An optical mirror slip with lanthanide oxide hydrophobic optical thin film and method for preparing the same

A technology of lanthanide oxides and optical lenses, which is applied in optics, optical components, gaseous chemical plating, etc., can solve the problems of few reports on thin film materials, and achieve the effects of good hydrophobicity, excellent optical properties, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

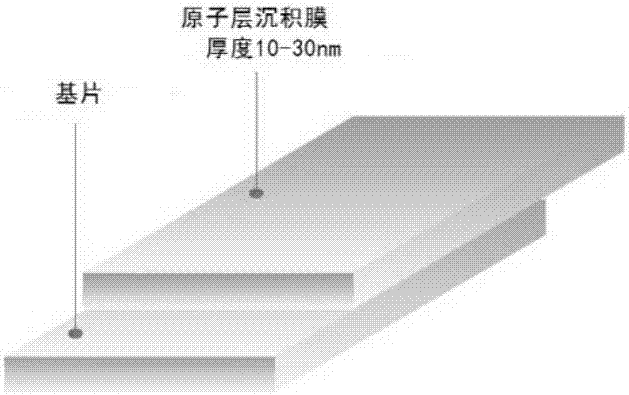

[0013] Example: Coating on the light incident side surface of a bandpass filter;

[0014] When preparing by atomic layer deposition coating process and equipment (model Nano9000, Ensure Nanotech), the preparation parameters adopted are: Ce(thmd) 4 The evaporation temperature of the precursor is 110°C, the pulse duration is 1s, and the pulse interval is 1.5s; the pulse duration of ozone is 1.5s, and the pulse interval is 2s; high-purity nitrogen (99.999%) is used as a dilution and buffer gas; The growth temperature of the atomic layer deposition film is 220° C.; the pressure of the reaction chamber is 2-3 mbar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com