Antistatic halogen-free flame-retardation-reinforced PET (polyethylene glycol terephthalate) material and preparation method of same

An antistatic and compound antistatic agent technology, applied in the field of antistatic halogen-free flame retardant reinforced PET material and its preparation, can solve the problem of increasing the flammability of the material and environmental pollution, difficult to achieve antistatic property, and the improvement effect cannot meet the demand and other problems, to achieve the effect of lasting antistatic effect, fast static decay speed and no dependence on relative humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

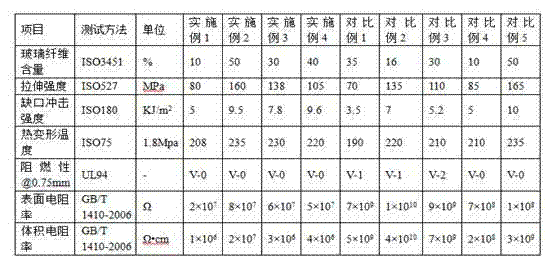

Examples

Embodiment 1

[0024] An antistatic halogen-free flame-retardant reinforced PET material, which is composed of the following components in parts by weight: 48.7 parts of PET resin with intrinsic viscosity of 0.6dl / g, organic magnesium hypophosphite and 26 parts of halogen-free flame retardant compound composed of melamine polyphosphate, 6 parts of composite antistatic agent, 8 parts of compatibilizer, 10 parts of glass fiber, and 1.3 parts of processing aid.

[0025] Described compound antistatic agent is the compound of three antistatic agents of alkyl imidazoline, sorbitan fatty acid ester, fatty acid polyethylene glycol ester (PEEM), and the weight ratio of these three kinds of compound is 25:25: 50.

[0026] The glass fiber refers to the glass fiber treated with the coupling agent, preferably a blend of methacryl coupling agent / (pyrogallol) phosphate coupling agent / aminophenyl coupling agent.

[0027] Among the processing aids, AO-18 is 0.5 part, and trimethylolpropane is 0.8 part....

Embodiment 2

[0034] The antistatic halogen-free flame-retardant reinforced PET material is composed of the following components in parts by weight: 37.2 parts of PET resin with intrinsic viscosity of 0.85dl / g, organic magnesium hypophosphite and 10 parts of halogen-free flame retardant compound composed of melamine polyphosphate, 2 parts of composite antistatic agent, 0.5 part of compatibilizer, 50 parts of glass fiber, and 0.3 part of processing aid.

[0035] Described compound antistatic agent is the compound of three antistatic agents of alkyl imidazoline, sorbitan fatty acid ester, fatty acid polyethylene glycol ester (PEEM), and the weight ratio of these three kinds of compound is 35:15: 50.

[0036] The glass fiber refers to the glass fiber treated with the coupling agent, preferably a blend of methacryl coupling agent / (pyrogallol) phosphate coupling agent / aminophenyl coupling agent.

[0037] In described processing aid, 0.1 part of triphenyl phosphate, 0.2 part of montanic acid est...

Embodiment 3

[0044] An antistatic halogen-free flame-retardant reinforced PET material, which is composed of the following components in parts by weight: 43.2 parts of PET resin with intrinsic viscosity of 0.7dl / g, organic magnesium hypophosphite and 18 parts of halogen-free flame retardant compound composed of melamine polyphosphate, 4 parts of composite antistatic agent, 4 parts of compatibilizer, 30 parts of glass fiber, and 0.8 part of processing aid.

[0045] Described composite antistatic agent is the compound of three antistatic agents of alkyl imidazoline, sorbitan fatty acid ester, fatty acid polyethylene glycol ester (PEEM), and the weight ratio of these three kinds of compounds is 30:20: 50.

[0046] The glass fiber refers to the glass fiber treated with the coupling agent, preferably a blend of methacryl coupling agent / (pyrogallol) phosphate coupling agent / aminophenyl coupling agent.

[0047] In described processing aid, 0.3 part of trimethyl phosphate, 0.5 part of montanic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com