Antistatic organosilicon pressure-sensitive adhesive containing electron transport material and preparation of adhesive

A technology of silicone pressure-sensitive adhesives and electron transport materials, applied in the direction of non-polymer organic compound adhesives, pressure-sensitive films/sheets, adhesives, etc., can solve the problems of easy precipitation of particles, sacrifice of light transmittance of tape, and dispersion of metal particles To avoid problems such as poor performance, to achieve good dispersion effect and simplify the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

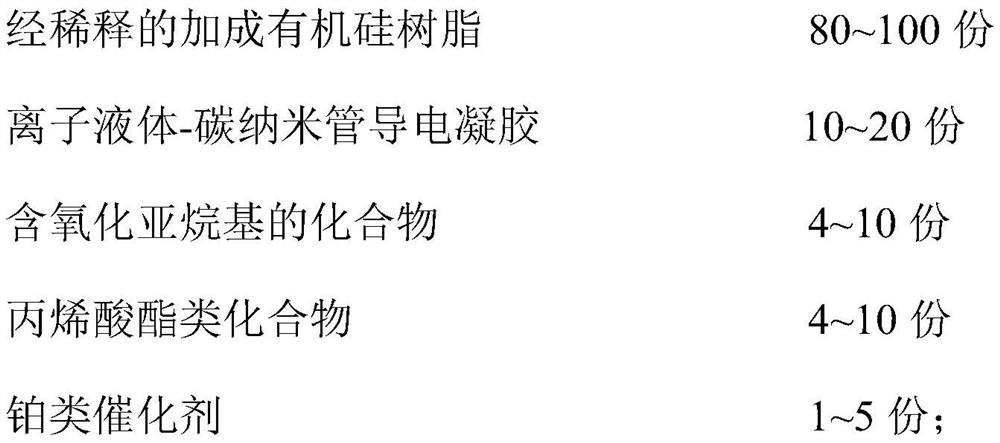

[0051] Stir and mix the following components at room temperature: 20 parts by mass of polydiorganosiloxane (Shin-Etsu KF-96, viscosity 100cP), 20 parts by mass of organopolysiloxane (SH- MQ silicone resin, MQ ratio 0.7), 10 parts by mass of polyorganosiloxane containing Si-H bonds (hydrogen content 1.58% (m / m) Shengchi SS-8-10), 50 parts by mass of ethyl acetate ester to obtain the diluted addition silicone resin G1.

