Patents

Literature

89results about How to "Does not affect optical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

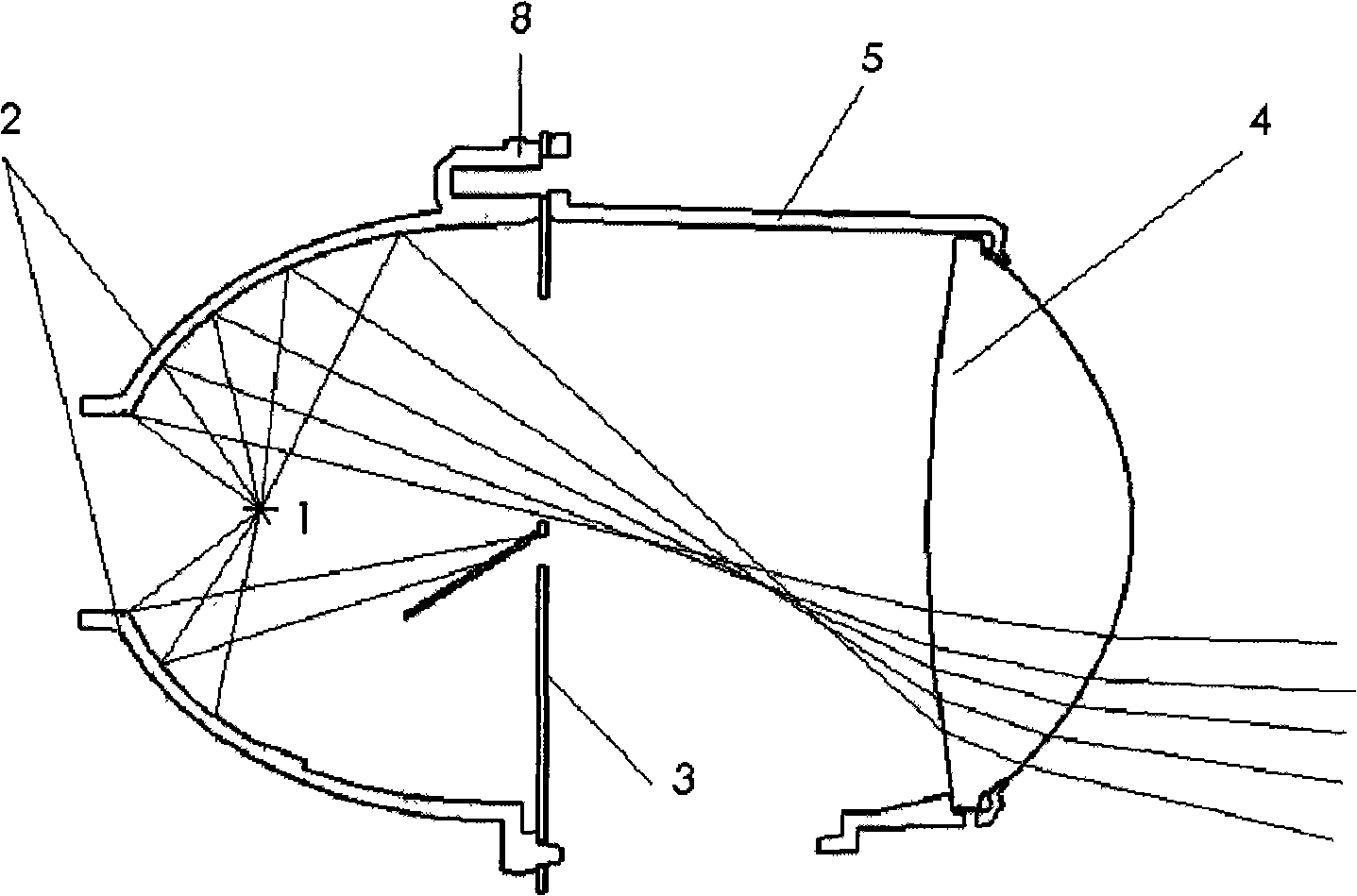

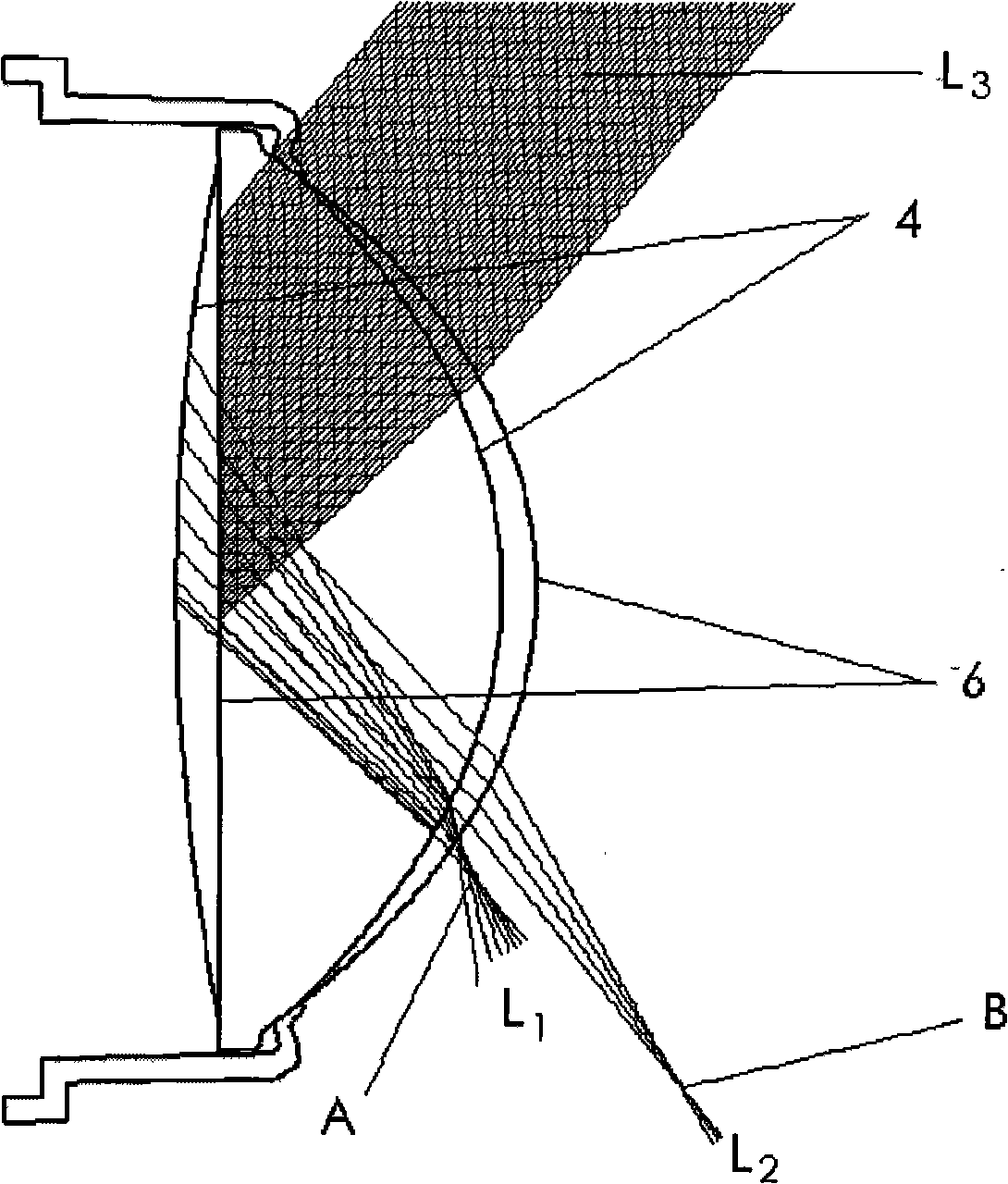

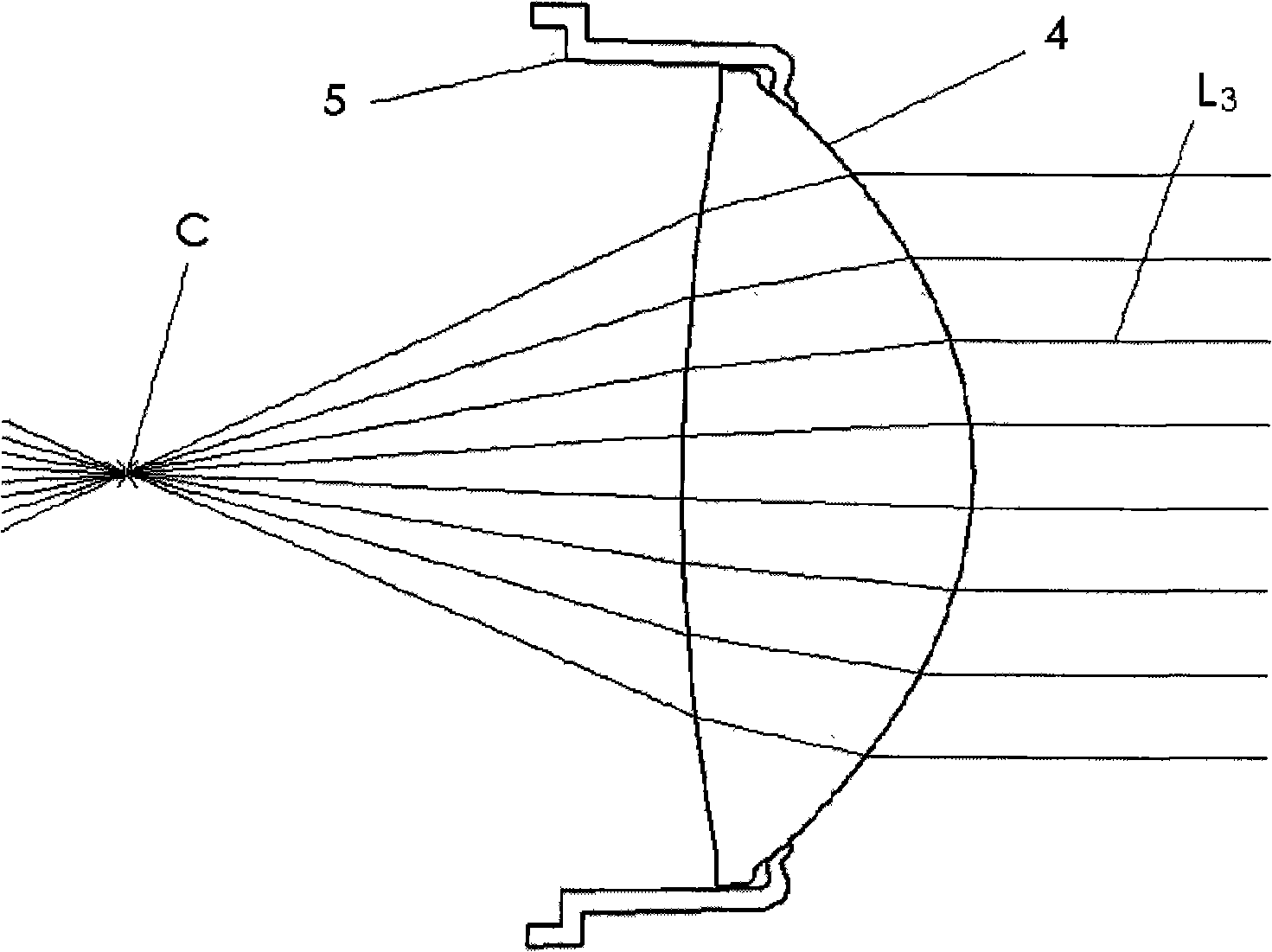

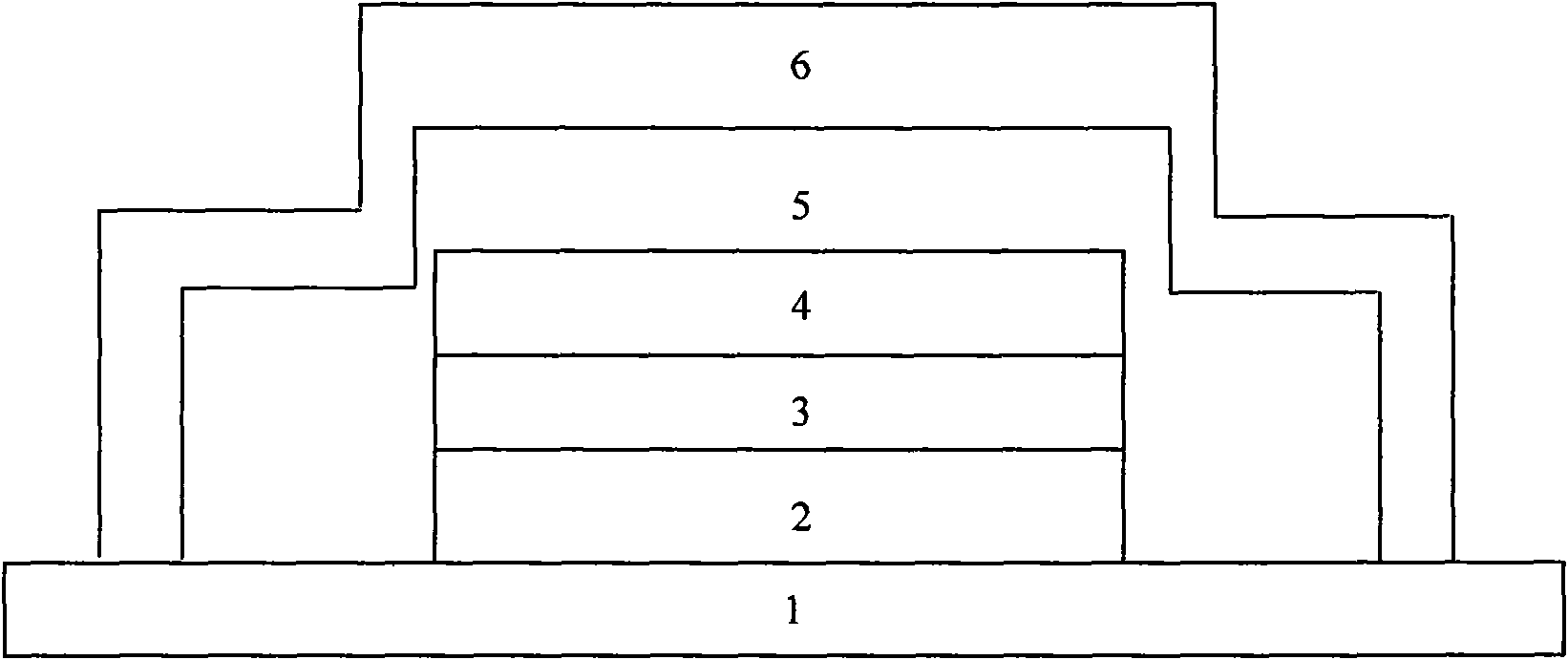

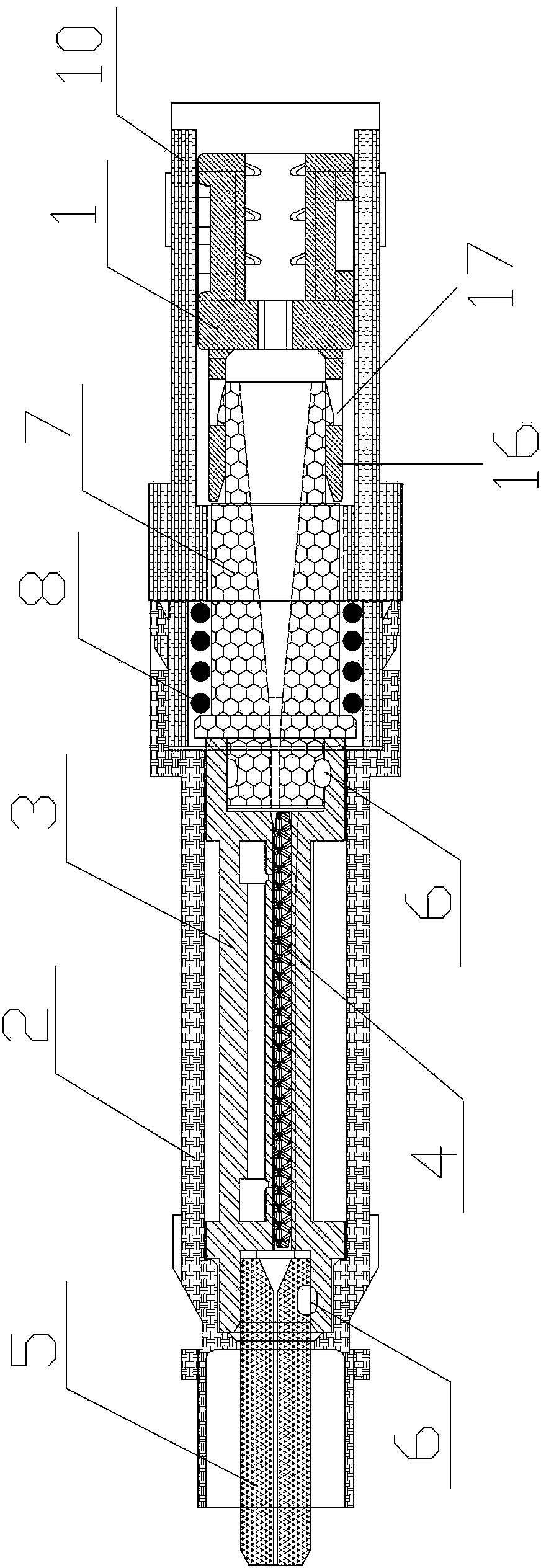

Automobile front shining lamp based on double-convex lens

The invention provides a car head light based on the biconvex lens, characterized in that the main light source is the discharge lamp or the halogen lamp, and the car head light is composed of a free-form surface reflector, a light screen, a biconvex lens, a lens holder and the like. The car head light based on the biconvex lens of the invention adopts the free-form surface reflector, to make the light source emergence flock. The focus of the biconvex lens is set near the dead line of the light screen to make the dead line distinct. The biconvex lens design can avoid the damage of the car lighting circle, the matched mirror or the other parts on the car caused by the light focus of the sunshine. The invention reduces the risk of the light design, advances the safety, the stability and the service life, has strong universality, which is suitable for a plurality of models of cars.

Owner:HASCO VISION TECHNOLOGY CO LTD

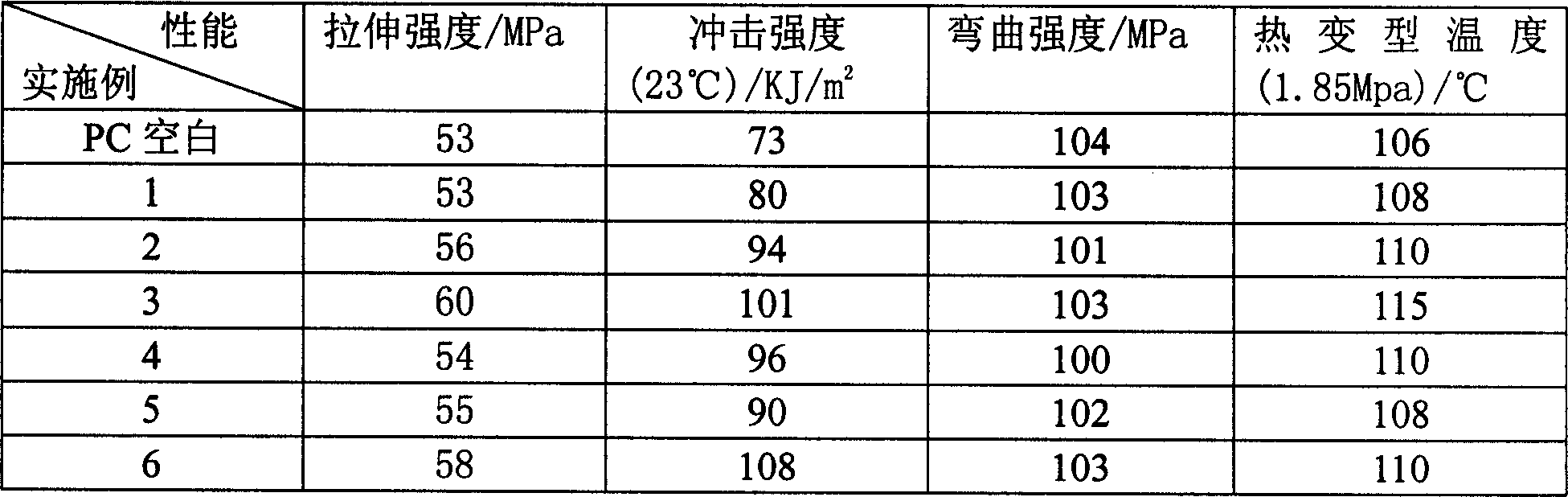

Acrylic ester modifier and preparation and use in bisphenol A poly carbonate

The acrylic ester modifier is prepared through drying nano silica, nano calcium carbonate, nano zinc oxide, nano zinc sulfide, nano titania or nano cadmium sulfide, adding silane as coupling agent and xylene to react under the xylene refluxing temperature, letting stand to separate lower layer matter, drying the lower layer matter to obtain nano alkylated particle as the acrylic ester modifier. The nano alkylated particle is mixed with emulsifier and deionized water, and through heating under nitrogen protection to 70 deg.c, dropping initiator, acrylic ester monomer to react, cooling, spray drying, modified acrylic ester is obtained. The weight ratio between modifier and the acrylic ester monomer is 2-10 to 90-98. The present invention can raise the performance of polymer.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

