Patents

Literature

43results about How to "Agglomeration does not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/polylactic acid composite material and preparation method thereof

ActiveCN102167894AGood mechanical propertiesGood electrical propertiesHeat deflection temperaturePolylactic acid

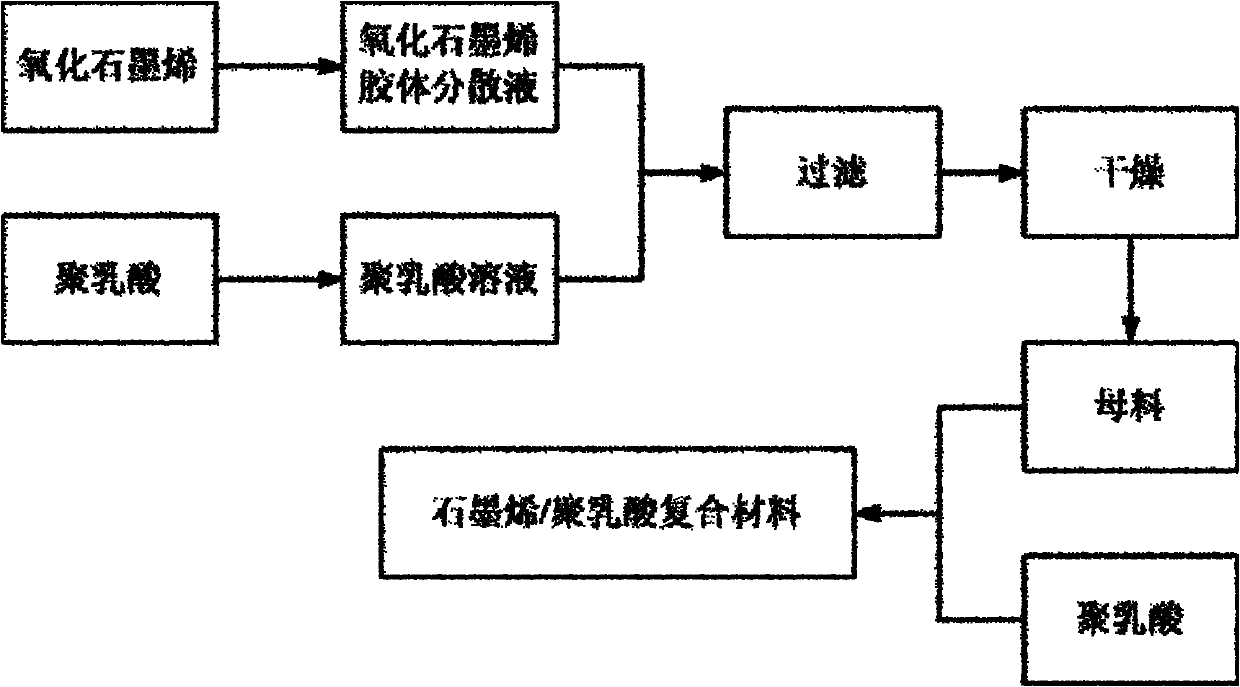

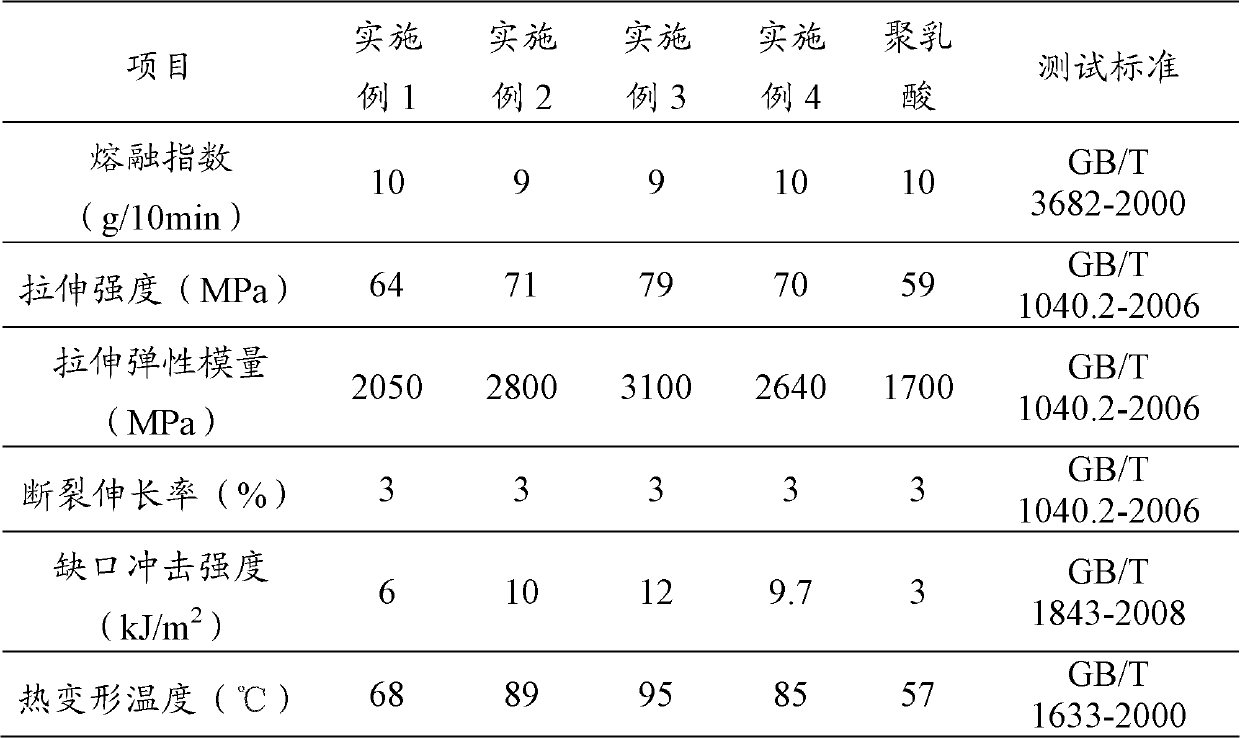

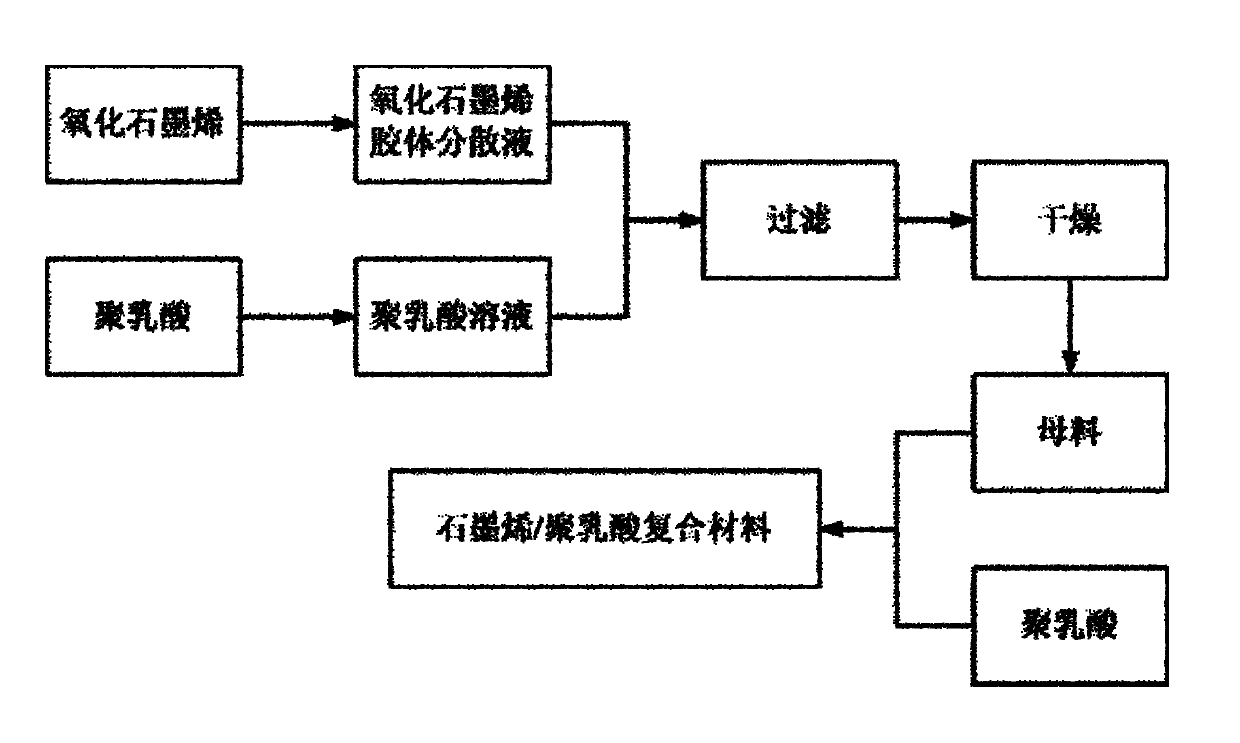

The invention provides a graphene / polylactic acid composite material, comprising the polylactic acid and graphene oxide, wherein the graphene oxide, by mass, accounts for 0.1% to 5% of the polylactic acid. The invention also provides a preparation method of the graphene / polylactic acid composite material,comprising the steps of: a) dispersing the graphene oxide in water for acquiring graphene oxide dispersion liquid; b) adding polylactic acid solution to the graphene oxide dispersion liquid under stirring condition, letting the uniformly stirred mixed solution stand for layering and filteringfor obtaining master batch; and c) blending the master batch with the polylactic acid for obtaining the graphene / polylactic acid composite material. Experiments show that the graphene / polylactic acidcomposite material provided in the invention has a tensile strength up to 79 MPa, a tensile elastic modulus up to 3100 MPa, a notch impact strength up to 12 KJ / m<2> and a heat deflection temperature up to 95 DEG C.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Non-ionic compound gas hydrate anti-agglomerant

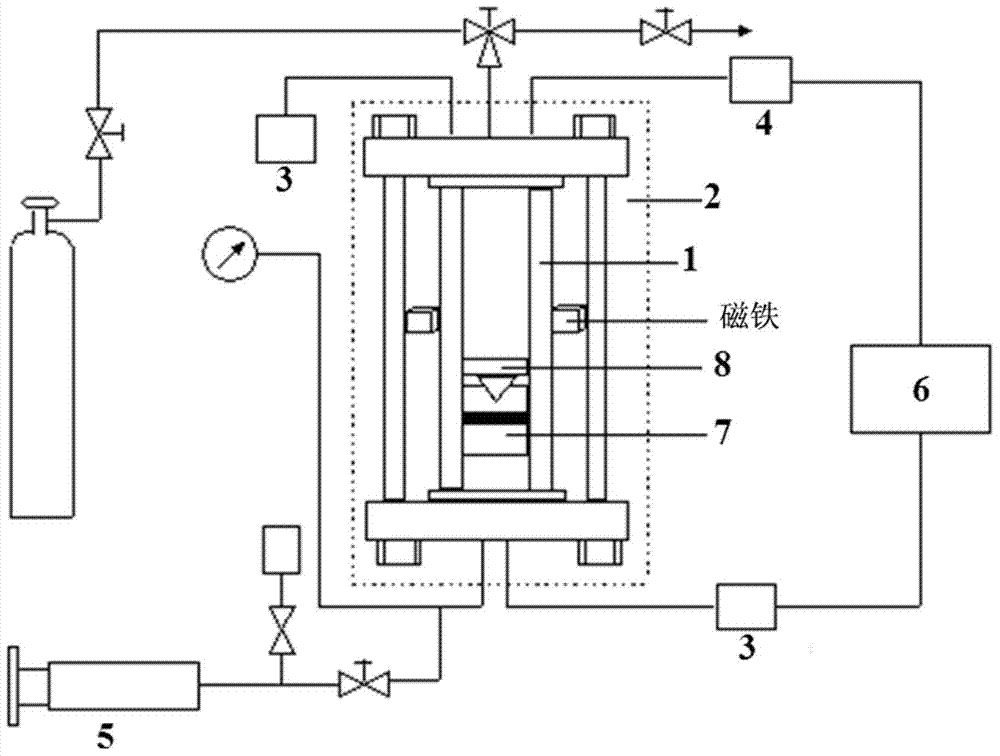

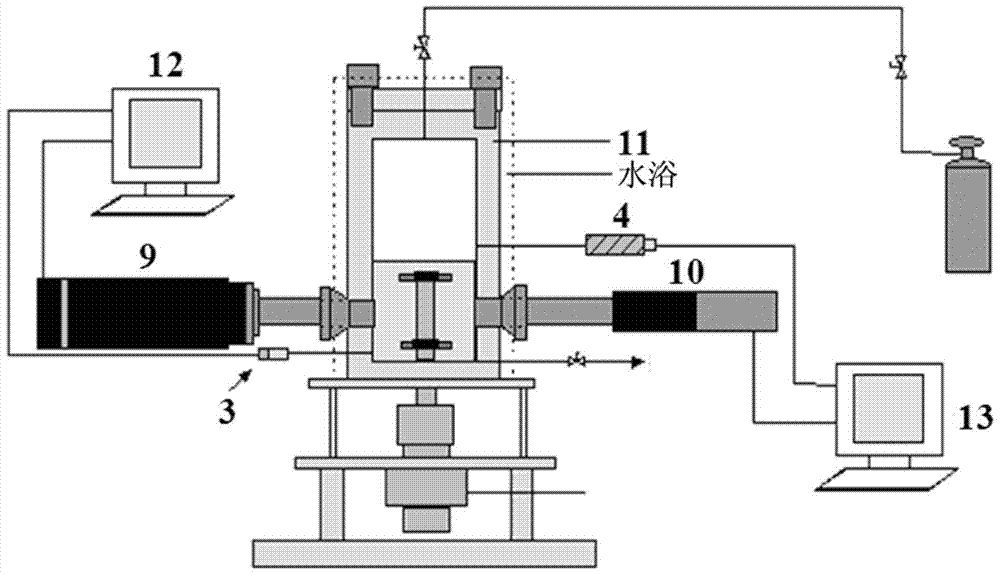

InactiveCN103865505AImprove adsorption capacityAvoid disadvantagesPipeline systemsDrilling compositionAlcoholAlkyl polyglycoside

The invention provides a non-ionic compound gas hydrate anti-agglomerant which consists of an alkyl polyglycoside non-ionic surfactant and a polyhydric alcohol non-ionic surfactant in a weight ratio of (0.01-100):1. The gas hydrate anti-agglomerant is used for anti-agglomerating treatment of an oil-gas-water three phase mixed conveying system, wherein the volume of water accounts for less than or equal to 60% of the total volume of oil and water. The invention further provides an anti-agglomerating method adopting the non-ionic compound gas hydrate anti-agglomerant. The method comprises the step of adding the non-ionic compound gas hydrate anti-agglomerant into the oil-gas-water three phase mixed conveying system. The non-ionic compound gas hydrate anti-agglomerant provided by the invention is suitable for oil-gas-water three phase co-existing systems and is less in use level, good in biodegradability, economic and environmental friendly and remarkable in anti-agglomerating effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Modified starch nano composite solid gum stock and preparation method thereof

InactiveCN101787649AParticle size can be adjustedImprove stabilityFibre treatmentPolyvinyl alcoholSlurry

The invention relates to a modified starch nano composite solid gum stock and a preparation method thereof, belonging to the technical field of fine chemical engineering. The modified starch nano composite solid gum stock is made from nano particles, the gum stock is in the shape of solid power and features good stability in the process of storage and usage and non-agglomeration of the nano particles. The preparation method comprises the following steps: adding soluble starch as polymeric dispersant when collosol reaction happens inorganic salt and acid or alkaline; then adding modified starch and carrying out ageing reaction with the nano particles before carrying out centrifugal separation; finally drying. As the gum stock is in the shape of solid powder, so that period of validity is lengthened, packaging, storage and transportation are facilitated, maintenance and transportation fees are reduced. With sizing agent prepared from the solid gum stock applied to warp sizing, the anchoring strength of the sizing agent is good, warp sizing filoplume is appressed, abrasive resistance is improved by 15-20%; in particular, the nano particles in the sizing agent features stability and non-agglomeration and retrogradation, improves weaving efficiency, can completely replace polyving alcohol and belongs to warp sizing assisting agent for ecological fabrics.

Owner:石绍华

Storable low temperature cured powder coating and preparation method thereof

InactiveCN101709164AGood storage stabilityLong storage timePowdery paintsEpoxyLow temperature curing

The invention discloses a storable low temperature cured powder coating and a preparation method thereof. The powder coating mainly comprises 30 to 40 percent of epoxy resin, 19 to 29 percent of modified polyester resin, 0.5 to 1.2 percent of acrylic acid, 0.08 to 0.15 percent of phosphite ester, 20 to 38 percent of pigment and filler, 0.2 to 3 percent of W-187 low temperature curing agent, and 0.15 to 0.6 percent of curing accelerator. The method for preparing the powder coating comprises the following steps: mixing, heating, melting, extruding, tabletting, cooling, crushing, ACM-crushing and sieving all the raw materials to achieve the fineness of 180 meshes, and packing a finished product. The storage time of the powder coating is greatly prolonged, and the curing temperature is reduced; the powder coating has excellent performance, and is widely applied to surface coating and painting of hardware, electric appliances, home appliances, automobiles, furniture, mechanical equipment and the like; the energy is reduced and the using cost is reduced, so the production cost of enterprises is reduced; and the method ensures the large-scale production of the enterprises, and increases the economic benefits of the enterprises.