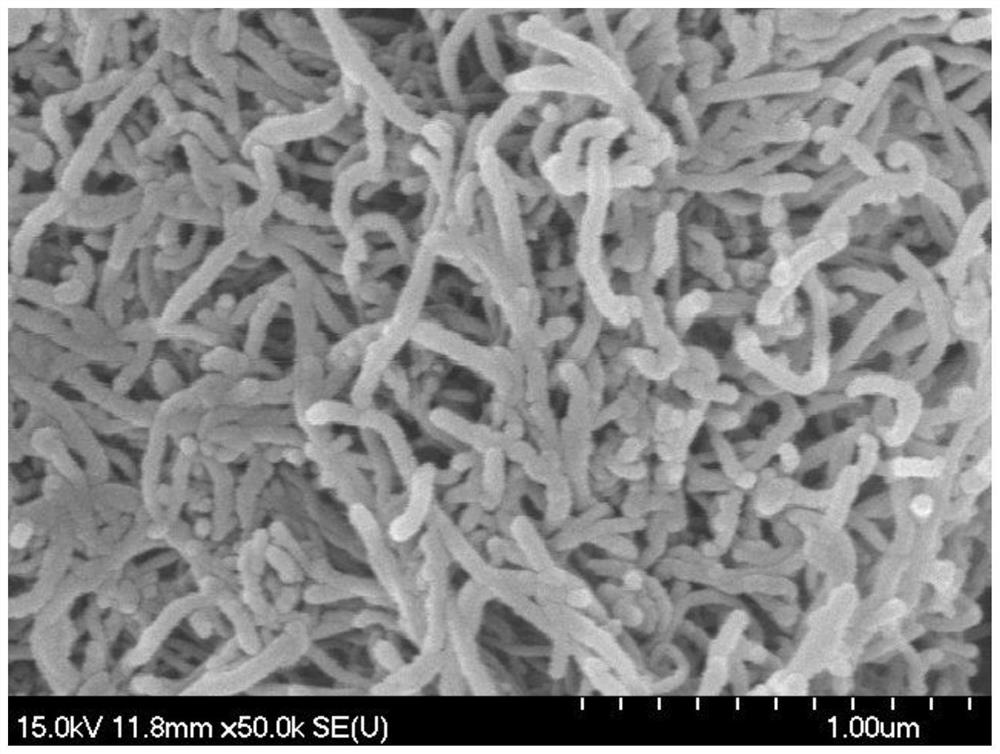

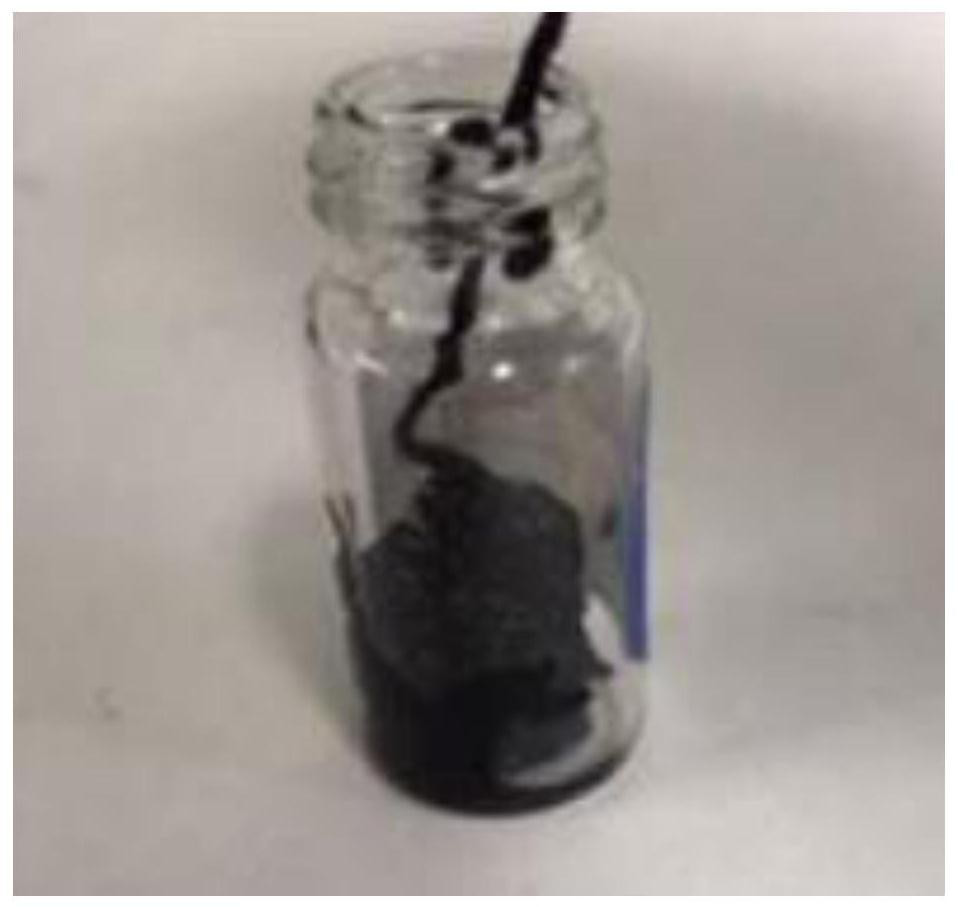

[0052] 10 parts by mass of 1-benzyl-3-methylimidazolium trifluoromethanesulfonate, 0.5 parts by mass of carbon nanotubes with a length of 3 μm and a diameter of 2 nm were heated and stirred at 60 ° C for 12 h, and then 1 part by mass of toluene was added at room temperature Stir for 12 hours to obtain ionic liquid-carbon nanotube conductive gel J1 with a viscosity of 2000mpa·s. Add 11.5 parts of the above-prepared gel to 5 parts by mass of polyethylene glycol diacrylate (compound A5), and 5 parts by mass of dipentaerythritol monohydroxypentaacrylate, and stir a...

Embodiment 2

[0055] Stir and mix the following components at room temperature: 25 parts by mass of polydiorganosiloxane (Dow Corning PMX200 viscosity 100cP), 16 parts by mass of organopolysiloxane containing M units and Q units (Sihai SH-MQ silicone resin , MQ ratio 0.7), 12 parts by mass of polyorganosiloxane containing Si-H bonds (Xinglongda 202, (containing H>1.55%, m / m)), 30 parts by mass of ethyl acetate, 17 parts by mass Parts of toluene to obtain the diluted addition silicone resin G2.

[0056] Stir 12 parts by mass of 1-allyl-3-methylimidazolium tetrafluoroborate and 0.003 parts by mass of multi-walled carbon nanotubes with a length of 20 μm and a diameter of 6 nm at 55° C. for 16 h, and then add 1.5 parts by mass of di The methyl chloride was stirred at room temperature for 10 h to obtain the ionic liquid-carbon nanotube conductive gel J2 with a viscosity of 1500 mpa·s. Add 6 parts by mass of polypropylene glycol dibenzyl acrylate (compound A6) and 4 parts by mass of trimethylolp...

Embodiment 3

[0059] The manufacture method of silicone resin G is the same as that in Example 1.

[0060] Stir 12 parts by mass of 1-allyl-3-methylimidazolium tetrafluoroborate and 0.01 parts by mass of multi-walled carbon nanotubes with a length of 10 μm and a diameter of 4 nm at 55° C. for 14 h, and then add 0.9 parts by mass of tetrahydrofuran Stir at room temperature for 10 h to obtain ionic liquid-carbon nanotube conductive gel J3 with a viscosity of 2500 mpa·s. Add 4 parts by mass of polypropylene glycol dibenzyl acrylate (compound A6) to 12.9 parts of gel, 6 parts by mass of glycerin propoxyacid (1PO / OH) triacrylic acid, and stir at 40°C for 12h to obtain an antistatic composition Dilution H3.

[0061] Add 20 parts by mass of antistatic composition dilution H3 and 1.2 parts by mass of Shin-Etsu platinum catalyst CAT-PL-56 to 100 parts by mass of the diluted addition silicone resin B3, and stir to obtain an antistatic composition containing an electron transport material. Voltage s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com