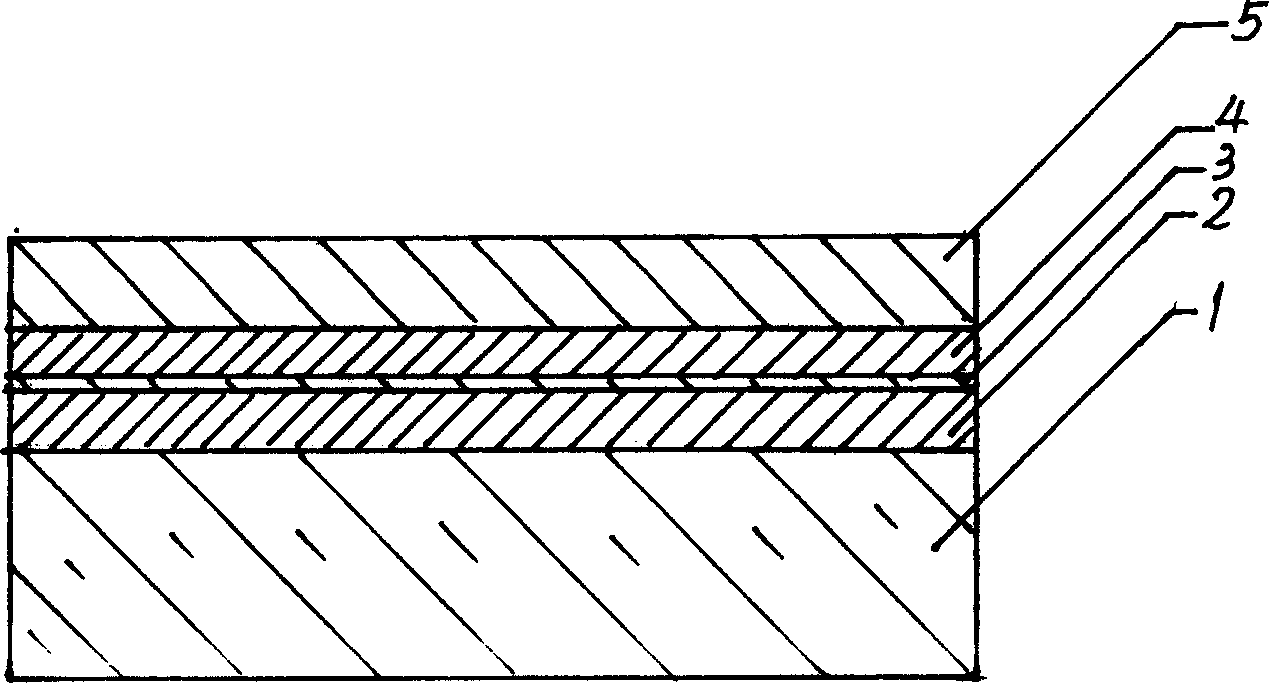

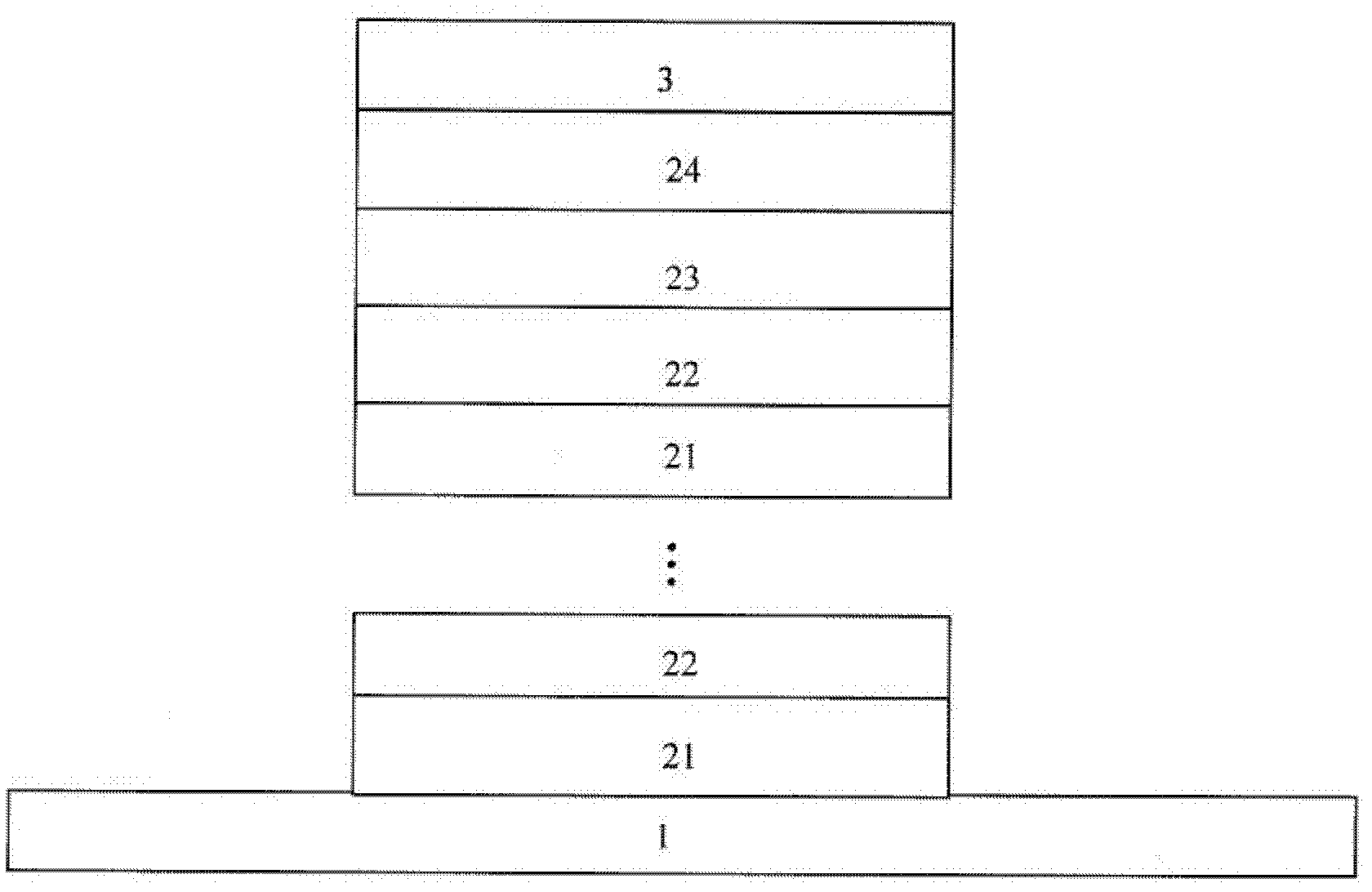

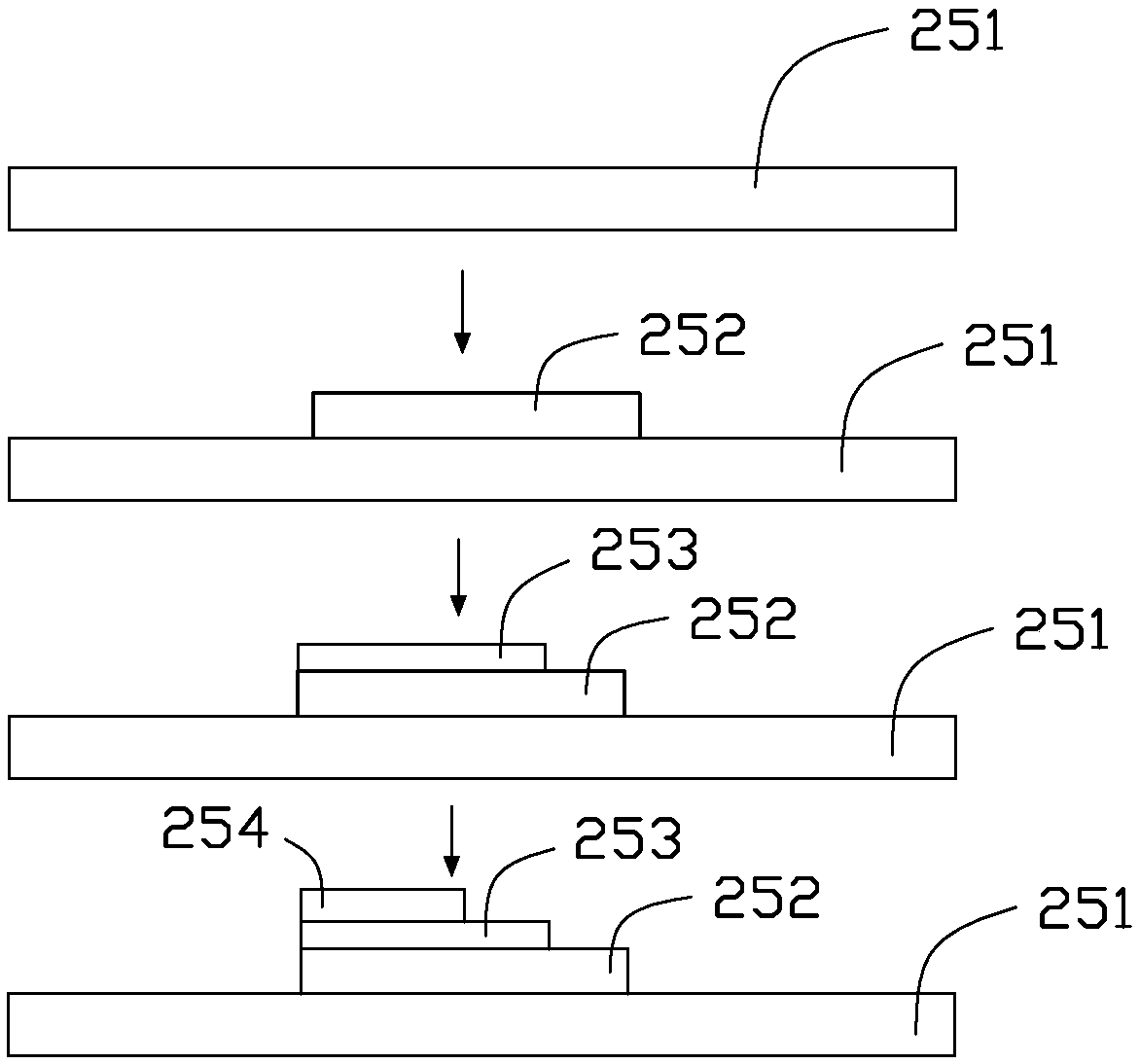

Compound encapsulation structure and method of organic electroluminescence device

InactiveCN101582489AHydrophilicPlay a protective effectSemiconductor/solid-state device detailsSolid-state devicesWater vaporOrganic electroluminescence

The invention relates to a new compound encapsulation structure and a method of an organic electroluminescence device. The compound encapsulation structure comprises a substrate and an ITO membrane, an electroluminescence material layer and an encapsulation layer which are overlaid on the substrate in sequence, wherein, the encapsulation layer is arranged on a metal layer and is used for retaining water vapor and oxygen. The inner side of the encapsulation layer is provided with a buffer layer which is used for assistant encapsulation and further retaining the water vapor and oxygen with the encapsulation layer together, thus forming the compound encapsulation structure. The preparation steps of the method include: (1) adopting vacuum evaporated LiF layer to prepare the buffer layer; and (2) preparing the encapsulation layer on the LiF layer. The compound encapsulation structure can improve the action of retaining the water vapor and oxygen, and the method is easy to operate with low cost.

Owner:SHANGHAI UNIV

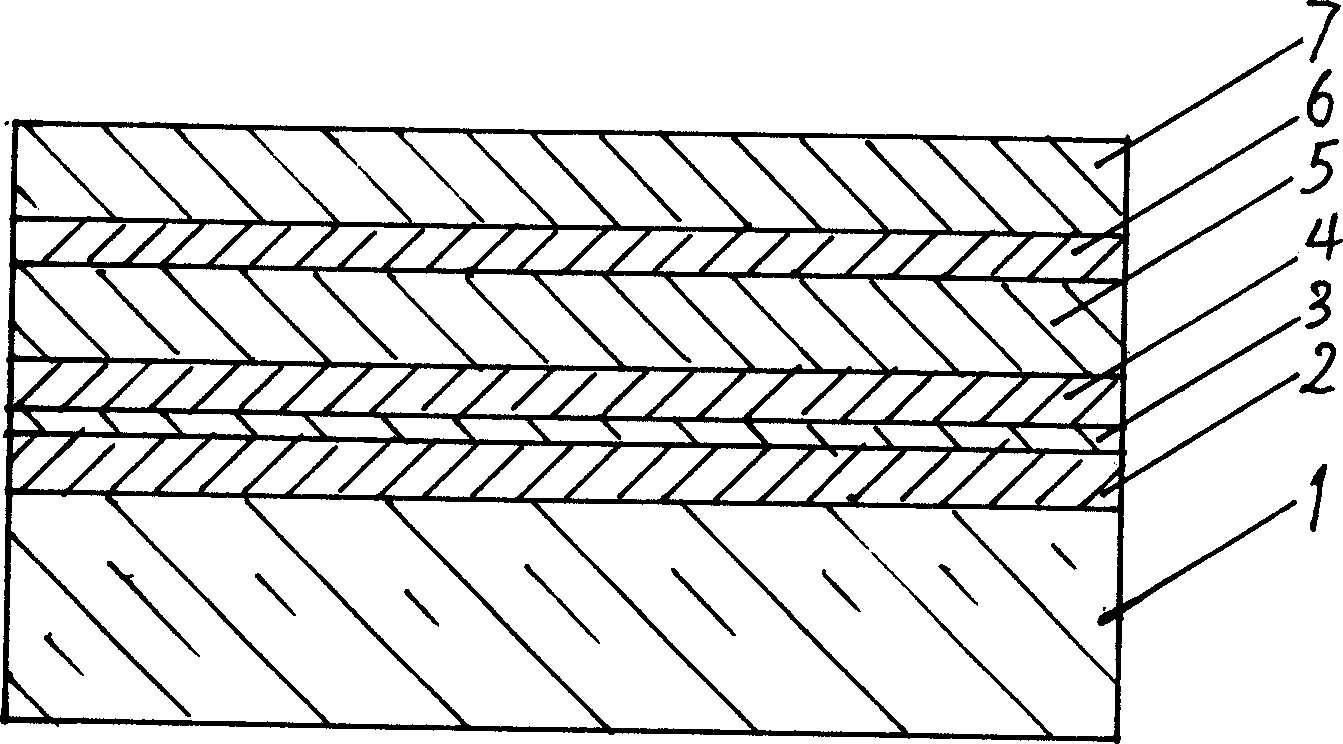

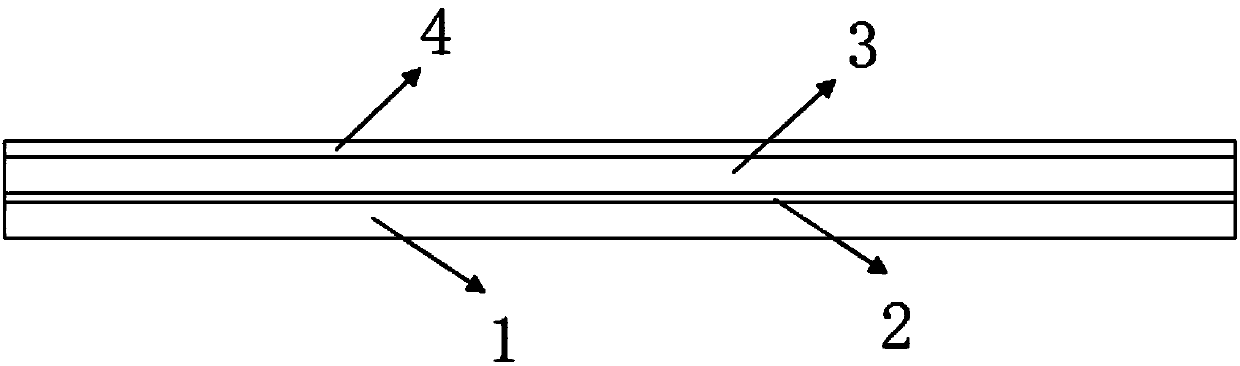

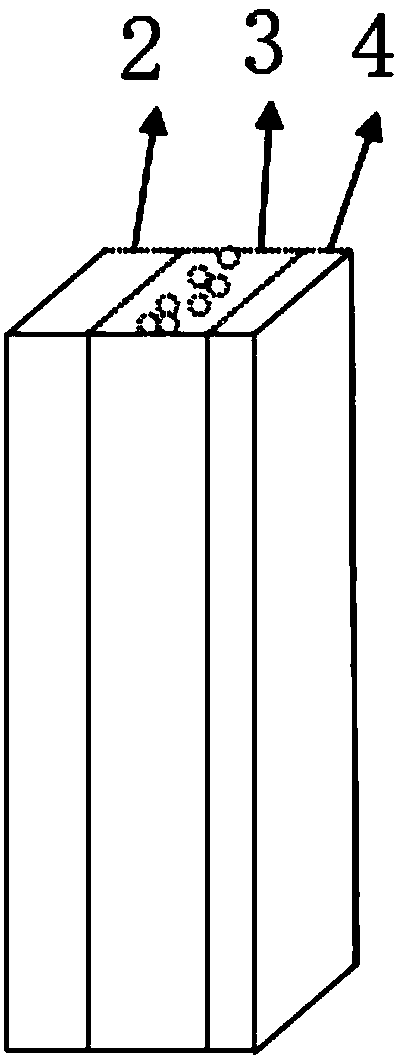

Quantum dot packaging body and application thereof

InactiveCN105565264AImprove water and oxygen barrier performanceImprove overall lifespanMaterial nanotechnologyIndividual molecule manipulationDisplay deviceQuantum dot

The present invention discloses a quantum dot packaging body which comprises a first packaging medium which is optically transparent and at least two quantum dot glass bodies dispersed in the first packaging medium. Each quantum dot glass body comprises glass located at the outer layer, a second packaging medium which is optically transparent and located at the inner layer, and at least one type of quantum dots dispersed in the second packaging medium. The first packaging medium consists of high polymer materials. By packaging the packaging body quantum dots in the glass body with a certain volume, the fragile disadvantages of glass tubes are avoided, and at the same time, a relative high luminous efficiency is kept. The present invention also discloses a light-emitting device, a backlight module and a display device. The present invention also discloses a preparation method of the quantum dot packaging body.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

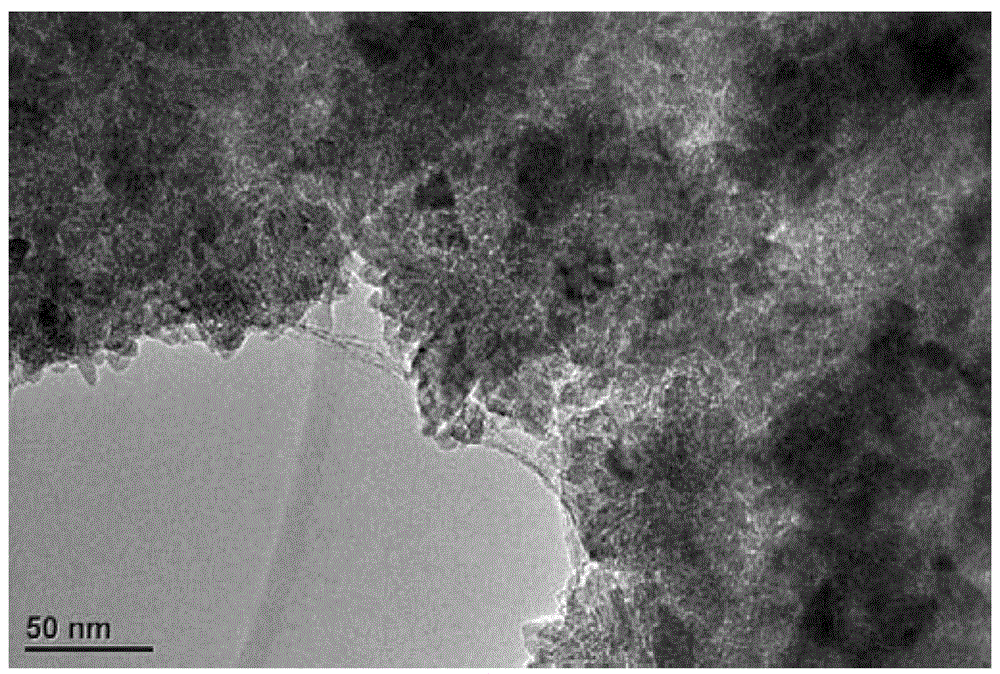

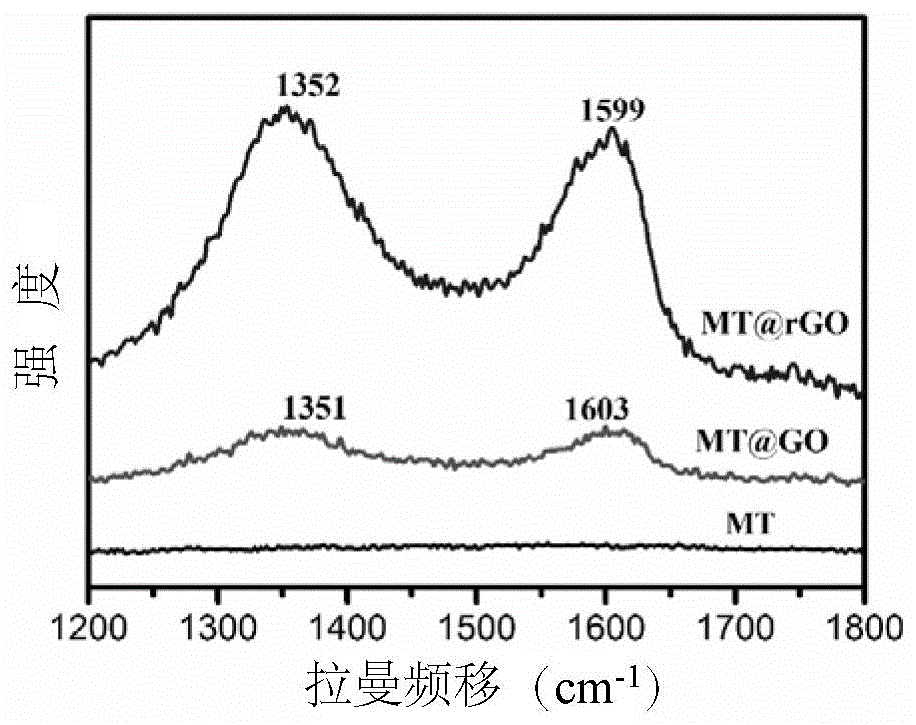

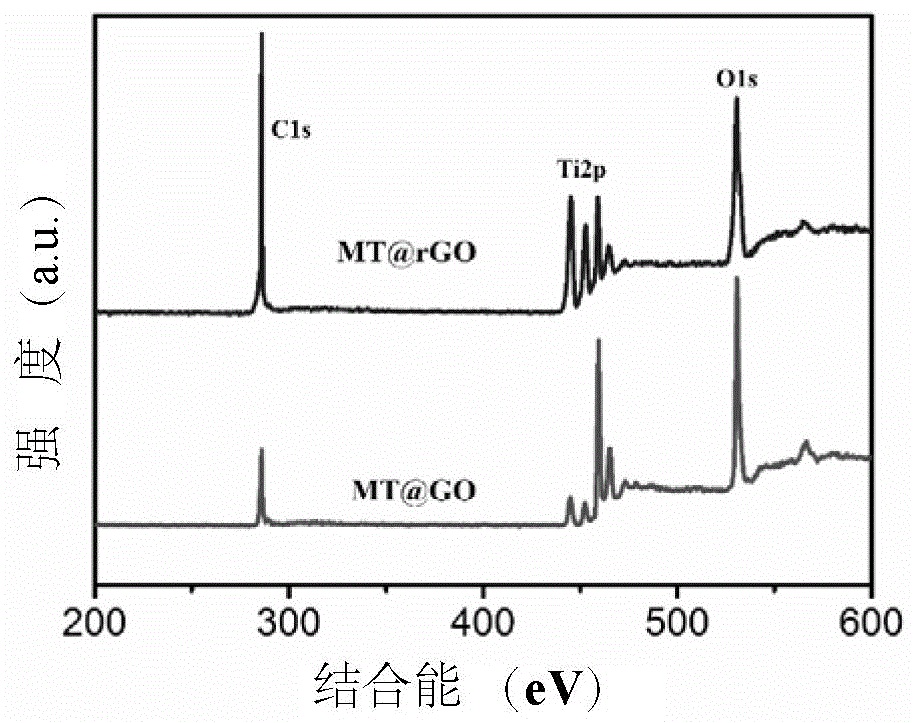

Method for preparing graphene-based conductive pearlescent pigment

ActiveCN105838115AMild and controllable reduction conditionsLow reaction temperaturePigment preparation by wet methodsInorganic pigment treatmentPolymer sciencePigment dispersion