Owner:FUJIAN WANAN IND

Reagent kit for preparing chemical mechanical polishing aqueous dispersion, and use thereof

InactiveCN101328399AAvoid condensationAgglomeration does not occurOther chemical processesNanoinformaticsOrganic acidSilicon dioxide

The invention relates to a kit for preparing water system dispersoid for chemically machinery grinding and use thereof, The object of the invention is to provide a preparation method of water system dispersoid for chemically machinery grinding, and kit for preparing water system dispersoid for chemically machinery grinding with excellent longterm storage stability even in the concentration state, wherein the water system dispersoid for chemically machinery grinding can control the surface effects such as depression, erosion, scratch and grinding teeth in the flatenning step of the grinding surface processed by chemically machinery grinding. The kit for preparing water system dispersoid for chemically machinery grinding comprises a first composition and second composition, wherein the first composition comprises white carbon black with average once grainsize of 15nm-40nm at the pH of 8-11, and the second composition comprises poly(methyl) acrylic acid and organic acid with more than two carbonyl groups at pH of 1-5.

Owner:JSR CORPORATIOON

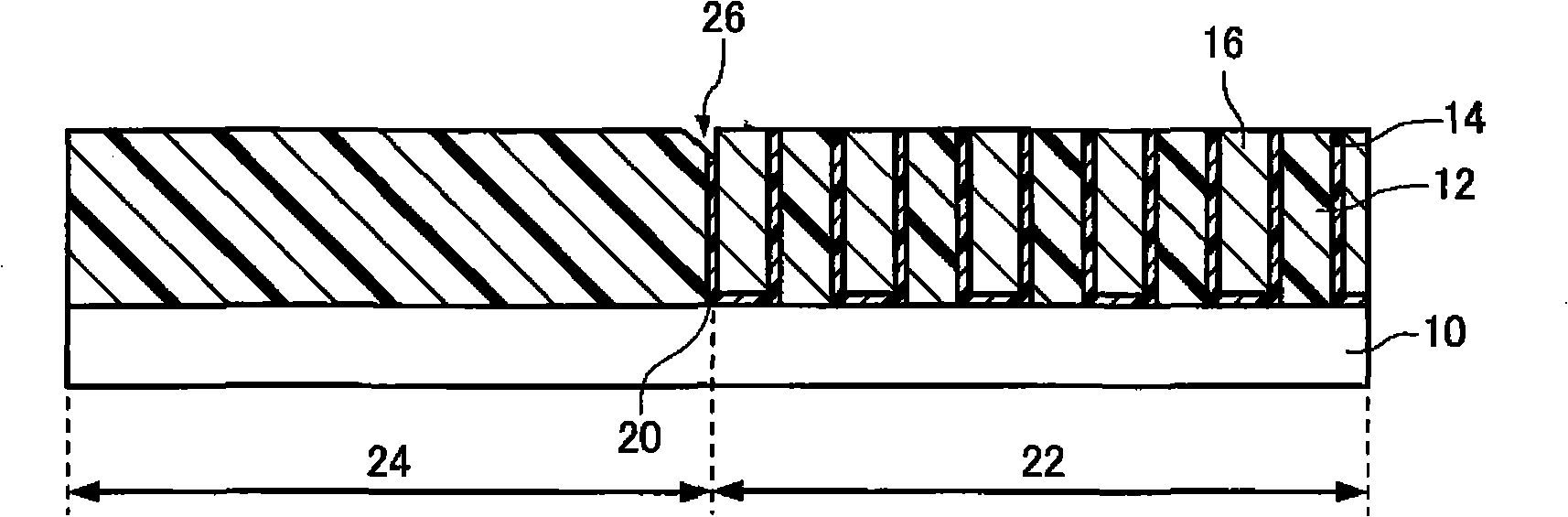

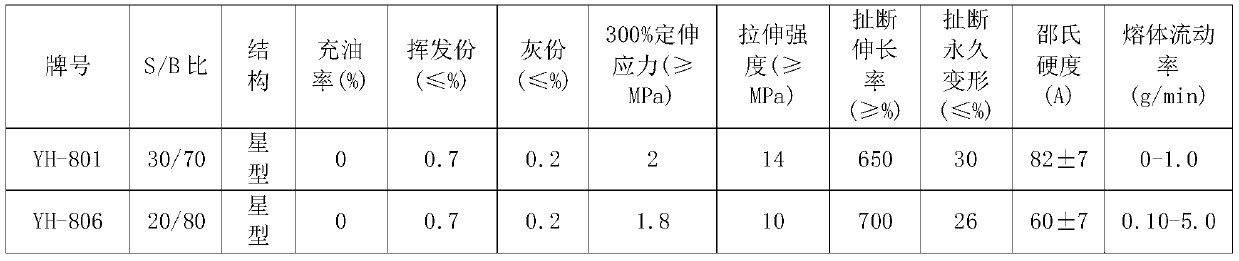

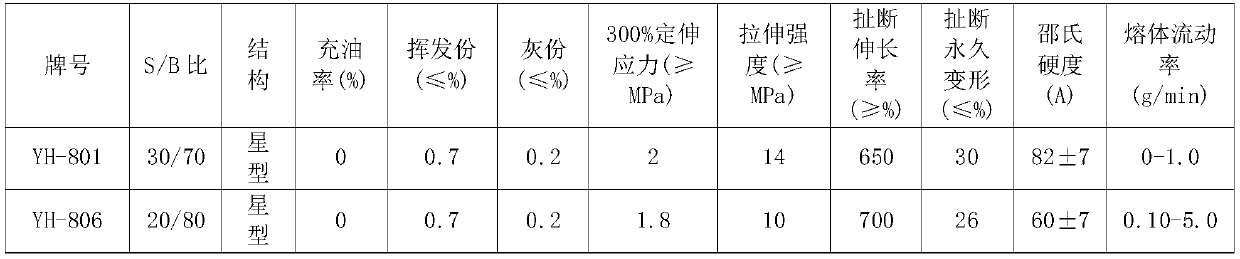

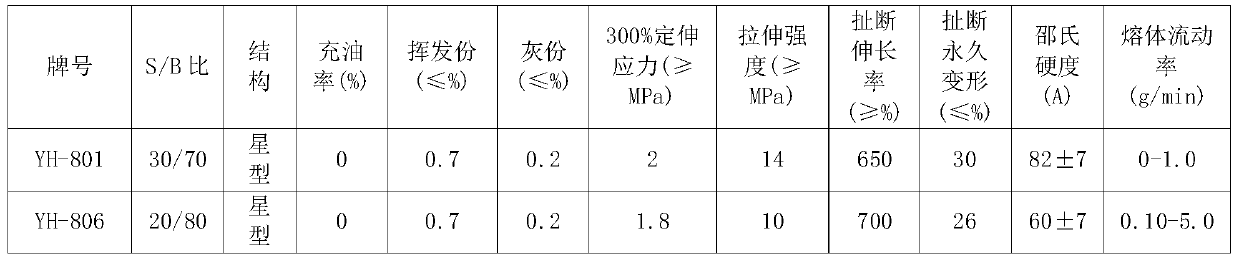

Special modified asphalt for cast asphalt concrete, and preparation method thereof

InactiveCN110499034AReduce penetrationHigh softening pointBuilding insulationsButadiene-styrene rubberToughening

The invention provides a special modified asphalt for cast asphalt concrete, and a preparation method thereof. The special modified asphalt comprises 100 parts of asphalt, 2-15 parts of an SBS (styrene-butadiene-styrene) block copolymer, 2-15 parts of hard asphalt and 1-10 parts of a toughening agent. The special modified asphalt for cast asphalt concrete can reach or exceed the softening point ofcommon cast asphalt, so the special modified asphalt has a good high-temperature stability; the special modified asphalt has a better low-temperature anti-cracking performance than common cast modified asphalt; and the special preparation method is adopted, so the modified asphalt of the invention has a very high storage stability, and is not prone to separate and crust at a high temperature.

Owner:上海同沥新材料科技有限公司

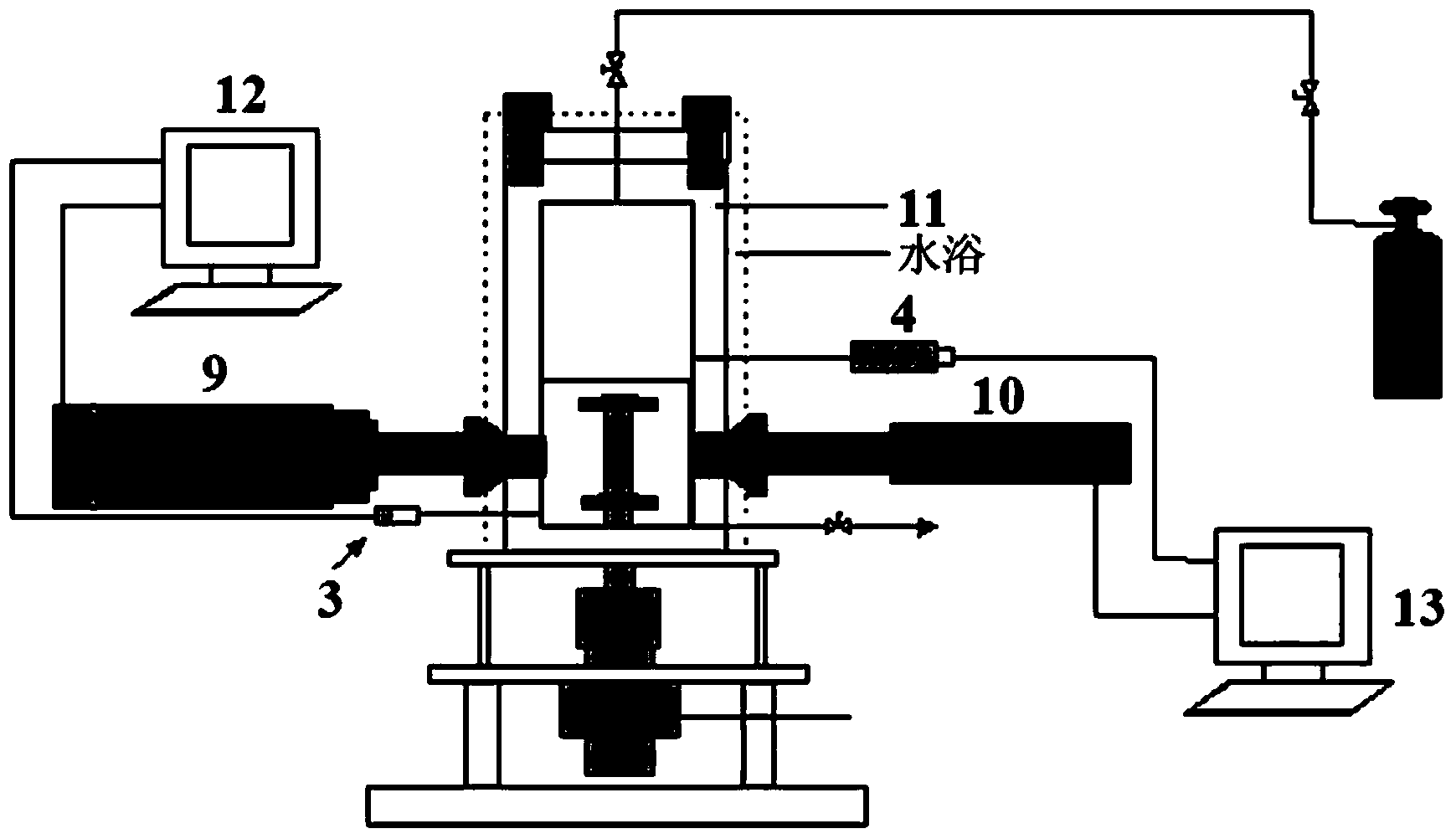

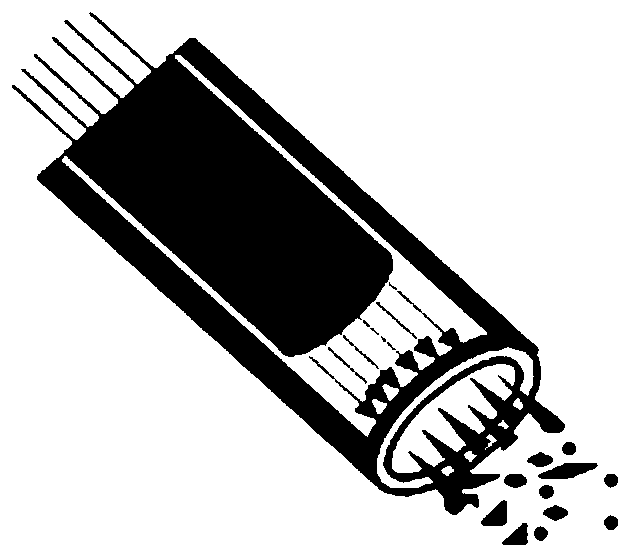

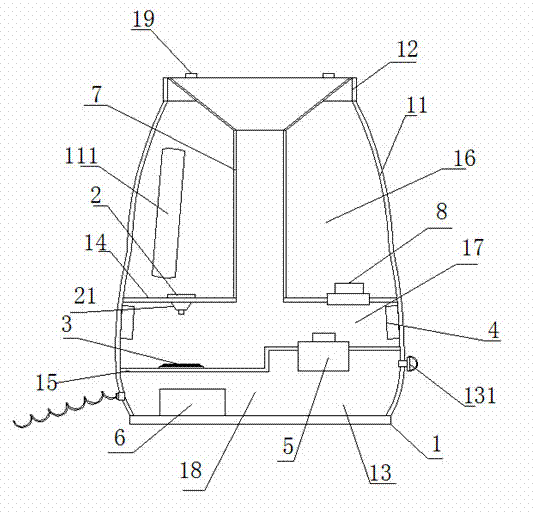

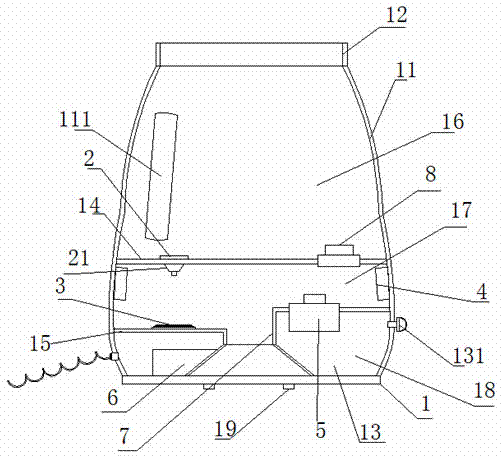

Ultrasonic-atomization microdose sprayer

The invention provides an ultrasonic-atomization microdose sprayer, relating to the technical field of plant protection machinery. According to the ultrasonic-atomization microdose sprayer, the internal space of a sprayer body is sequentially partitioned into a water storage zone, an atomization zone and a circuit zone from top to bottom by a partition plate I and a partition plate II; a water outlet is formed in the bottom of the water storage zone, and a high-pressure flow control valve is mounted at the water outlet; an ultrasonic generator is correspondingly arranged below the water outlet and is fixedly arranged on the partition plate II; electrostatic electric field electrodes are arranged on the sidewall of the atomization zone; a pressurizing device is further arranged on the partition plate II. The sprayer provided by the invention has the advantages that the problems in the current production practice process that the drug delivery is labor-consuming and time-consuming, the deposition performance of droplets on targets is relatively poor, the effective utilization ratio of pesticides is low, high-capacity spraying results in pollution and waste and the like are solved, a timesaving, laborsaving, efficient and safe new way is provided for the drug delivery of agriculture and forestry and foliage application, and the popularization and application values are considerable.

