformly adding the potassium persulfate initiator solution into the reactor while stirring, and performing reacting after the initiator is added; then performing warming at the speed being 1 DEG C / min, and continuously performing reacting; and after finishing reaction, performing cooling at room temperature, so as to obtain a polyquaternium, wherein the conversion rate of monomer is 85 percent or more, and the intrinsic viscosity is 0.45 dL / g to 1.35dL / g. The product obtained in the invention has favorable water solubility and an excellent antistatic property; and the product only needs to be made into a water solution with a concentration of 0.2% so as to achieve an anti-static electricity capacity of a fiber fabric.

Owner:CHINA RES INST OF DAILY CHEM IND

A kind of paint production method

ActiveCN104449025BWith weak magneticImprove antistatic performanceMagnetic paintsAnti-corrosive paintsAdhesiveAcrylic resin

The invention discloses a method for producing an oil paint, and relates to the field of chemical processes. The method comprises the following steps: feeding, premixing, grinding, mixing a paint, introducing oxygen, filtering and the like, namely adding materials to a twin-cylinder high-speed disperser in opening mixing during feeding; firstly adding 1 / 5 of polyurethane acrylic resin to a first cylinder to render; adding a little of conductive carbon black, chlorinated paraffin, magnetic iron powder, zeolite powder and nickel powder, adding part of polyurethane acrylic resin at an interval of 1 minute, and completely adding the residual polyurethane acrylic resin for 3-4 times; adding a mixed solution of double distilled water, butanol, an organic silicone resin fluid and an isocyanate adhesive to a second cylinder, and carrying out hydrolytic crosslinking reaction; and adding nano powder, and carrying out catalytic reaction, mixing the materials which are processed in the first cylinder and the second cylinder at the ratio, thus various defects of the oil paint can be improved; resources can be reasonably distributed; and the method is economic and applicable.

Owner:丹阳恒安化学科技研究所有限公司

Color master batch with anti-ultraviolet function and preparation method thereof

ActiveCN114292420AImproved performance against UV agingExtended service lifeLinear low-density polyethyleneAntioxidant

The invention belongs to the technical field of high polymer materials, and particularly relates to a color master batch with an anti-ultraviolet function and a preparation method of the color master batch. The color master batch comprises the following components in parts by weight: 30-50 parts of linear low-density polyethylene, 20-40 parts of toner, 2-10 parts of a composite ultraviolet light absorber, 2-10 parts of a light stabilizer GW540, 2-10 parts of a composite antioxidant, 10-15 parts of a dispersant and 10-15 parts of a lubricant. Wherein the composite ultraviolet light absorber is a mixture of an ultraviolet light absorber UVP327, an ultraviolet light absorber RMB and nano titanium dioxide; the composite antioxidant is a mixture of an antioxidant 1010 and an antioxidant 168. The composite ultraviolet light absorber, the composite antioxidant and the light stabilizer GW540 form a matching relationship, so that the ultraviolet aging resistance of the color master batch is improved together, and the service life of a product prepared from the color master batch is prolonged.

Owner:诺曼化学(盘锦)有限公司

Antistatic halogen-free flame-retardation-reinforced PET (polyethylene glycol terephthalate) material and preparation method of same

ActiveCN102382431BDoes not affect mechanical and physical propertiesDoes not affect surface propertiesGlass fiberPolyethylene terephthalate

The invention discloses an antistatic halogen-free flame-retardation-reinforced PET (polyethylene glycol terephthalate) material containing the components in parts by weight as follows: 37.2-48.7 parts of PET resin, 10-26 parts of halogen-free flame retardant compound, 10-50 parts of glass fiber, 2-6 parts of composite antistatic agent, 0.5-8 parts of compatibilizer and 0.3-1.3 parts of processing additive. A preparation method of the PET material includes the steps as follows: (1) placing the composite antistatic agent, the compatibilizer and the processing additive in a high-speed mixing machine to dry mix for 2-4 minutes, wherein the revolving speed is 700-900 revolutions per minute; (2) placing the halogen-free flame retardant compound in the high-speed mixing machine to dry mix for 2-4 minutes, wherein the revolving speed is 600-800 revolutions per minute; and (3) adding the mixtures obtained from the step (1) and the step (2), the PET resin and the glass fiber in a double-screw extruder respectively through a feeder, and then conducting mixing, scattering, melt extrusion and granulation. The antistatic halogen-free flame-retardation-reinforced PET material has the advantagesof being excellent in antistatic effect and reinforced in flame retardation.