The invention relates to a method for preparing graphene-based conductive pearlescent pigment .The method comprises the steps of mixing oxidized graphene solution with pearlescent pigment dispersion liquid, and heating and stirring the mixed solution for one hour to one week at 20-100 DEG C to obtain oxidized graphene-based pearlescent pigment; preparing oxidized graphene-based pearlescent pigment dispersion liquid, adding a metallic reducing agent, conducting uniform mixing, and then conducting heating and stirring for 10 seconds to 24 hours at 10-100 DEG C, so that the graphene-based conductive pearlescent pigment is obtained .The method is convenient to operate, high in efficiency, environmentally friendly, free of pollution, low in cost and capable of achieving large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

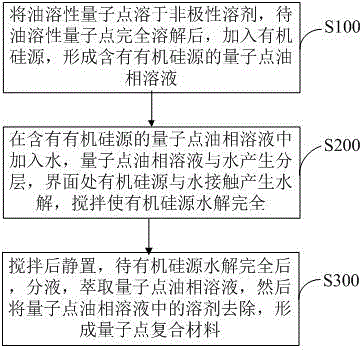

Quantum dot composite material and preparation method thereof and quantum dot LED

InactiveCN106753333AImprove luminous efficiencyReduced luminous efficiencyLuminescent compositionsSemiconductor devicesQuantum dotOil phase

The invention discloses a quantum dot composite material and a preparation method thereof and a quantum dot LED. The method comprises the steps of making oil soluble quantum dots dissolve in non-polar solvent, after the oil soluble quantum dots completely dissolve, adding organic silicon source to form a quantum dot oil phase solution containing the organic silicon source, adding water into the quantum dot oil phase solution containing the organic silicon source, wherein the different layers are generated between the quantum dot oil phase solution and the water, and at the interface the organic silicon source and the water make contact to generate hydrolysis reaction; stirring to make the organic silicon source completely hydrolyzed; after stirring, keeping the solution static to separate the solution, extracting the quantum dot oil phase solution, removing the solvent in the quantum dot oil phase solution to form the quantum dot composite material. The preparation process of the quantum dot composite material neither needs specialized acid and alkaline environments, nor reduces the luminescent efficiency of the quantum dots. In the preparation process of an LED device, the material does not need to be packaged with organic resins, therefore the preparation process of the LED devices is simplified, the cost is reduced, and the service life of the LED devices is prolonged.

Owner:TCL CORPORATION

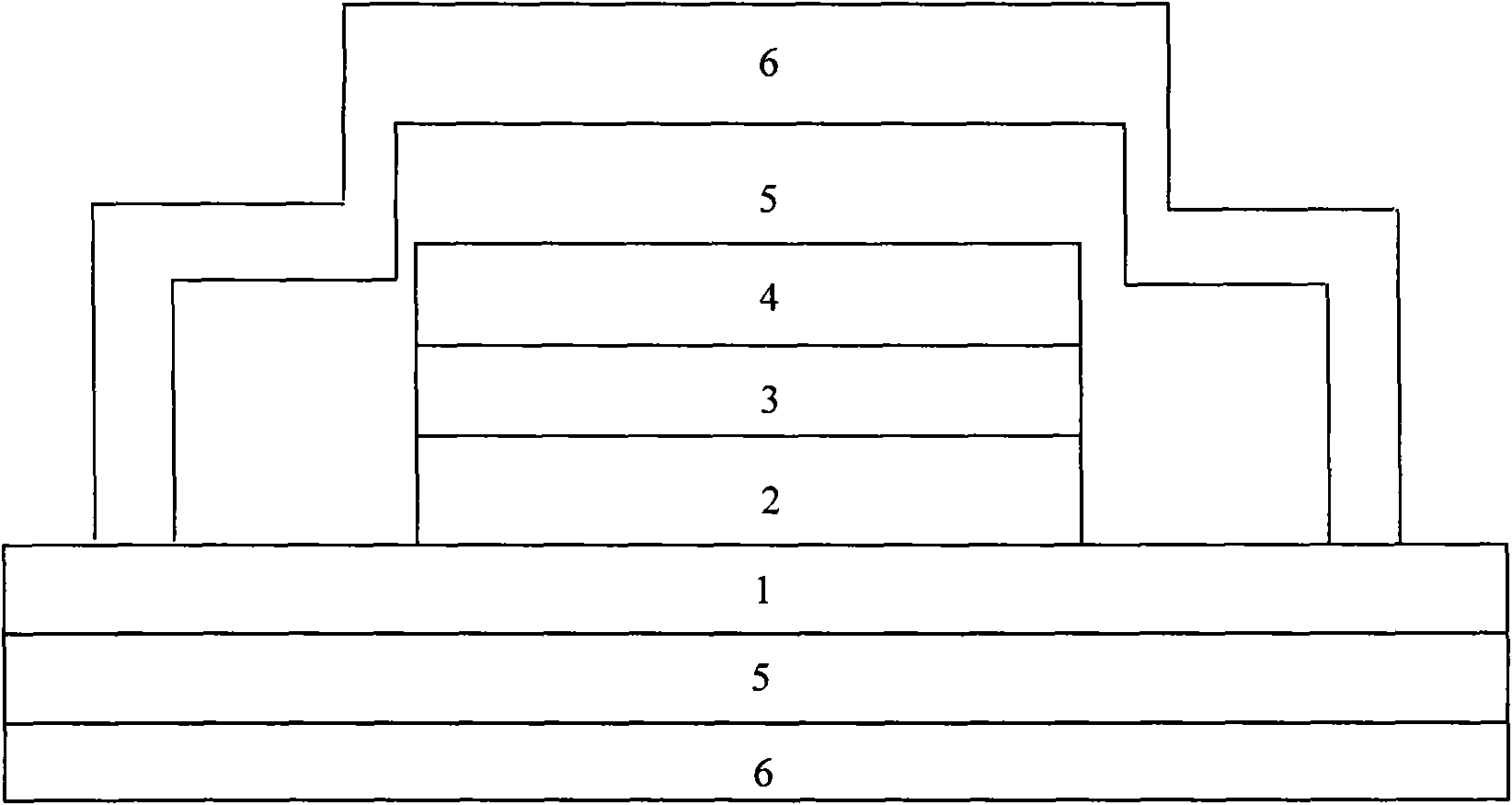

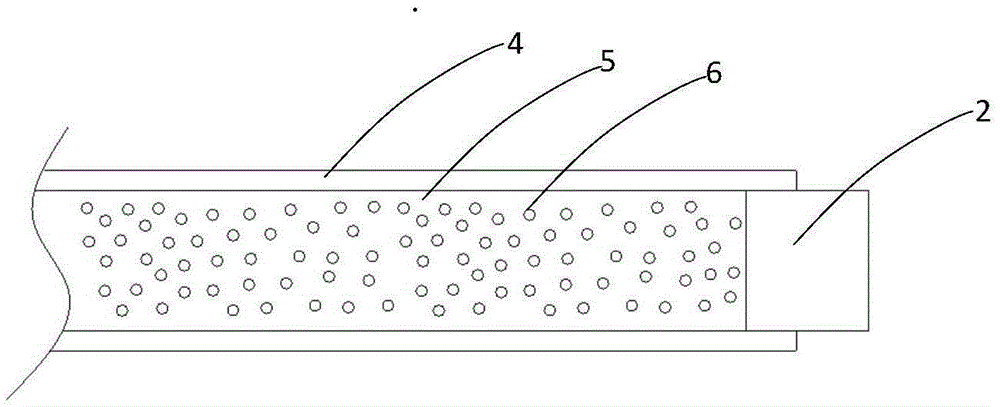

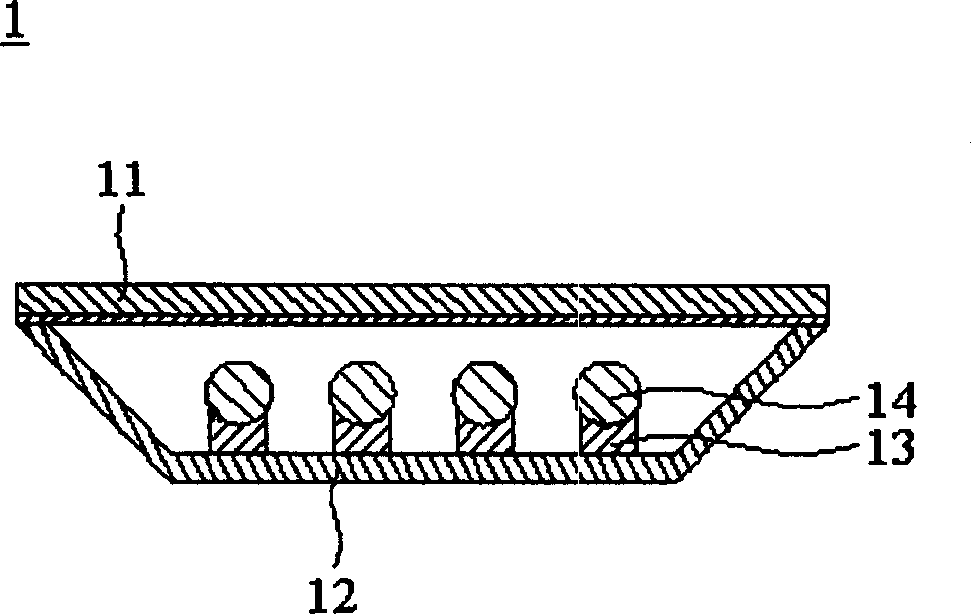

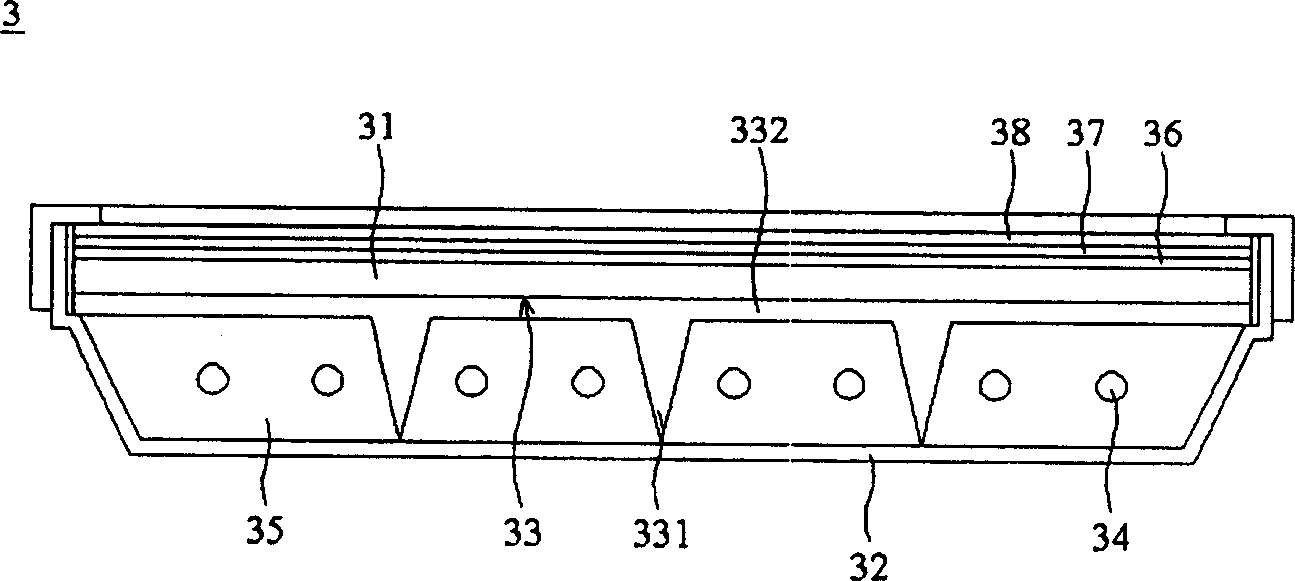

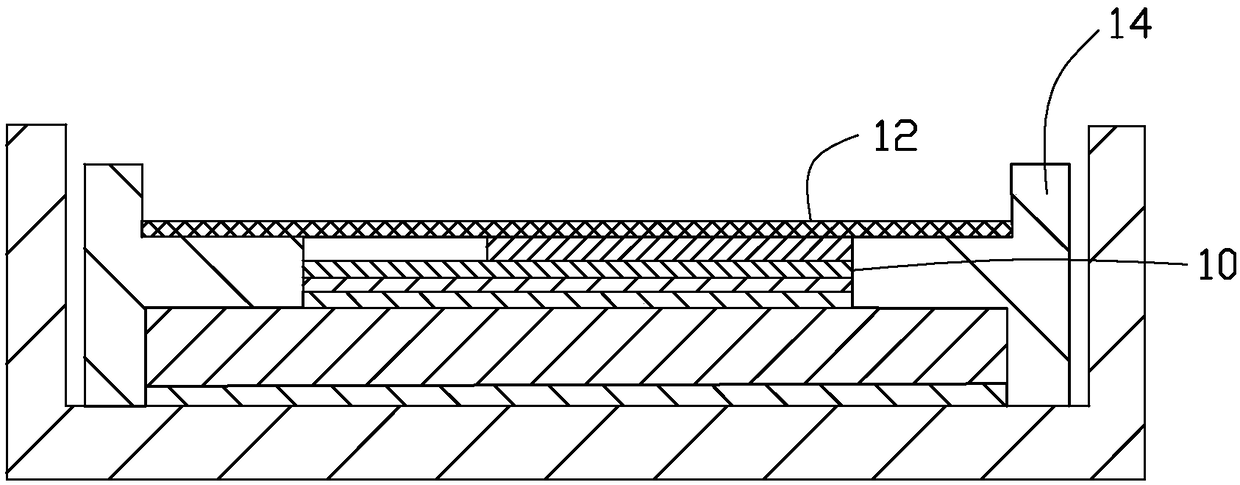

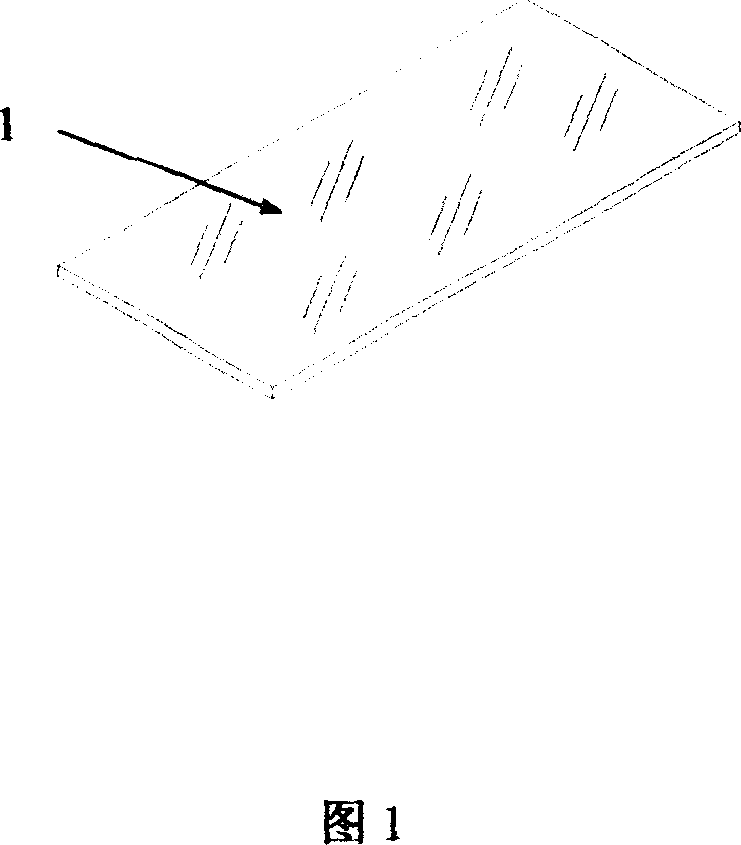

Back-to-light module

InactiveCN1591126AAvoid bending deformationDoes not affect optical performanceDiffusing elementsNon-linear opticsEngineeringLight source

The present invention relates to a downward-vertical type backlight moudle. It includes a scattering plate, a reflecting plate, several light sources and at least one transmission supporting frame placed betwwen the scattering plate and reflecting plate. The reflecting plate is connected on the scattering plate to form a cavity, and the light source is placed in the described cavity, the utilization of the above-mentioned transmission supporting frame can prevent the scattering plate from producing curved deformation.