Owner:LESHAN NORMAL UNIV

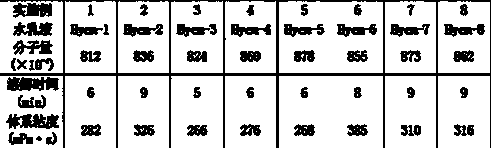

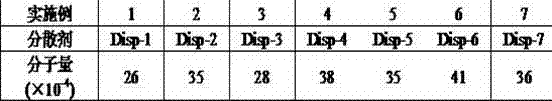

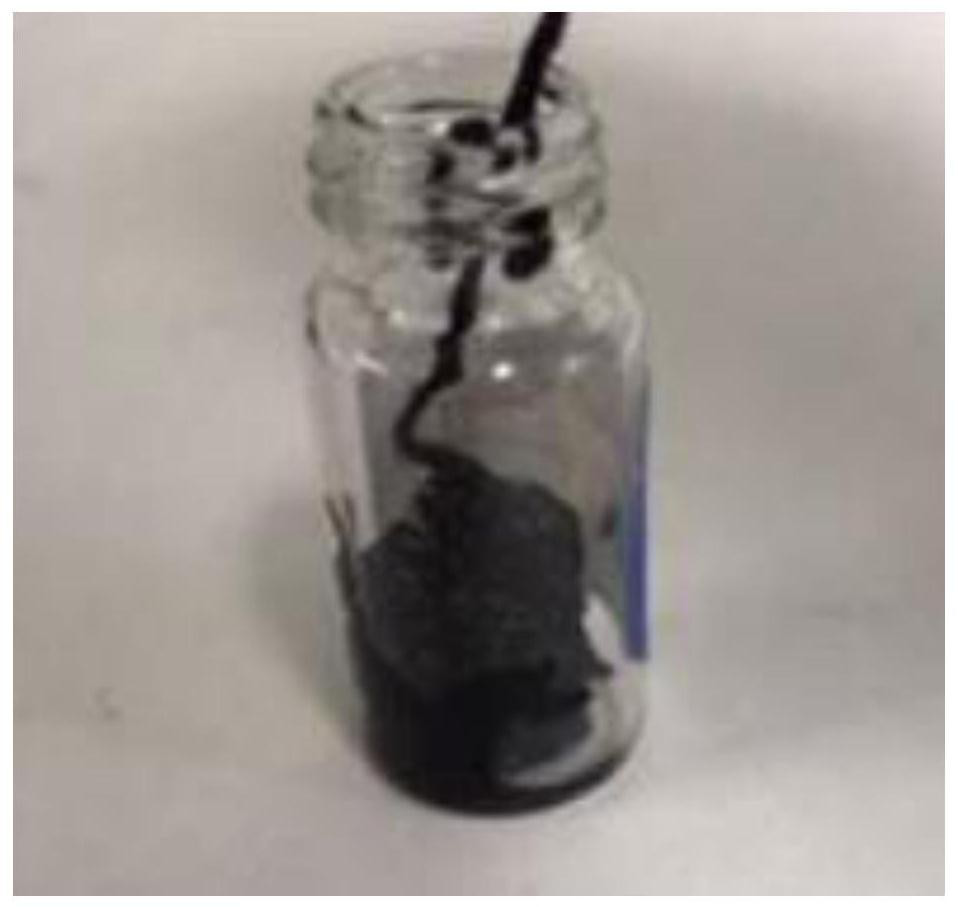

Reaction type dispersing agent and preparation method for polyacrylamide water emulsion

The invention provides a reaction type dispersing agent and a preparation method for the polyacrylamide water emulsion. The method for preparing the water emulsion comprises the steps of preparing the reaction type dispersing agent; balancing the concentration of free radicals by multiple sections of composite initiating systems under the participation of a saline solution system and the dispersing agent, and performing water emulsion dispersing polymerization on acrylamide and cationic monomers. The water emulsion product can be quickly dissolved, has a high molecular weight, is high in flowability and high in stability and can be widely applied to the field of water treatment of all industries.

Owner:DESHI ENERGY TECH GRP CO LTD

Corn instant porridge

The invention discloses a corn instant porridge, which is produced according to the following preparation method: taking and uniformly mixing corn flour, water and salt to obtain raw mixed material, puffing the raw mixed material into a wet soft porous sponge body with the density of 0.8-1.1 kg / L to complete first maturation, putting the wet soft porous sponge body into an extrusion molding machine before curing and shaping, extruding the wet soft porous sponge body into a solid body with the density of 1.3-1.4kg / L to complete second maturation, drying the solid body obtained in the previous step with hot wind at the temperature of 20-40 DEG C to obtain dry clinker when the moisture is reduced to be less than or equal to 13%, crushing the dry clinker into particles of 10-50 meshes to obtain thin particle materials, blowing the soot of the thin particle materials to remove flour attached to the surface of the particle material and obtain the finished corn instant porridge. The corn instant porridge is in porridge blocks when being brewed, retains the nutrient components of the corn to the maximum extent, is easy to digest and absorb by the human body, and has good taste.

Owner:吉林曙光农牧有限公司

Silicon rubber with temperature self-control performance

InactiveCN103214857ALittle temperature dependenceGood heat stabilityUltrasound attenuationOrganic Oxide

The invention aims at providing temperature self-control silicon rubber which is used for solving the problem that the existing temperature self-control material is improved polyethylene and conductive particles are difficult to uniformly fill due to polymerization-adhesion trend of conductive particles under a base molten state. During a processing and using process of the product, the polymerization-adhesion trend can continue, so that the function attenuation of the product is accelerated; and the product is short in service life and poor in safety due to heat insulation or spontaneous combustion. The highest temperature maintaining range of the product is narrow due to the limit of the characteristics of the base material. The technical key point of the invention is that the silicon rubber comprises the following components in parts by weight: 100 parts of raw silicon rubber, 30-60 parts of reinforcing agent, 6-35 parts of conductive medium, 5.5-16 parts of constitution controller and 0.5-2 parts of vulcanizing agent organic oxide. The silicon rubber with the temperature self-control performance has the positive effect that the highest temperature maintaining range ranges from a certain DEG C to 200 DEC or higher. The silicon rubber with the temperature self-control performance can be used within a wider environment temperature range. Moreover, an open circuit due to sparse conductive particles is avoided and a short circuit due to gathering of conductive particles is also avoided, so that the self rubber with the temperature self-control performance is high in safety, longer in service life and strong in practicability.

Owner:肖万军

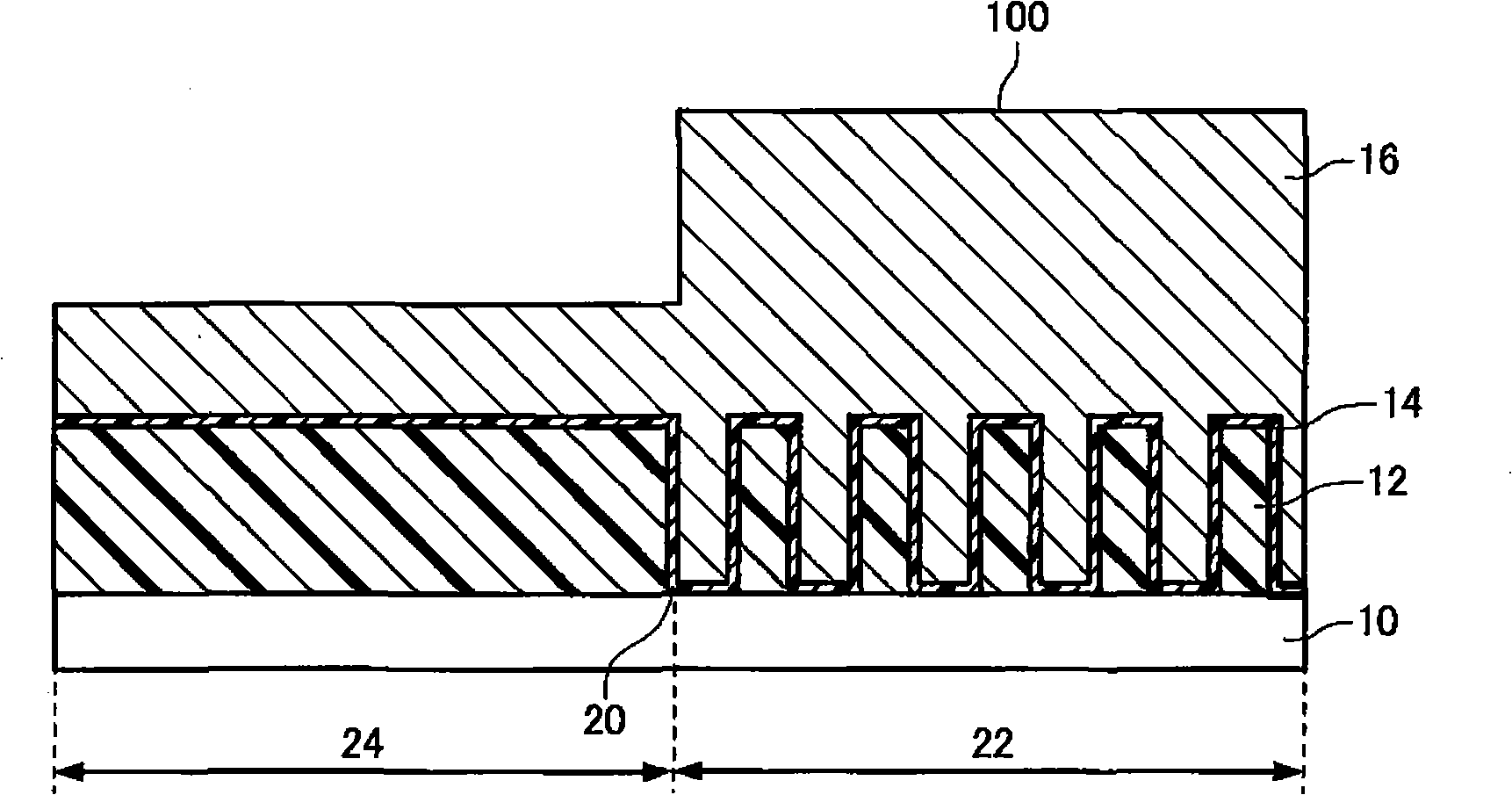

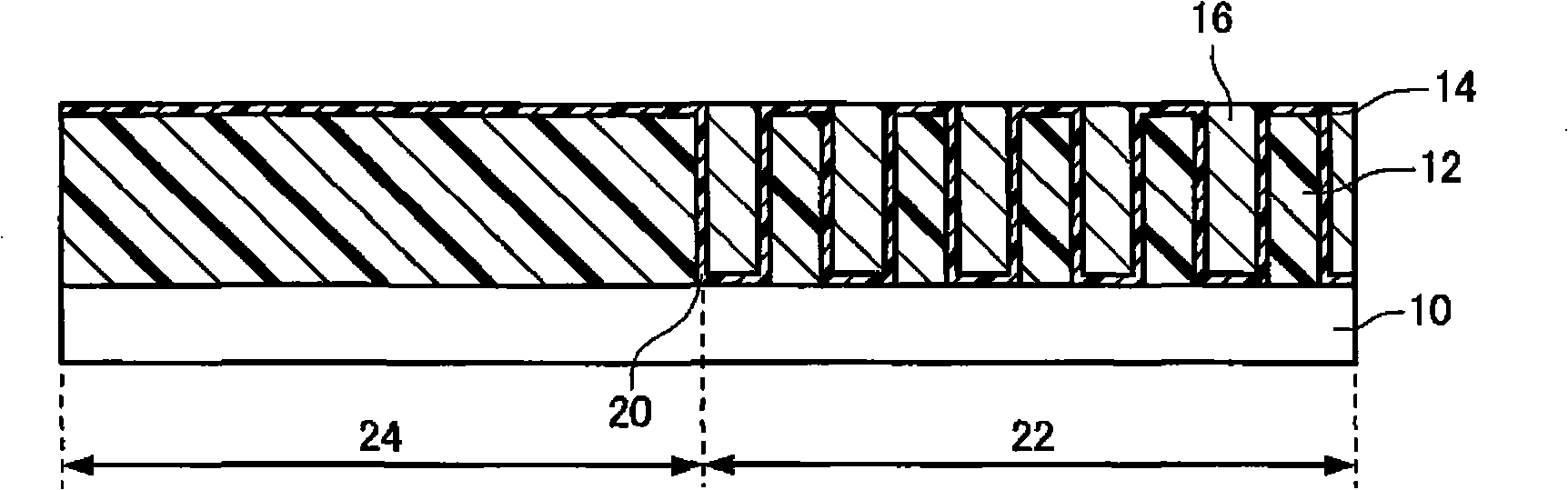

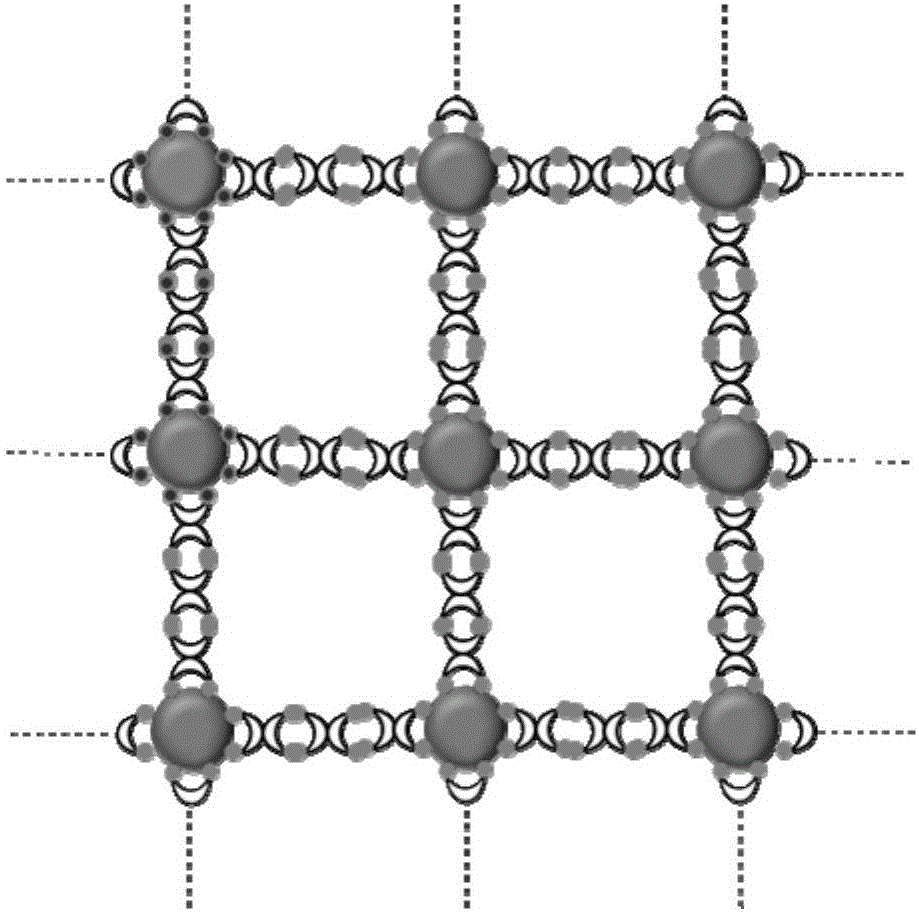

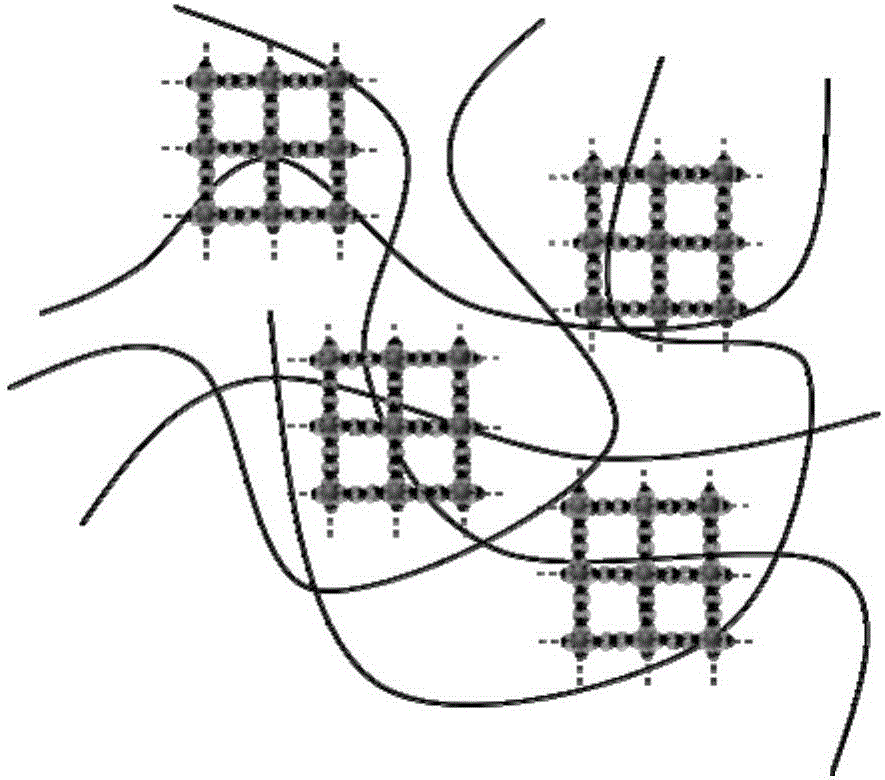

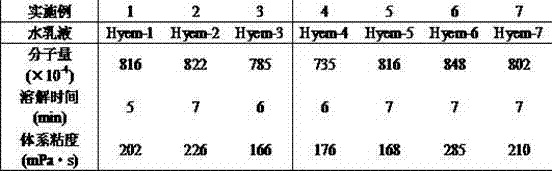

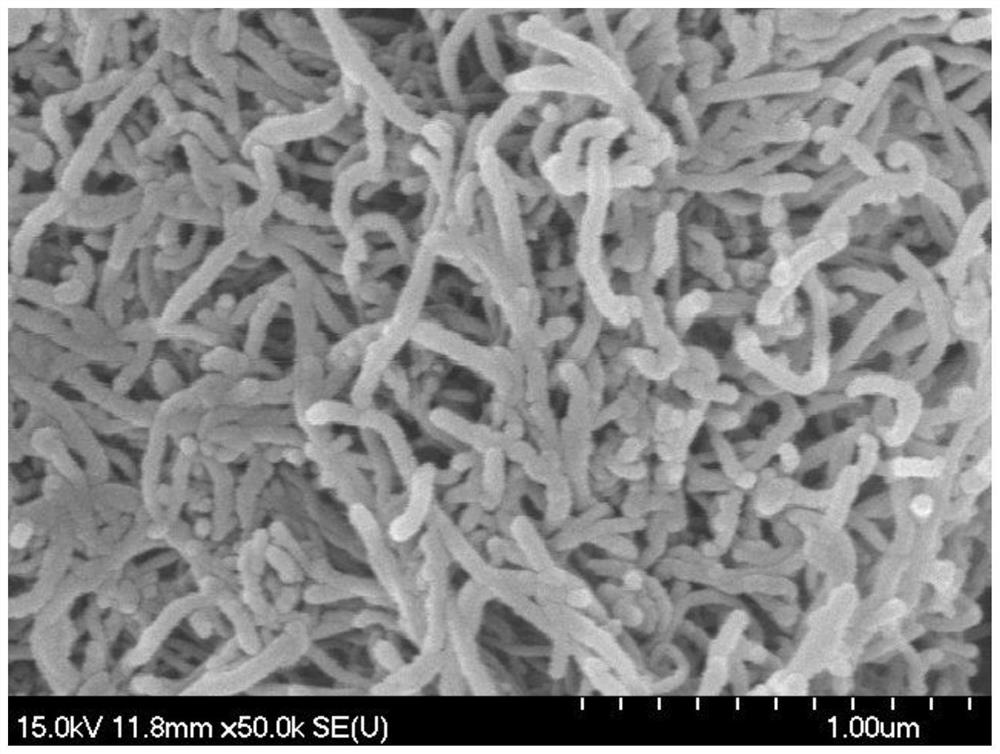

Clustered nanocrystal networks and nanocrystal composites

ActiveCN106574177AInhibit deteriorationSafe handlingMaterial nanotechnologyNanoopticsPolymer scienceNanocrystal

The present invention relates to a clustered nanocrystal network comprising a core comprising a metal or a semiconductive compound or mixture thereof and at least one polythiol ligand, wherein said core is surrounded by at least one polythiol ligand, and wherein each core surrounded by at least one polythiol ligand is crosslinked with at least one another polythiol ligand stabilizing another core. Furthermore, the present invention relates to nanocrystal composites comprising clustered nanocrystal networks. Clustered nanocrystal networks according to the present invention can be prepared by one-pot synthesis and can be embedded into the polymer matrix to form high quality and stable nanocrystal composites.

