Multilayer film reflector based on Pt separation layer and manufacturing method of multilayer film reflector

A manufacturing method and multi-layer film technology, applied in the application of diffraction/refraction/reflection for processing, radiation/particle processing, nuclear engineering, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

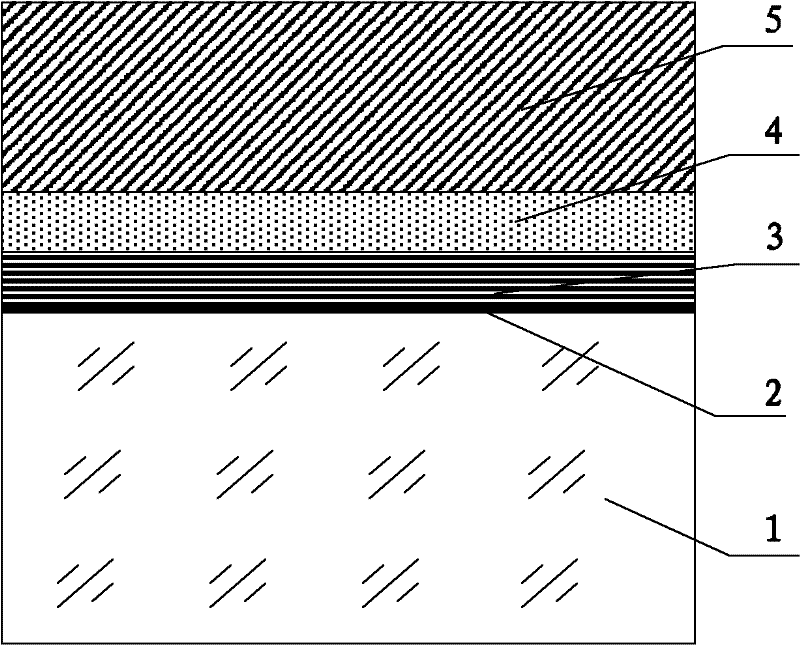

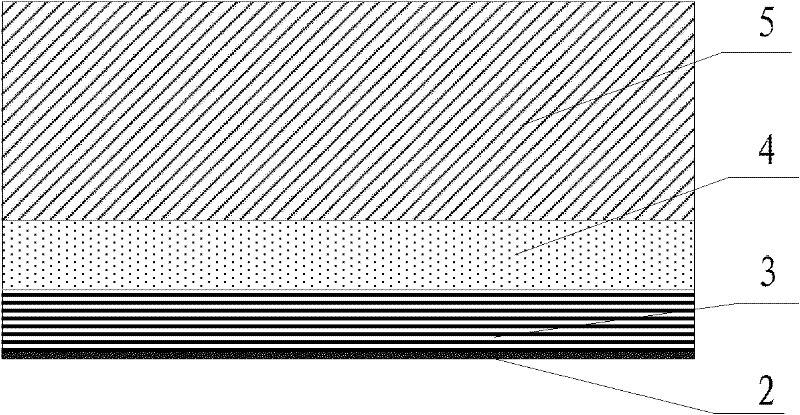

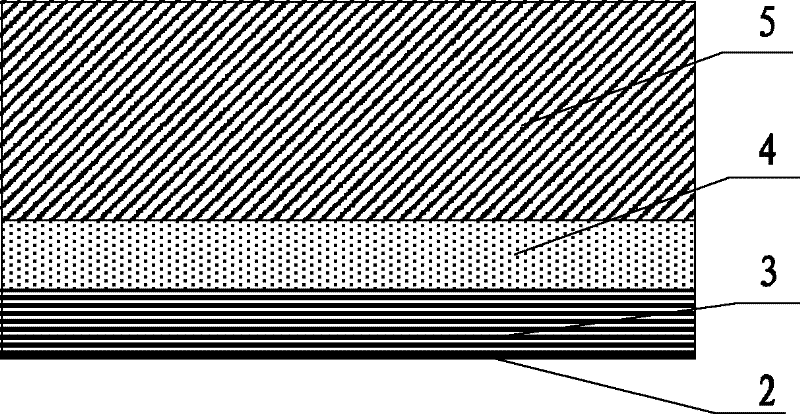

[0025] A kind of manufacturing method of the multilayer film reflector based on platinum separating layer, such as figure 1 As shown, the ultra-smooth glass substrate 1 is selected as the mother board, and the Pt separation layer 2 with a thickness of 3-10 nanometers is plated on the glass mother board 1 by the magnetron sputtering method. In the present embodiment, the thickness of the Pt separation layer 2 is Be 5 nanometers, then plate X-ray multilayer film 3 again, then on X-ray multilayer film 3, evenly spray the thick liquid epoxy resin of about 10-30 micron, the thickness of epoxy resin is 20 micron in the present embodiment In a vacuum environment, the aluminum sheet base 5 with a thickness of 100-500 microns is glued and pressed on the epoxy resin. After the resin is cured to form the epoxy resin layer 4, the aluminum substrate 5, the cured epoxy resin layer 4, the X-ray multilayer film 3 and the Pt separation layer 2 are automatically separated from the mother glass ...

Embodiment 2

[0028] A method for manufacturing a multilayer film mirror based on a platinum separation layer. An ultra-smooth glass substrate is selected as a mother board, and a Pt separation layer with a thickness of nanometers is plated on the glass mother board by magnetron sputtering, and then plated Prepare the X-ray multilayer film, and then uniformly spray liquid epoxy resin about 10 microns thick on the X-ray multilayer film, stick and press the aluminum sheet substrate with a thickness of 100 microns on the epoxy resin in a vacuum environment, and control the temperature. 60°C, after the epoxy resin is cured to form an epoxy resin layer, the aluminum substrate, the cured epoxy resin layer, the X-ray multilayer film and the Pt separation layer are automatically separated from the mother glass as a whole. A layer of liquid epoxy buffers the effect of surface irregularities on the aluminum sheet substrate on the structure of the film. The X-ray multilayer film and the Pt separation ...

Embodiment 3

[0031] A method for manufacturing a multilayer film mirror based on a platinum separation layer. Select an ultra-smooth glass substrate as a mother board, and use a magnetron sputtering method to plate a Pt separation layer with a thickness of 10 nanometers on the glass mother board, and then Plating X-ray multi-layer film, and then evenly spraying about 30 micron thick liquid epoxy resin on the X-ray multi-layer film, sticking the 500 micron thick aluminum substrate on the epoxy resin in a vacuum environment, controlling the temperature After the epoxy resin is cured to form an epoxy resin layer, the aluminum substrate, the cured epoxy resin layer, the X-ray multilayer film and the Pt separation layer are automatically separated from the glass mother board as a whole. A layer of liquid epoxy buffers the effect of surface irregularities on the aluminum sheet substrate on the structure of the film. The X-ray multilayer film and the Pt separation layer replicate the surface topo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com