Owner:AU OPTRONICS CORP

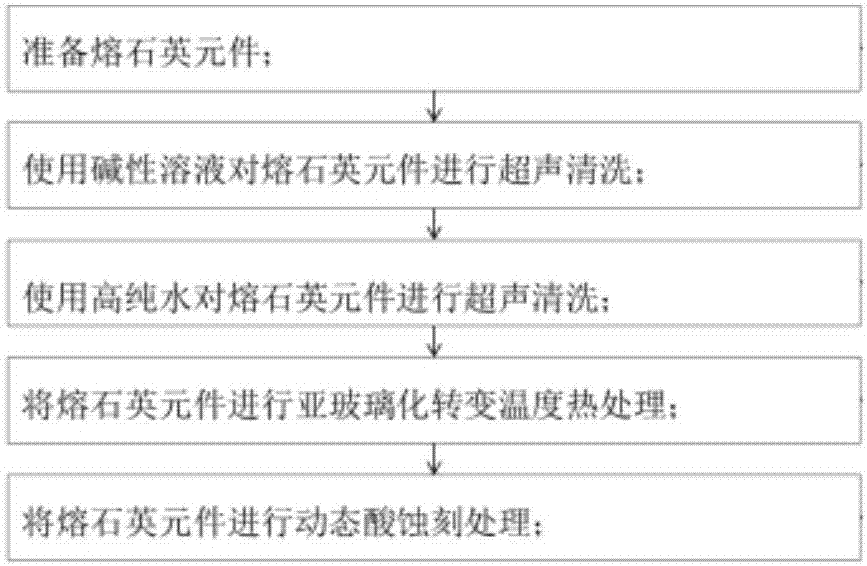

Method for improving uvioresistant laser damage for fused quartz optical element

ActiveCN107021650AImprove surface cleanlinessImproved resistance to UV laser damageVitrificationAcid etching

The invention discloses a method for improving uvioresistant laser damage for fused quartz optical element, comprising: using an alkaline solution to perform ultrasound cleaning on the fused quartz element; using ultrapure water to perform ultrasound cleaning on the fused quartz element cleaned by the alkaline solution, and drying the same; performing secondary vitrification conversion temperature heating treatment on the fused quartz element cleaned by the ultrapure water; and performing dynamic acid etching and drying on the fused quartz element after the heat treatment. The invention achieves the purposes of eliminating the structural defects of the fused quartz and improving uvioresistant laser damage for fused quartz by controlling parameters such as the temperature and the time of the secondary vitrification conversion temperature heating treatment, frequency of the dynamic acid etching sound field, solution concentration, and etching time, so as to meet running requirements of solid laser device with high power.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

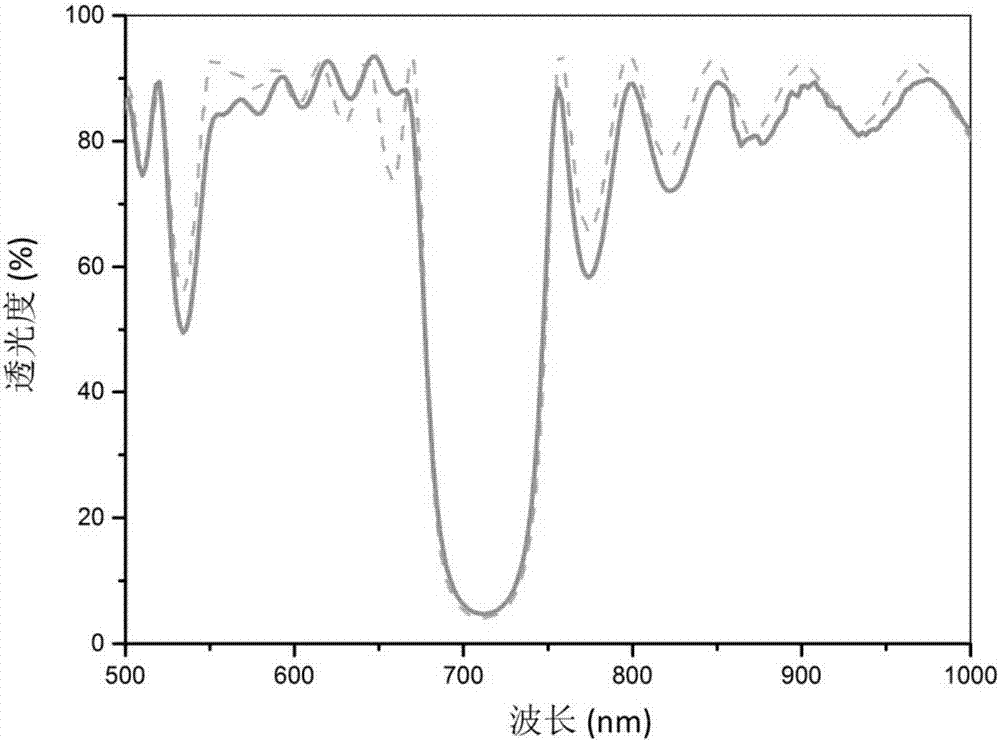

Flexible low radiation window film and real time control method for producing the same

InactiveCN1546722AStrong absorption capacityWith UV protectionVacuum evaporation coatingSputtering coatingEngineeringAlloy

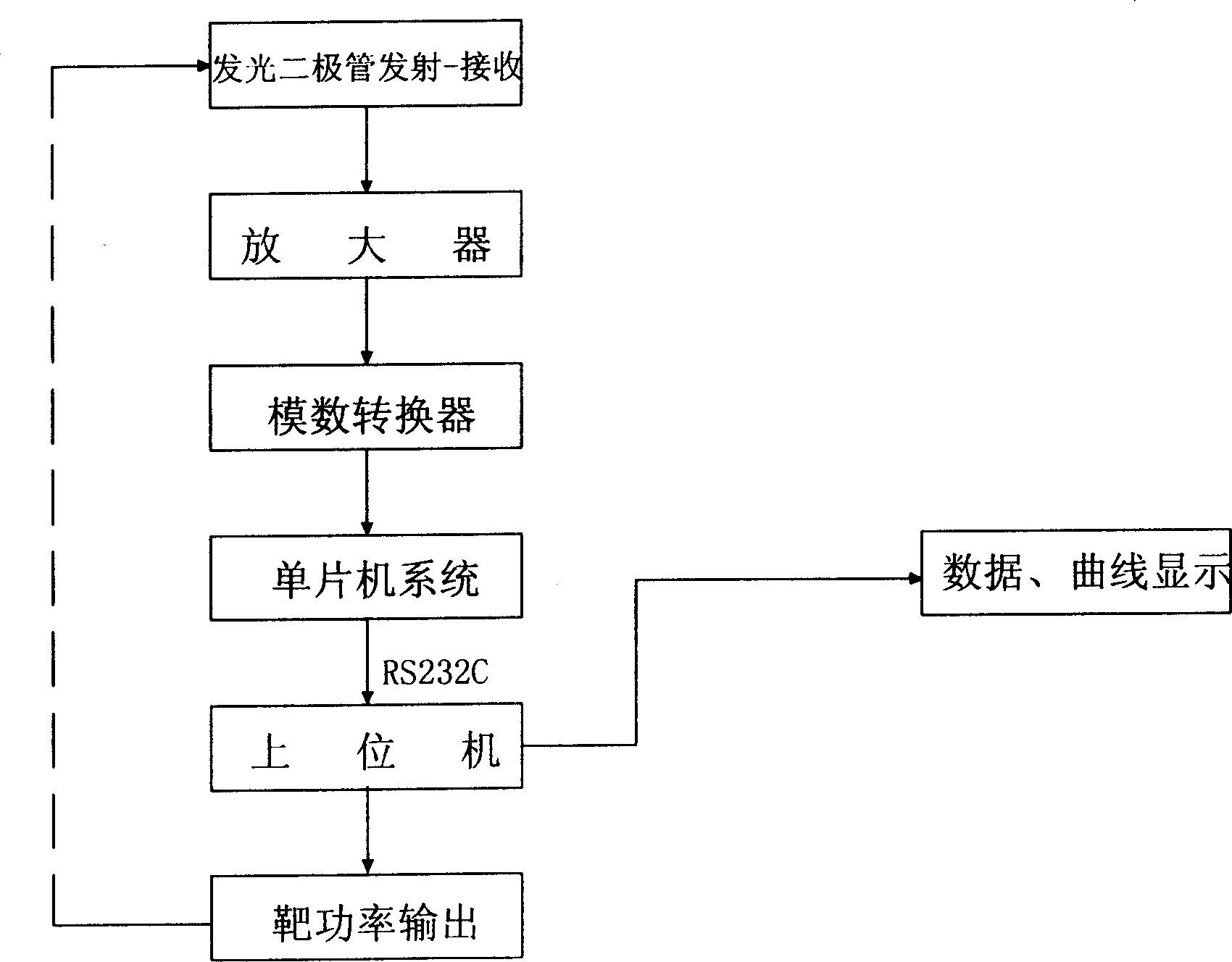

A flexible low radiation window film formed by plural layers coated on transparent flexible base material, wherein the Ag(Au) film is silver alloy comprising Ag and doped 15-20 wt% of homogeneous distribution Au. the real time window film monitoring method comprises arranging a plurality of light-emitting diode emission-receiving transducers on the material collecting roller on the multiple target magnetron sputtering coiling film plating machine in cross direction, whose output signals are magnified by amplifier and converted into digital information, and sent to one-chip computer for comparing and processing, and connected to the upper position through the interfaces, the target power output is controlled thus realizing the real time control for the continuous layer's film thickness.

Owner:湖南三才光电信息材料有限公司

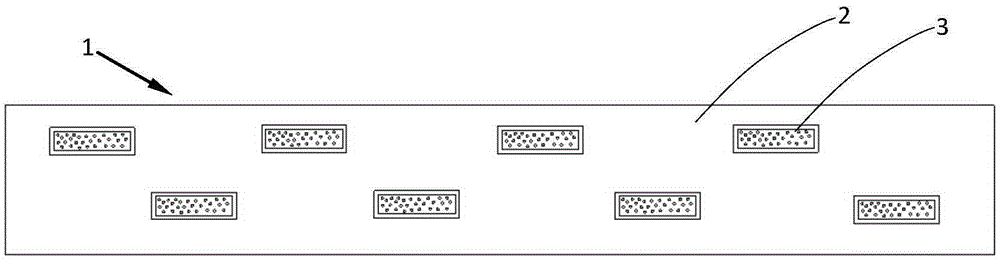

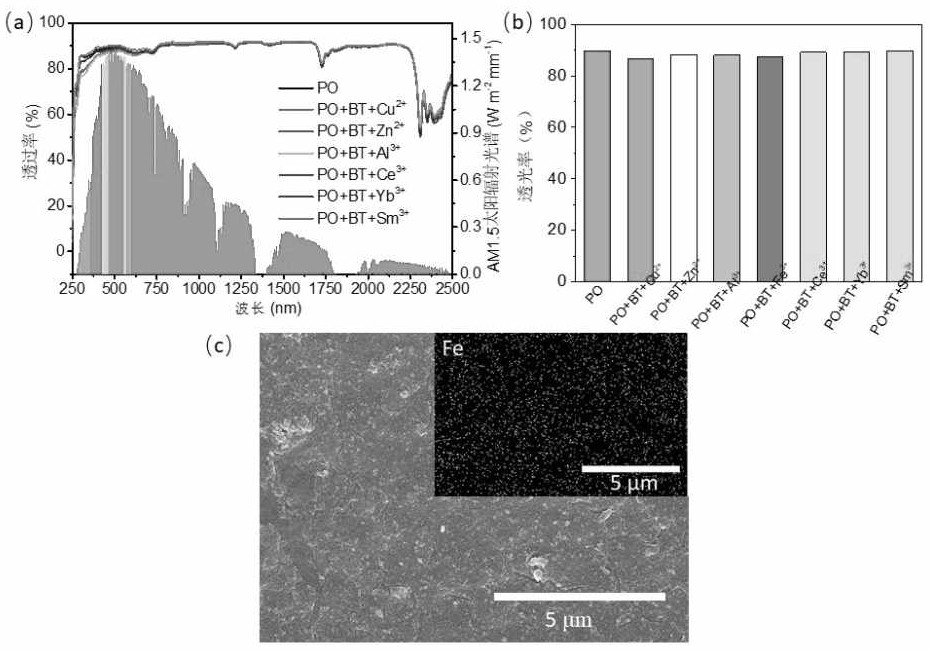

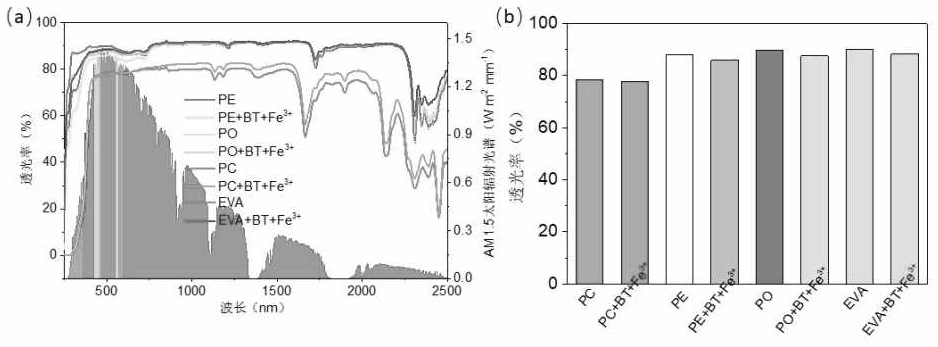

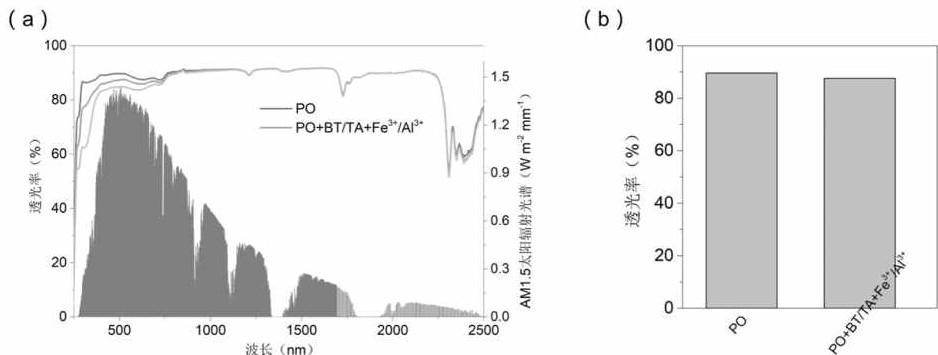

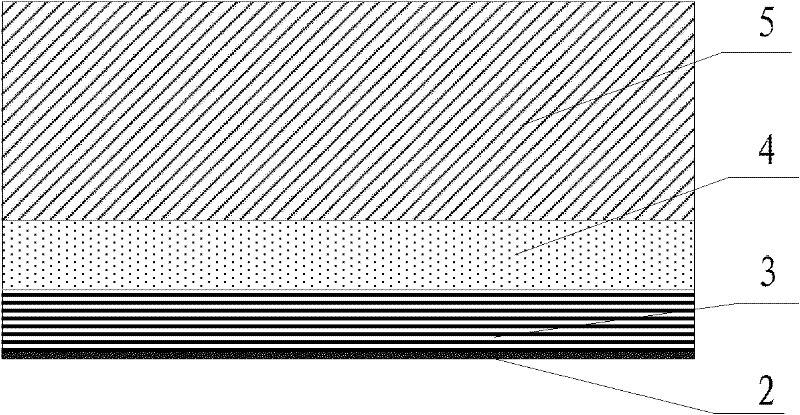

Greenhouse covering film material easy to clean, preparation method and cleaning method

ActiveCN112690148ADoes not affect optical performanceLight in massClimate change adaptationGreenhouse cultivationGreenhouseOptical transmittance

The invention belongs to the technical field of preparation of greenhouse covering film materials and system design of the greenhouse covering film materials, and particularly discloses a greenhouse covering film material easy to clean, a preparation method and a cleaning method. An outer layer of a greenhouse covering film easy to clean is composed of a polyphenol-metal nano-particle thin film, has good optical transmittance, and does not affect the optical performance of an original greenhouse covering film body film; and the thin film is small in mass and good in biocompatibility, does not corrode or damage the surfaces of a greenhouse covering film and a greenhouse covering glass body, and can be used on a large scale. The prepared polyphenol-metal nano-particle thin film can prevent dust from being directly deposited on the surfaces of the greenhouse covering film and greenhouse covering glass; and when the light transmittance of the greenhouse covering film becomes poor due to the dust deposition amount, the nano-particle thin film formed by plant polyphenol and metal ions can be dissociated by spraying a cleaning agent and washing with clear water, and meanwhile, the dust adhered to the nano-particle thin film is removed together, so that the greenhouse covering film is easy to clean.