Owner:SUZHOU RAINBOW MATERIALS CO LTD

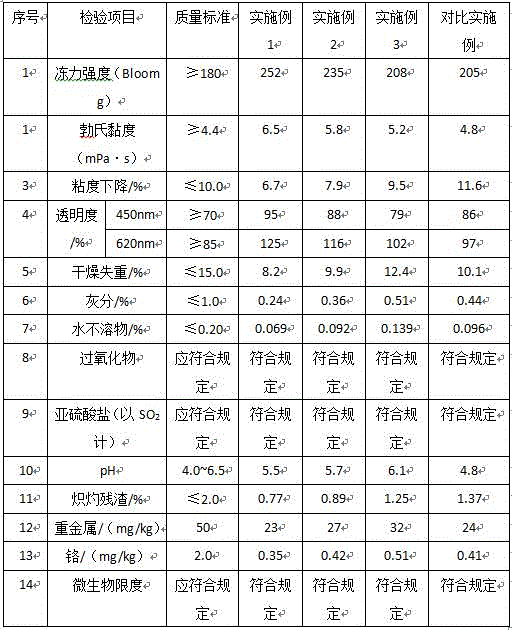

Technology for producing leather gelatin with high freezing force and high viscosity by alkali-alkali-acid ternary method

ActiveCN102181233AReduce processing timeAgglomeration does not occurGlue/gelatin preparationFiltrationIon exchange

The invention relates to making technology of gelatin, in particular to a technology for producing leather gelatin with high freezing force and high viscosity by an alkali-alkali-acid ternary method. The technology includes pretreatment process, gelatin extraction, filtration, ion exchange, concentration, high temperature sterilization, drying, crushing, mixing and metal detection, thus obtainingthe finished product. The technology is characterized in that the pretreatment process is a mixed acid-alkali method and forms the alkali-alkali-acid ternary method for producing leather gelatin withhigh freezing force and high viscosity, together with the follow-up process. The product is high in freezing force, and achieves acid-method level, as well as the viscosity between the acid method and the alkali method, obviously higher than alkali method. Compared with the alkali method, the technology has the treatment time of leather shortened greatly by 35-40 days. The acid (pH ranging between 3.0-4.5) gelatin extraction only needs to be done for 5 times, reduced by twice compared with 7 times of the alkali method. The production efficiency is improved by 20%, and water and energy are saved by 10%. The temperature for alkali treatment is controlled between 15-25oC, product quality is ensured and meanwhile, compared with former requirement of 5-15oC, a large quantity of energy is saved.

Owner:罗赛洛(温州)明胶有限公司

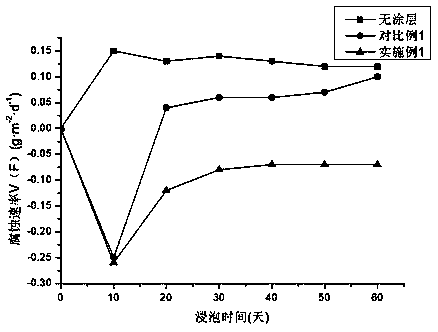

Steel surface composite coating and preparation method thereof

InactiveCN110922865AImprove corrosion resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesMeth-Pyromellitic dianhydride

The invention discloses a steel surface composite coating, and belongs to the technical field of steel corrosion prevention. The steel surface composite coating comprises the following raw materials in parts by weight: 20 to 30 parts of 2-tert-butylamino-4-ethylamino-6-methylthio-1, 3, 5-triazine, 13 to 17 parts of graphene oxide, 300 to 400 parts of water-borne acrylic acid modified epoxy resin,20 to 30 parts of methyl tetrahydrophthalic anhydride, 20 to 30 parts of methyl nadic anhydride and 10 to 20 parts of pyromellitic dianhydride. The steel surface composite coating disclosed by the invention is excellent in corrosion resistance, capable of effectively preventing seawater from corroding steel materials, excellent in friction resistance, also excellent in blue-green algae resistance,and suitable for coating the surfaces of pipelines and ships in the ocean.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

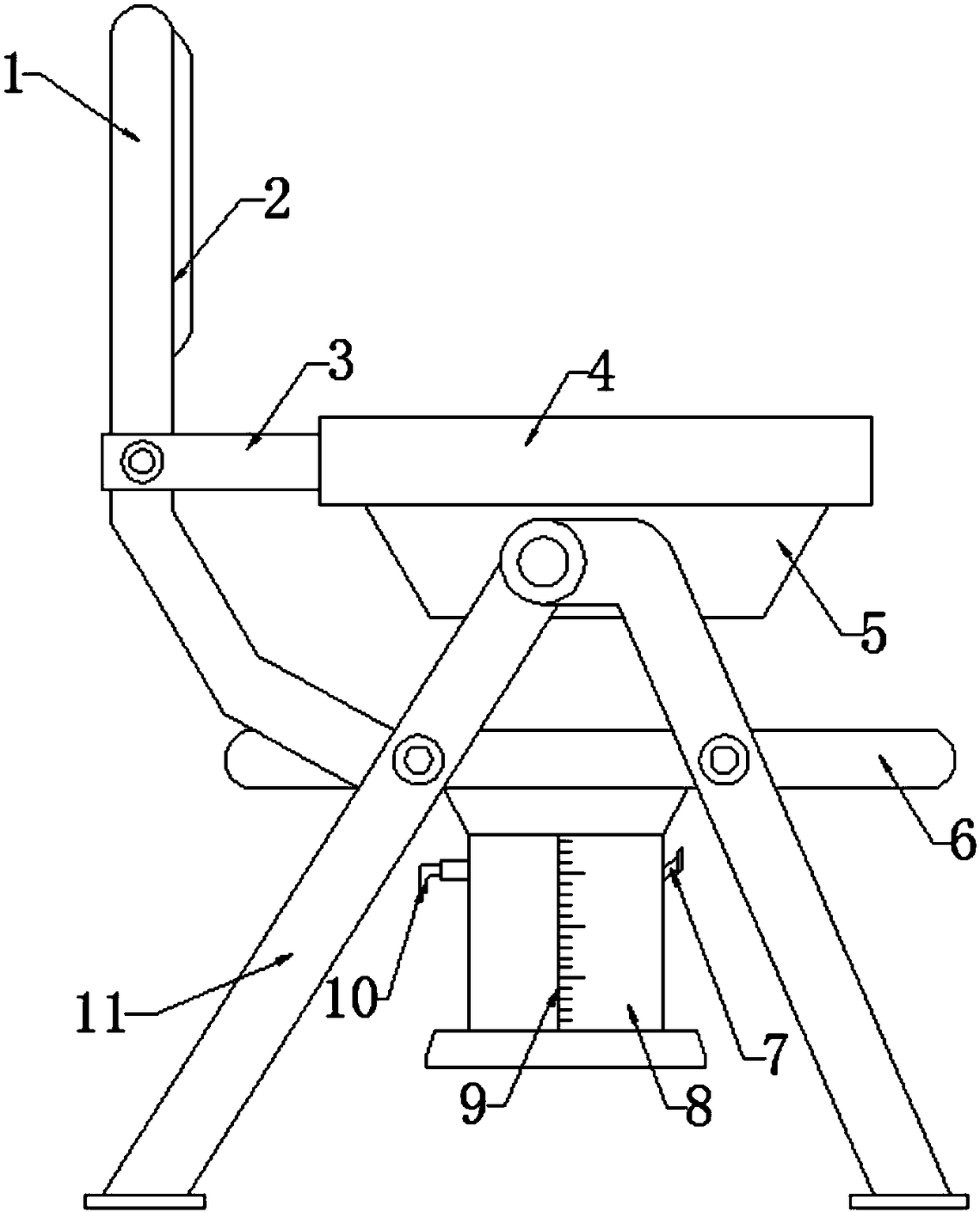

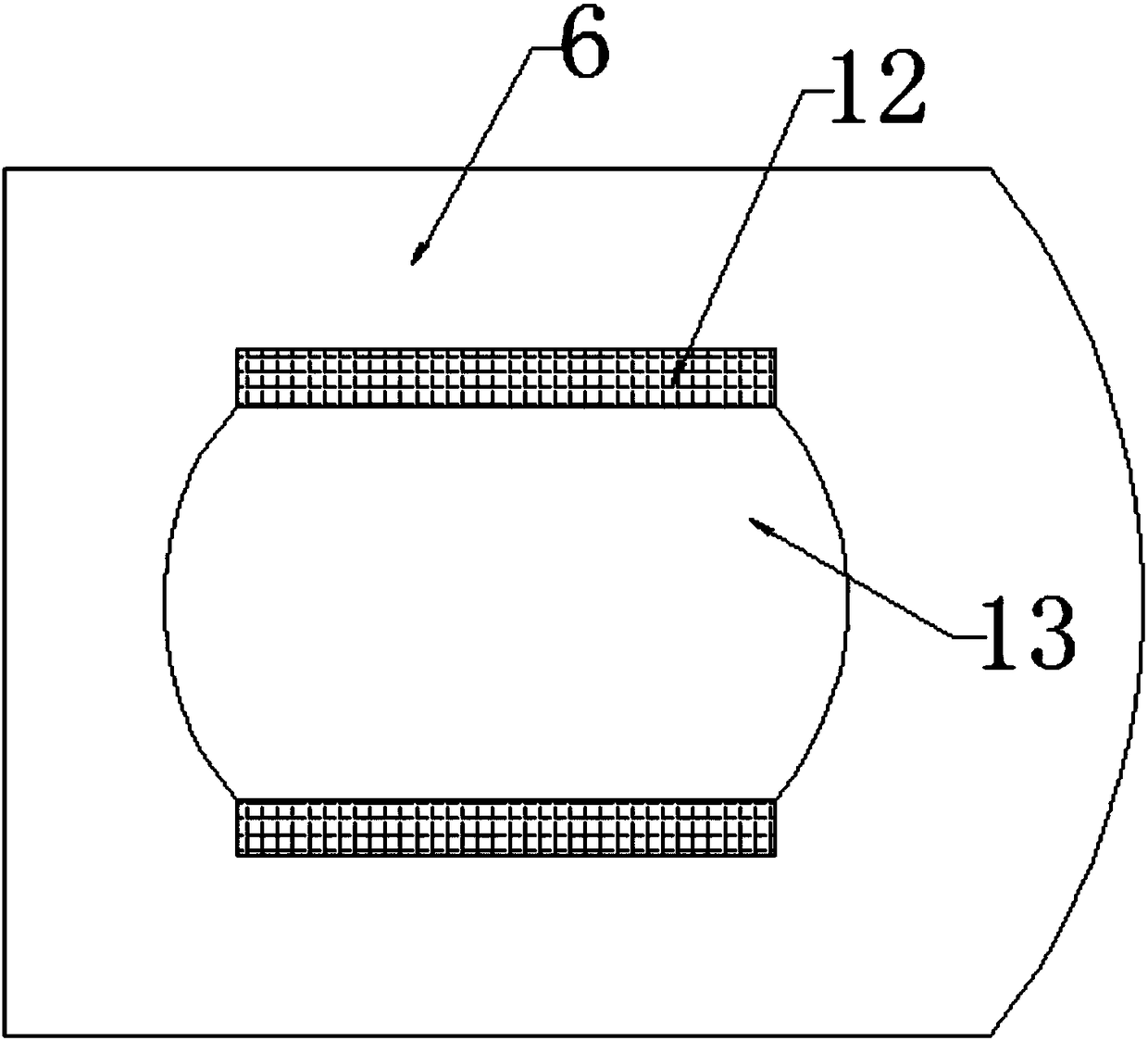

Integrated 24-hour urine sample subsistence device

InactiveCN108392225AEasy to moveEasy to operateSurgeryVaccination/ovulation diagnosticsEngineeringUrine sample

The invention discloses an integrated 24-hour urine sample subsistence device. The integrated 24-hour urine sample subsistence device comprises a seat cushion, wherein a through hole is formed in thecenter of the surface of the seat cushion; air cushion plates are symmetrically arranged on two sides of the through hole; two sides of the seat cushion are rotatably connected with supporting racks through rotating shafts; the inner side of each supporting rack is rotatably connected with a backrest plate through the corresponding rotating shaft; massaging blocks are fixed on the inner surface ofthe backrest plate; the middle of the backrest plate is rotatably connected with a connecting rod through a rotating shaft; a urine guiding bin is fixed on the bottom of the seat cushion; a sponge layer is arranged on one side of the inner wall of the urine guiding bin; the upper surface of the sponge layer is connected with a lifting handle; an electric agitator is fixed on the bottom of the urine guiding bin; a reagent adding tube is arranged on one side of the electric agitator; a urine draining tube is arranged on the other side of the electric agitator; and scale marks are arranged on the front surface of the electric agitator. The device is simple and reasonable in integral structural design, flexible and convenient to operate and safe and comfortable to use, and has high practicality.