Owner:KINGFA SCI & TECH CO LTD +1

Antistatic composite non-woven fabric

InactiveCN111114023AHigh tensile strengthImprove flexural strengthSynthetic resin layered productsRubber layered productsGlass fiberPolymer science

The invention relates to an antistatic composite non-woven fabric, which comprises a first non-woven fabric layer, a second non-woven fabric layer, a wear-resistant layer, an antistatic layer, a tear-resistant layer and supporting threads, wherein the wear-resistant layer is arranged between the first non-woven fabric layer and the antistatic layer, the tear-resistant layer is arranged between thesecond non-woven fabric layer and the antistatic layer, the antistatic layer is arranged between the wear-resistant layer and the tear-resistant layer, the supporting threads are arranged between thefirst non-woven fabric layer and the second non-woven fabric layer, the antistatic layer is formed by thermoplastic polyurethane filled with natural rubber and acetylene carbon black, and the supporting threads are glass fiber silk threads. According to the invention, the antistatic composite non-woven fabric is simple in structure; the antistatic effect can be effectively achieved by utilizing the antistatic layer made of polyurethane, so that the quality of an electronic precision instrument is protected; and the tensile strength, the bending strength, the toughness and the stability of thenon-woven fabric can be effectively improved through the additionally-arranged tear-resistant layer and the supporting threads, so that the service life of the non-woven fabric is prolonged, the functions are diversified, the application range of the non-woven fabric is enlarged, and the non-woven fabric can be widely applied and popularized.