Owner:SICHUAN UNIV +1

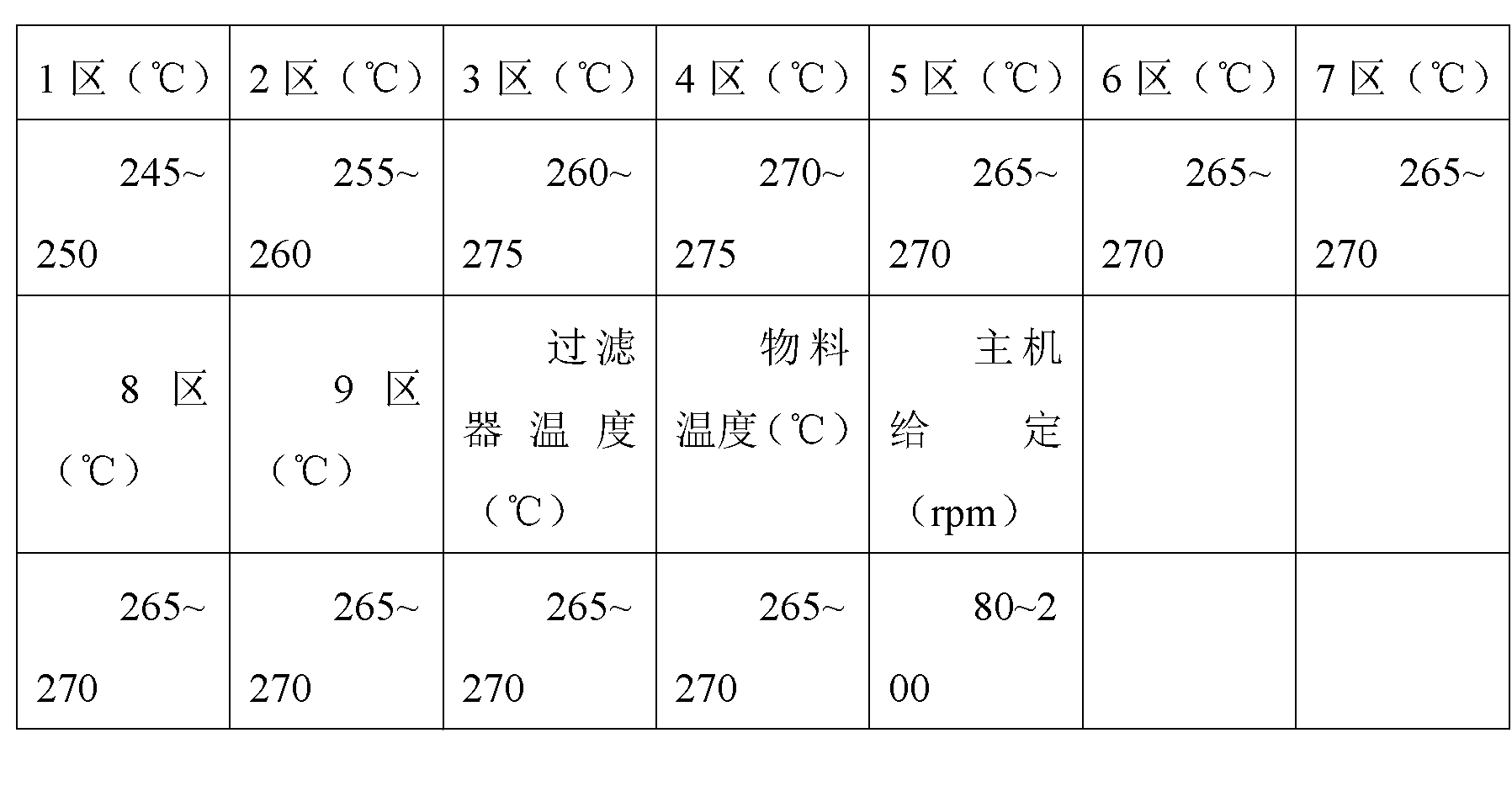

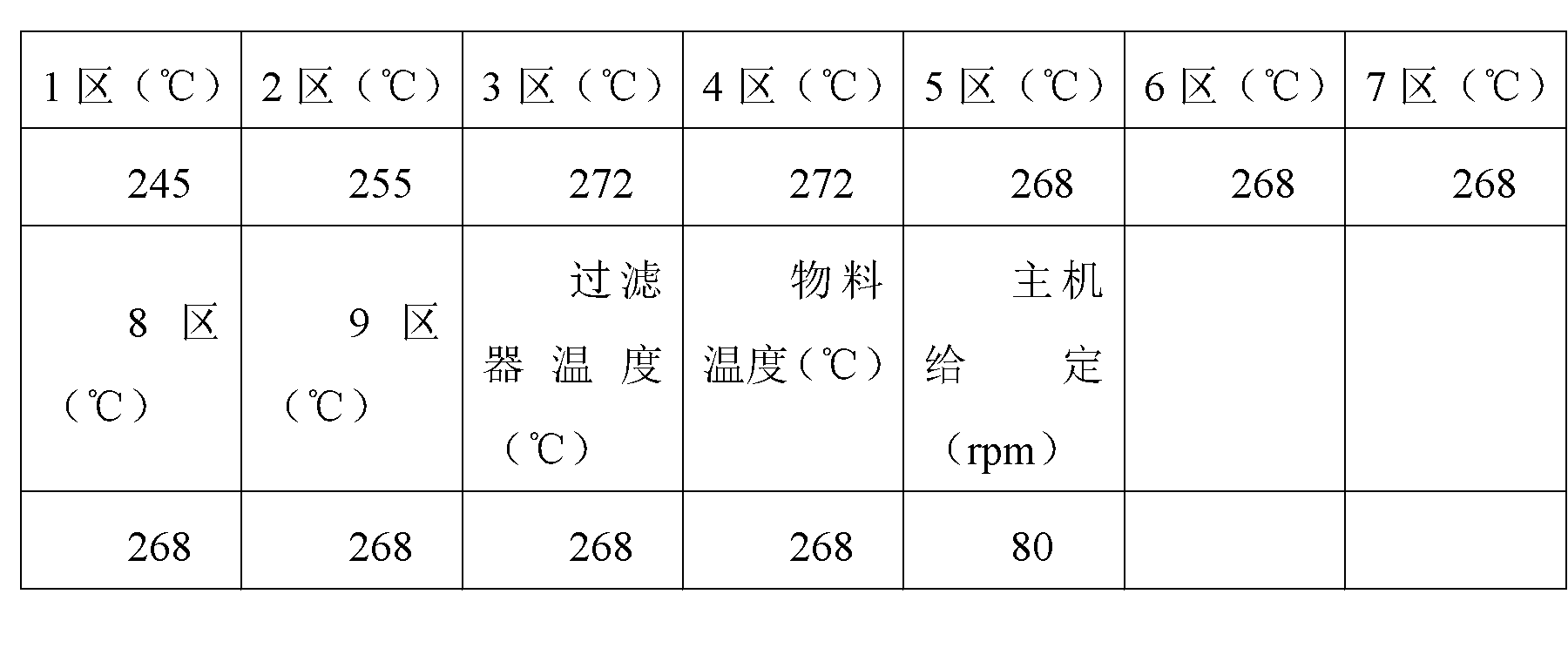

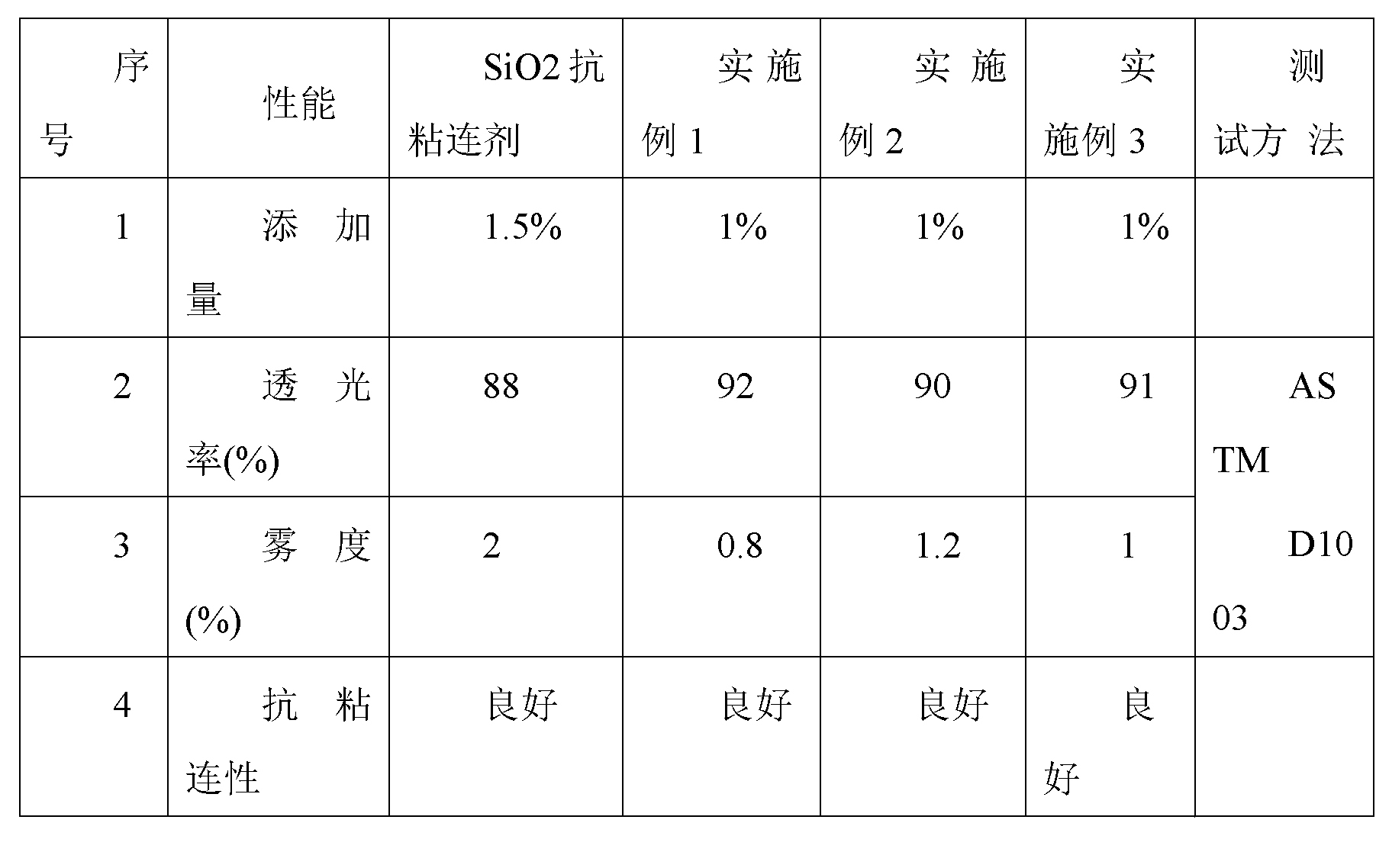

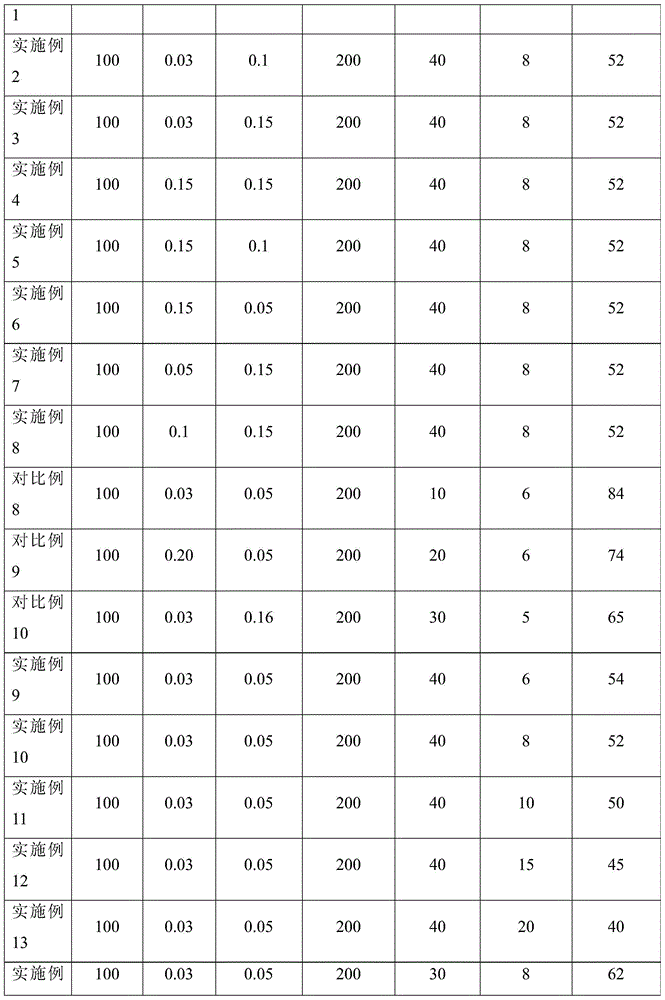

Antiblocking parent stock for optical base film, and preparation method thereof

The invention belongs to the field of optical polyester films, and particularly relates to an antiblocking parent stock for optical base film, and a preparation method thereof, which can not influence on the optical performance of the film while improving the antiblocking property of the film. The antiblocking parent stock for optical base film comprises the following ingredients in percentage by weight: 90-99% of powder PET resin, and 1-10% of antiblocking agent. The antiblocking agent can not influence on the optical performance of the film while achieving the antiblocking property of the film. The closer the antiblocking agent and the refractive index of base body polyester are, the lower the refraction and diffuse reflection degree on a phase interface is, the light transmittance is high and the haze is low.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

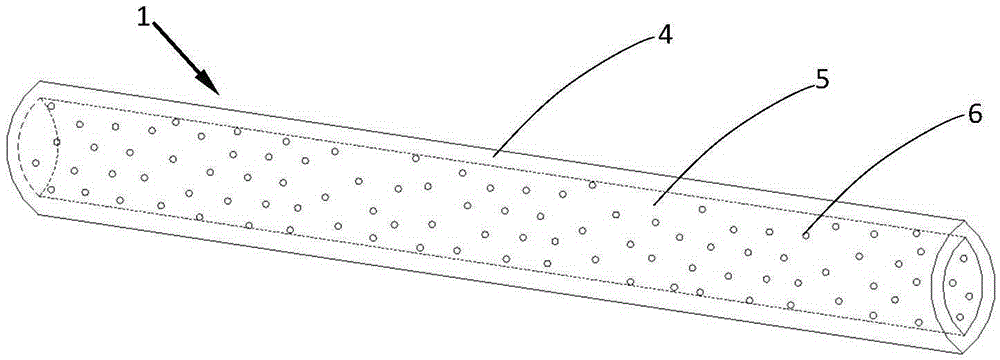

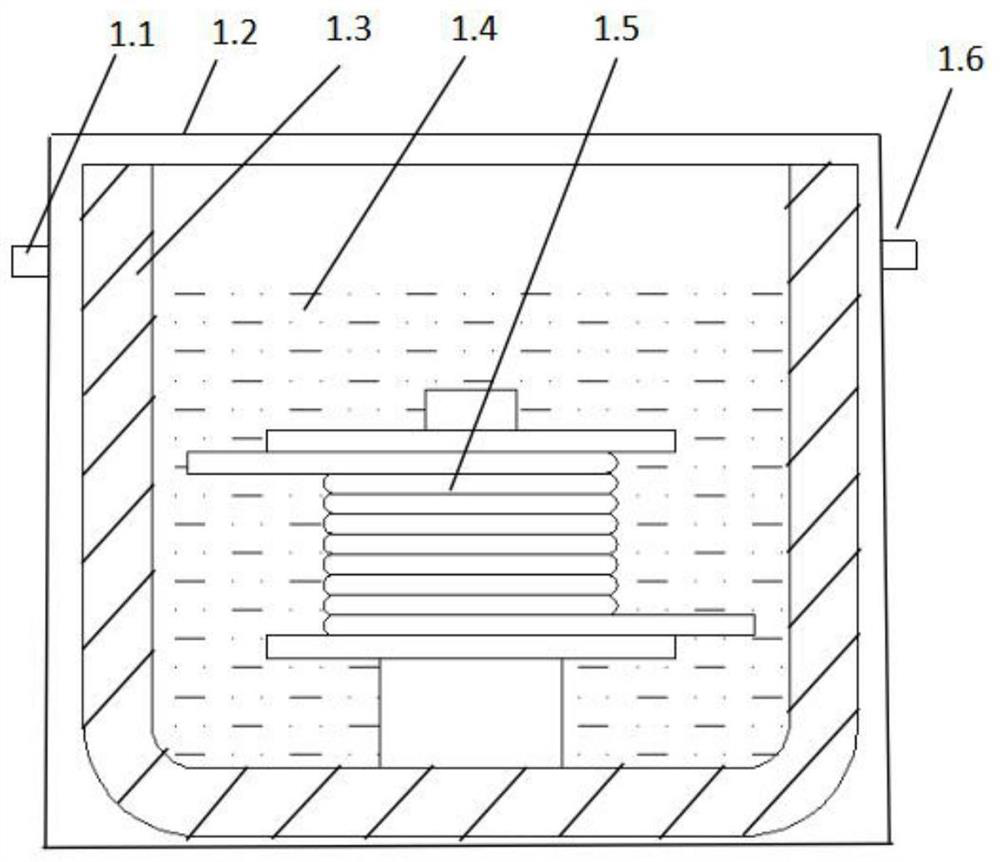

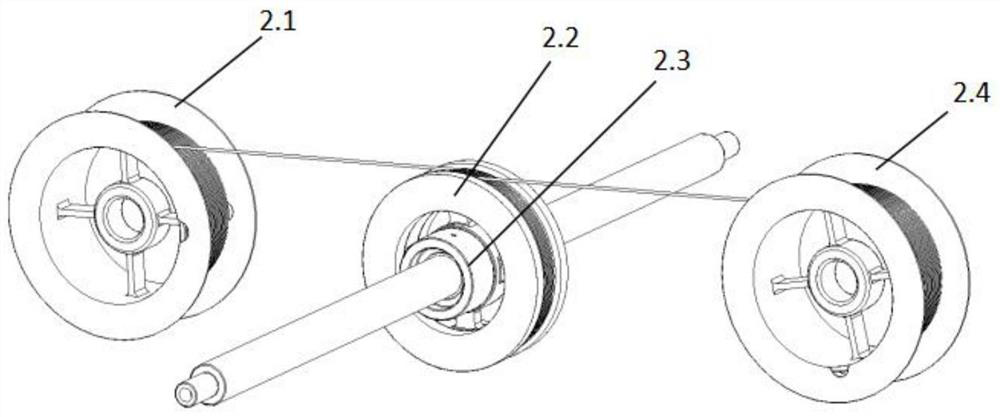

Magnetic fluid-based tension-free hollow-core microstructure optical fiber ring winding method

ActiveCN113432591ADoes not affect optical performanceAvoid destructionSagnac effect gyrometersCore (optical fiber)Composite material

The invention relates to a magnetic fluid-based tension-free hollow-core microstructure optical fiber ring winding method. The method comprises the following steps of: 1, injecting magnetic fluid into a hollow-core microstructure optical fiber before winding so as to fill an area occupied by air; 2, dividing the hollow-core microstructure optical fiber filled with the magnetic fluid into a section A and a section B which are equal from the middle point, and winding the section A and the section B on two wire supply wheels respectively in advance; then, arranging a magnetic force generating device in the axis of the annular winding framework, adsorbing magnetic fluid in the hollow microstructure optical fibers through magnetic force, fixing the midpoints of the hollow microstructure optical fibers to the intersection of a wheel shaft of the winding framework and a wheel edge on one side, and then stacking the hollow microstructure optical fibers sequentially layer by layer according to a preset symmetrical winding method based on magnetic force guidance, coating the curing colloid on the optical fiber in the process of magnetically adsorbing the hollow-core microstructure optical fiber; and 3, discharging the magnetic fluid, and curing the hollow-core microstructure optical fiber ring. According to the invention, the damage to the micro-nano structure body of the hollow-core micro-structure optical fiber caused by the tensile force in the traditional winding method is avoided.

Owner:TIANJIN NAVIGATION INSTR RES INST

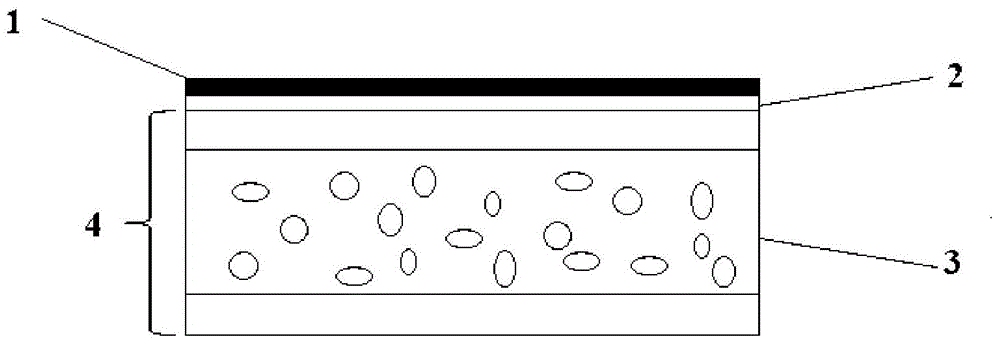

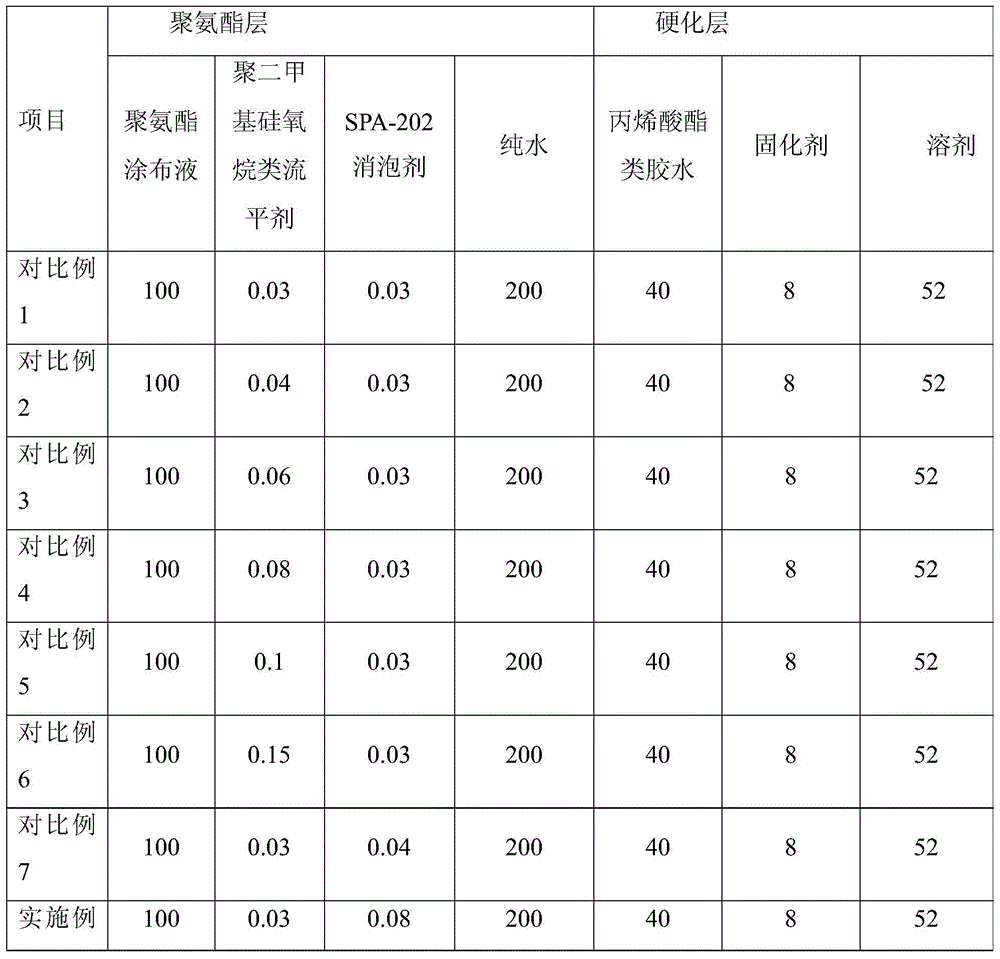

High-stiffness coated reflecting film and preparation method thereof

ActiveCN104635285AIncreasing the thicknessImprove stiffnessMirrorsHigh stiffnessLiquid-crystal display

The invention relates to a reflecting film used by a backlight source in a liquid crystal display, in particular to a high-stiffness coated reflecting film, aims to overcome the defect of press white spot in the existing display screen, and provides the high-stiffness coated reflecting film and a preparation method thereof. The high-stiffness coated reflecting film consists of a reflecting layer, a polyurethane layer and a hardened layer, wherein the polyurethane layer is coated on the upper surface of the reflecting layer; the hardened layer is coated on the upper surface of the polyurethane layer. The high-stiffness coated reflecting film has higher reflectiveness, hardness and stiffness; after the reflecting film is applied to a backlight module, the defect of press white spot in the display screen can be effectively overcome.

Owner:NINGBO CHANGYANG TECH

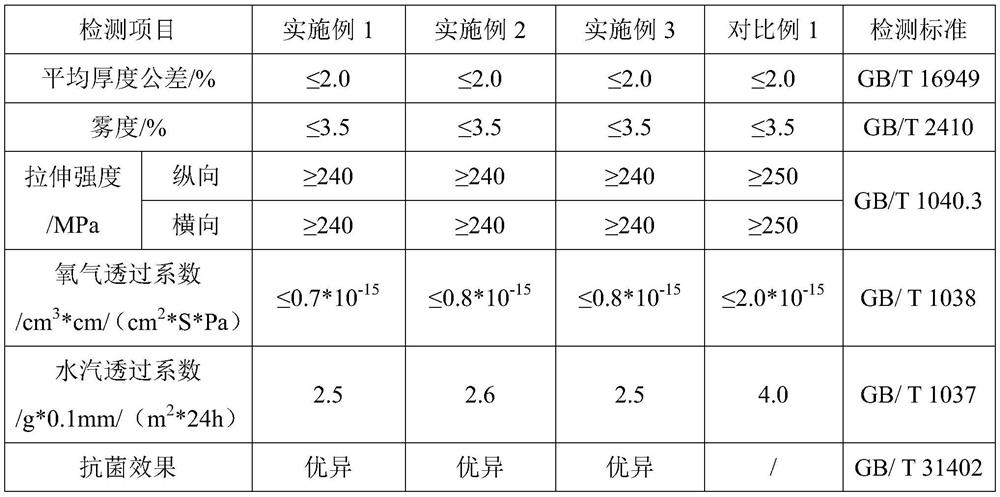

Antibacterial barrier BOPET film and preparation method thereof

PendingCN111703160AGood antibacterial effectLong-lasting antibacterial effectLamination ancillary operationsSynthetic resin layered productsThin membraneAnti bacterial

The invention discloses an antibacterial barrier BOPET film and a preparation method thereof, and relates to the technical field of BOPET films, wherein the BOPET film is composed of an upper surfacelayer, a core layer and a lower surface layer; the upper surface layer and the lower surface layer are antibacterial layers and are prepared from the following raw materials: silver-loaded carbon nanotubes, glass beads and polyester chips; and the core layer is a barrier layer and is prepared from the following raw materials: EVOH, nano montmorillonite and polyester chips. According to the invention, the formula is optimized and the process parameters are adjusted; on the basis of ensuring good physical and mechanical properties and optical properties, the prepared BOPET film is excellent in antibacterial and barrier properties, the antibacterial rate reaches 99%, the oxygen diffusion coefficient is only 1 / 3 of that of a common BOPET film, and the BOPET film can be widely applied to the fields of food packaging and other industrial packaging.

Owner:ANHUI GUOFENG PLASTIC

Production method of low-emissivity glass

InactiveCN103771726AImprove wear resistanceHigh light transmittanceSputteringAluminum doped zinc oxide

The invention discloses a production method of a low-emissivity glass. The production method comprises the steps of A, sputtering a ceramic titanium target with alternating-current medium-frequency power supply, namely, forming a TiO2 dielectric layer on a glass substrate through magnetron sputtering; B, sputtering a chromium plane target with direct-current power supply, namely, forming a CrNx barrier layer on the TiO2 dielectric layer through magnetron sputtering; C, sputtering an aluminum-doped zinc oxide ceramic rotating target with alternating-current power supply, namely, forming an AZO flat layer on the TiO2 dielectric layer through magnetron sputtering; D, sputtering a silver plane target with direct-current power supply,namely, forming an Ag functional layer on the AZO flat layer through magnetron sputtering; E, sputtering with direct-current power supply, namely, forming a (NiCr)xOy layer on the Ag functional layer through magnetron sputtering; F, sputtering a tin target with alternating-current medium-frequency power supply, namely, forming a SnO2 protection layer on the (NiCr)xOy layer through magnetron sputtering; and G, sputtering a graphite target with direct-current power source, namely, forming a C layer on the SnO2 protection layer obtained in the step F through magnetron sputtering. The invention aims at providing the production method, which is simple in process, convenient to operate and relatively low in production cost, of the low-emissivity glass.

