Compound encapsulation structure and method of organic electroluminescence device

A technology of electroluminescent devices and packaging structures, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems that restrict the practical application of thin film packaging, damage to light-emitting devices, etc., achieve high resistivity, reduce damage, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

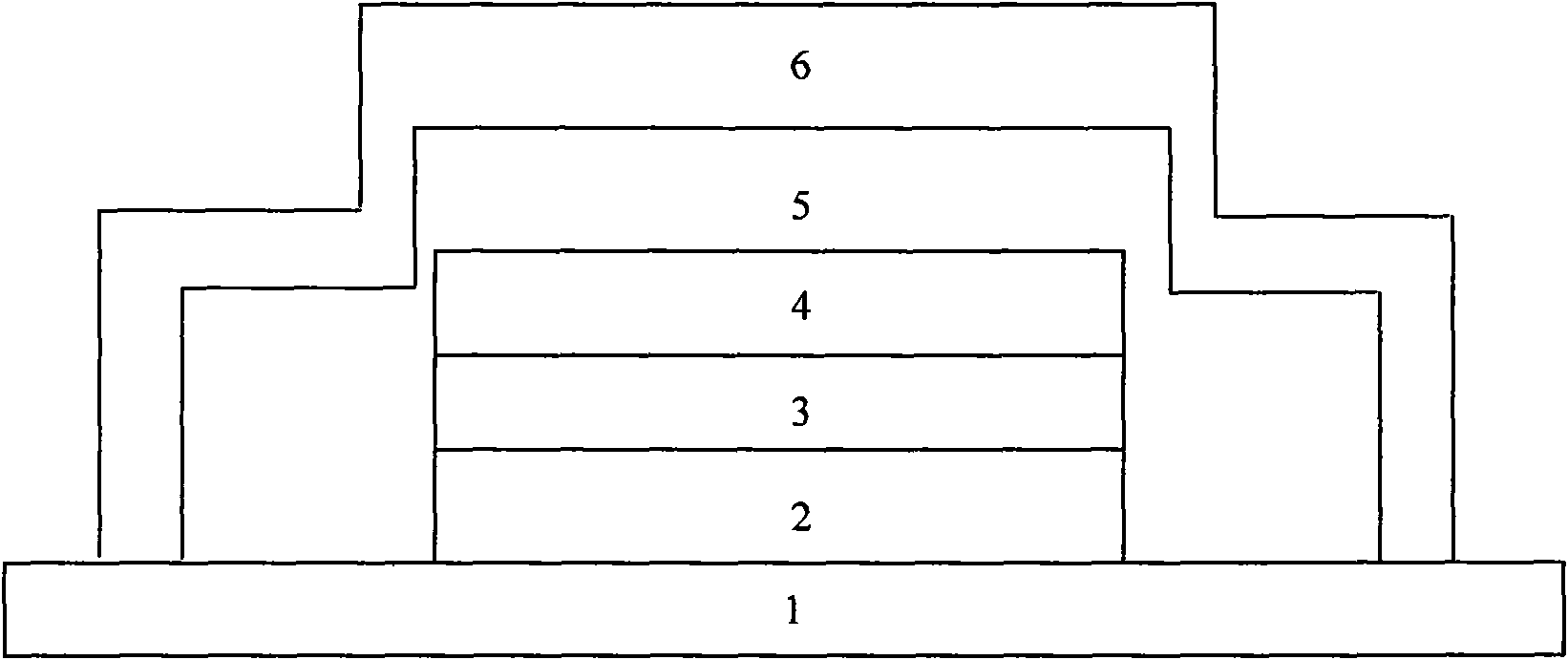

[0023] Such as figure 1 As shown, the composite packaging structure of the glass organic electroluminescent display device includes a substrate 1, an ITO film 2, an organic electroluminescent material layer 3, a metal layer 4, a packaging buffer layer 5, and a packaging layer 6. The ITO thin film 2 is fabricated on the substrate 1, the organic electroluminescent material layer 3 is fabricated on the ITO thin film 2, the metal layer 4 is deposited on the organic layer 3 by thermal evaporation, and the packaging buffer layer 5 is fabricated on the metal layer 4. On, finally make encapsulation layer 6. By connecting the positive electrode ITO film and the negative electrode metal electrode layer, the organic material layer is passed a direct current to drive light emission.