Owner:SHANGHAI EAST HOSPITAL

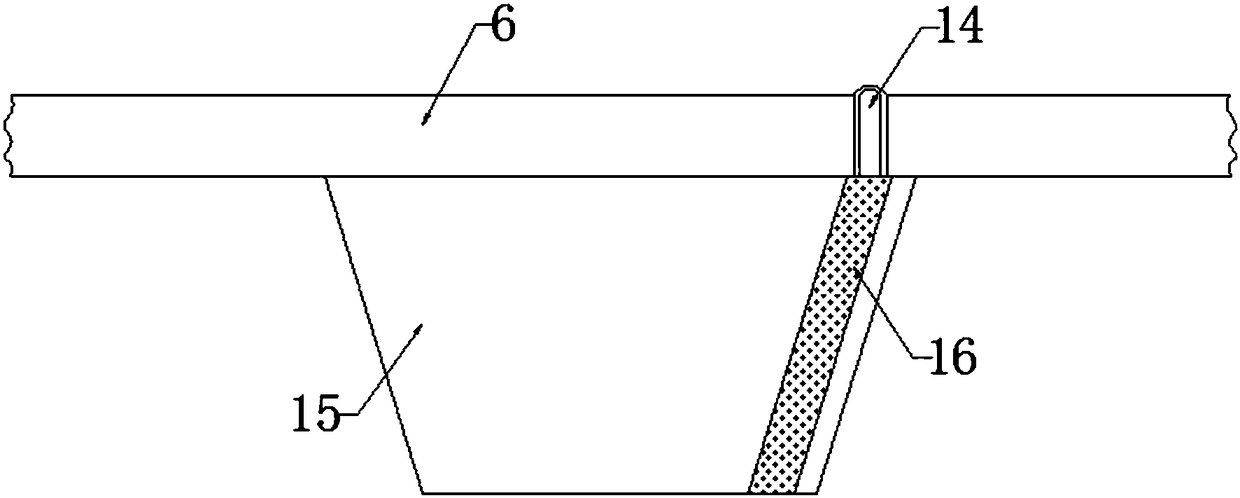

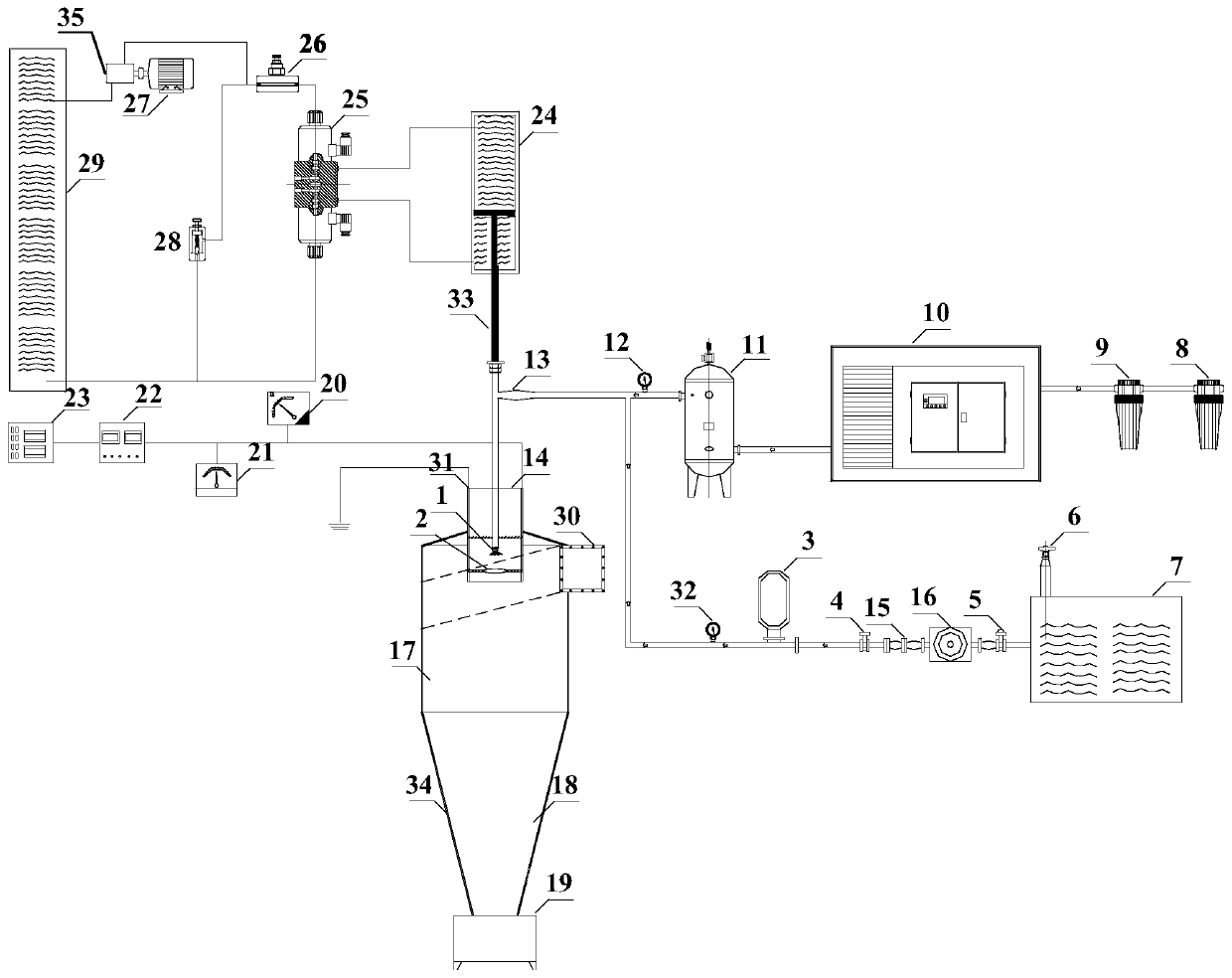

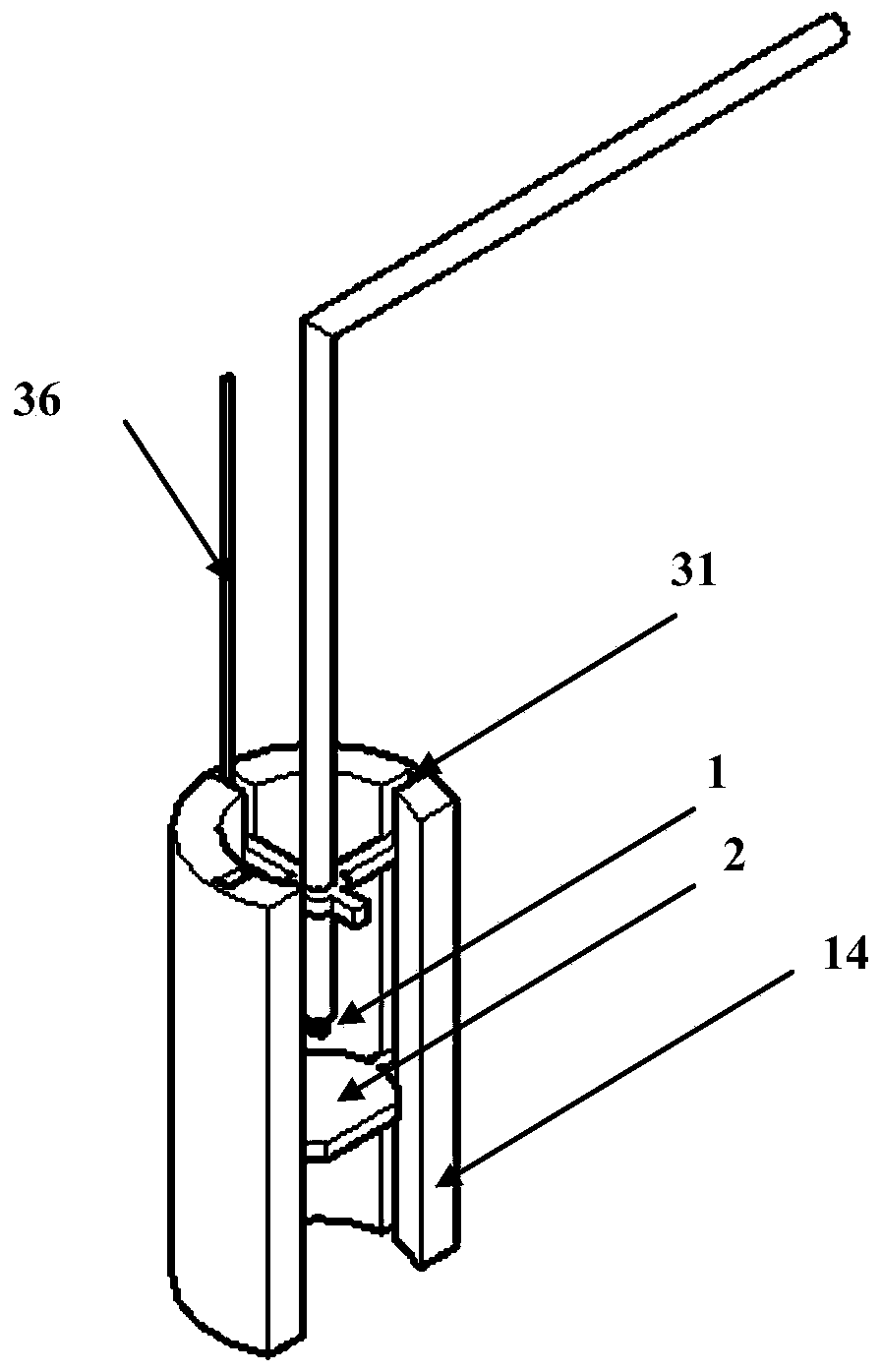

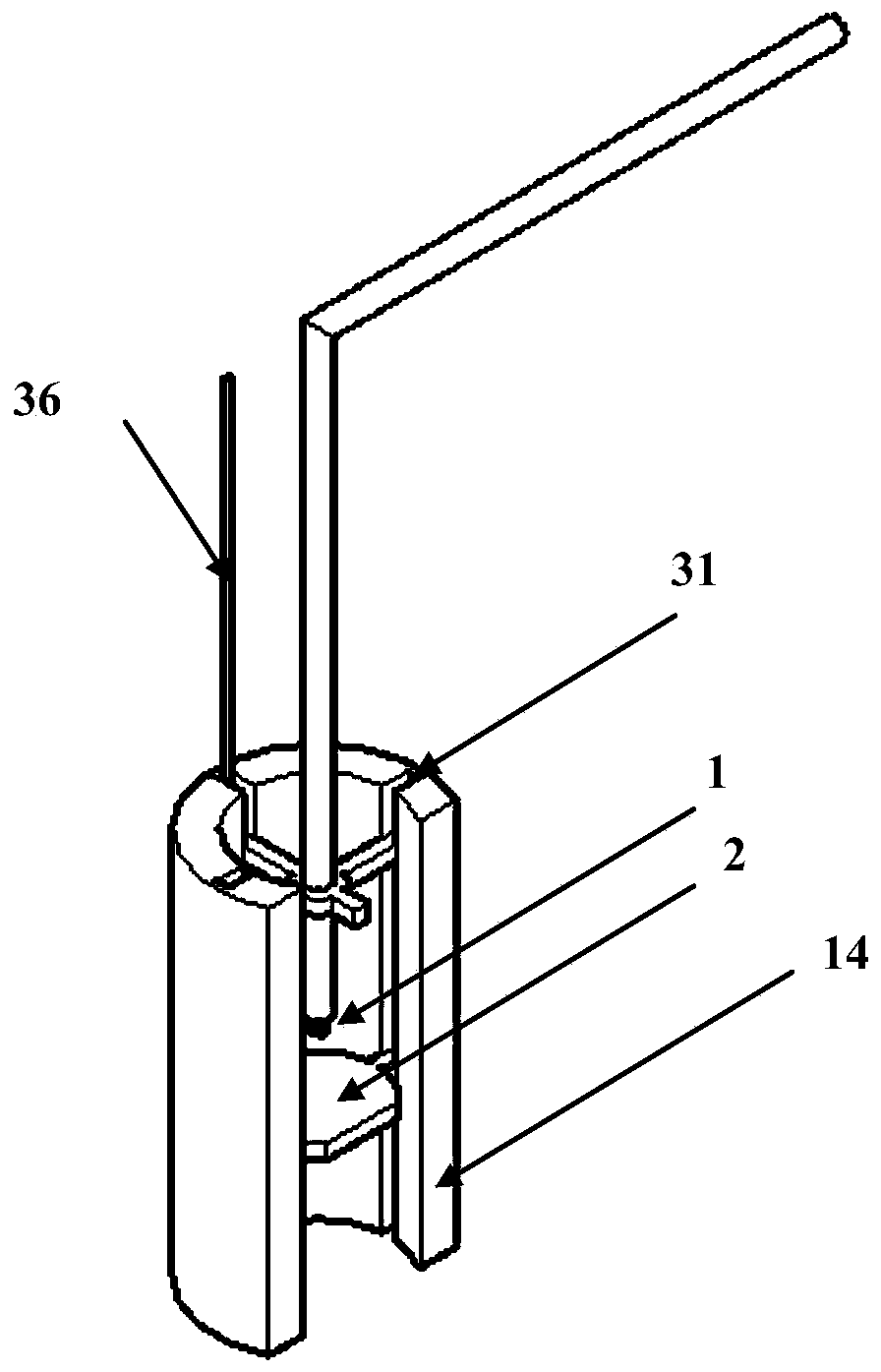

Charged micro-fog cyclone dust removal system for fine particles, and dust removal method thereof

InactiveCN111167249AOvercoming low dust removal rateOvercome the shortcomings of wet dust removal such as large water consumptionCombination devicesParticulatesCyclonic separation

The invention discloses a charged micro-fog cyclone dust removal system for fine particles and a dust removal method thereof, and belongs to the field of dust removal operation. Thecharged micro-fog cyclone dust removal system comprises a micro-fog system gas path, a micro-fog system water path, a charge generation system, an atomizing nozzle, an annular electrode, an exhaust cylinder, a hydraulicsubsystem and a cyclone separation subsystem; an outlet of the micro-fog system gas path and an outlet of the micro-fog system water path are both communicated with the atomizing nozzle; theannular electrode is arranged below the atomizing nozzle; the annular electrode is connected with the charge generation system; wherein the atomizing nozzle and the annular electrode are both arranged in the exhaust cylinder, the exhaust cylinder is provided with an exhaust cylinder slideway, the atomizing nozzle is provided and connected with an atomizing nozzle sliding block, the atomizing nozzle slidingblock is matched with the exhaust cylinder slideway, thecyclone separation subsystem is connected below the exhaust cylinder, and the atomizing nozzle is connected with thehydraulic subsystem. The charged micro-fog cyclone dust removal system can effectively overcomethe problems of low dust removal rate of fine-particle dust and high water consumption of wet dust removal in anexisting cyclone dust removal system, and improvethe dust removal rate of fine-particle dust below 2.5 <mu>m.

Owner:LIAONING TECHNICAL UNIVERSITY

Preparation of novel environment-friendly efficient gas hydrate inhibitor and application thereof

ActiveCN111057529AHas nucleationUniform and stable slurryPipeline systemsDrilling compositionActive agentPyrrolidinones

The invention relates to the technical field of oil and gas production, in particular to preparation of a novel environment-friendly efficient gas hydrate inhibitor and an application thereof. The novel environment-friendly efficient gas hydrate inhibitor is prepared from a 2-vinylpyridine-N-vinyl-2-pyrrolidone copolymer with the mass concentration of 0.6 percent to 1.0 percent, a nonionic surfactant with the mass concentration of 1.8% to 3.4%, glycol ethers with the mass concentration of 4.1% to 5.8%, a water-soluble monomer with the mass concentration of 2.4% to 4.2% and the balance deionized water. The preparation method of the inhibitor comprises the following steps: oil phase preparation, water phase preparation, mixed reaction and the like. The inhibitor prepared by the invention hasa good inhibition effect, can effectively inhibit hydrate nucleation, enables the generated hydrate to be in a uniform and stable slurry state, disenables a hydrate aggregation phenomenon, has the advantages of low toxicity, no volatilization, easy degradation, environmental friendliness and the like, and has a good application prospect.

Owner:郑州洁灵科技有限公司

Preparation method of cationic polyacrylamide aqueous emulsion

The invention provides cationic polyacrylamide aqueous emulsion and a preparation method of cationic polyacrylamide aqueous emulsion. The method for preparing the aqueous emulsion comprises the steps of preparing a reaction type dispersing agent; and balancing the free radical concentration through a multistage complex initiation system under the participation of a salt liquid system and the dispersing agent, and carrying out dispersion polymerization of acrylamide and cationic monomer aqueous emulsion. The aqueous emulsion can be dissolved rapidly, has high molecular weight, good mobility and high stability, and can be widely applied to the water treatment fields of all industries.

Owner:DESHI ENERGY TECH GRP CO LTD

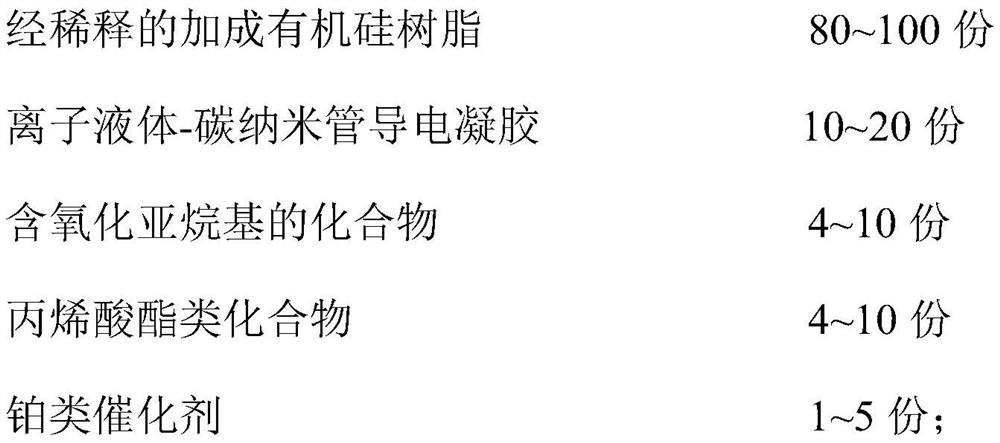

Antistatic organosilicon pressure-sensitive adhesive containing electron transport material and preparation of adhesive

ActiveCN112608689AFix incompatibilitiesDoes not affect curabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer sciencePtru catalyst

The invention provides an antistatic organic silicon pressure-sensitive adhesive containing an electron transport material and a preparation method of the antistatic organic silicon pressure-sensitive adhesive. The antistatic organosilicone pressure-sensitive adhesive is prepared from the following raw materials in parts by mass: 80-100 parts of diluted addition organosilicone resin, 10-20 parts of ionic liquid-carbon nanotube conductive gel, 4-10 parts of a compound containing alkylene oxide, 4-10 parts of an acrylate compound and 1-5 parts of a platinum catalyst. The carbon nano tube and ionic liquid mixed gel is used as an antistatic agent, the problem of incompatibility between the carbon nano tube and the pressure-sensitive adhesive is solved, the gel premixing method is applied, the dispersion effect is good, the gel can be stored for a long time, and the agglomeration phenomenon is avoided; and the antistatic effect can be achieved only by adding a small amount of the antistatic agent, and the curing property, the mechanical property and the optical property of a formed film are not influenced.

Owner:ZHEJIANG UNIV OF TECH

Buckwheat instant porridge

InactiveCN101828676AAgglomeration does not occurRetain nutrientsFood preparationPolygonum fagopyrumSizing

The invention discloses a buckwheat instant porridge, which is produced by a preparation method comprising: uniformly mixing buckwheat, water and table salt to make a raw material; bulking the raw material to make a wet soft porous sponge body with a density of 1 to 1.2kg / L and finishing primary cooking; before the solidification and sizing of the wet soft porous sponge, placing the wet soft porous sponge into an extrusion forming machine to extrude a solid body with a density of 1.3 to 1.4kg / L and finishing secondary cooking; drying the solid body prepared by the previous step with hot air at 20 to 40 DEG C till the water content is less than or equal to 13 percent and obtaining a dry cooked material; crushing the dry cooked material into 10 to 15 mesh particles to obtain a fine particle material; and subjecting the fine particle material to soot blowing treatment to remove the flour attached onto the surface of the fine particle material to obtain the finished buckwheat instant porridge. The buckwheat instant porridge can be made into porridge quickly when soaked in water, retain the nutrients of the buckwheat to a maximum degree, be digested and absorbed by human body easily and offer a good mouthfeel.