Owner:JIEYANG HONGGUANG COATED GLASS

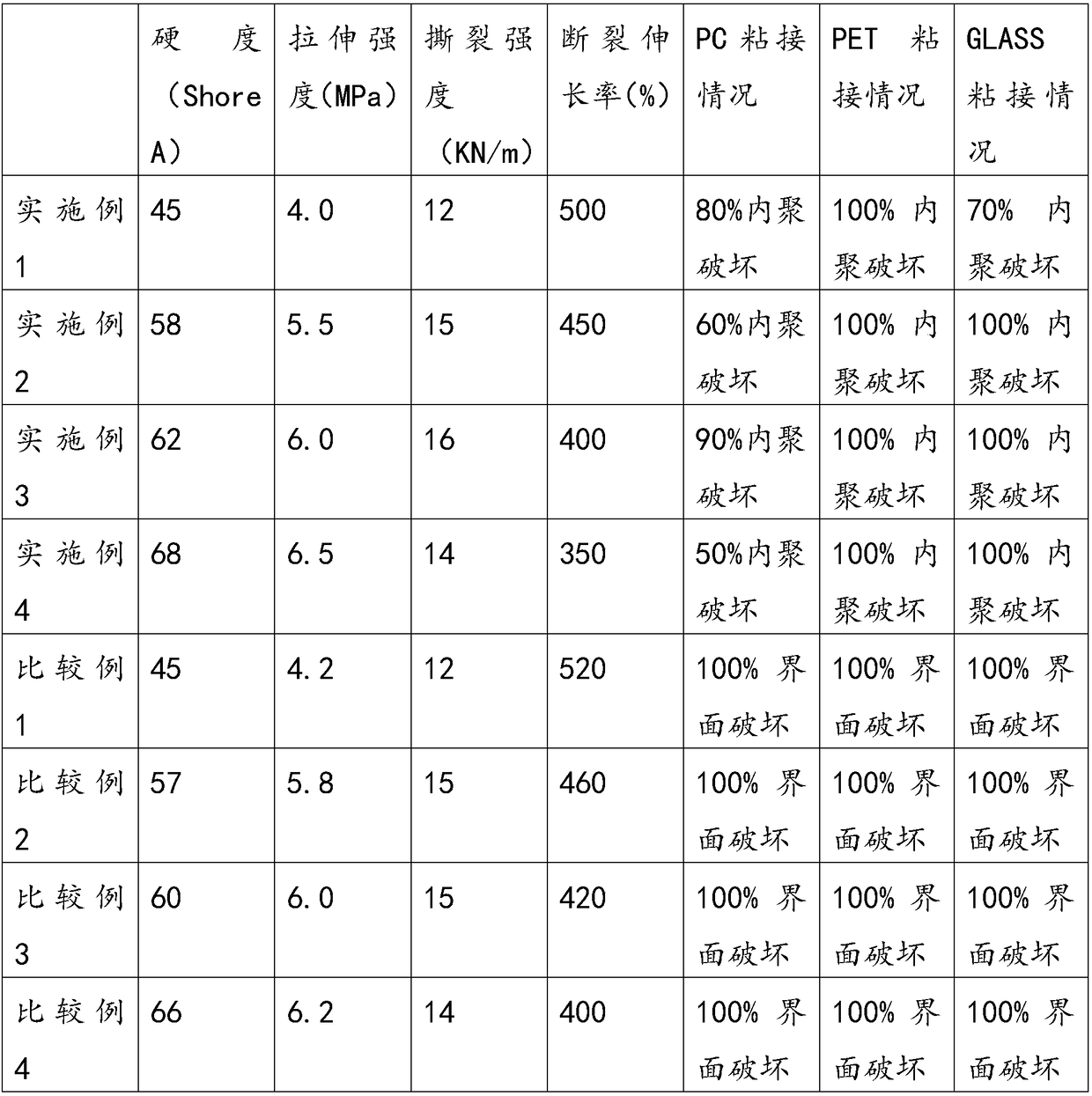

Odorless addition type liquid silicone rubber tackifier and preparation method and application thereof

InactiveCN108164705ARaw materials are easy to getLow costMacromolecular adhesive additivesHydrogenOrganic solvent

The invention discloses an odorless addition type liquid silicone rubber tackifier and a preparation method and application thereof. The preparation method is as follows: mixing an organic compound containing phenyl and vinyl groups, a platinum catalyst and an organic solvent evenly for standby use; adding phenyl hydrogen-containing silicone oil and an organic solvent to a round bottom flask, heating up while stirring, and dropwise adding a mixture containing the organic compound containing the phenyl and vinyl groups, the platinum catalyst and the organic solvent into the round bottom flask whenthe temperature of the round bottom flask reaches 60-90DEG C for the adding time of 1-2h; after the adding is completed, controlling the reaction temperature at 60-100 DEG C for 1-8h; and after thereaction is completed, cooling a reaction solution to room temperature, filtering the reaction liquid by suction, and performing rotary evaporateion to get the tackifier. The preparation process is simple, the raw material is cheap and easy to obtain, the method is easy in industrial production, and the tackifier is colorless and tasteless, good in stability, has good compatibility with additiveliquid silicone rubber (LSR), and does not affect the odor and optical and mechanical properties of the LSR.

Owner:SHENZHEN KANGLIBANG TECH

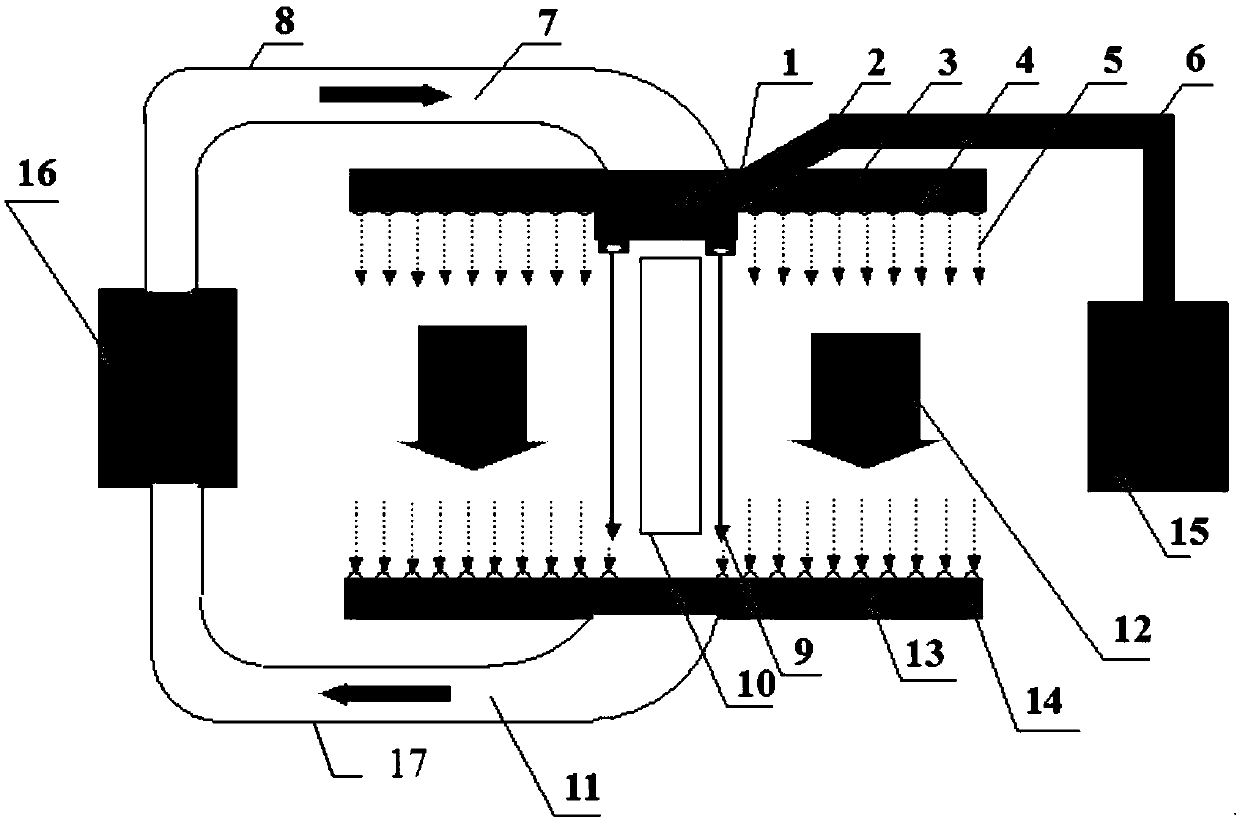

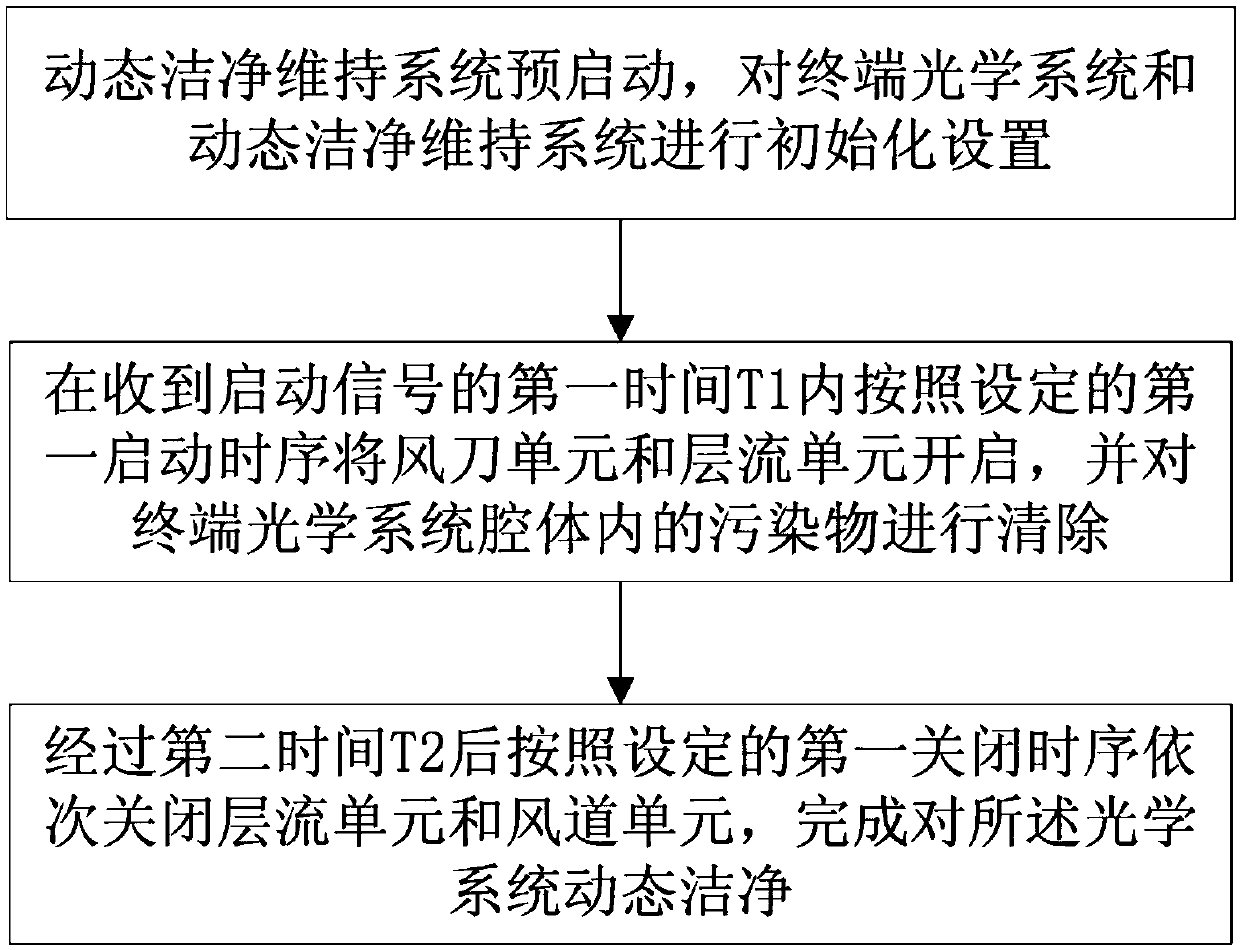

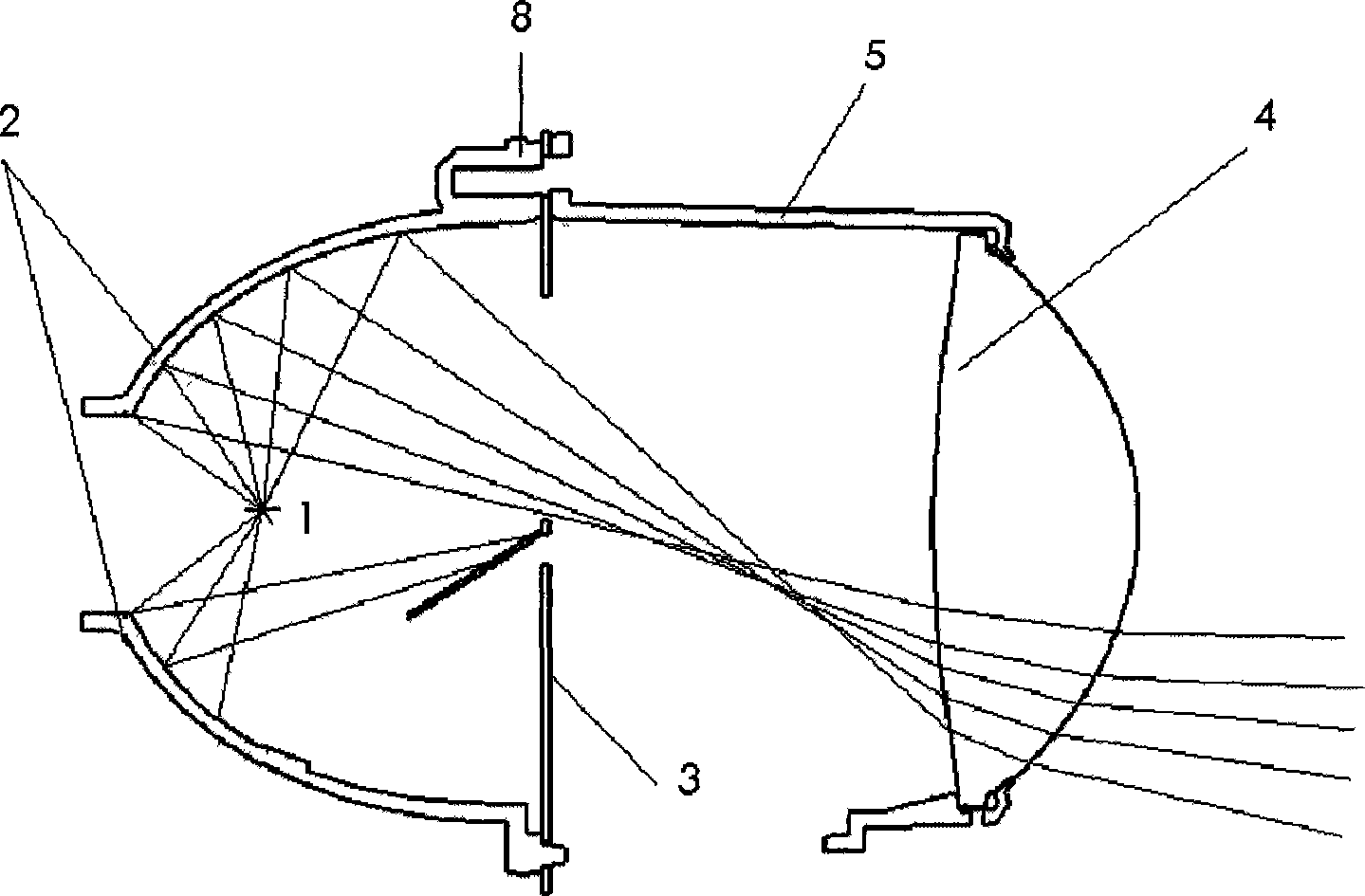

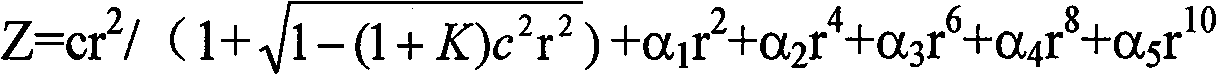

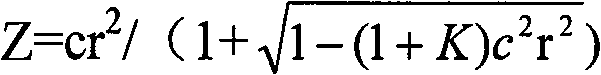

Dynamic clean maintenance system and method for high power terminal optical system

ActiveCN109622555APrevent adhesionDoes not affect optical performanceFouling preventionCleaning using gasesHigh power lasersAir knife

The invention discloses a dynamic clean maintenance system and method for a high power terminal optical system, and belongs to the technical research field of high power laser devices. The system comprises a laminar flow unit and a wind knife unit, the laminar flow unit is used for providing dynamic clean laminar flow, and the wind knife unit is used for providing a high pressure air knife air curtain. During the long-term operation of the high power terminal optical system, the life of optical elements is greatly shortened due to the fact that dust and aerosol pollutants produced by targetingare deposited on the surface of the internal optical elements in the high power terminal optical system, and the clean control of the terminal optical elements becomes a bottleneck of limiting the high throughput operation of the device; therefore, a technical measure for realizing the surface clean control of the optical elements by coupling the wind knife air curtain protection and the clean laminar flow protection is provided, the dust and aerosol pollutants produced by targeting can be prevented from being attached to the surfaces of the optical elements and are discharged out of the terminal optical system in time, so that the surface cleanliness of the optical elements in the terminal optical system is maintained for a long time.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

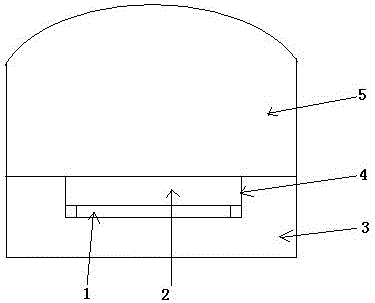

Automobile front shining lamp based on double-convex lens

The invention provides a car head light based on the biconvex lens, characterized in that the main light source is the discharge lamp or the halogen lamp, and the car head light is composed of a free-form surface reflector, a light screen, a biconvex lens, a lens holder and the like. The car head light based on the biconvex lens of the invention adopts the free-form surface reflector, to make thelight source emergence flock. The focus of the biconvex lens is set near the dead line of the light screen to make the dead line distinct. The biconvex lens design can avoid the damage of the car lighting circle, the matched mirror or the other parts on the car caused by the light focus of the sunshine. The invention reduces the risk of the light design, advances the safety, the stability and theservice life, has strong universality, which is suitable for a plurality of models of cars.

Owner:HASCO VISION TECHNOLOGY CO LTD

Field assembly type optical fiber connector

ActiveCN102998753BGood repeatabilityEnhance compressive and tensile strengthCoupling light guidesFiberOptical fiber connector

The invention relates to a field assembly type optical fiber connector. The end of a neck insert core is connected with a dark fiber and inserted into the head of a box shell after cementing, a plastic bolt is pressed in to fix the neck insert core with the box shell, a V-shaped slot aluminum sheet is arranged inside the box shell, a wire block is arranged at the tail of the box shell which is fixed with the wire block through a plastic bolt, a metal collet is sleeved on the box shell, a spring is sleeved on the head of the wire block, a spring seat is sleeved at the tail of the wire block and contacts with the spring, a wire fixing slot is inserted into the spring seat and contacts with the wire block, an inner shell is covered on the peripheries of the neck insert core, the box shell and the spring seat, a square cover is clamped into the spring seat so as to fix the skin of the optical fiber, a key is placed into the end of the inner shell, a dustproof cap is sleeved on the neck insert core tightly so as to protect the neck insert core, and the head of the inner shell is sleeved into a short shell. The connector is resistant to high and low temperatures, good in repeatability, high in crush resistance and tensile property, compact in structure, provided with an interlock structure and high in reliability.

Owner:JIANGSU UNIKIT OPTICAL TECH

Multifunctional transparent electrode structure of ultraviolet organic light-emitting device

InactiveCN103000815AImprove UV transmittanceImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceEvaporation

A multifunctional transparent electrode structure of an ultraviolet organic light-emitting device is characterized in that a transparent electrode film is manufactured on a substrate directly, an organic light-emitting material layer is manufactured on the transparent electrode film, a metal layer is deposited on the organic layer by heat evaporation, and a packaging layer is manufactured finally. The multifunctional transparent electrode structure of the ultraviolet organic light-emitting device is of a double-layer structure comprising an inorganic material film for increasing ultraviolet light transmittance and a transparent conducting oxide inorganic material film. The multifunctional transparent electrode structure has the advantages of high work function, high stability, high reflectance, high light transmittance, low resistivity and the like and is particularly suitable for a transparent electrode of the ultraviolet organic light-emitting device, the work function is increased, the optical performance and the electrical property of the ultraviolet organic light-emitting device can be unaffected, and the inorganic material film for increasing the ultraviolet light transmittance can be applied to outside one side of the transparent electrode of the substrate and the back of the substrate so as to increase ultraviolet light extraction efficiency.