Owner:扬州亿诺无纺有限公司

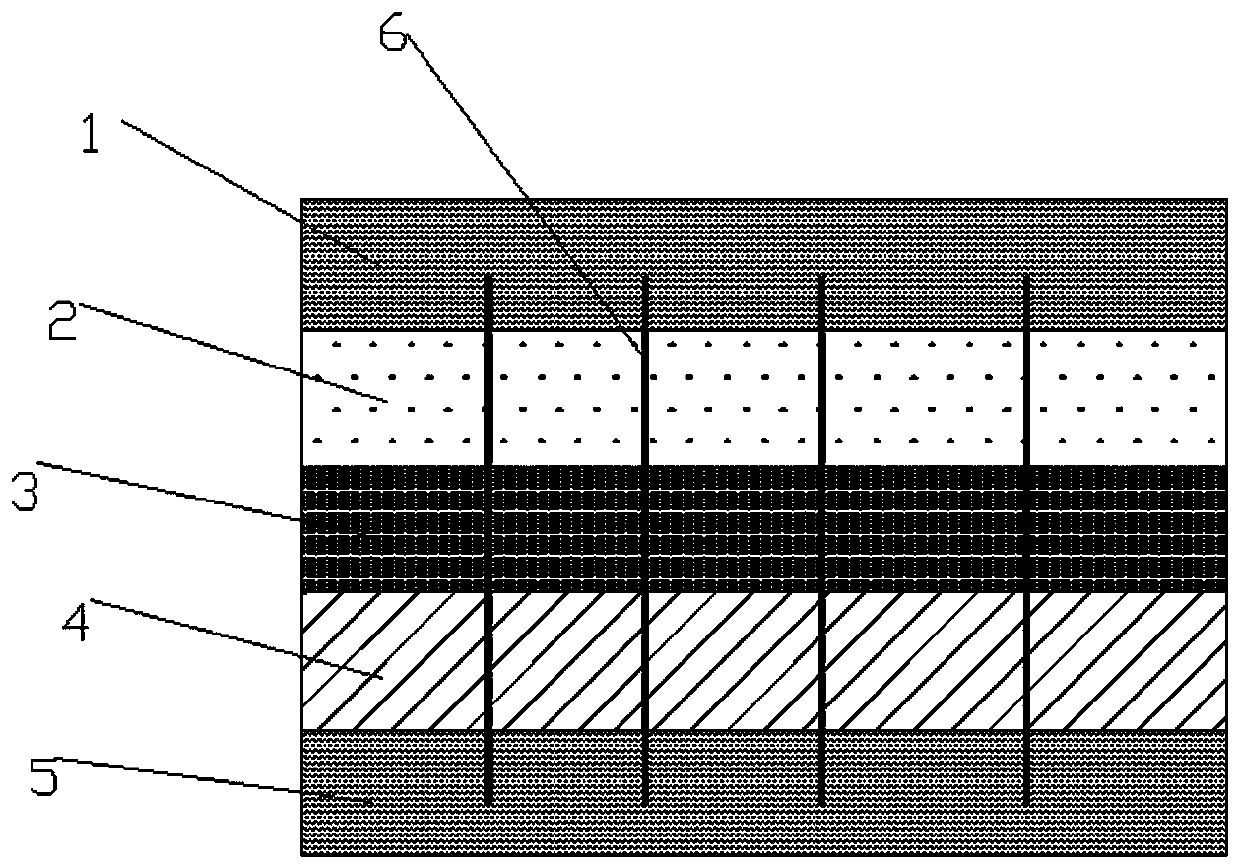

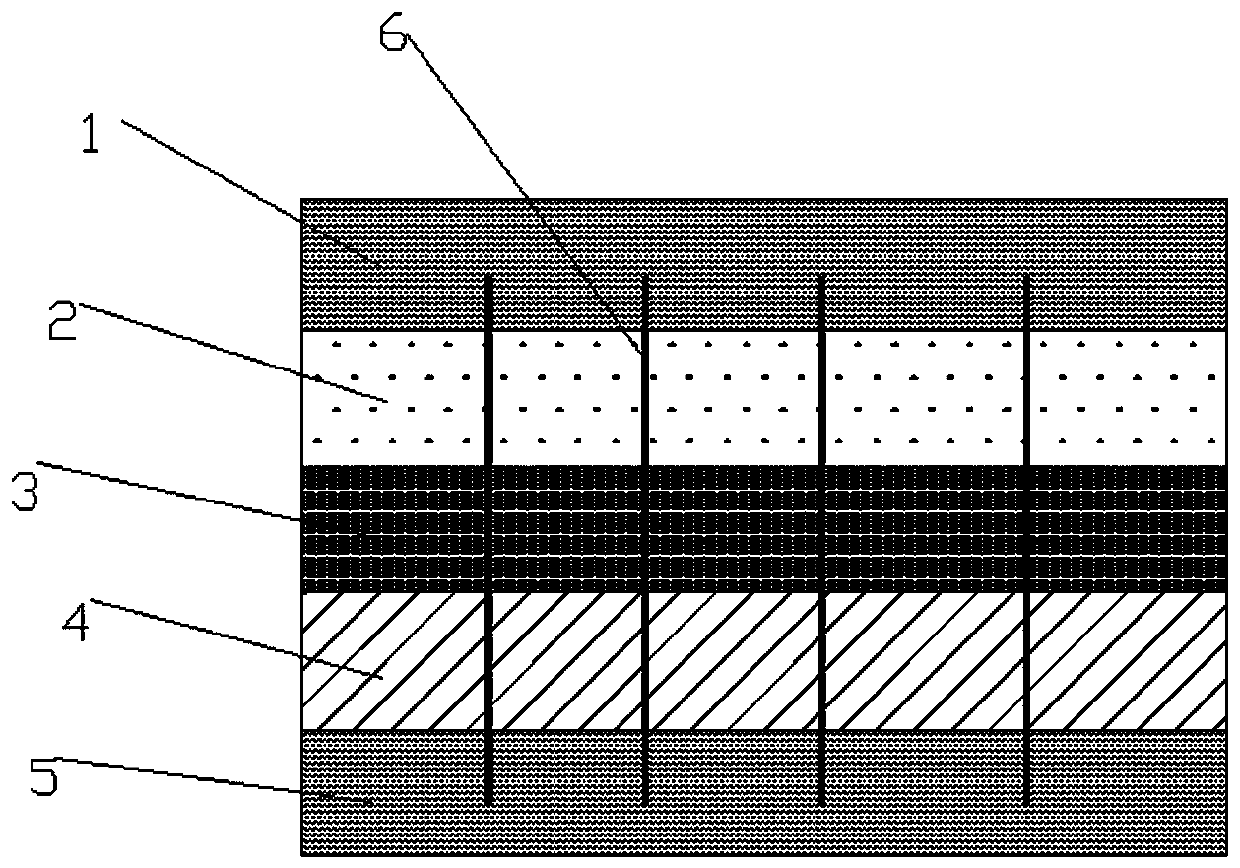

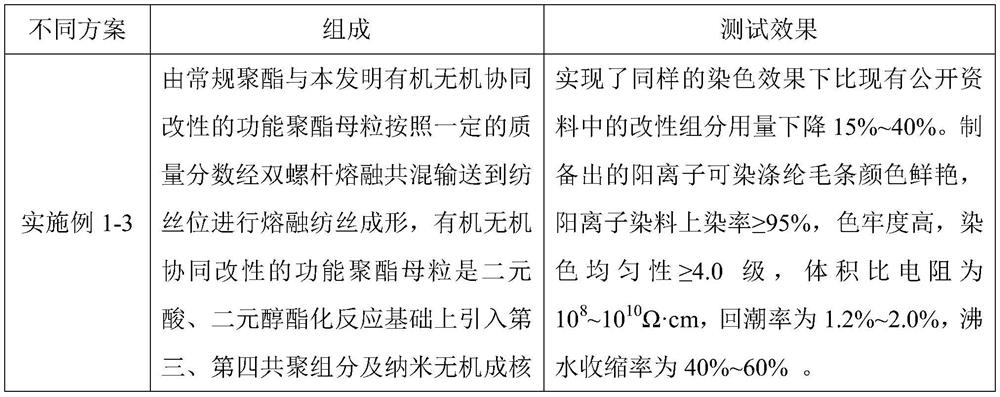

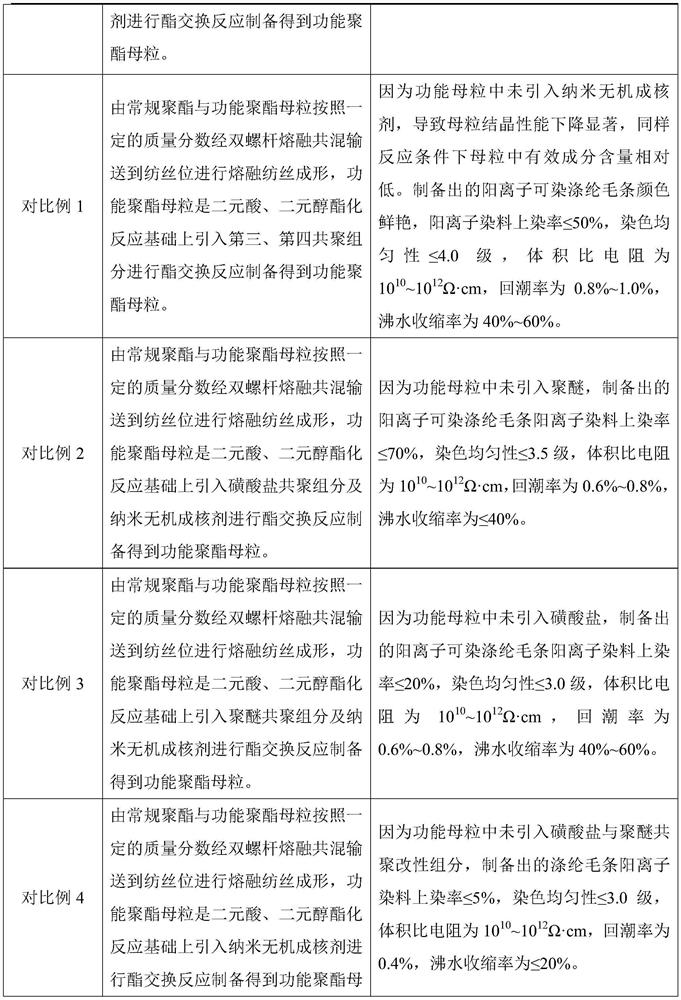

Cationic dyeable antistatic polyester wool top and preparation method thereof

PendingCN113930862AFlexible preparation methodEasy to adjustElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention discloses a cationic dyeable antistatic polyester wool top and a preparation method thereof. The preparation method comprises the following steps of carrying out melt blending on conventional polyester and organic-inorganic synergistically modified functional polyester master batches through double screws, and conveying to a spinning position for melt spinning formation. The organic-inorganic synergistically modified functional polyester master batches are prepared by introducing a third copolymerization component, a fourth copolymerization component and an inorganic nucleating agent on the basis of esterification reaction of dibasic acid and dihydric alcohol and carrying out ester exchange reaction. Compared with conventional polyester, the organic-inorganic synergistically modified functional polyester master batches have higher fluidity and are easy to migrate to the fiber surface in the shearing process, and the prepared cationic dyeable antistatic polyester wool top has a 'skin-core 'structure. According to the cationic dyeable antistatic polyester wool top and the preparation method thereof provided by the invention, the organic-inorganic synergistically modified functional polyester master batches and the conventional polyester are blended and spun to prepare the polyester wool top, so that the process complexity is greatly reduced; and meanwhile, the cationic dyeable effect of the cationic dyeable antistatic polyester wool top can be flexibly adjusted according to the amount of the added master batches.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Manufacturing method of antifouling sofa fabric