Owner:吉林曙光农牧有限公司

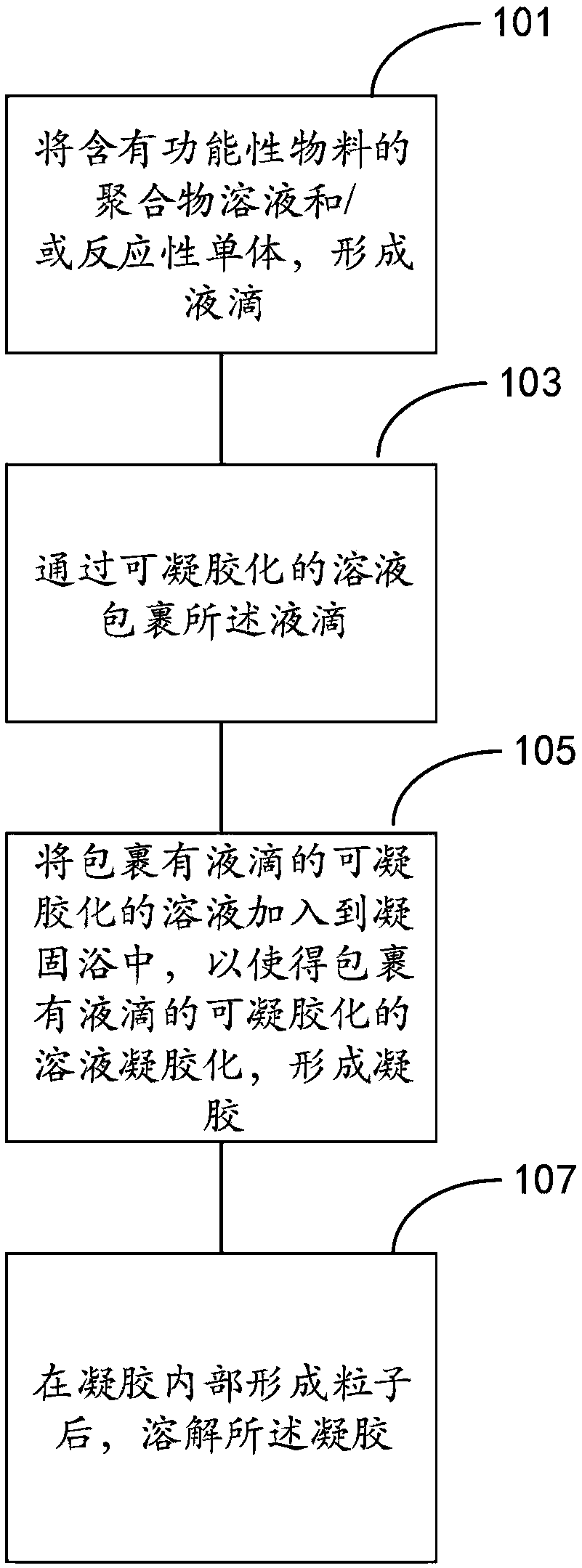

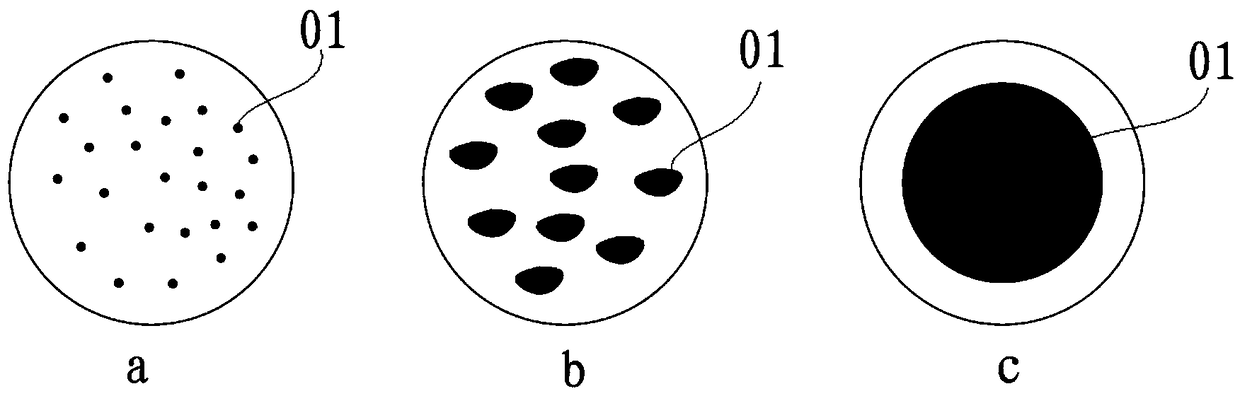

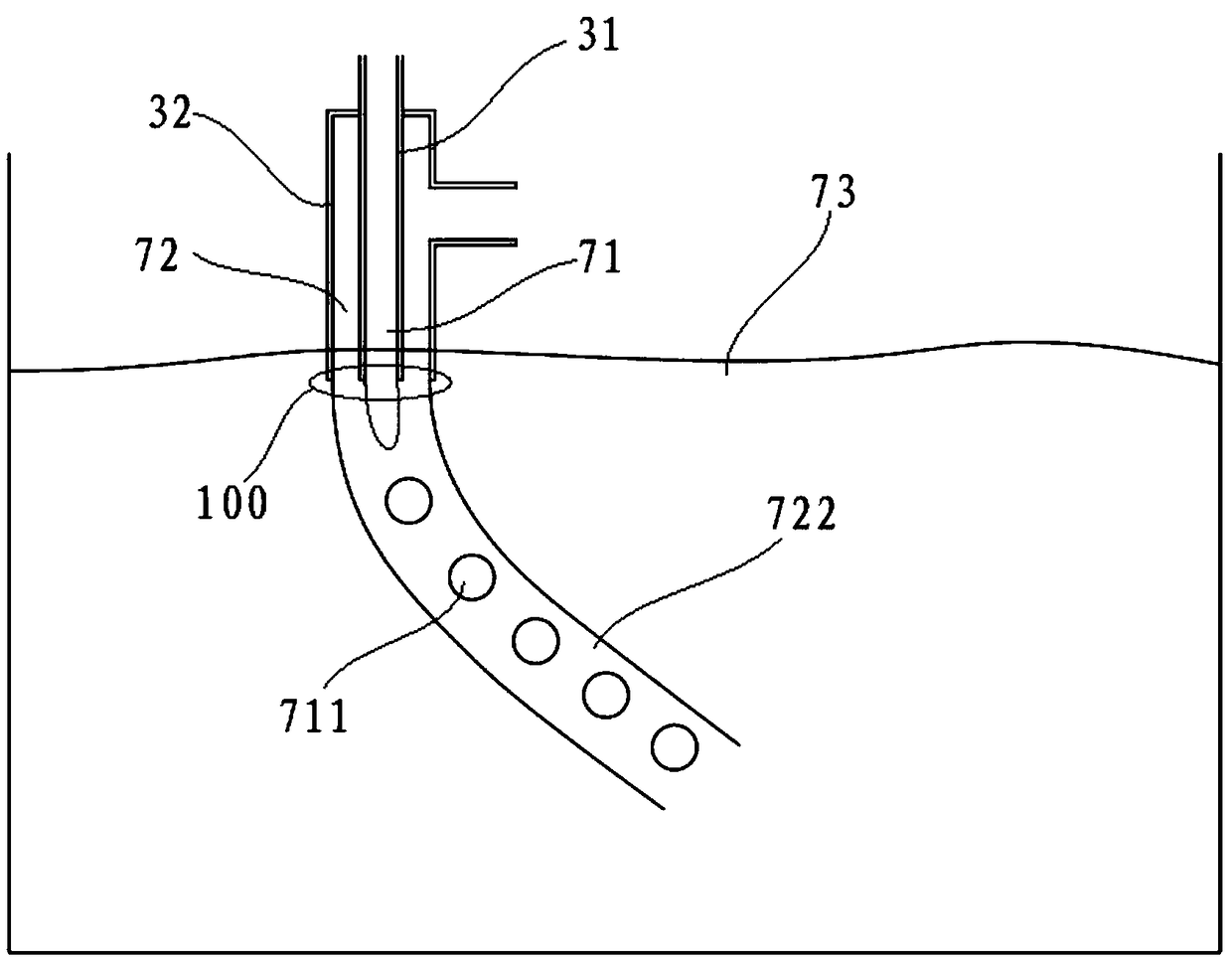

Polymer particle preparation method

ActiveCN109265711ANo collisionAvoid destructionCell culture supports/coating3D culturePolymer sciencePolymer solution

The invention discloses a polymer particle preparation method. A polymer solution containing a functional material and / or a reactive monomer is formed into drops; the drops are wrapped by a gelatinizable solution; the gelatinizable solution wrapping the drops is added into coagulating bath, so that the gelatinizable solution wrapping the drops is gelatinized, and thereby gel is formed; and after particles are formed in the gel, the gel is dissolved. The polymer particle preparation method provided by the invention can obtain particles with good uniformity.

Owner:胡权

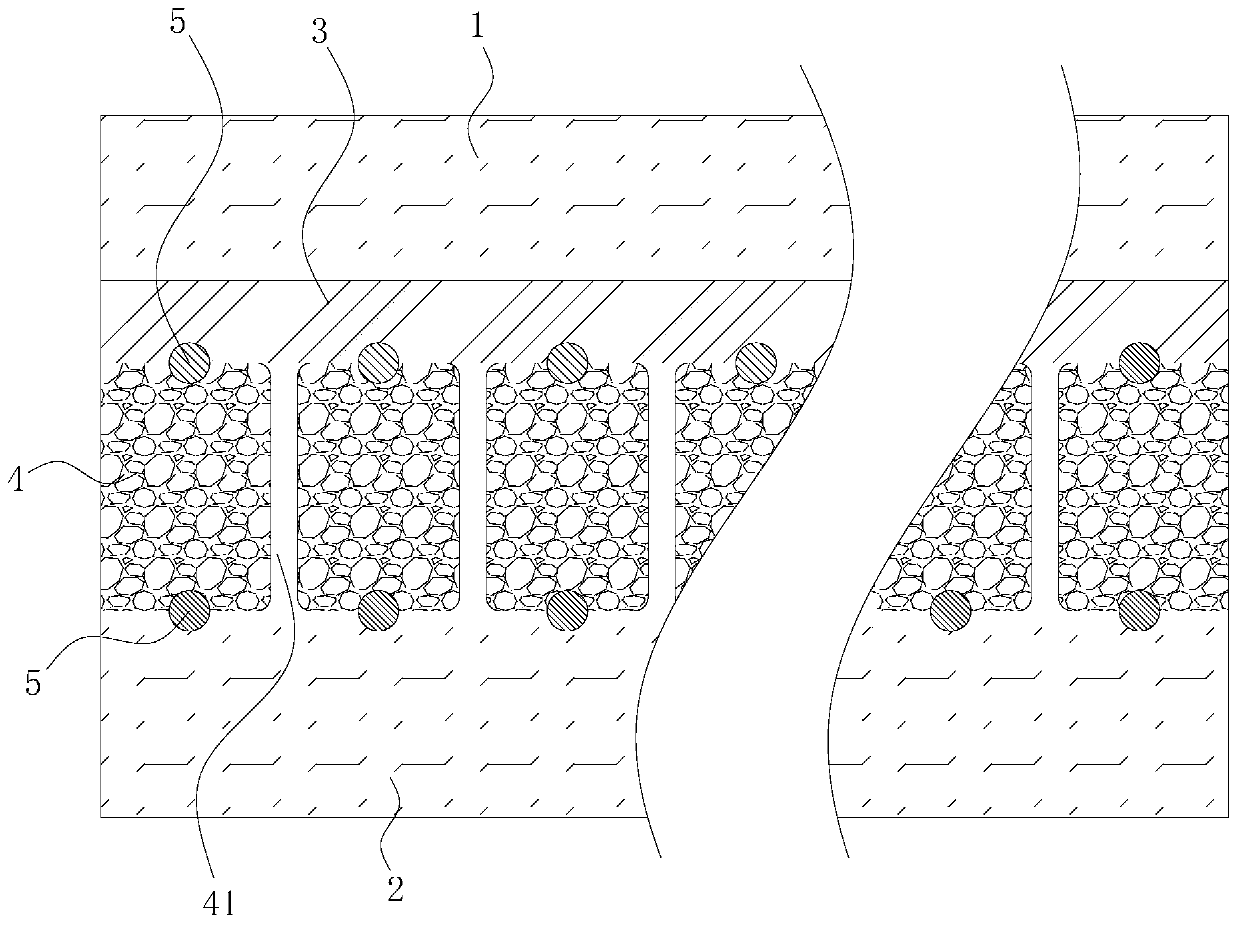

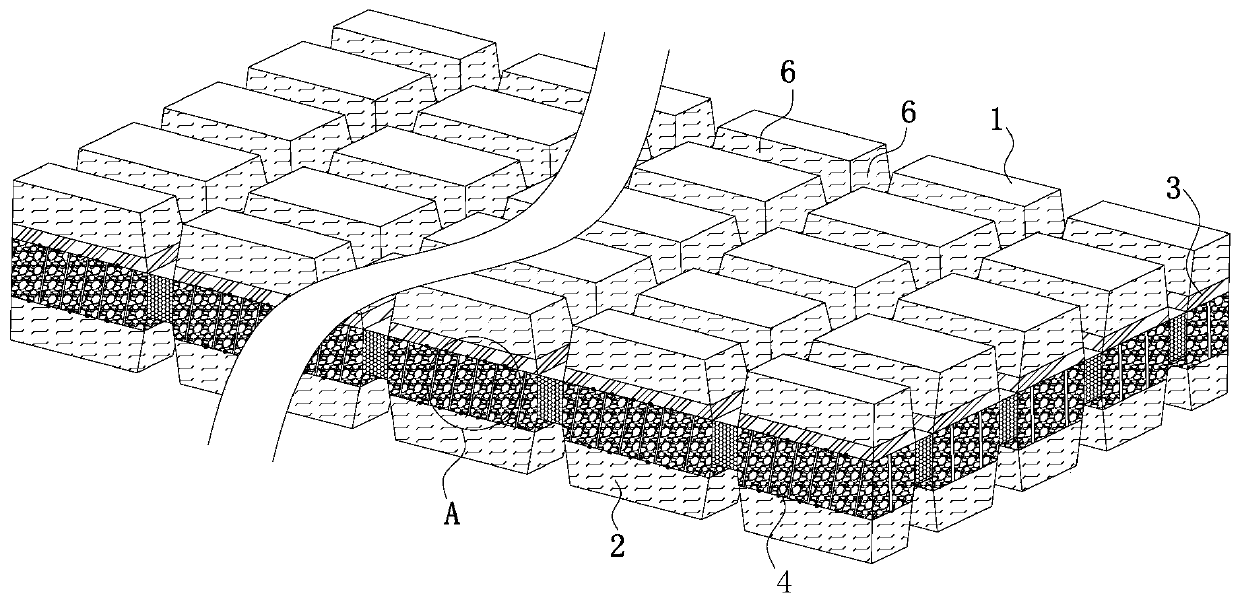

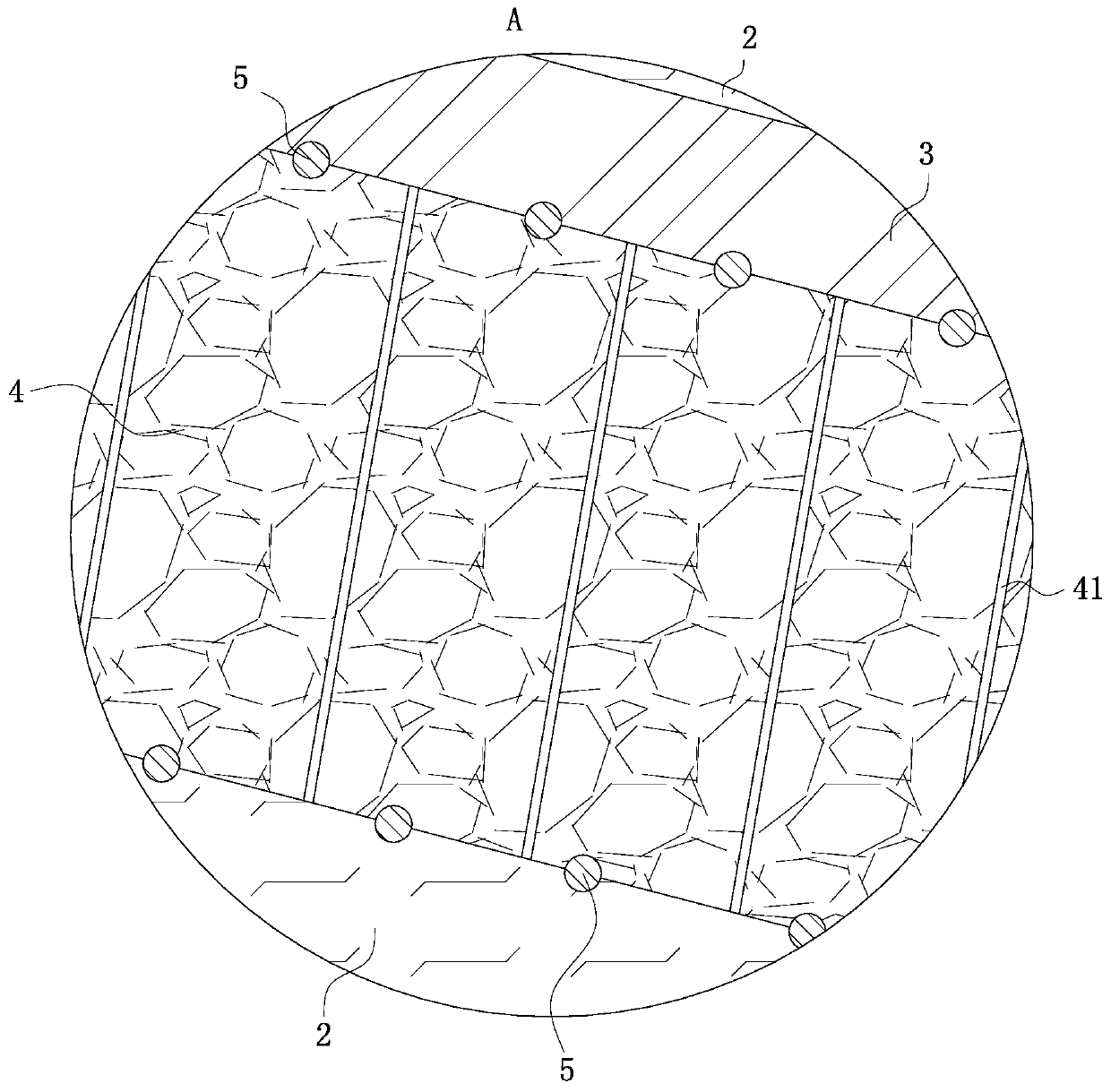

Medical sanitary non-woven fabric

ActiveCN111529209AExtended service lifeImprove impermeabilityAbsorbent padsBaby linensPolymer scienceAdhesive