[0024] The preparation method of this composite encapsulation layer is as follows: adopt LiF material as encapsulation buffer layer 5, use and prepare the same evaporation equipment of OLED device, the evap...

Embodiment 2

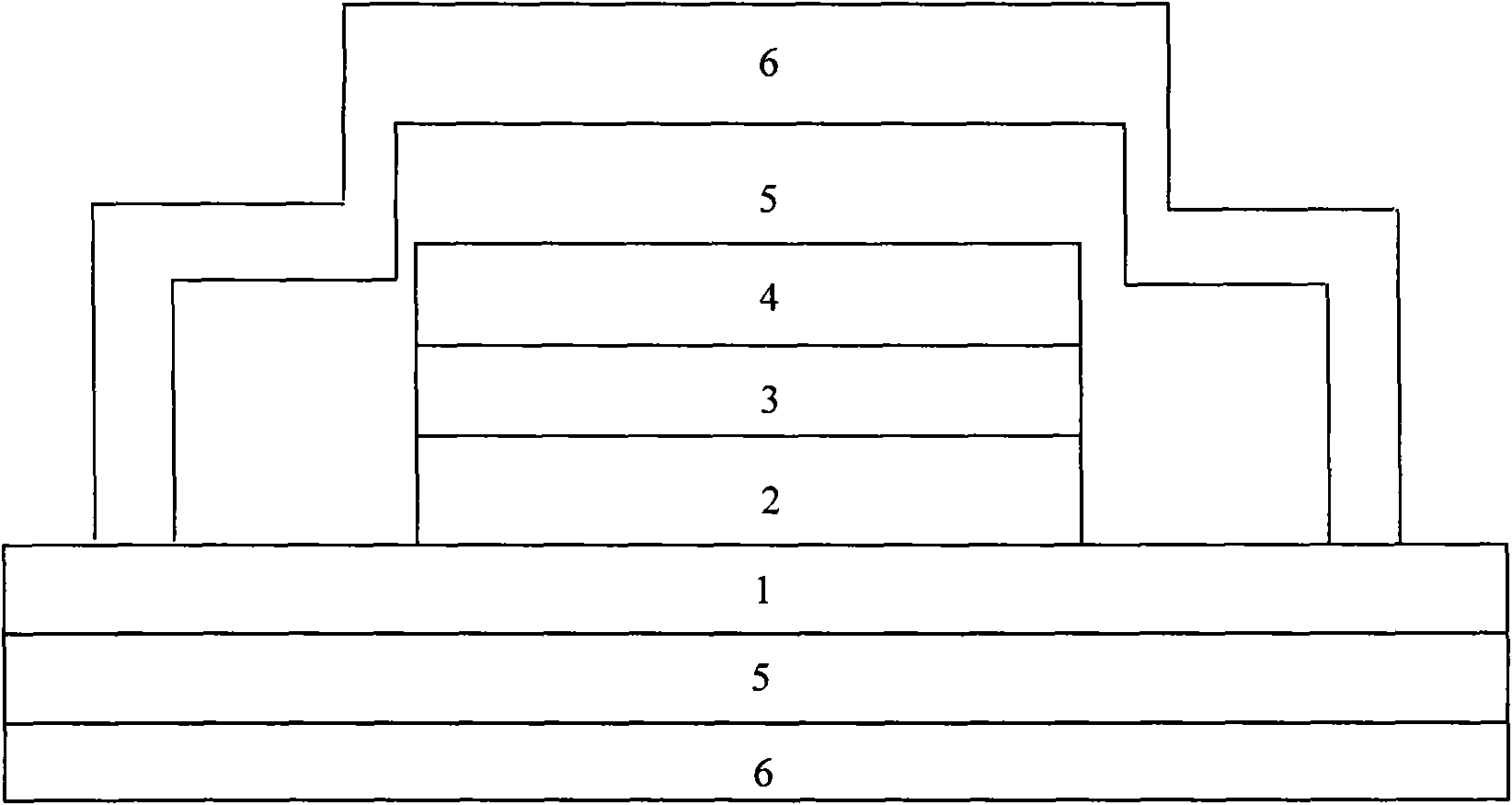

[0030] Embodiment two: if figure 2 As shown, the present embodiment is basically the same as the first embodiment, except that the buffer layer 5 and the encapsulation layer 6 are also prepared on the back surface of the substrate 1 (the surface without ITO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com