ActiveCN106283340BIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnTextile printer

The invention provides a method for making an antifouling sofa fabric, which belongs to the technical field of home textiles and comprises the following steps: (1) selecting raw materials for spinning; (2) yarn antifouling finishing; (3) warping and sizing; (4) weaving (5) transfer printing; (6) solid color finishing; (7) antifouling finishing; (8) water repellent finishing; (9) bonding: on the upper and lower sides of the sponge The adhesive is applied on the sides respectively, and pressure is applied to the upper base cloth layer, sponge and lower base cloth layer stacked up and down, so that the three are bonded into one; (10) sewing; the yarn processed by the warping and sizing machine The sizing rate on the line is high and the hairiness is small, which can reduce the static electricity generated by the friction between the yarns, effectively reducing the static electricity of the fabric itself, so the woven fabric is not easy to generate static electricity, and relatively difficult to absorb dust. The sofa fabric produced has multiple anti-fouling capabilities, and the anti-fouling effect is remarkable.

Owner:海宁宝祥布业有限公司

Production method of multifunctional MLCC release film base film

PendingCN114179477AHigh heat distortion temperatureHigh impact strengthSynthetic resin layered productsFlat articlesThermoplasticPolymer science

The invention discloses a production method of a multifunctional MLCC release film base film. The base film comprises an outer surface layer, a middle core layer and an inner surface layer. The outer surface layer is prepared from PET, ABS, PC, an antioxidant, PE-g-MAH, PBT, glass fibers and talcum powder; the middle core layer is