Graphene/polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of graphene/polylactic acid composite material and its preparation, can solve the problems of insufficient notched impact strength, unobvious impact toughness, poor heat resistance of composite materials, etc., and achieve easy mass production , good electrical properties, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

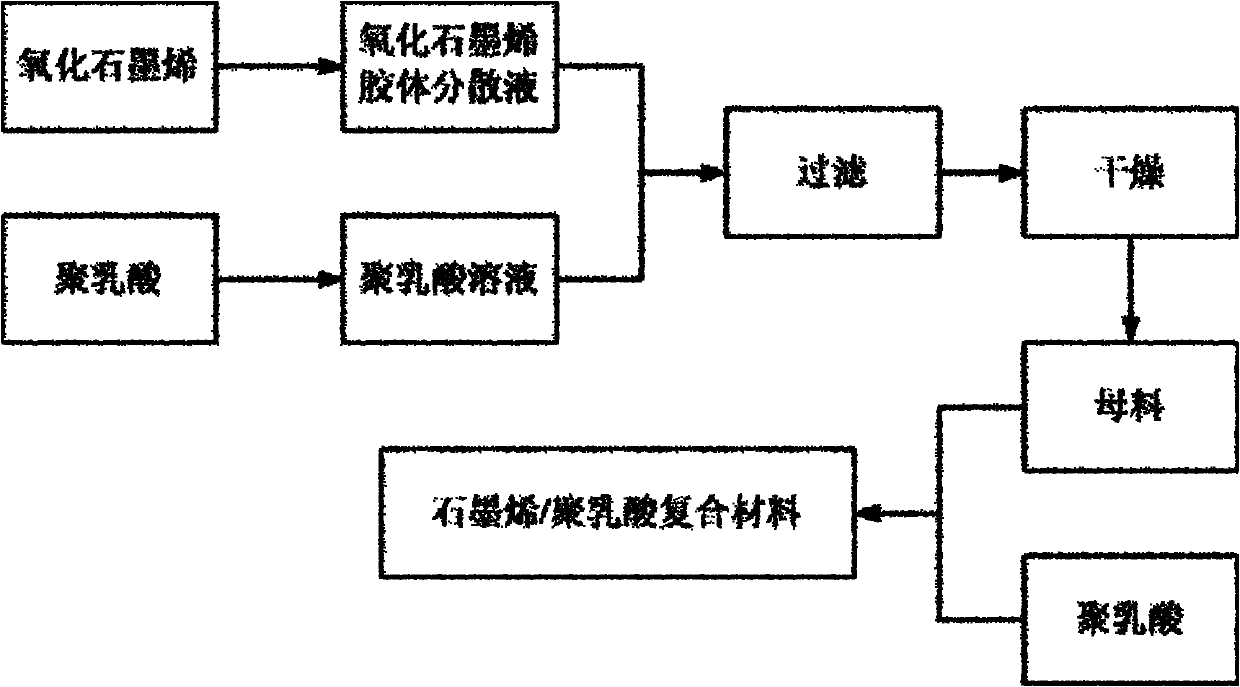

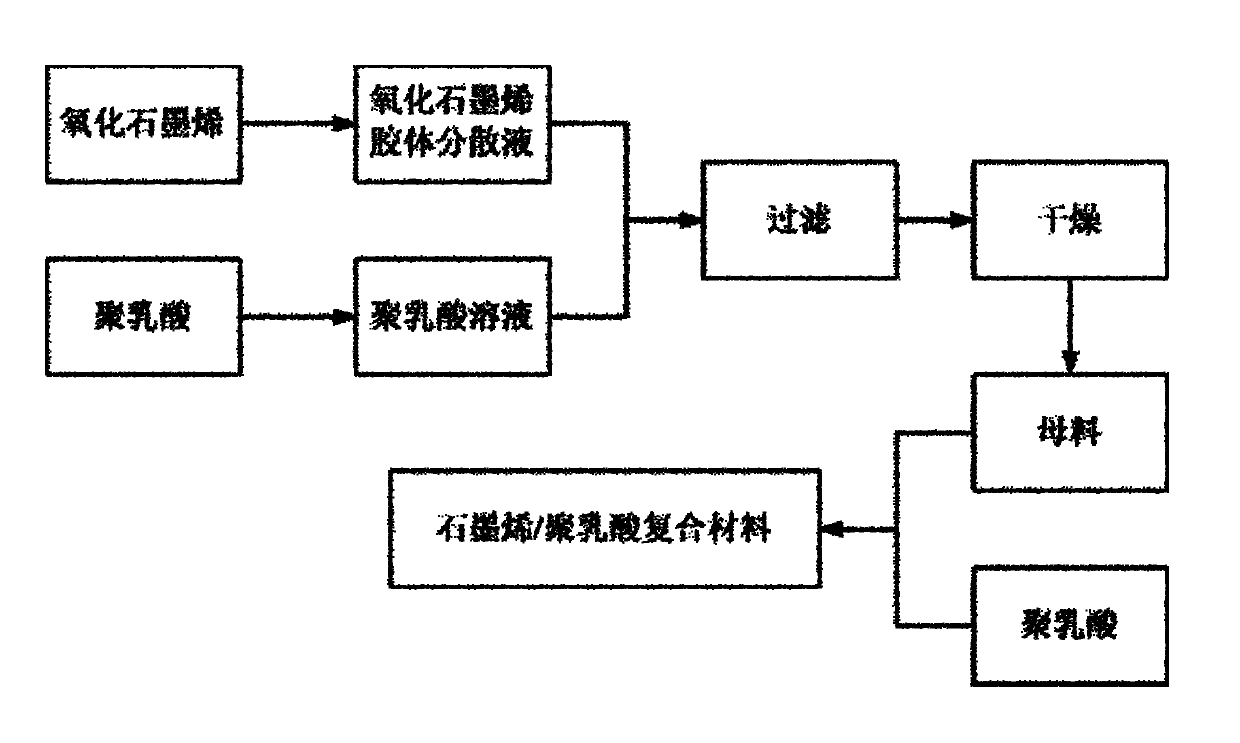

[0029] The present invention also provides a kind of preparation method of graphene / polylactic acid composite material, comprises the following steps:

[0030] a) dispersing graphene oxide in water to obtain a graphene oxide dispersion;

[0031] b) under the condition of stirring, adding the polylactic acid solution into the graphene oxide dispersion, leaving the uniformly stirred mixed solution to stand for layering, and obtaining the masterbatch after filtering;

[0032] c) blending the masterbatch with polylactic acid to obtain a graphene / polylactic acid composite material.

[0033] Similar to graphene, graphene oxide is a material composed of carbon six-membered rings with a two-dimensional monoatomic layer planar structure, and is prone to agglomeration. In the present invention, firstly, graphene oxide is dispersed in water to prepare a graphene oxide dispersion liquid. In order to disperse the graphene oxide uniformly, the present invention preferably adopts an ultras...

Embodiment 1

[0054] Ultrasonic disperse graphene oxide in deionized water to prepare a 0.3 mg / mL graphene oxide colloidal dispersion; dissolve polylactic acid in chloroform under heating and stirring to prepare a 0.1 g / mL polylactic acid solution; Under the conditions of 60°C and vigorous stirring, slowly add 1000mL polylactic acid solution into 1000mL graphene oxide colloidal dispersion liquid, stir at constant temperature 60°C for 5h, let the obtained mixture stand for layers, filter out the lower precipitate, and dry , get the masterbatch;

[0055] 30g of masterbatch and 30g of polylactic acid were added to an internal mixer, and melt-blended at 170°C to obtain a graphene / polylactic acid composite material. In the graphene / polylactic acid composite material, graphene accounts for about 0.15% by mass of polylactic acid;