Owner:江苏广发光电科技有限公司

Anti-UV protective film of OLED screen body for vehicle light

PendingCN107901551AStrong stickinessReduce volatilitySynthetic resin layered productsOptical signallingUv protectiveUltraviolet

The invention relates to an anti-UV protective film of an OLED screen body for a vehicle light. The anti-UV protective film comprises release paper, an adhesive layer, a resin film and a UV barrier layer which are arranged in sequence from bottom to top, and has the total thickness of 40 to 100 [mu]m; the resin film contains an ultraviolet absorbent; the visible light transmittance of a composition comprising the adhesive layer, the resin film and the UV barrier layer is 75 to 90 percent; the adhesive layer is used for connecting the OLED screen body with the resin film, and has the characteristics of low volatilization and low fogging degree; the resin film is made of PET or PEI resin, thus guaranteeing the high-temperature resistance and the tear strength of a protective film main body;the ultraviolet absorbent is UV-P or UV-531. With the barrier rate of 95 to 100 percent, the anti-UV protective film can prevent ultraviolet radiation at the wavelength of 5 to 430 nm; the anti-UV protective film is high in adhesiveness, can resist high temperature, is easy to construct, and provides a good anti-UV radiation effect for the OLED screen body for the vehicle light.

Owner:HASCO VISION TECHNOLOGY CO LTD

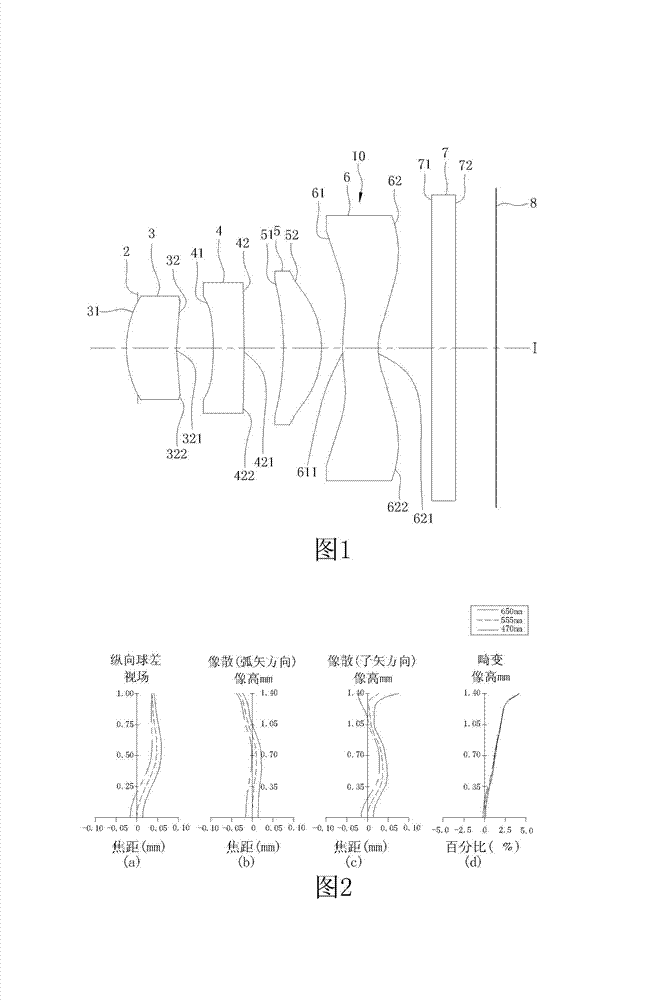

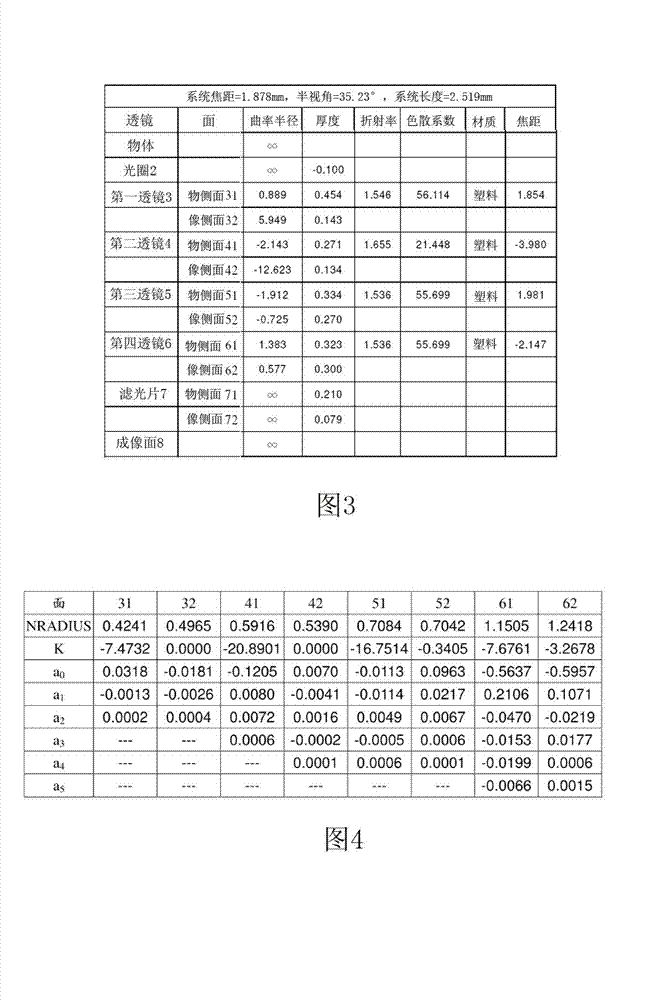

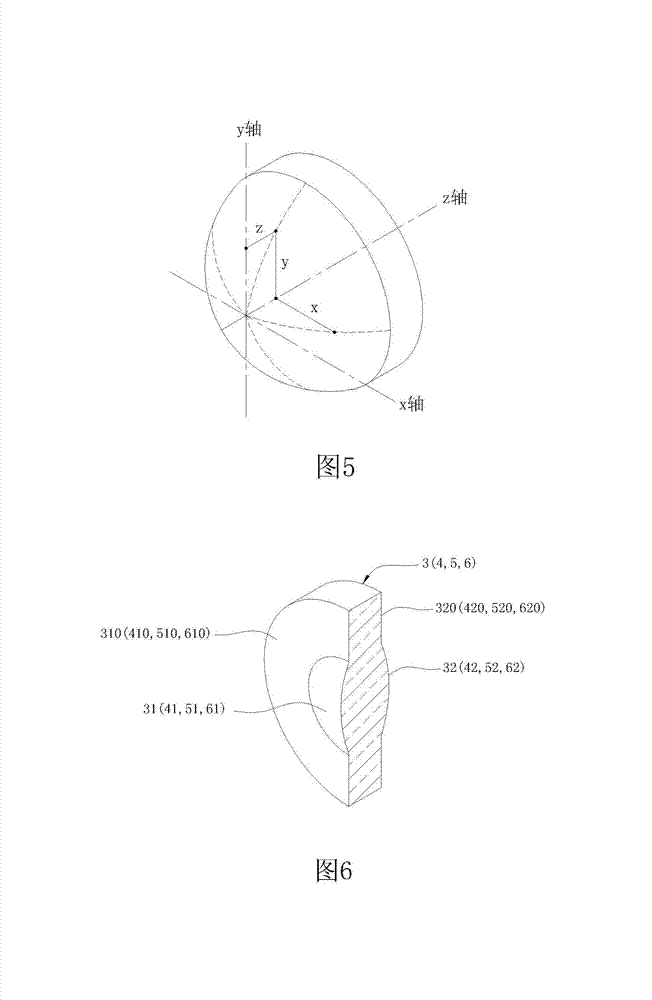

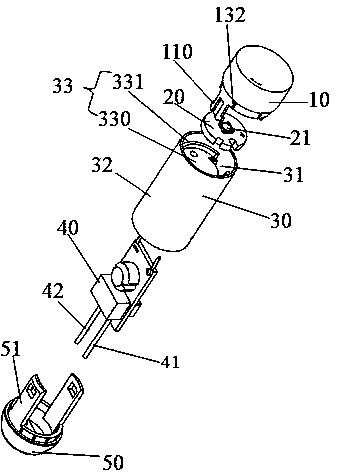

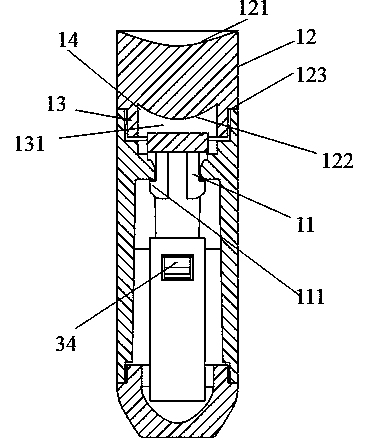

Optical imaging lens and electronic device applying same

ActiveCN103076671AReduce gapHigh sensitivityTelevision system detailsColor television detailsCamera lensOptical property

The invention provides an optical imaging lens and an electronic device applying the same. The optical imaging lens sequentially comprises a first lens, a second lens, a third lens and a fourth lens from an object side and an image side; and each lens comprises an object side face facing to the object side and an image side face facing to the image side. The first lens is a lens with a positive refractive index; and the object side face of the first lens is a convex face. The second lens is a lens with a negative refractive index; and the image side face of the second lens is provided with a convex face part located in an area near the circumference. The image side face of the third lens is a convex face. The object side face of the fourth lens is provided with a convex face part located in an area near an optical axis; and the image side face of the fourth lens is provided with a concave face part located in the area near the optical axis, and a convex face part located in the area near the circumference. The electronic device applying the optical imaging lens comprises a shell and an image module comprising the four-sheet optical imaging lens. The electronic device applying the optical imaging lens provided by the invention still has good optical properties when the length of the optical imaging lens is reduced.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

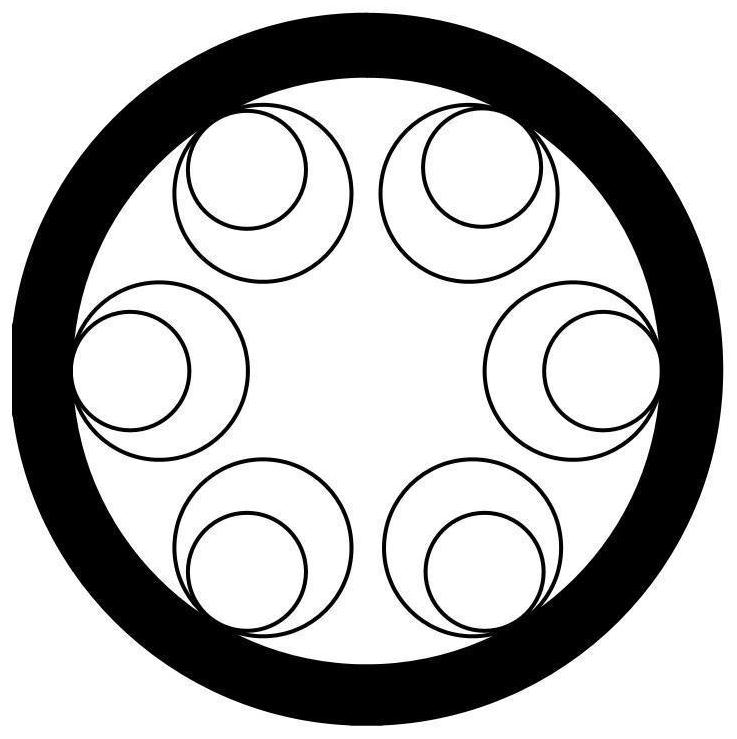

LED lamp

InactiveCN104251394AEasy to assemblePrecise positioningPoint-like light sourceElectric lightingEngineeringLED lamp

The invention discloses an LED (Light Emitting Diode) lamp which comprises a lens, an LED light source plate and a radiator, wherein the LED lamp is further provided with a clamping device, and the lens is connected with the radiator through the clamping device.

Owner:OPPLE LIGHTING ELECTRICAL ZHONG SHAN CO LTD

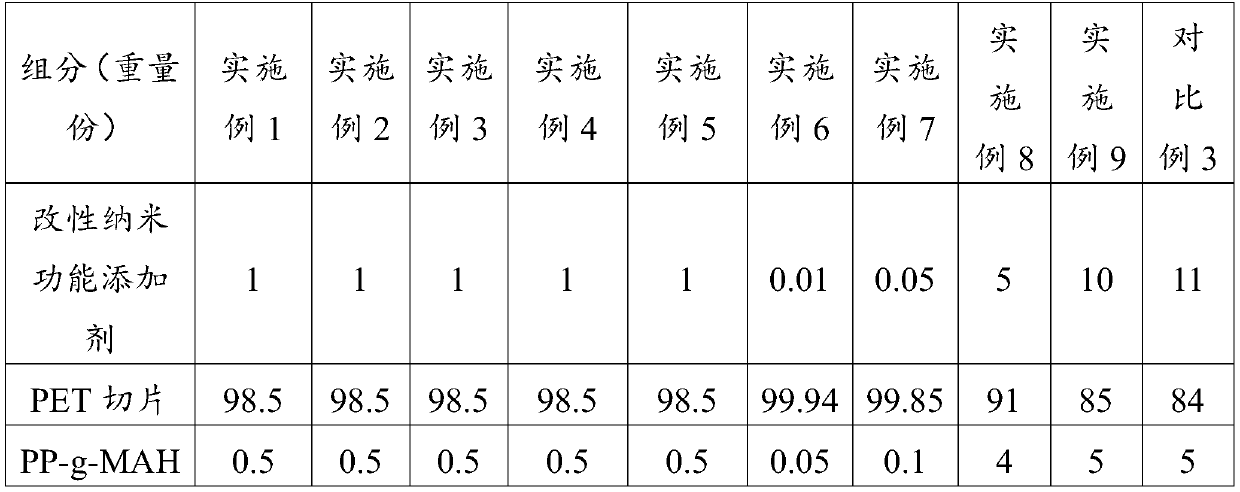

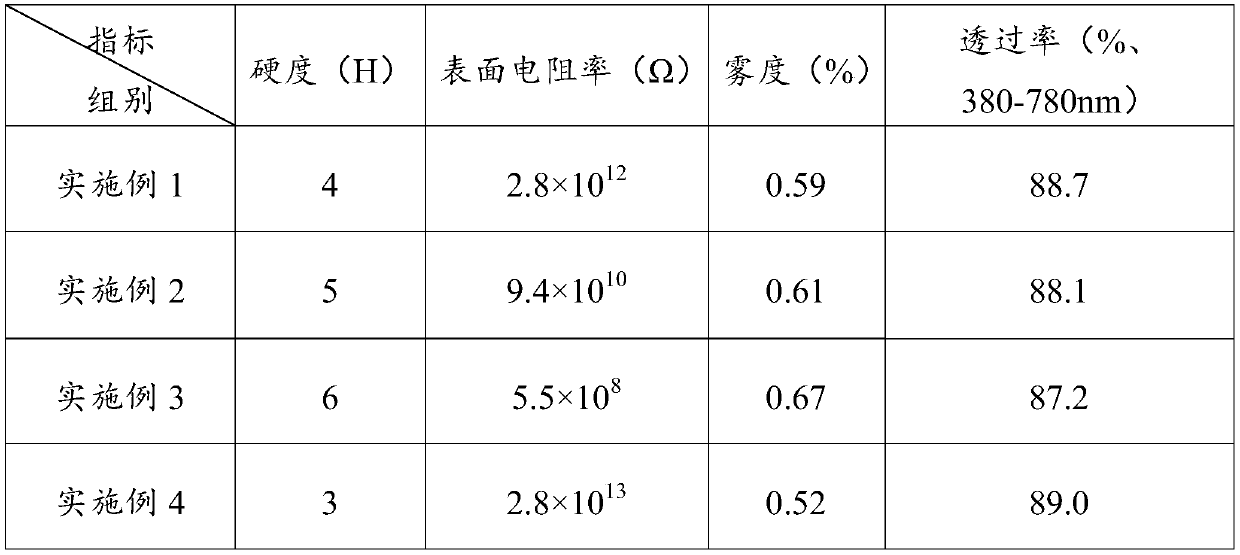

Antistatic scratch-proof transparent BOPET film, and preparation method thereof

The invention discloses an antistatic scratch-proof transparent BOPET film. The antistatic scratch-proof transparent BOPET film comprises, by weight, PET slice 90-99.9% and nano-modified PET slice 0.1-10%; the nano-modified PET slice contains the following components, by weight, a modified nano-functional additive 0.01 to 10 parts, PET slice 85 to 99.94 parts and a compatibilizer 0.05 to 5 parts;the modified nano-functional additive is modified graphene and / or modified carbon nanotube. According to the preparation method of the BOPET film, creative utilization and selection of components suchas carbon nanotube and graphene materials with a series of excellent characteristics and chemical grafting modifying technology are adopted, so that excellent physical and chemical combination effects between the nano functional materials and the PET slice substrate are achieved, the prepared PET substrate has excellent antistatic performance, high hardness, and scratch resistance, and at the same time, it is ensured that the optical performance is not affected, and the appearance abnormality in the latter stage operation is reduced.

Owner:广东格瑞纳思薄膜科技有限公司

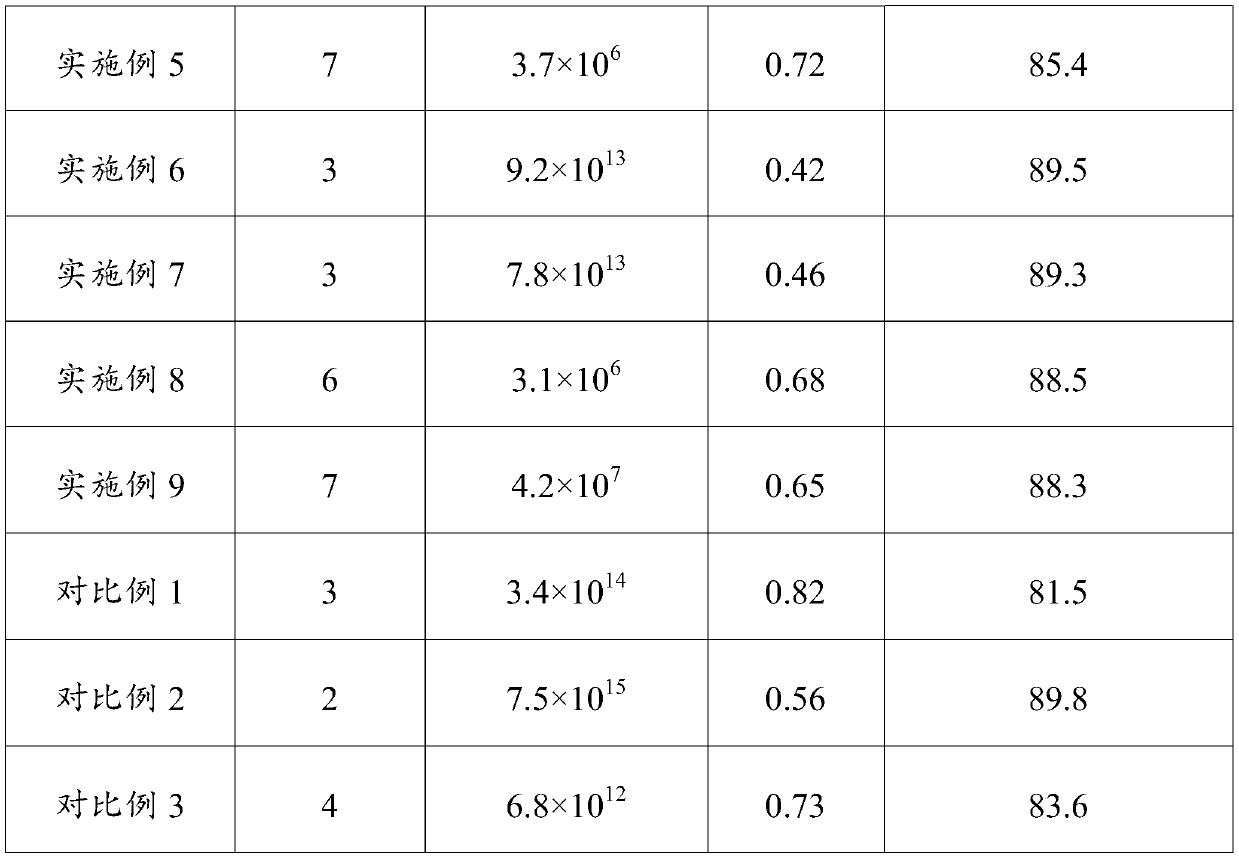

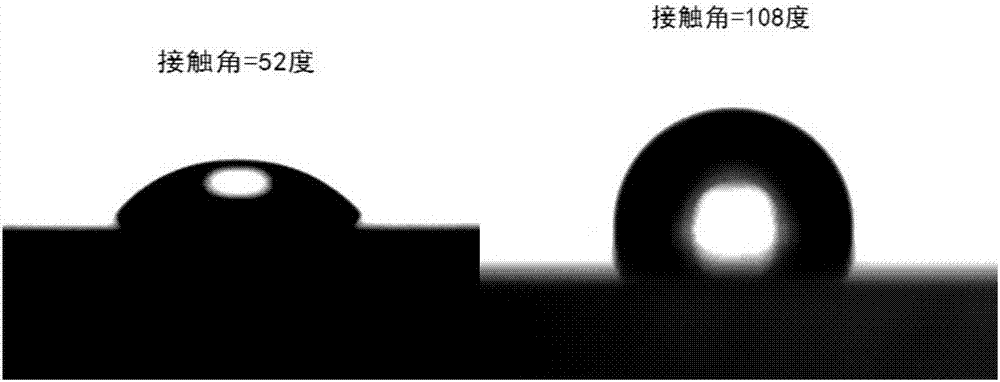

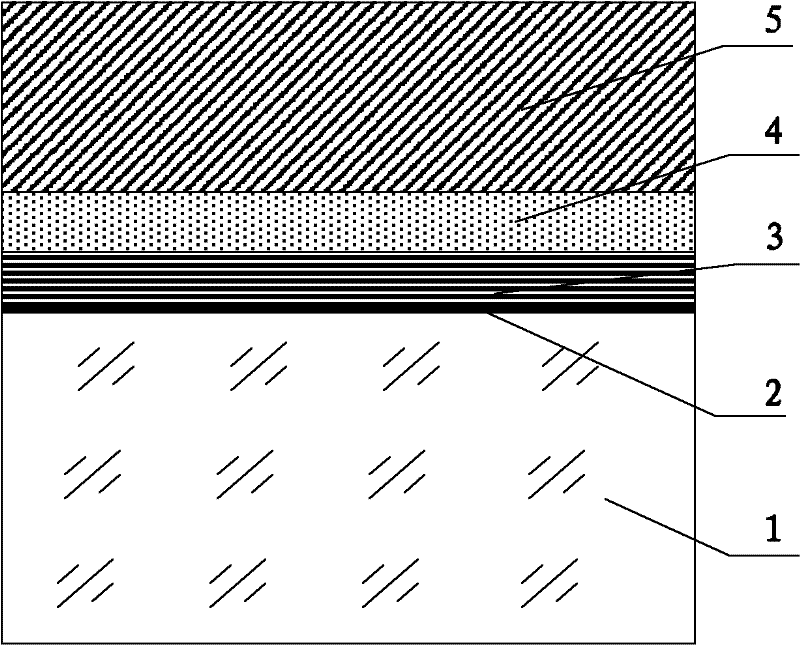

An optical mirror slip with lanthanide oxide hydrophobic optical thin film and method for preparing the same