prepared from PET (Polyethylene Terephthalate), EPR (Ethylene Propylene Rubber), EPR-g-MAH (Ethylene Propylene Rubber-g-MAH), PE-g-MAH, TPEE (Thermoplastic Polyether Ether The inner surface layer is composed of PET, PP, EPDM-g-GMA, butyl acrylate, methyl methacrylate and zinc stearate. The toughening effect can be achieved, the thermal deformation temperature and impact strength of the film can be improved, and the antistatic function and multiple functions are achieved.

Owner:ZHEJIANG JINRUI THIN FILM MATERIAL

A kind of color film substrate and its manufacturing method and display panel

ActiveCN112882274BGood shading effectShorten the lengthNon-linear opticsDisplay deviceReflective layer

The present application discloses a color filter substrate, a manufacturing method thereof, and a display panel. The color filter substrate includes a substrate, a black matrix layer, a first groove, and a reflective layer; the substrate includes a display area and a non-display area, and the substrate includes a display area and a non-display area. The non-display area is arranged around the display area; the black matrix layer is arranged on the substrate and includes at least a first black matrix layer arranged in the display area and a second black matrix layer formed in the non-display area a matrix layer; the first grooves are arranged in the second black matrix layer, and are arranged around the display area; the reflective layer covers the first grooves, and is reflective by coating the first grooves It can effectively increase the shading effect of the edge black matrix layer, and at the same time can reduce the length of the black matrix in the non-display area at the edge, thereby reducing the size of the non-display area and realizing a narrow frame. The reflective layer can effectively block static electricity from damaging the display device and play an antistatic effect. .

