Preparation method of cationic polyacrylamide aqueous emulsion

A polyacrylamide and acrylamide technology, applied in the field of polymer synthesis, can solve the problems of easy to obtain gel products, polymerization failure, etc., and achieve the effects of environment and operator friendliness, good stability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Synthesis of reactive dispersant Disp-1

[0033]Add 150kg of dimethyl diallyl ammonium chloride and 12kg of styrene into the two-cubic reaction kettle, add 550kg of ethanol to dissolve; feed nitrogen into the reaction kettle to remove oxygen for 20 minutes; add 3.5kg of mercaptoethonium hydrochloride and 280 g of azobisisobutyronitrile. The reaction was stirred at 70°C for 4 hours. Add sodium hydroxide solution to adjust the pH value to 7.0, remove most of the solvent under reduced pressure, precipitate with 60 kg of ether three times, centrifuge, and dry to obtain a white solid macromonomer precursor;

[0034] Add 100kg of the above-mentioned macromonomer precursor and 460kg of tetrahydrofuran to the reaction kettle, and dissolve evenly; dissolve 18.2kg of acryloyl chloride in 80kg of tetrahydrofuran, add it to the above solution under stirring, and add 50kg of 30% sodium carbonate aqueous solution dropwise at the same time , using a jacketed reactor with a refri...

Embodiment 2

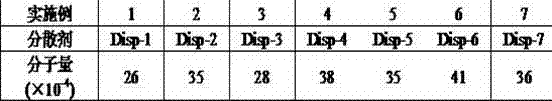

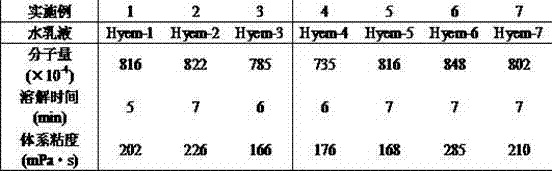

[0038] Same as Example 1, the difference is that the amount of styrene in step (1) is changed to 5 kg, and the amount of mercaptoethonium hydrochloride is changed to 2.0 kg to obtain the corresponding product dispersant Disp-2. The molecular weight test results are shown in Table 1; The reactive dispersant Disp-1 in step (2) was changed to Disp-2 to obtain the CPAM aqueous emulsion product Hyem-2, and its performance test results are shown in Table 2.

Embodiment 3

[0040] (1) Synthesis of reactive dispersant Disp-3

[0041] Add 150 kg of methyl propyl diallyl ammonium chloride and 15 kg of styrene into two cubic reaction kettles, add 550 kg of ethanol to dissolve; feed nitrogen into the reaction kettle to remove oxygen for 20 minutes; add 3.3 kg of mercaptoethonium hydrochloride and 280 g of azobisisobutyronitrile. The reaction was stirred at 70°C for 4 hours. Add sodium hydroxide solution to adjust the pH value to 7.0, remove most of the solvent under reduced pressure, precipitate with 60 kg of ether three times, centrifuge, and dry to obtain a white solid macromonomer precursor;

[0042] Add 100kg of the above-mentioned macromonomer precursor and 460kg of tetrahydrofuran to the reaction kettle, and dissolve evenly; dissolve 20.1kg of acryloyl chloride in 80kg of tetrahydrofuran, add it to the above solution under stirring, and add 55kg of 30% sodium carbonate aqueous solution dropwise at the same time , use a jacketed reactor with re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com