Medical sanitary non-woven fabric

A non-woven and hygienic technology, applied in the fields of application, medical science, clothing, etc., can solve the problems of air permeability, secondary pollution, liquid leakage, etc., improve impermeability, isolate bacterial pollution, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

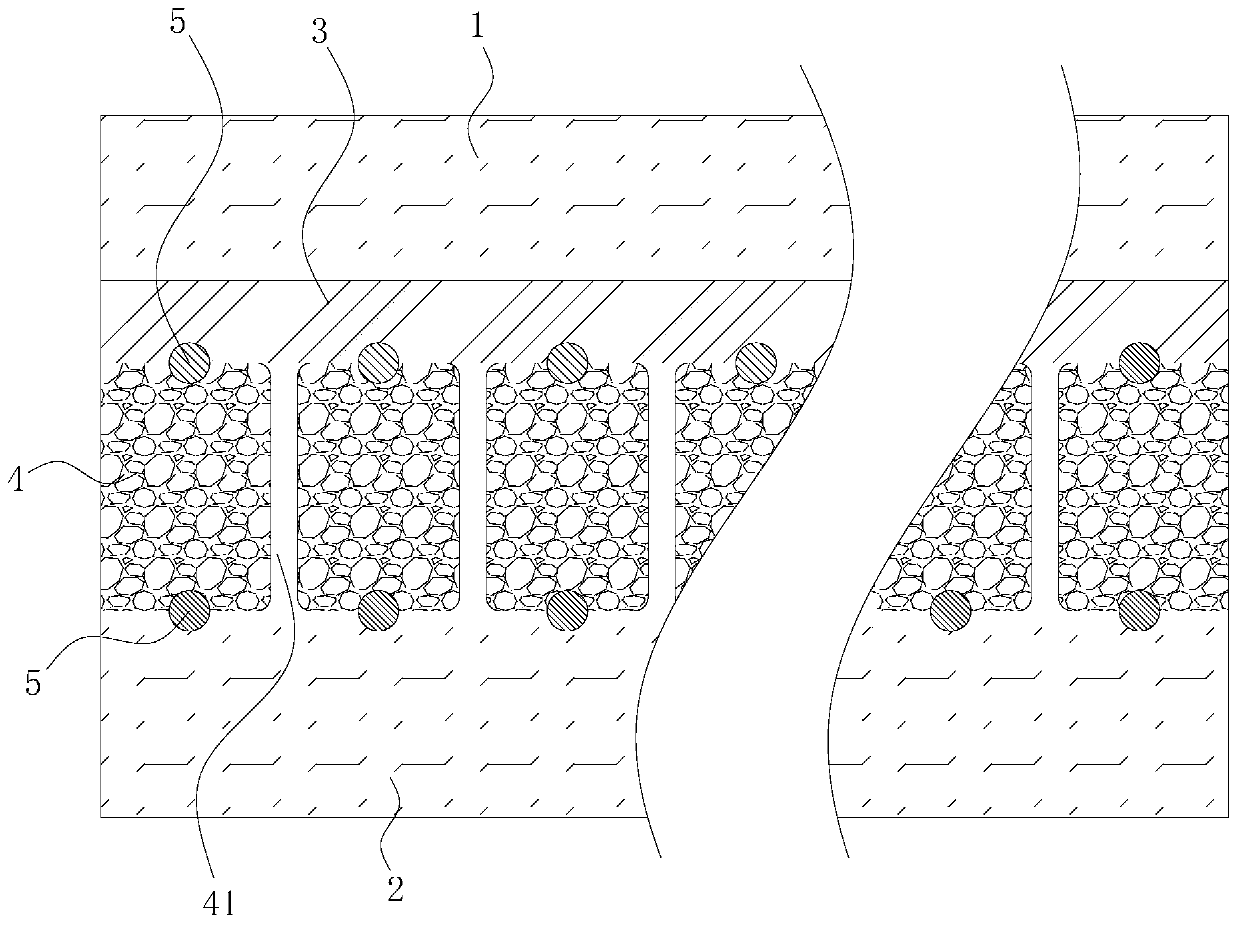

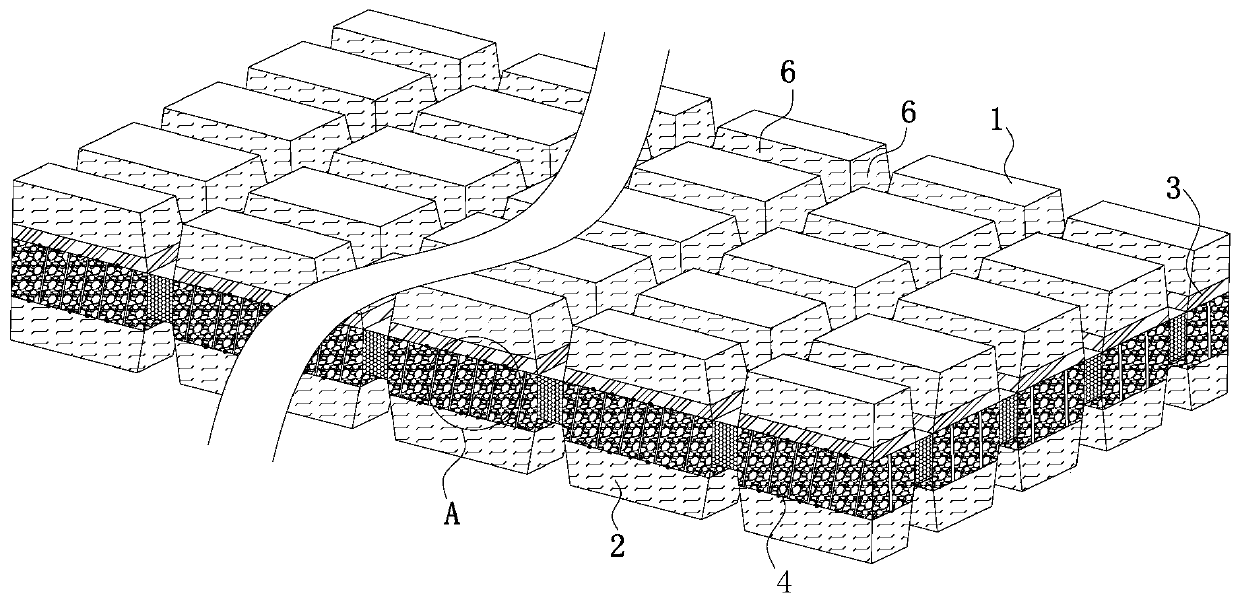

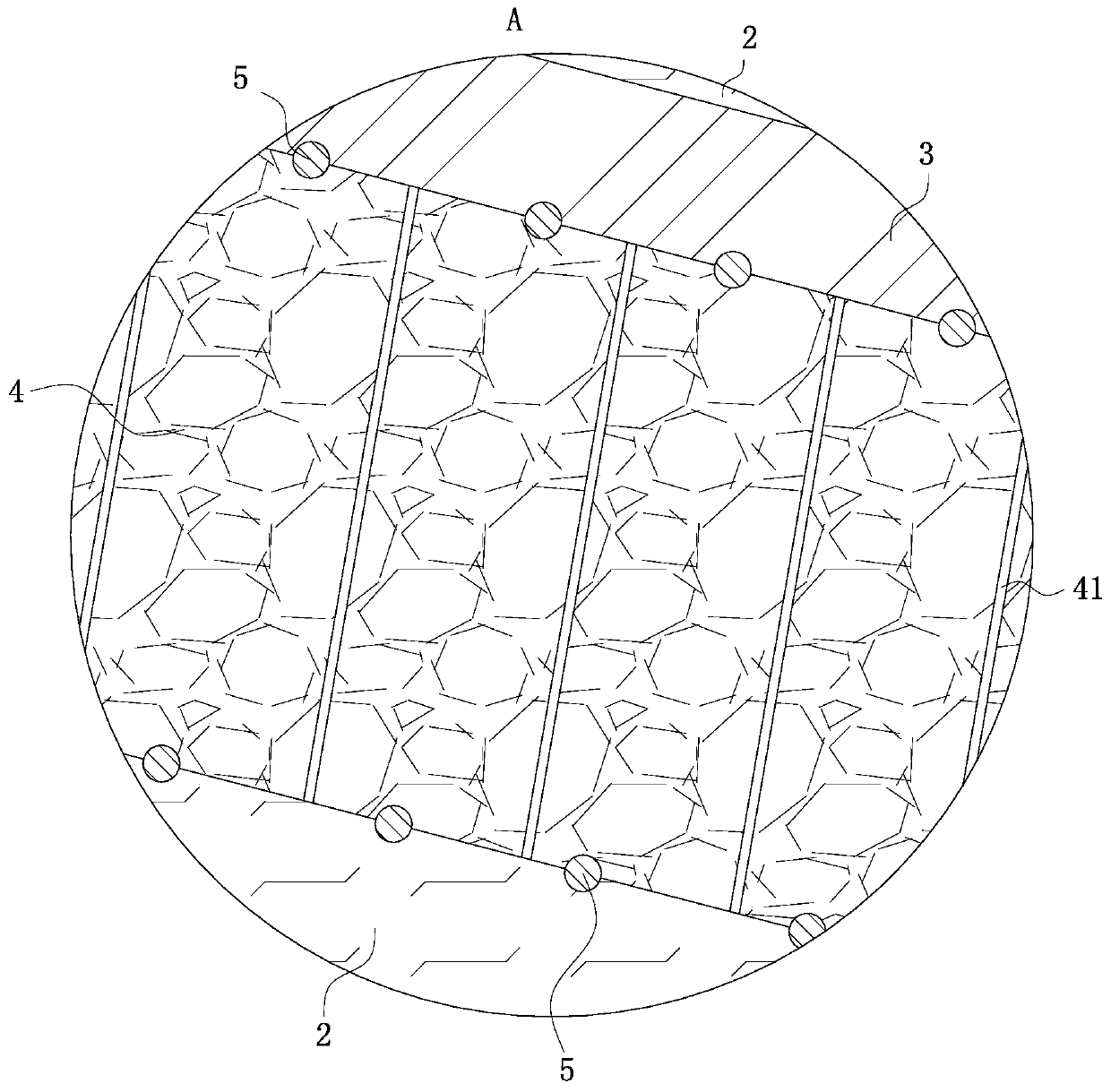

[0026] Such as Figure 1 to Figure 3 As shown, a kind of medical sanitary non-woven fabric of the present invention comprises a surface layer 1, an intermediate layer 4 and a contact layer 2, the surface layer 1 is above the intermediate layer 4; the contact layer 2 is below the intermediate layer 4; The surface layer 1 is a non-woven fabric with a thickness of 12-14 g / m 2 ; The contact layer 2 is a non-woven fabric with a thickness of 10-12g / m 2 ; The middle layer 4 is a polymer water-absorbing resin with a thickness of 18-20g / m 2 ;

[0027] When working, the contact layer 2 of the non-woven fabric is used as the use surface to cover the wound or the appliance that needs to be in contact. After the non-woven fabric is covered, the interstitial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com