The invention belongs to the technical field of non-woven fabrics, in particular to a medical sanitary non-woven fabric. The fabric comprises a surface layer, an intermediate layer and a contact layer, wherein the surface layer is arranged above the intermediate layer; the contact layer is arranged under the intermediate layer; the surface layer is a non-woven fabric; the contact layer is a non-woven fabric; the intermediate layer is high-molecular water-absorbing resin. The medical sanitary non-woven fabric has a simple structure, and the production process is simple and implementable; besides, the use of an adhesive is omitted, the production cost is effectively reduced, strength of the product is improved by pressed lines formed by ultrasonic pressing, dislocation and aggregation of composition of the product can be avoided, and performance of the product is ensured.

Owner:济南瑞凝医药科技有限公司

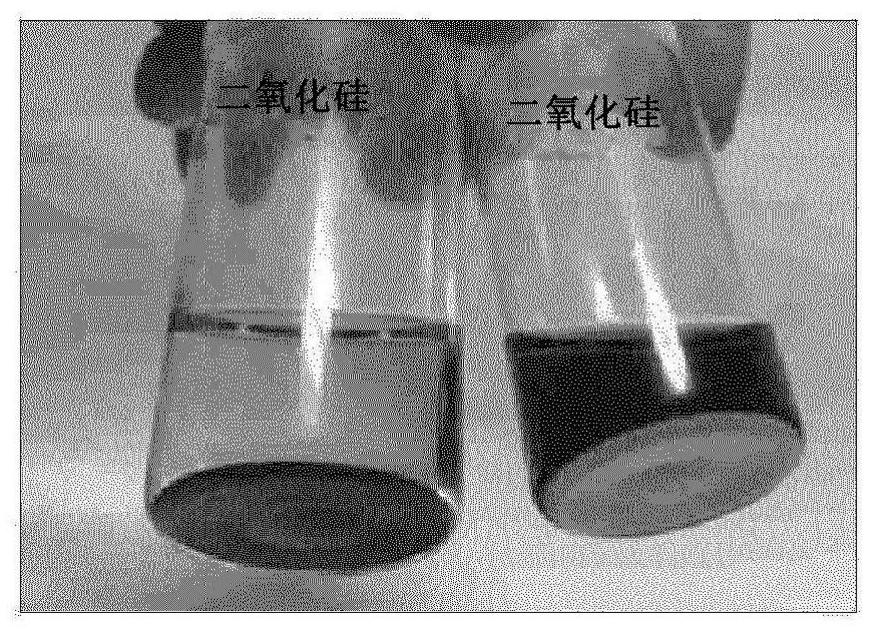

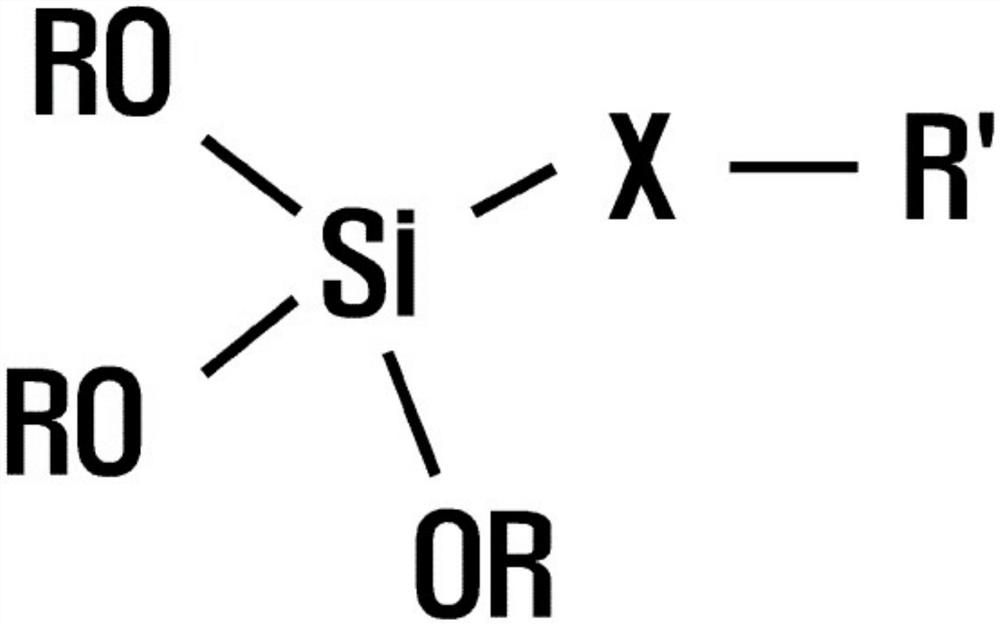

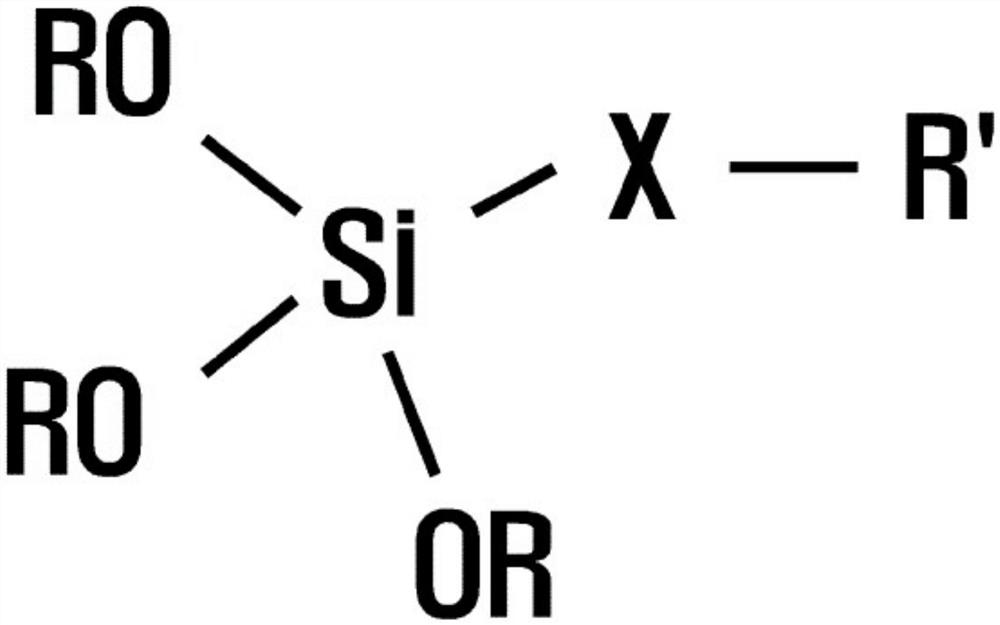

Gardenia red pigment stably adsorbed on surface of silica, and cosmetic composition containing same

PendingCN111971019AImprove thermal stabilityAgglomeration does not occurCosmetic preparationsHair cosmeticsSilicon dioxideOrganic chemistry

The present invention relates to a gardenia red pigment stably adsorbed on the surface of silica, and a cosmetic composition containing same, and more specifically, to a gardenia red pigment stably adsorbed on the surface of silica, the silica surface having a specific reactive group introduced thereto, and a cosmetic composition containing same. Compared to conventional gardenia red pigments, thegardenia red pigment stably adsorbed on the surface of silica, according to the present invention, has improved thermal stability, does not aggregate at a low pH level, and may be applied to cosmeticcompositions other than water-phase cosmetic compositions, and thus can have a further expanded range of use.

Owner:AMOREPACIFIC CORP

Preparation method of non-cracking stone-like coating

InactiveCN109207009AImprove mechanical propertiesGood alkali resistanceAntifouling/underwater paintsPaints with biocidesIndiumMechanical property

The invention provides a preparation method of a non-cracking stone-like coating, and the preparation method comprises the following steps: (1) adding oleic acid, triethanolamine and polyethanolamineto a reaction vessel, mixing uniformly, heating, holding for reaction, adding boric acid and molybdic acid to the reaction vessel to obtain a component A; (2) adding anhydrous aluminum chloride, thulium chloride and gadolinium chloride to water, and continuously adding ammonia water thereto to obtain a component B; (3) adding alpha-alumina, indium oxide and gallium oxide to anhydrous ethanol for ball milling and mixing with high-purity ceramic balls, then calcining, and grinding to obtain a component C; (4) adding an anti-cracking silicon-acrylic emulsion, natural coloring sand, a film formingauxiliary, a dispersing agent, a defoaming agent, the component A, the component B and the component C to a high-speing stirring and dispersing machine for uniformly dispersing to obtain the non-cracking stone-like coating. The non-cracking stone-like coating is less prone to cracking during the initial drying process, and the mechanical properties are remarkable.

Owner:郭平

Technology for producing leather gelatin with high freezing force and high viscosity by alkali-alkali-acid ternary method

ActiveCN102181233BReduce processing timeAgglomeration does not occurGlue/gelatin preparationFiltrationIon exchange

The invention relates to making technology of gelatin, in particular to a technology for producing leather gelatin with high freezing force and high viscosity by an alkali-alkali-acid ternary method. The technology includes pretreatment process, gelatin extraction, filtration, ion exchange, concentration, high temperature sterilization, drying, crushing, mixing and metal detection, thus obtaining the finished product. The technology is characterized in that the pretreatment process is a mixed acid-alkali method and forms the alkali-alkali-acid ternary method for producing leather gelatin with high freezing force and high viscosity, together with the follow-up process. The product is high in freezing force, and achieves acid-method level, as well as the viscosity between the acid method and the alkali method, obviously higher than alkali method. Compared with the alkali method, the technology has the treatment time of leather shortened greatly by 35-40 days. The acid (pH ranging between 3.0-4.5) gelatin extraction only needs to be done for 5 times, reduced by twice compared with 7 times of the alkali method. The production efficiency is improved by 20%, and water and energy are saved by 10%. The temperature for alkali treatment is controlled between 15-25oC, product quality is ensured and meanwhile, compared with former requirement of 5-15oC, a large quantity of energy is saved.

Owner:罗赛洛(温州)明胶有限公司

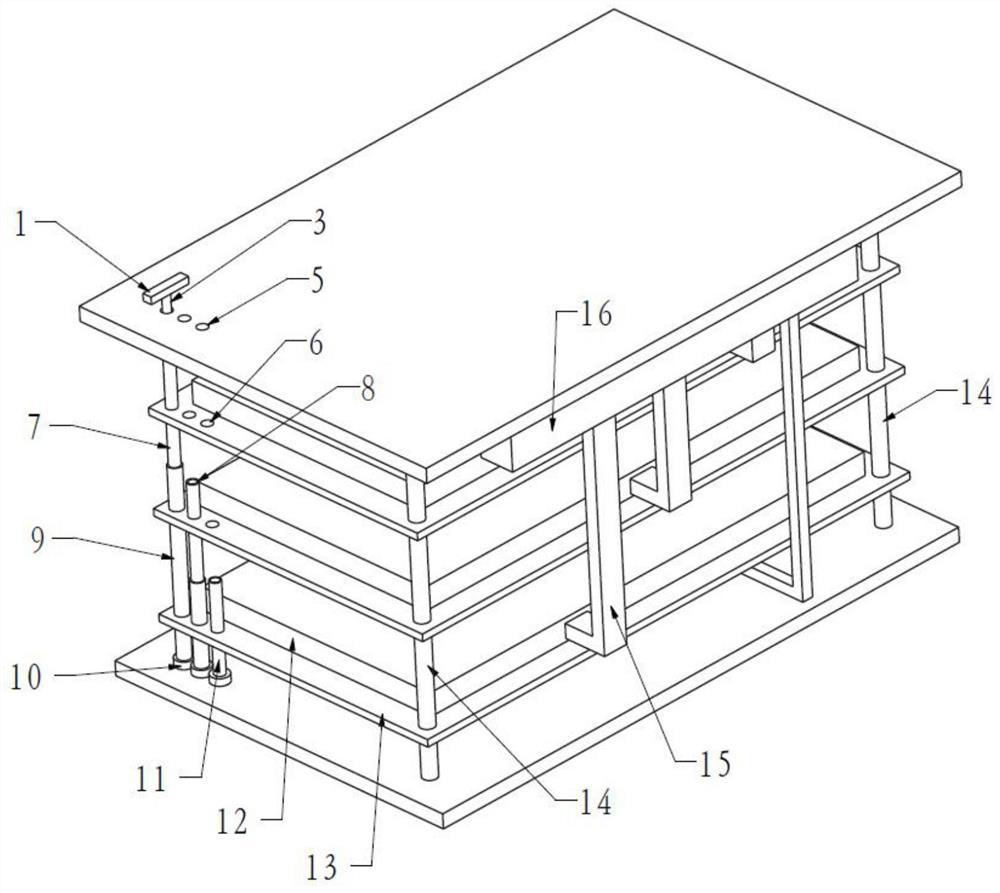

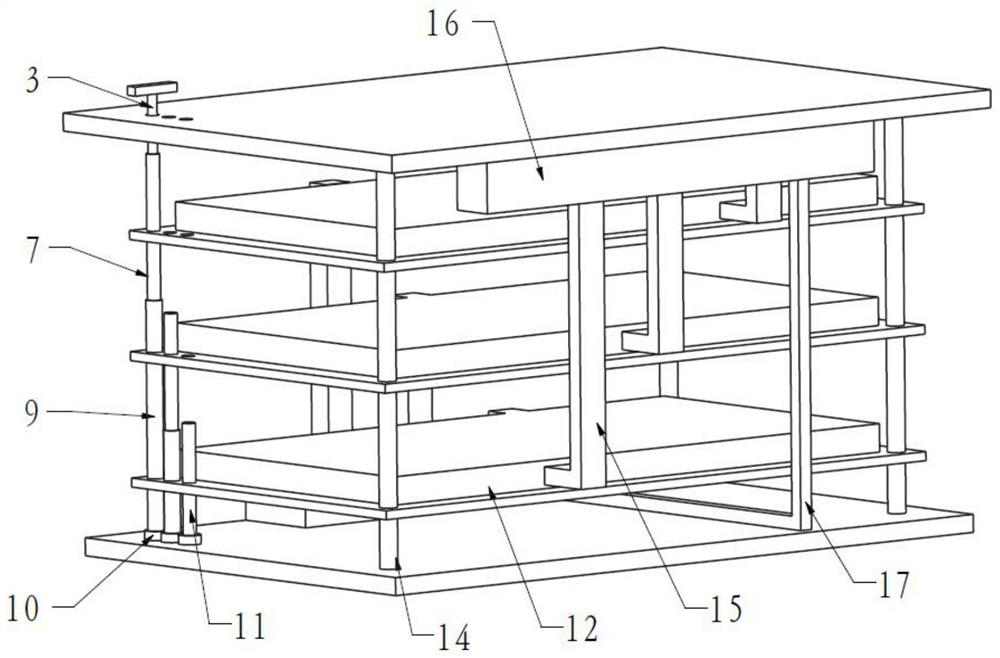

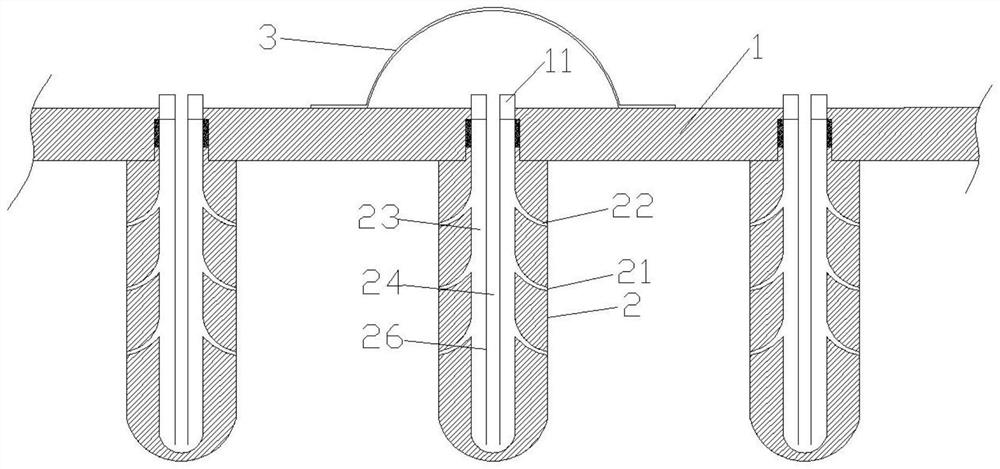

Rice cultivation auxiliary device

InactiveCN113924892AThe distance is easy to adjustUnattendedSaving energy measuresPressurised distribution of liquid fertiliserWater storage tankAgricultural engineering

