Steel surface composite coating and preparation method thereof

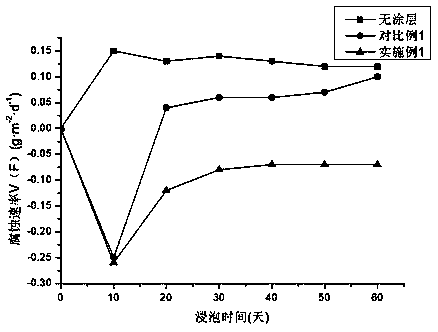

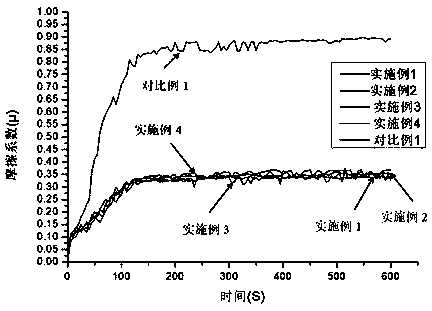

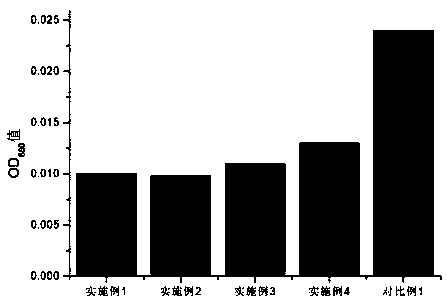

A composite coating and steel surface technology, applied in the field of steel anti-corrosion, can solve the problems of weak bonding force of steel substrate, lower tribological performance and corrosion resistance of epoxy resin coating, coating erosion, etc., and achieve excellent corrosion resistance Excellent performance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A composite coating on a steel surface, comprising the following raw materials: 2g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, 1.3g of graphene oxide, water-based acrylic modified 30 g of epoxy resin, 2 g of methyl tetrahydrophthalic anhydride, 2 g of methyl nadic anhydride, 1 g of pyromellitic anhydride.

[0032] The preparation method of above-mentioned composite coating on steel surface, comprises the following steps:

[0033] S1. Weigh 2 g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, dissolve it in an appropriate amount of isopropanol and stir until completely dissolved;

[0034] S2. Weigh 1.3 g of graphene oxide and dissolve it in an appropriate amount of deionized water, heat in a water bath at 40° C. and perform magnetic stirring until the graphene oxide is completely dissolved;

[0035] S3. Slowly drop the graphene aqueous solution in step S2 into the 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine isopropanol sol...

Embodiment 2

[0040] A composite coating on steel surface, comprising the following raw materials: 3g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, 1.7g of graphene oxide, water-based acrylic modified 40 g of epoxy resin, 3 g of methyl tetrahydrophthalic anhydride, 3 g of methyl nadic anhydride, 2 g of pyromellitic anhydride.

[0041] The preparation method of above-mentioned composite coating on steel surface, comprises the following steps:

[0042] S1. Weigh 3 g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, dissolve it in an appropriate amount of isopropanol and stir until completely dissolved;

[0043] S2. Weigh 1.7 g of graphene oxide and dissolve it in an appropriate amount of deionized water, heat in a water bath at 40°C and perform magnetic stirring until the graphene oxide is completely dissolved;

[0044] S3. Slowly drop the graphene aqueous solution in step S2 into the 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine isopropanol solutio...

Embodiment 3

[0049] A composite coating on steel surface, comprising the following raw materials: 2.5 g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, 1.5 g of graphene oxide, water-based acrylic modified 35 g of permanent epoxy resin, 2.5 g of methyl tetrahydrophthalic anhydride, 2.5 g of methyl nadic anhydride, and 1.5 g of pyromellitic anhydride.

[0050] The preparation method of above-mentioned composite coating on steel surface, comprises the following steps:

[0051] S1. Weigh 2.5 g of 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-triazine, dissolve it in an appropriate amount of isopropanol and stir until completely dissolved;

[0052] S2. Weigh 1.5 g of graphene oxide and dissolve it in an appropriate amount of deionized water, heat in a water bath at 40° C. and perform magnetic stirring until the graphene oxide is completely dissolved;

[0053] S3. Slowly drop the graphene aqueous solution in step S2 into the 2-tert-butylamino-4-ethylamino-6-methylthio-1,3,5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com