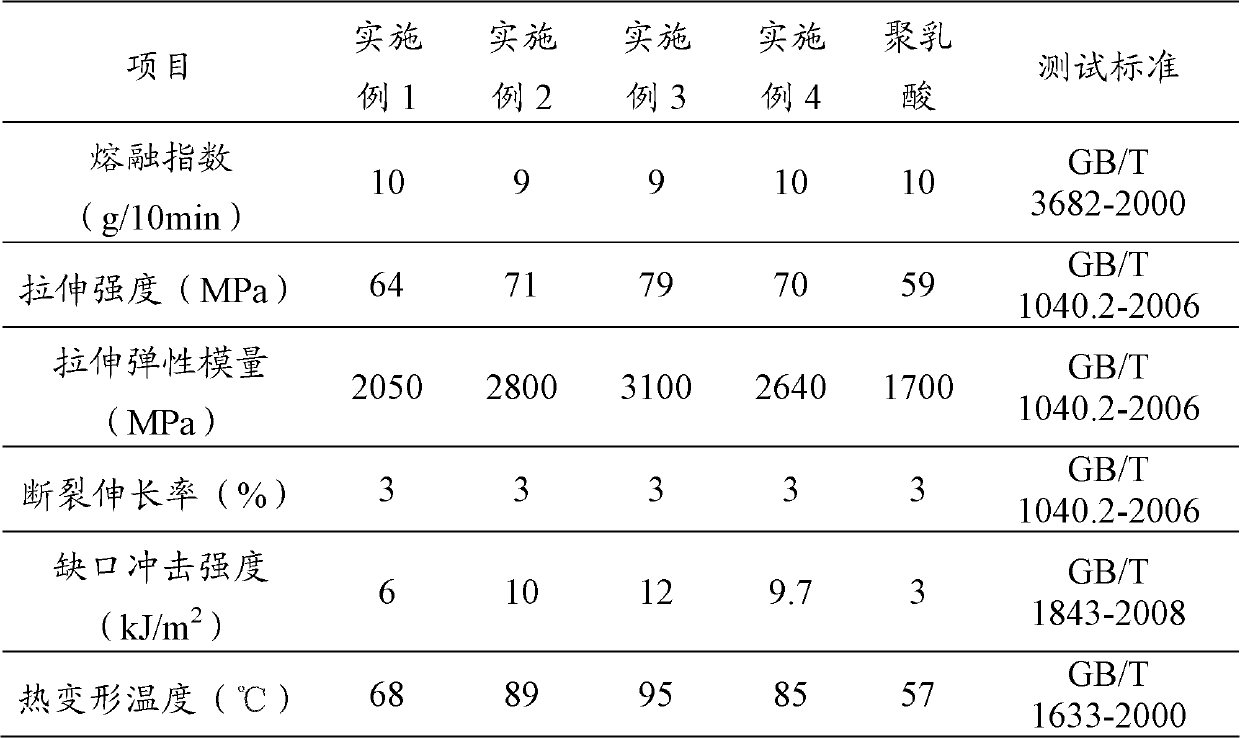

[0056] The performance test of the graphene / polylactic acid composite material is carried out, and the results are shown in Table 1. Table 1 is the performance paramet...

Embodiment 2

[0058] Graphene oxide was ultrasonically dispersed in deionized water to prepare a 2 mg / mL graphene oxide colloidal dispersion; polylactic acid was dissolved in chloroform under heating and stirring to prepare a 0.1 g / mL polylactic acid solution; Under the conditions of 60°C and vigorous stirring, slowly add 1000mL of polylactic acid solution to 1000mL of graphene oxide colloidal dispersion liquid, stir at a constant temperature of 60°C for 5h, let the obtained mixture stand for layers, filter out the lower layer of precipitate, after drying, get the masterbatch;

[0059] 30g of masterbatch and 30g of polylactic acid were added to an internal mixer, and melt-blended at 170°C to obtain a graphene / polylactic acid composite material. In the graphene / polylactic acid composite material, the mass percentage of graphene in polylactic acid is about 0.99%;

[0060] The performance test of the graphene / polylactic acid composite material is carried out, and the results are shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com