Back-to-light module

A backlight module, a direct-type technology, applied in the field of direct-type backlight modules, can solve problems such as reducing the performance of LCD panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

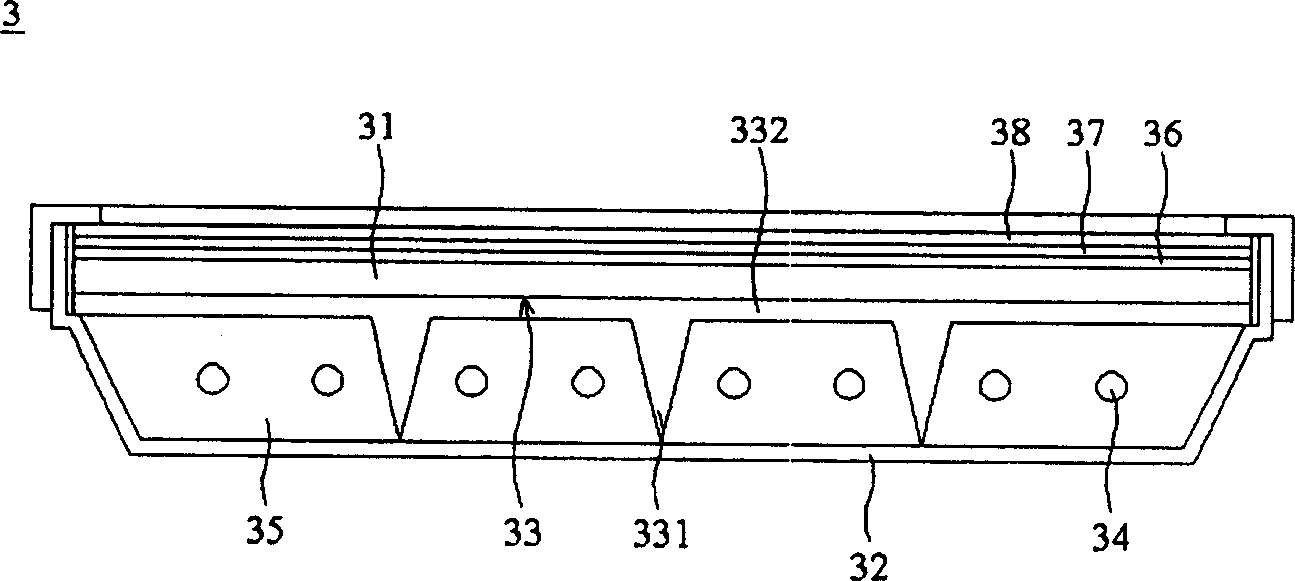

[0014] image 3 It is a cross-sectional view of the first embodiment of the direct type backlight module of the present invention. In this embodiment, the direct type backlight module 3 is connected by a diffuser plate 31 and a reflector plate 32, a cavity 35 is formed between the diffuser plate 31 and the reflector plate 32, and a plurality of light sources 34 are arranged in the cavity 35, In this embodiment, the light source 34 may be a light tube. In order to prevent the diffusion plate 31 from being deformed due to the excessive area of the diffusion plate 31 or the heating of the lamp tube, a light-transmitting support frame 33 is arranged between the diffusion plate 31 and the reflector plate 32 as abutment to prevent the diffusion plate 31 from being deformed.

[0015] In this embodiment, the light-transmitting support frame 33 may be an integral molding structure formed by an injection molding method, and has a plurality of support feet 331 that are commonly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com