Magnetic fluid-based tension-free hollow-core microstructure optical fiber ring winding method

A technology of microstructured optical fiber and winding method, which is applied in the directions of instruments, surveying and navigation, measuring devices, etc., can solve the problems of difficulty in matching the mechanical structure characteristics of hollow-core microstructured optical fibers, and achieve the effect of ensuring optical transmission characteristics and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

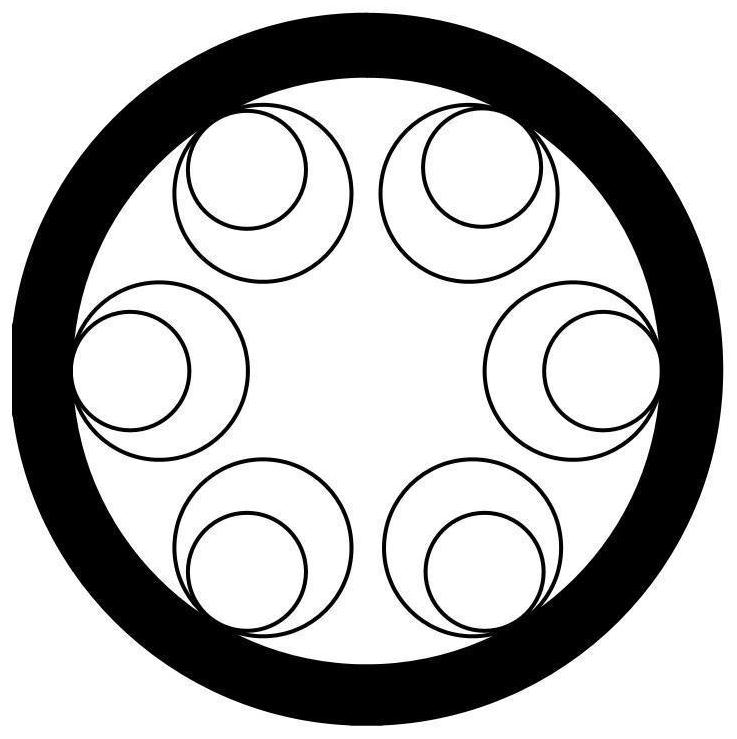

[0022] figure 1 It is a cross-sectional schematic diagram of a hollow-core microstructure optical fiber. The white area in the figure is the proportion of air, and the black area represents the silica microstructure. The wall thickness of the internal microstructure unit is on the order of nanometers. It is connected to The outer large silica structure cladding is anchored. It can be seen from the cross-sectional schematic diagram that the hollow-core microstructured fiber has two obvious characteristics: one is that the air inside the fiber has a large proportion; the other is that the mechanical strength of the connection between the microstructure unit and the cladding is relatively weak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com