InactiveCN107462943ADoes not affect optical performanceGood optical performanceChemical vapor deposition coatingOptical elementsLanthanideOptoelectronics

The invention provides lanthanide oxide hydrophobic optical thin film prepared by using an atomic layer deposition method. A film layer is made of lanthanide oxide, so that when being applied to the surface of a substrate of an optical mirror slip, the film layer does not influence the optical performance of the original mirror slip. The lanthanide oxide hydrophobic optical thin film can be applied to the surfaces of optical devices requiring the hydrophobic property, such as an anti-fog optical transmitting mirror and a reflector. The lanthanide oxide thin film needs to be prepared by using atomic layer deposition coating technology and equipment and has the advantages of good hydrophobic property, excellent optical performance and wide application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

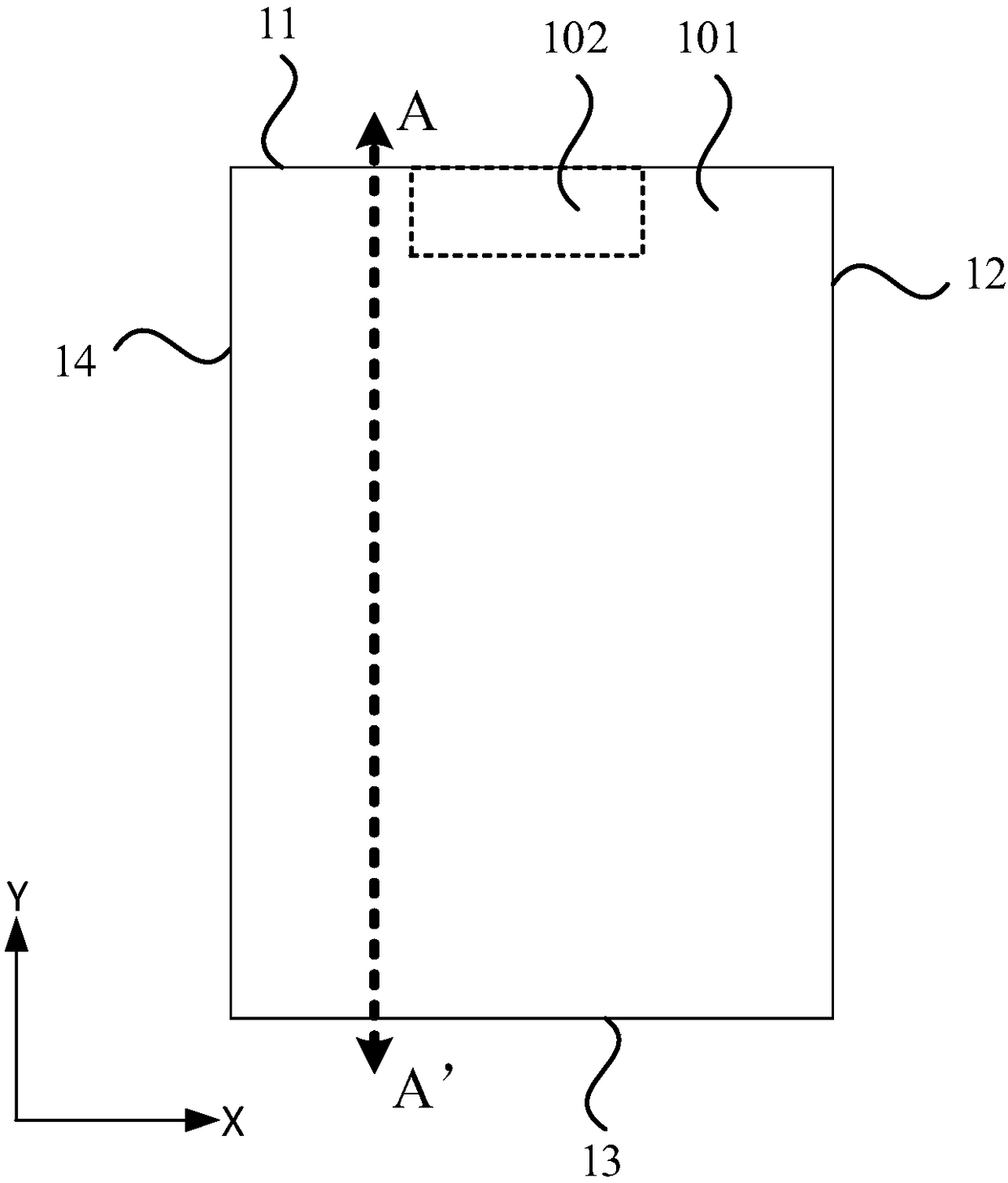

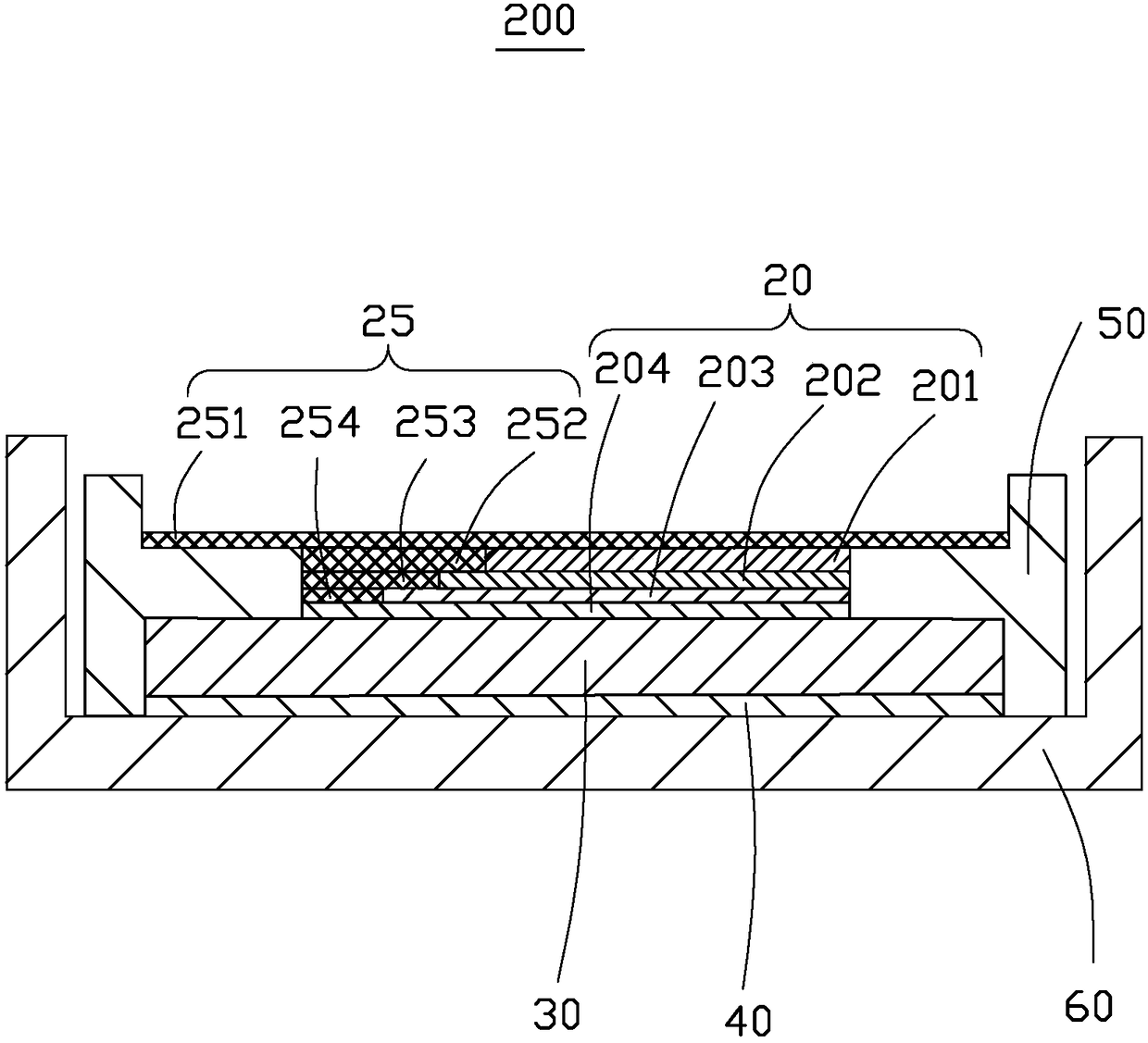

2D/3D switchable optical module and production method thereof and display device

ActiveCN108535880ADoes not affect the direction of propagationDoes not affect optical performanceOptical elementsOptical ModuleDisplay device

The invention provides a 2D / 3D switchable optical module and a production method thereof and a display device. The 2D / 3D switchable optical module comprises a 2D / 3D switchable area and at least one 2Ddisplay area, wherein the at least one 2D display area is positioned on one or more edges of the 2D / 3D switchable optical module. The invention provides the 2D / 3D switchable optical module and the production method thereof and the display device so as to be adapted to a specially-shaped screen.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

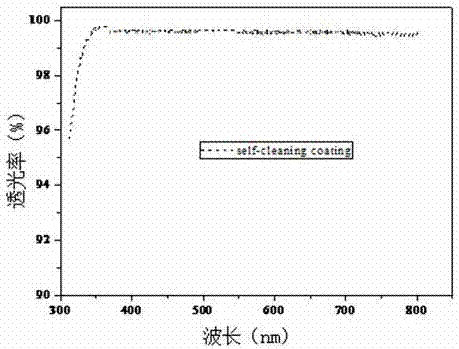

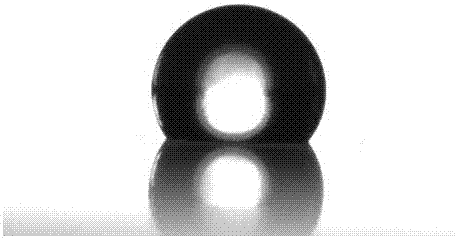

A transparent superhydrophobic self-cleaning coating

ActiveCN105086537BFast curingEasy constructionAntifouling/underwater paintsPaints with biocidesArchitectural glassSilica nanoparticles

A transparent super-hydrophobic self-cleaning coating, which uses a one-step direct hydrolysis method to synthesize silica nanoparticles with active hydrophobic groups, and then prepares a coating to obtain a highly transparent self-cleaning coating. The self-cleaning paint consists of hydrophobic silicon dioxide nanoparticles with active groups, alcohol solvents and additives. The content of silica nanoparticles with hydrophobic active groups is 1%-10%, the content of alcohol solvents is 90%-98%, and the content of additives is 0.1%-1%. After the film is formed, the light transmittance of the coating is greater than 98%, and the water contact angle is greater than 150°. It has good self-cleaning performance and can be widely used in architectural glass curtain walls, automotive glass, photovoltaic modules, optical devices, etc.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Multilayer film reflector based on Pt separation layer and manufacturing method of multilayer film reflector

InactiveCN102682867ADoes not affect optical performanceReduce absorptionHandling using diffraction/refraction/reflectionEpoxyOptical property

The invention relates to a multilayer film reflector based on a Pt separation layer and a manufacturing method of the multilayer film reflector. The manufacturing method comprises the following steps: plating a Pt separation layer on a high-smoothing glass mother board, then plating an X-ray multilayer film, uniformly spraying liquid epoxy resin, pressing an ultrathin aluminum sheet substrate on the sprayed liquid epoxy resin in a vacuum environment; and after the epoxy resin is solidified at a high temperature, automatically separating the whole set consisting the aluminum sheet substrate, the solidified epoxy resin, the X-ray multilayer film and the Pt separation layer from the glass mother board. As the Pt separation layer which is 3-10 nanometers in thickness is arranged, the method overcomes the detect of the traditional copy process that only an Au or Pt single-layer metal film reflector and a Pt / C periodical film reflector can be prepared due to difficult separation, so that the common X-ray multilayer film material can be used for copying an ultrathin high-smoothing reflector; moreover, the Pt separation layer which is 3-10 nanometers in thickness has low absorption to the hard X ray, and therefore, the addition of the Pt separation layer hardly affects the optical property of the reflector.

Owner:TONGJI UNIV

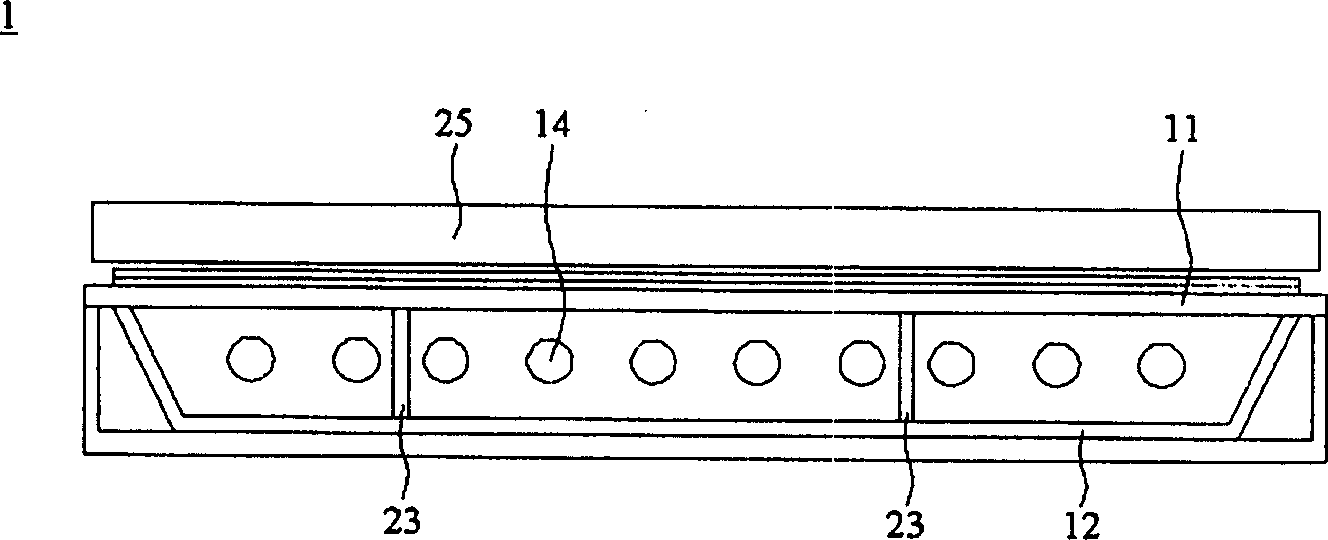

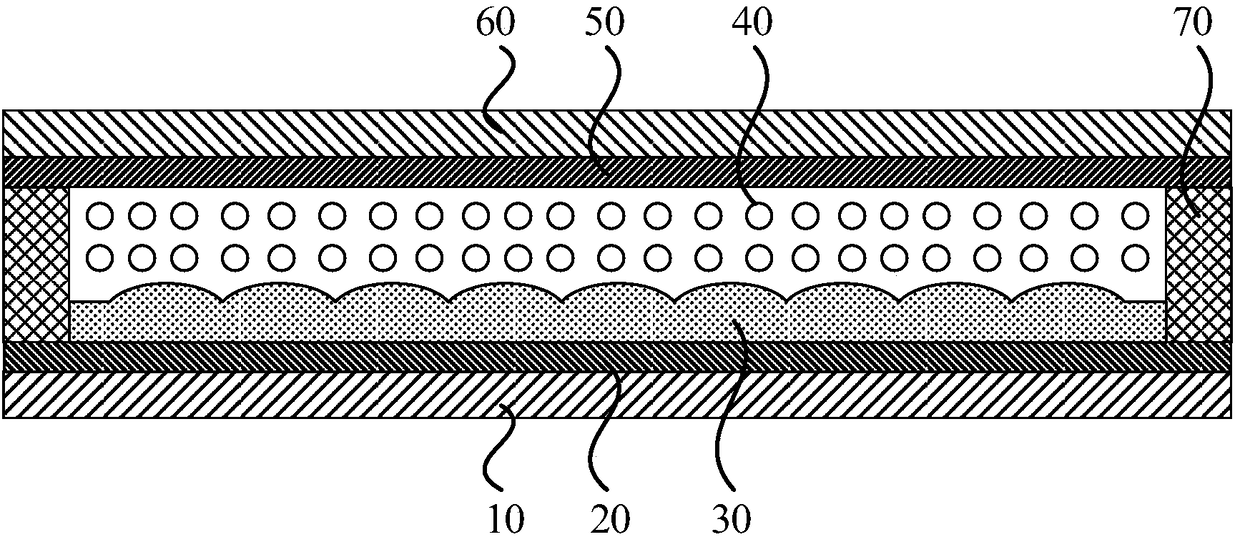

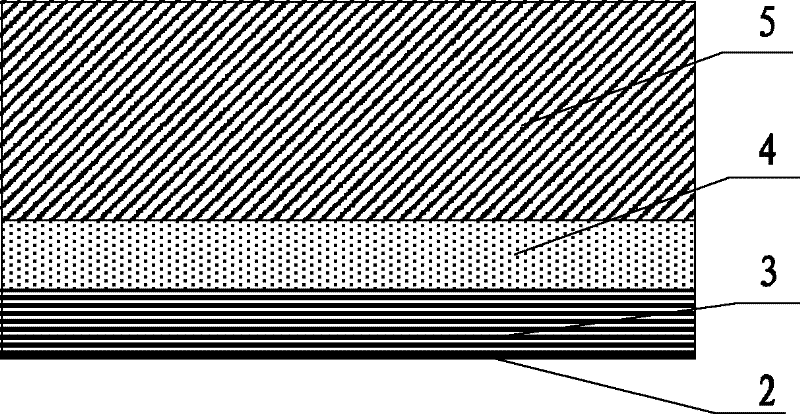

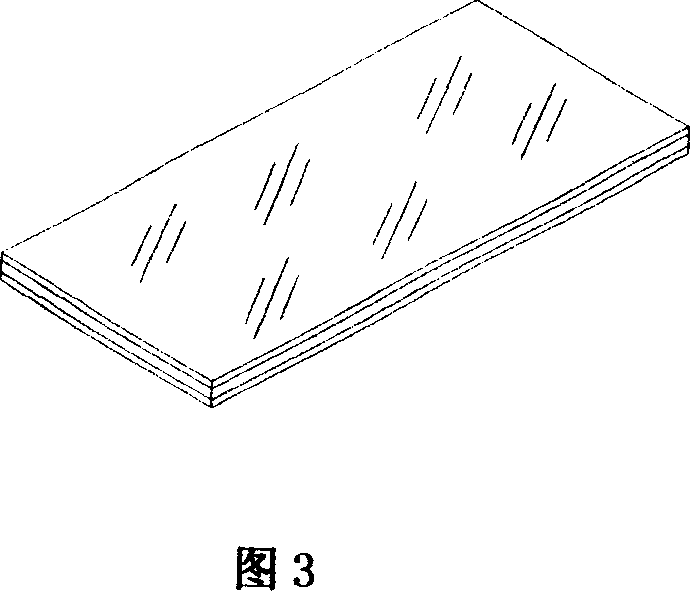

Backlight module, preparing method thereof and liquid crystal display device

InactiveCN108061986AGood adhesionDoes not affect optical performanceNon-linear opticsLiquid-crystal displayColloid

The invention provides a backlight module which comprises a plurality of optical films and further comprises multiple layers of colloid sequentially overlapped. Each layer of colloid is attached to one optical film so that all the optical films can be fixed. The invention further provides a liquid crystal display device using the backlight module, and a preparing method of the backlight module. The preparing method of the backlight module includes the steps of overlapping the optical films, overlapping the multiple layers of colloid, and attaching the overlapped colloid to the optical films. According to the backlight module, the multiple layers of colloid are overlapped to be attached to the optical films of different layers, the process is simple, the optical films are good in attachmentfixity, and optical performance of the optical films is not affected.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Cover board arrangement for visual window

InactiveCN1960611AImprove permeabilityAppropriate light transmissionMagnetic/electric field screeningScreening apparatusMetal meshWindow covering

The invention comprises two window covering boards in same thickness. The microelement is added into the window covering boards in high temperature condition to increase its transparency; there is a conducting metal mesh between two window covering boards to shield electromagnetic wave.

Owner:深圳市天阳谷科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com