Owner:HKC CORP LTD

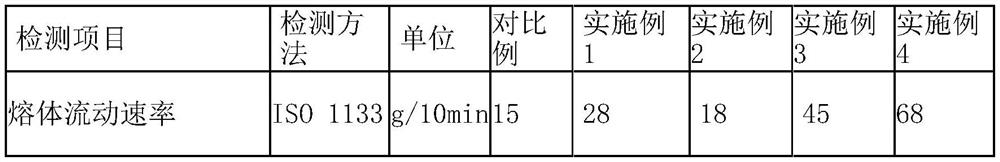

A kind of high texture automobile interior material and preparation method thereof

The invention relates to a high-texture automotive interior material and a preparation method thereof. The material is prepared from components in parts by weight as follows: 40-70 parts of polypropylene, 1-10 parts of a softening agent, 10-25 parts of a reinforcing agent, 2-5 parts of an accelerant, 5-20 parts of elastomers, 5-25 parts of mineral powder and 1-3 parts of a functional aid. Orientedfiber forming is realized with a strong shear and ultra-high-speed stretching method, the strength, rigidity, toughness and heat resistance of original polypropylene materials are substantially improved, the high-quality appearance product is obtained, good dispersion of the elastomers in a system is realized through high shearing dispersion, the surface of the obtained material touches soft andhas low gloss, the hard-plastic sense of the product is eliminated, the visual grade and the hand feeling comfortability of the automotive plastic interior are improved, and the most comfortable interior space is created.

Owner:NANJING JULONG SCI&TECH CO LTD +1

General-purpose pitch-based carbon fiber spinning finish

InactiveCN103757899BAvoid stickingTensile strength has no effectCarbon fibresIsolation effectAntistatic agent

The invention discloses general grade pitch-based carbon fiber spinning oil. The oil is prepared by mixing deionized water, a lubricating agent, an antistatic agent, an emulsifying agent and a balance regulator in a stirring state. The general grade pitch-based carbon fiber spinning oil has the beneficial effects that the viscosity of the oil is 2-20mPa.s and the light transmittance is 80-98%; the oil has an antistatic effect when sprayed onto fiber surfaces, ensures cohesive forces between fiber monofilaments, achieves a fiber packing effect and prevents fiber adhesion; oil films formed on the fiber surfaces not only protect the monofilament surfaces from being damaged in spinning but also have the same adhesion prevention and isolation effects in the non-melting and carbonizing processes, so that the problems of easiness in adhesion, static electricity, wear and the like in the general grade pitch-based carbon fiber preparation process can be solved; test results indicate that the contact angles between the general grade pitch-based carbon fiber spinning oil and the fiber surfaces are 0-5 degrees, the oil can be well coated on the fiber surfaces, and the fiber strength retention rate is 95-100%, so that the oil basically has no impact on the tensile strength of fibers.

