Ultrasonic-atomization microdose sprayer

An ultrasonic atomization and sprayer technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of large-volume spray pollution waste, low effective utilization rate of pesticides, poor deposition performance, etc. Large size, large coverage area, good deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

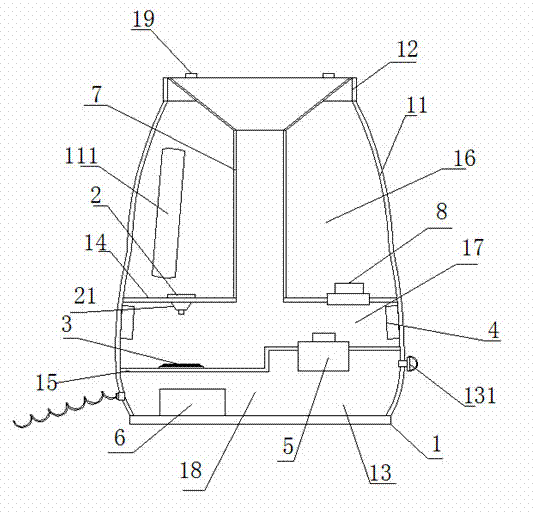

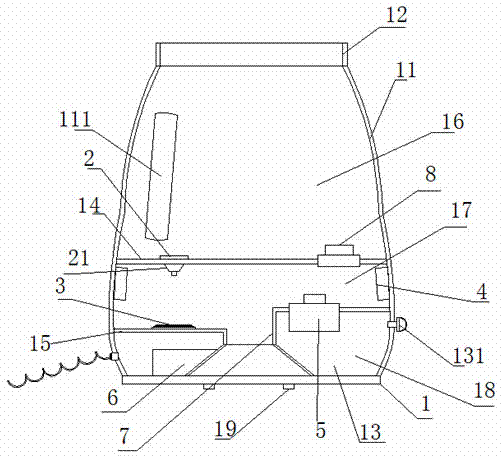

[0030] As a preferred embodiment of the present invention, with reference to the attached figure 1, the present invention includes a nebulizer body 1 and an ultrasonic generator 3, the nebulizer body 1 includes a housing 11, a top cover 12 and a base 13; the inner space of the nebulizer body 1 is separated from top to bottom by a partition I14 and a partition II15 It is a water storage area 16, an atomization area 17 and a circuit area 18; the bottom of the water storage area 16 is provided with a water outlet 2, and a high-pressure flow control valve 21 is installed at the water outlet 2; the ultrasonic generator 3 is correspondingly arranged Below the water outlet 2, and fixed on the partition II15; the side wall of the atomization area 17 is provided with an electrostatic electric field electrode 4; the partition II15 is also provided with a pressurizing device 5; inside the circuit area 18 A control circuit 6 for controlling the ultrasonic generator 3, the electrostatic fi...

Embodiment 2

[0034] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention includes a nebulizer body 1 and an ultrasonic generator 3, the nebulizer body 1 includes a housing 11, a top cover 12 and a base 13; the inner space of the nebulizer body 1 is separated from top to bottom by a partition I14 and a partition II15 It is a water storage area 16, an atomization area 17 and a circuit area 18; the bottom of the water storage area 16 is provided with a water outlet 2, and a high-pressure flow control valve 21 is installed at the water outlet 2; the ultrasonic generator 3 is correspondingly arranged Below the water outlet 2, and fixed on the partition II15; the side wall of the atomization area 17 is provided with an electrostatic electric field electrode 4; the partition II15 is also provided with a pressurizing device 5; inside the circuit area 18 A control circuit 6 for controlling the ultrasonic generator 3, the electrostatic f...

Embodiment 3

[0039] As another preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention includes a nebulizer body 1 and an ultrasonic generator 3, the nebulizer body 1 includes a housing 11, a top cover 12 and a base 13; the inner space of the nebulizer body 1 is separated from top to bottom by a partition I14 and a partition II15 It is a water storage area 16, an atomization area 17 and a circuit area 18; the bottom of the water storage area 16 is provided with a water outlet 2, and a high-pressure flow control valve 21 is installed at the water outlet 2; the ultrasonic generator 3 is correspondingly arranged Below the water outlet 2, and fixed on the partition II15; the side wall of the atomization area 17 is provided with an electrostatic electric field electrode 4; the partition II15 is also provided with a pressurizing device 5; inside the circuit area 18 A control circuit 6 for controlling the ultrasonic generator 3, the electrost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com