The invention discloses a rice cultivation auxiliary device, and belongs to the technical field of rice cultivation. The rice cultivation auxiliary device comprises a box body, wherein a plurality of layers of movable support plates are arranged in the box body, a cultivation tray is arranged on each layer of support plate, guide rods are arranged in three of four corners of each support plate in a penetrating manner, limiting through holes are formed in the other corners of the support plates at intervals, a screw rod is arranged in a screw hole in the support plate on the uppermost layer, the lower end of the screw rod is connected with a limiting rod, the limiting rod is connected with a bearing on a bottom plate of the box body, the support plates on the lower layers are connected with the screw rods through screw holes, the support plate on the lowermost layer is connected with the limiting screw rod through the screw hole, the upper ends of the screw rod and the limiting screw rod can be matched with a threaded rod, and the upper end of the threaded rod penetrates through a limiting screw hole in a top cover of the box body; a fertilizer box is arranged at the top of the inner wall of the box body, and the fertilizer box communicates with each layer of cultivation tray through a control pipe; a water storage tank is arranged on the bottom plate of the box body, all layers of the cultivation trays communicate with the water storage tank through filter pipes, and the water storage tank communicates with the fertilizer box through a circulating water pipe.

Owner:辰溪县千鑫生态农业科技发展有限公司

Buckwheat instant porridge

InactiveCN101828676BAgglomeration does not occurRetain nutrientsFood preparationPolygonum fagopyrumSolid body

The invention discloses a buckwheat instant porridge, which is produced by a preparation method comprising: uniformly mixing buckwheat, water and table salt to make a raw material; bulking the raw material to make a wet soft porous sponge body with a density of 1 to 1.2kg / L and finishing primary cooking; before the solidification and sizing of the wet soft porous sponge, placing the wet soft porous sponge into an extrusion forming machine to extrude a solid body with a density of 1.3 to 1.4kg / L and finishing secondary cooking; drying the solid body prepared by the previous step with hot air at 20 to 40 DEG C till the water content is less than or equal to 13 percent and obtaining a dry cooked material; crushing the dry cooked material into 10 to 15 mesh particles to obtain a fine particlematerial; and subjecting the fine particle material to soot blowing treatment to remove the flour attached onto the surface of the fine particle material to obtain the finished buckwheat instant porridge. The buckwheat instant porridge can be made into porridge quickly when soaked in water, retain the nutrients of the buckwheat to a maximum degree, be digested and absorbed by human body easily and offer a good mouthfeel.

Owner:吉林曙光农牧有限公司

A kind of production technology of medicinal gelatin

ActiveCN104371559BLarge specific surface areaHigh degree of expansionGlue/gelatin preparationIon exchangeGelatin

The invention relates to a production technique of a gelatin, particularly a production technique of a pharmaceutical gelatin, which comprises the following steps: pretreatment technique, degelatinizing, filtering, ion exchange, film concentration, plate drying, sterilization, gumming, drying, pulverization and inspection to obtain the finished product. The invention is characterized in that the pretreatment technique adopts an alkali-hydrogen peroxide-acid composite process and combines with the subsequent techniques to constitute an acid-alkali-hydrogen peroxide three-element process for producing the high-quality gelatin. The jelly strength and viscosity of the first three gelatins extracted in the degelatinizing process are obviously improved as compared with the single acid process or alkali process. The skin material treatment time is greatly shortened as compared with the alkali process. Besides, the alkali treatment is performed at normal temperature, thereby saving the energy and water on the premise of ensuring the high quality of the product.

Owner:HUNAN ER KANG PHARMA

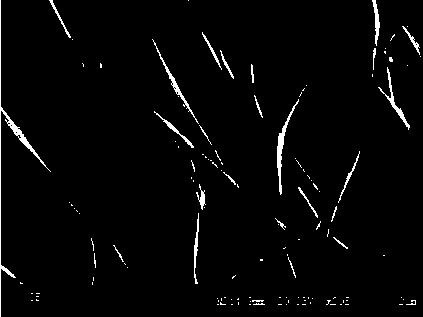

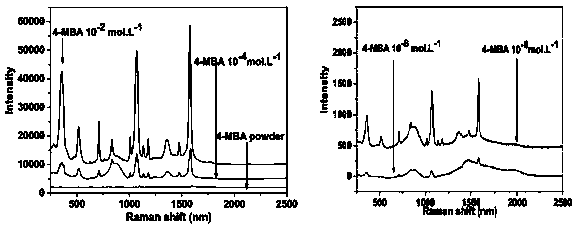

The purposes of a kind of composite sers substrate in detection malachite green

InactiveCN106093003BEasy to prepareThe preparation method is easy to obtainMaterial nanotechnologyRaman scatteringMalachite greenMalachite green stain

The invention provides a method for preparing an AgVO3 nanobelt / Ag nanoparticles composite SERS substrate, and provides the composite SERS substrate, which comprises a nanobelt and metal nanoparticles, wherein the nanobelt is AgVO3, and the Ag nanoparticles are absorbed on the surface. The composite SERS substrate preparation method comprises the following steps: 1) preparing the AgVO3 nanobelt; 2) taking the AgVO3 nanobelt and performing ultrasonic dispersion on the AgVO3 nanobelt in an aqueous solution containing a reducing agent, stirring the materials for 1-12 hours; and 3) centrifuging the nanobelt and re-performing ultrasonic dispersion on an AgVO3 solution, standing for 12-24 hours to obtain the product. Compared with the powder SERS substrate, the position and the relative distance of the Ag nanoparticles in an AgVO3 / Ag nano compound are fixed, aggregation phenomenon is not generated, the activity can be kept; compared with a laser etched substrate, the substrate preparation method has the advantages of simpleness, easy acquisition, no requirement of special equipment, and easy popularization.

Owner:TONGHUA NORMAL UNIV

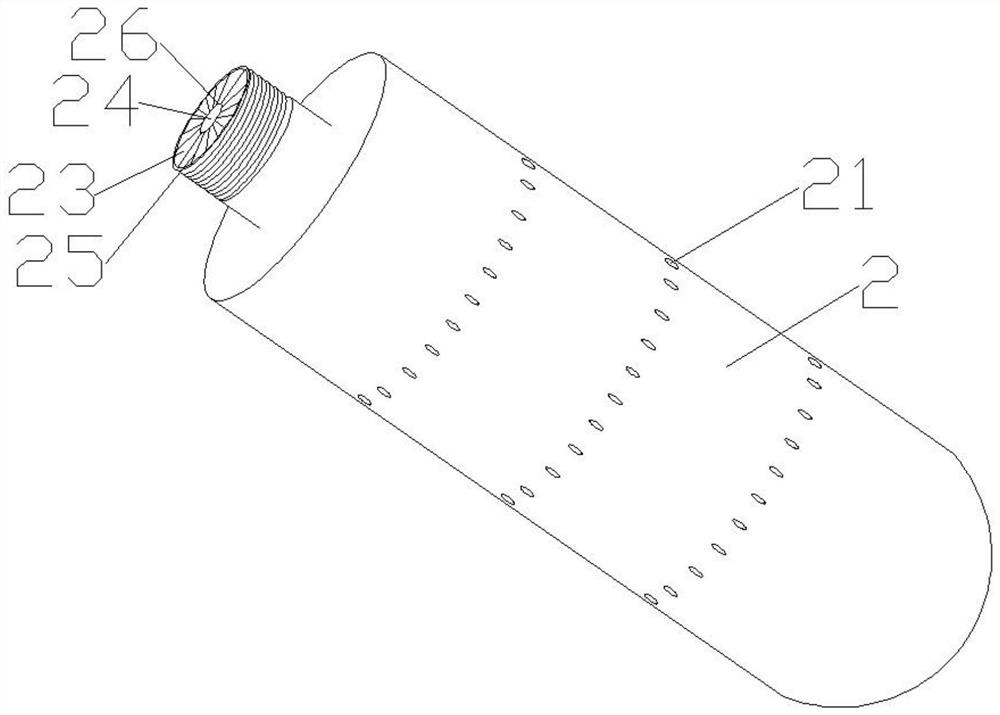

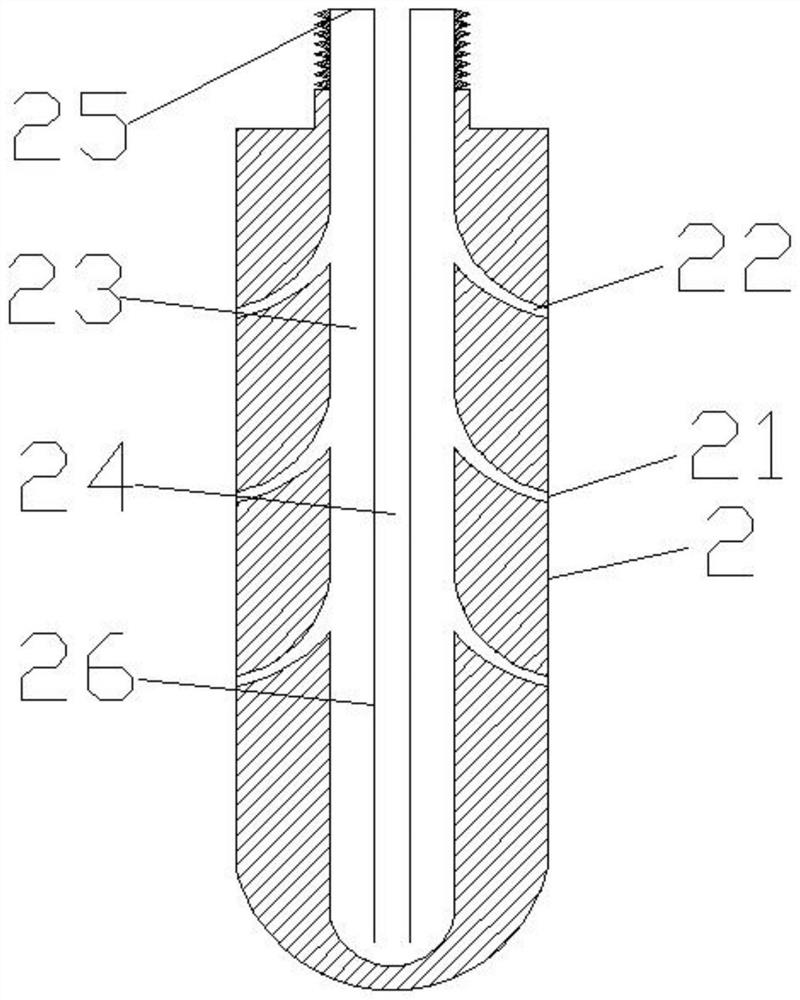

A mold for producing Longlu capsules

The invention discloses a mold for producing Longlu capsules, comprising a steel plate, a mold column and a handle; the main body of the mold column is a cylinder, and the bottom end is a semicircle; Air inlet and outlet; the air passage is an arc-shaped flared structure; the smaller end of the vertical section of the air passage is fixedly connected with the air hole, and the other end is fixedly connected with the air inlet; the main body of the air inlet is a cylinder The bottom end is semi-circular or semi-elliptical; the cross section of the main body of the air inlet is annular; the annular center of the air inlet is provided with an air outlet; the cross section of the air outlet is circular, and the circular edge and the air inlet The edges of the annular inner ring are overlapped; an annular wall is arranged at the overlap of the air outlet and the air inlet; the steel plate and the die column are detachably connected with threads; The mold for producing Longlu capsules of the invention has the advantages of rapid exhaust, rapid cooling, easy demoulding, easy disassembly, and high productivity.

Owner:TIANJIN HEZHI PHARMA CO LTD

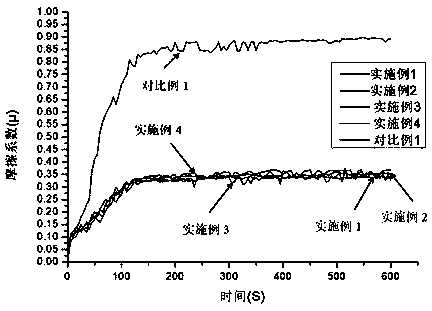

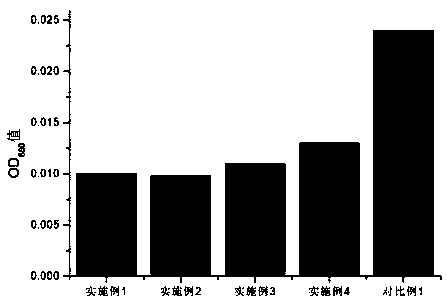

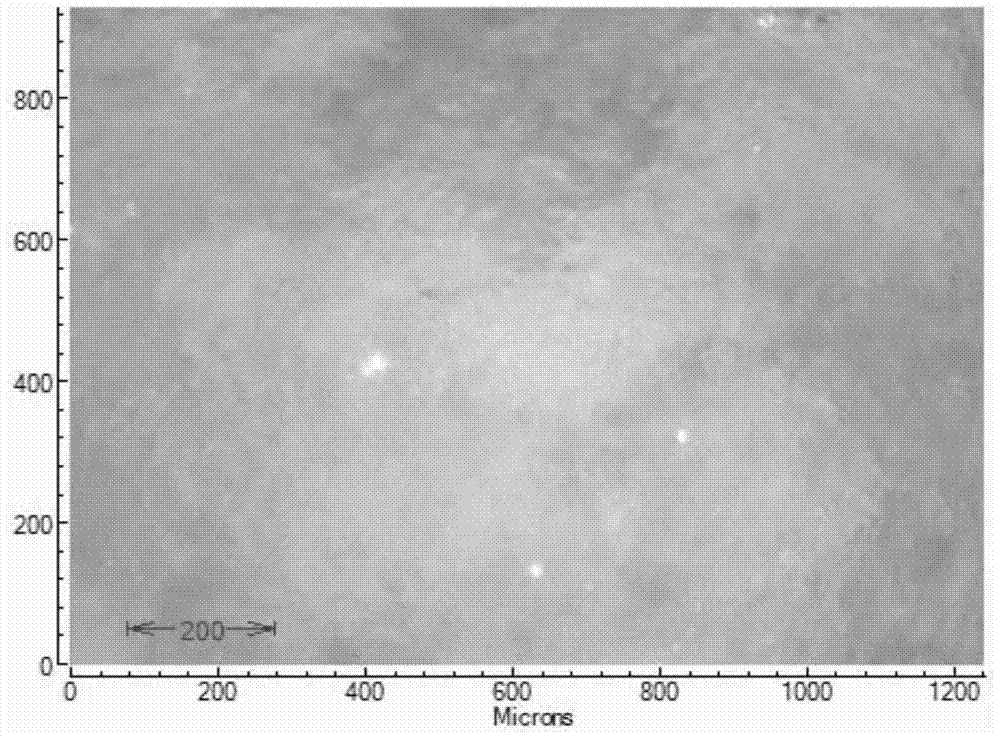

A kind of composite gas hydrate polymerization inhibitor and its application

The invention discloses a compound gas hydrate polymerization inhibitor and application thereof. The compound gas hydrate polymerization inhibitor consists of a betaine zwitterionic surfactant and a polyalcohol nonionic surfactant in the mass ratio of (0.01-100):1. The compound gas hydrate polymerization inhibitor is applied to prevention of gas hydrate polymerization in an oil-gas-water three-phase mixed conveying system. The compound gas hydrate polymerization inhibitor has the advantages that (1) used raw materials are low in toxicity, and have high biodegradability in nature, so that severe environmental pollution is avoided; (2) the defects of the conventional gas hydrate inhibitors such as large using amount, high cost and high pipeline quality requirement in a thermodynamic inhibitor, low super-cooling degree bearing capacity of a kinetic inhibitor, and the like are overcome; the particle size of the gas hydrate can be effectively controlled, and gas hydrate particles are uniformly distributed into an oil phase, so that the problem concerned with safe flow of oil-gas-water phases is solved effectively; (4) the adding amount is small, the polymerization resistance is high, and the application prospect is good.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com