Owner:SHAANXI NORMAL UNIV

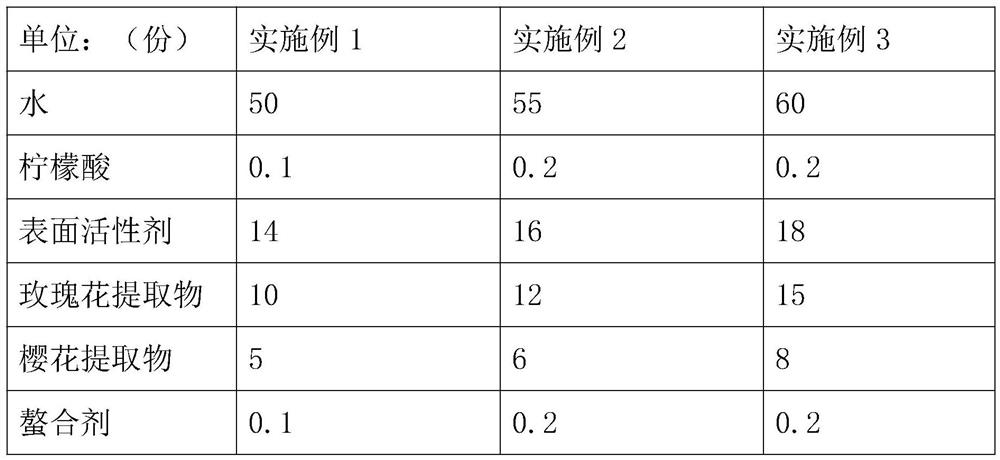

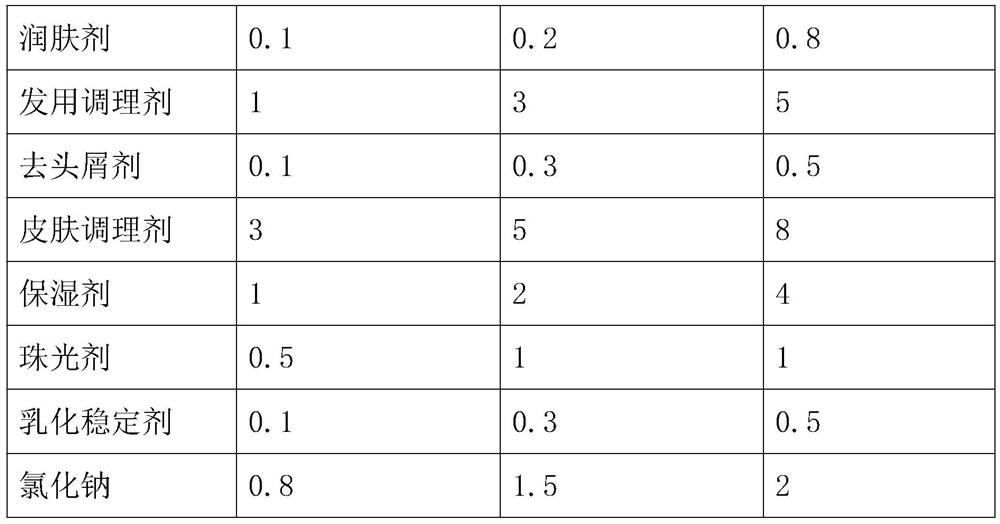

Processing and production process of shampoo containing sakura moisturizing component

PendingCN113456556APlay antistatic effectReduce the situation of fried hairCosmetic preparationsHair cosmeticsEngineeringSurface-active agents

The invention discloses a processing and production process of shampoo containing a sakura moisturizing component. The shampoo comprises the following components in parts by mass: 50-60 parts of water, 0.1-0.2 part of citric acid, 14-18 parts of a surfactant, 10-15 parts of a rose extract, 5-8 parts of an oriental cherry extract, 0.1-0.2 part of a chelating agent, 0.1-1.0 part of an emollient, 1-5 parts of a hair conditioner, 0.1-0.5 part of an anti-dandruff agent, 3-8 parts of a skin conditioner, 1-4 parts of a humectant, 0.5-1 part of a pearling agent, 0.1-0.5 part of an emulsion stabilizer and 0.8-2 parts of sodium chloride. A surfactant containing polyquaternium-10 and guar hydroxypropyltrimethylammonium chloride is added in the formula, so that an antistatic effect is achieved, and the condition of hair frying is reduced; by adding a certain part of rose extract and oriental cherry extract, the shampoo has good moistening and moisturizing effects on hair, can be easily absorbed by scalp, is healthy and safe, can effectively supplement moisture to the hair and the scalp, solves the problem of dryness, moistens damaged hair, and can effectively moisten the scalp. The undesirable conditions of pore blockage, redness, swelling and inflammation and the like are avoided.

Owner:苏州博克生物科技股份有限公司

Decorative paper suitable for digital printing

ActiveCN114517423AGuaranteed printing effectGood ink absorptionNon-fibrous pulp additionCoatings with pigmentsPolymer scienceDigital printing

The invention provides decorative paper suitable for digital printing, which is prepared by mixing and stirring a modified ethylene acrylic acid copolymer dispersion liquid, isopropanol, an auxiliary agent and water to prepare a coating, then coating the surface of decorative base paper with the coating through an anilox roller, and drying to form an ink absorption coating. Compared with decorative base paper, the decorative paper has a better ink absorption effect and a very good antistatic property, and ensures a digital printing effect.

Owner:杭州锦添装饰纸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com