Backlight module, preparing method thereof and liquid crystal display device

A backlight module and accommodating technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of offset of the film and the inability to effectively fix the optical film, and achieve the effect of good adhesion and fixation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

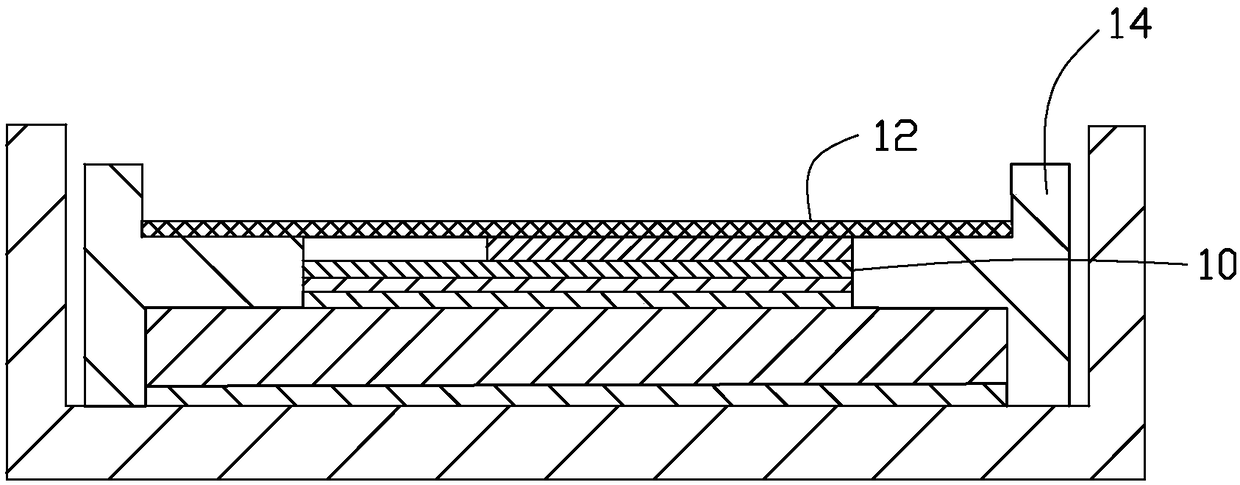

[0026] The technical problem solved by the present invention stems from the discovery that the multiple optical films contained in the backlight module are usually only stacked in sequence and pressed tightly in the plastic frame of the backlight module, and only one layer of adhesive tape is adhered to the top of the backlight module. Fixed, this method cannot effectively fix the optical films of each layer, resulting in the risk of shifting the lower layer of the film during use. The optical film is thin, and each optical film may shift during use, while the optical film The optical characteristics should be considered between the sheets, so more glue cannot be inserted between the films. The present invention designs the structural design and bonding method of the glue based on the discovery of such problems. See the following backlight module embodiment for details.

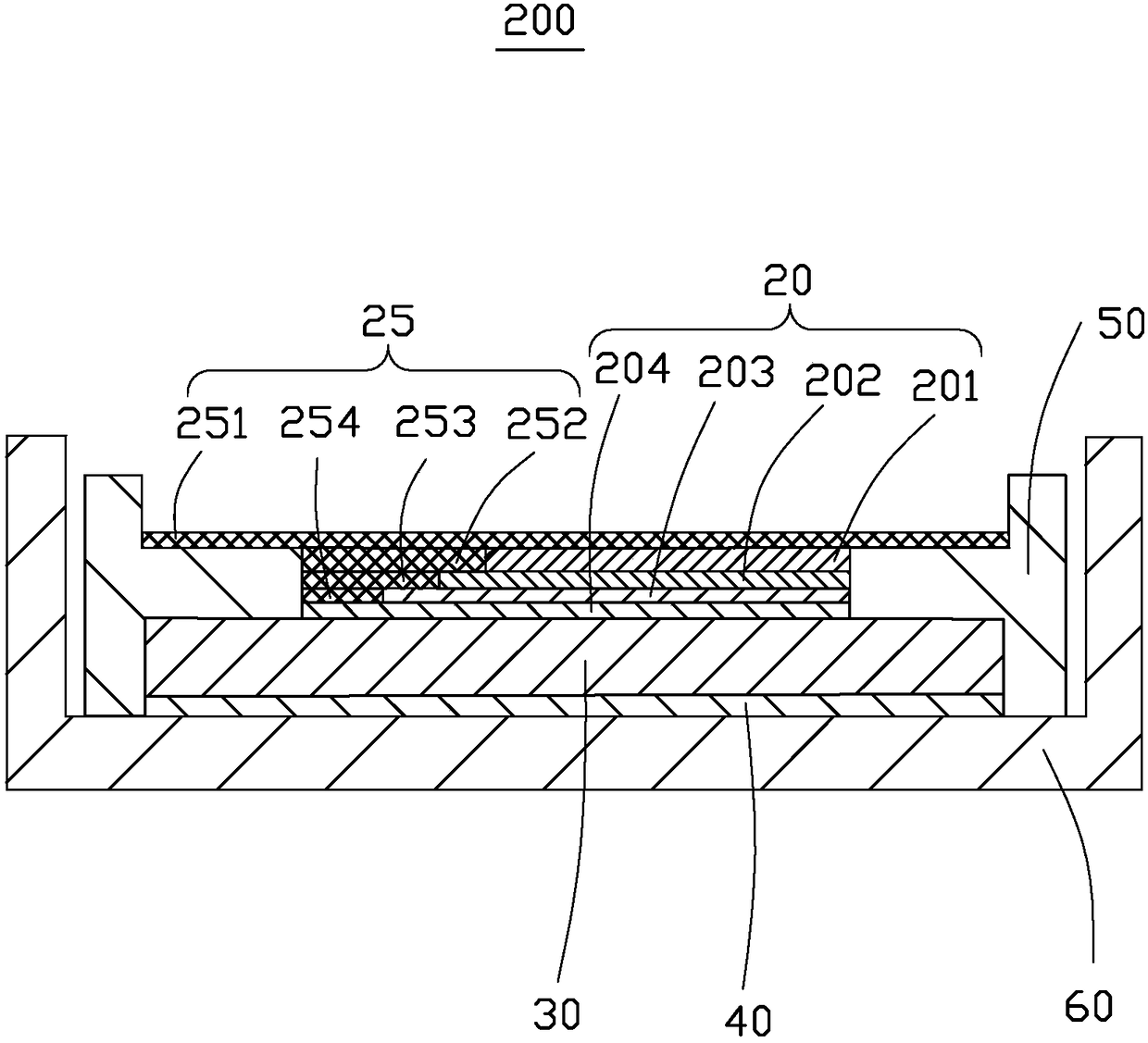

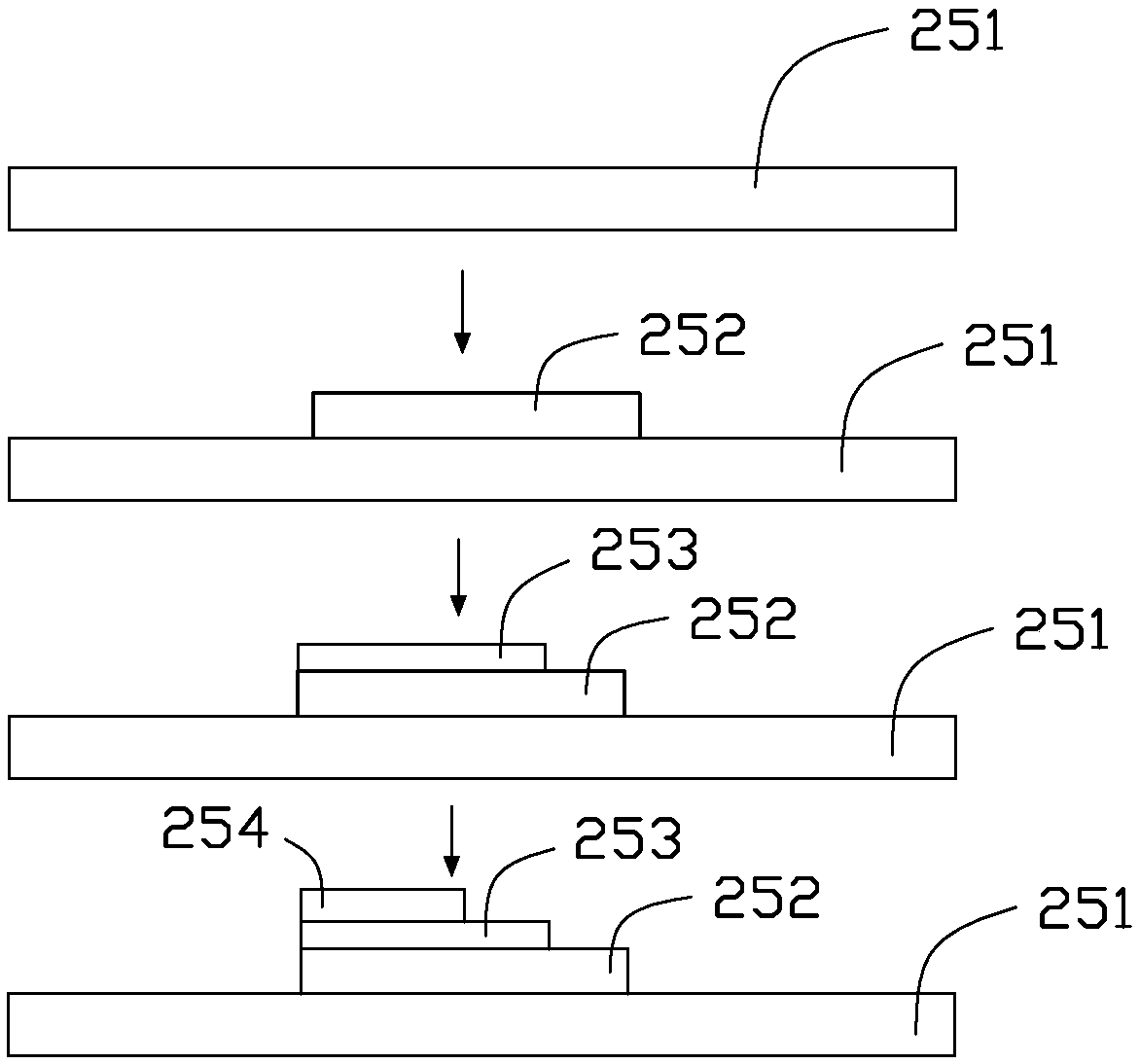

[0027] see figure 2 , the embodiment of the present invention provides a backlight module 200 , which inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com