Anti-sidewise-bending deformation control device of H-shaped steel component and welding method

A technology of deformation control and H-shaped steel, which is applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of difficult control and tediousness, achieve the effect of not easy to deform and bend, reduce frictional resistance, and ensure structural strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

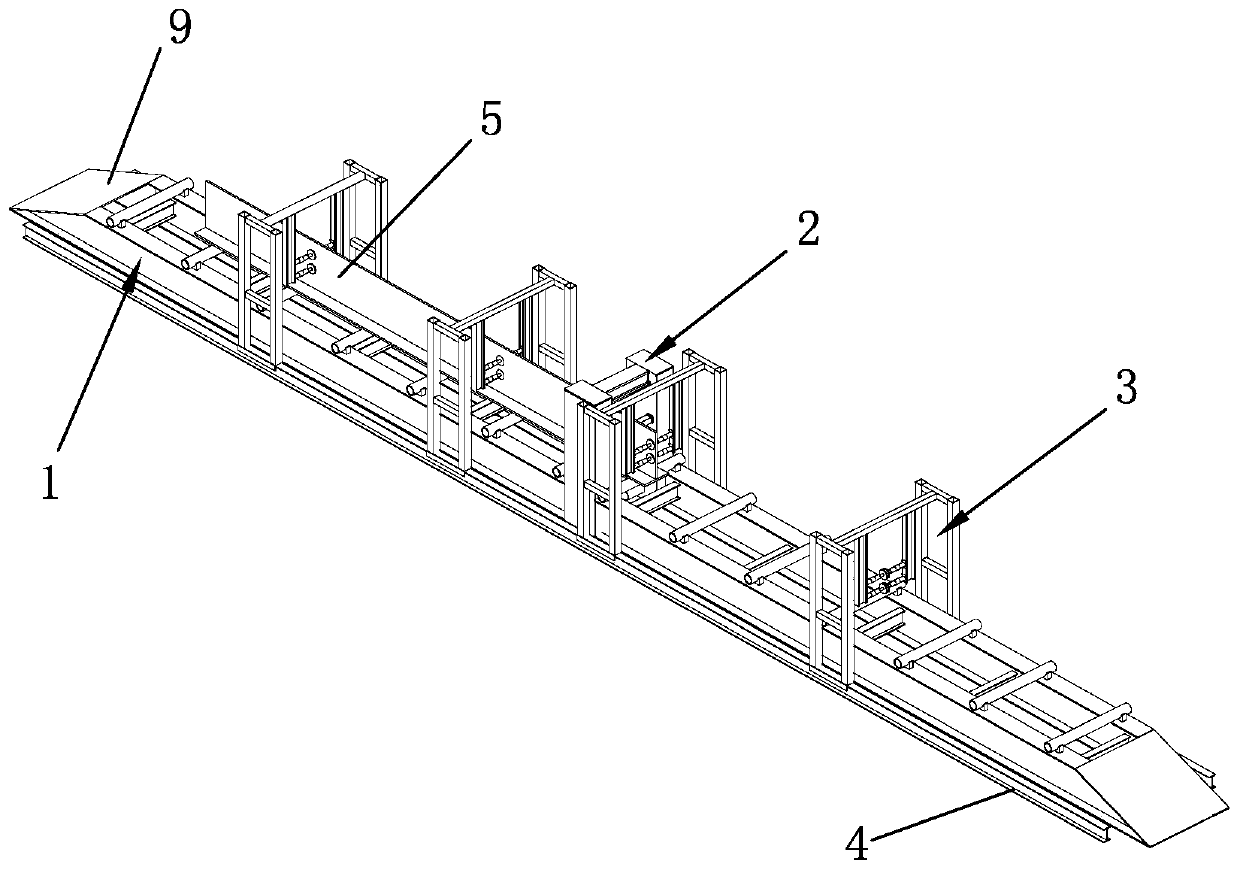

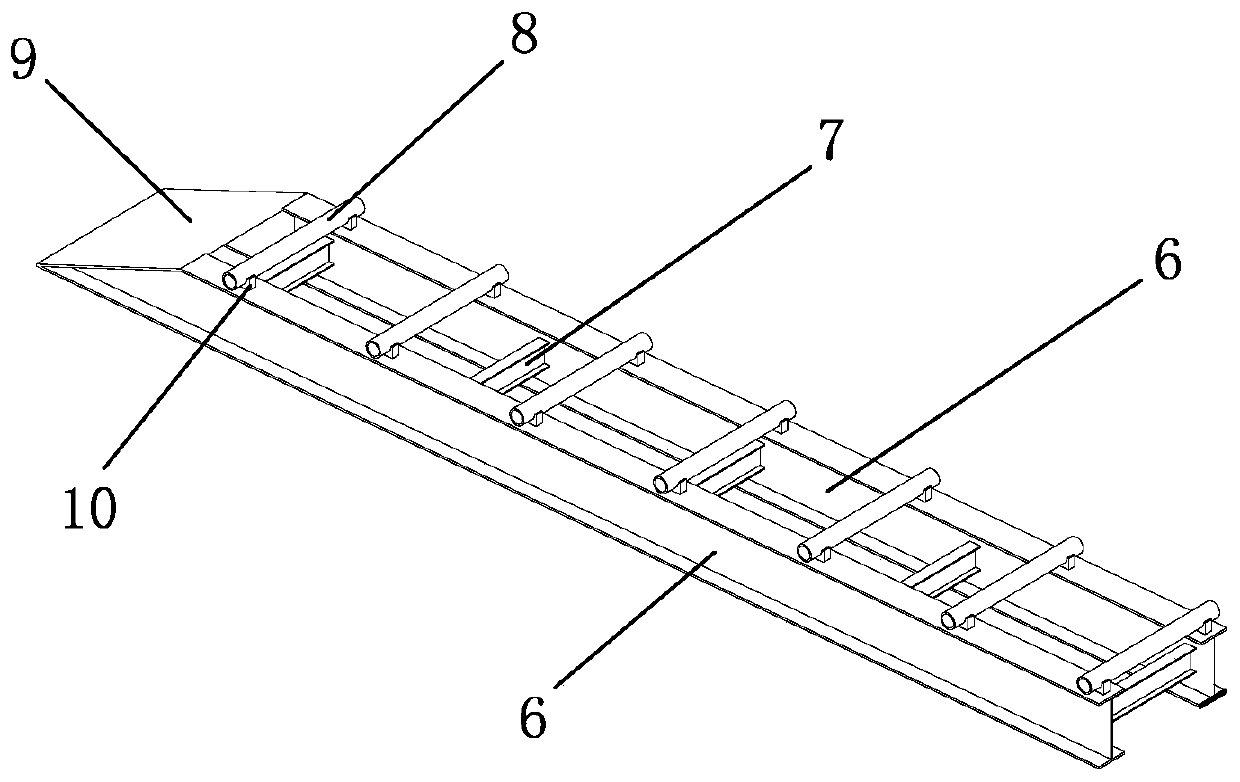

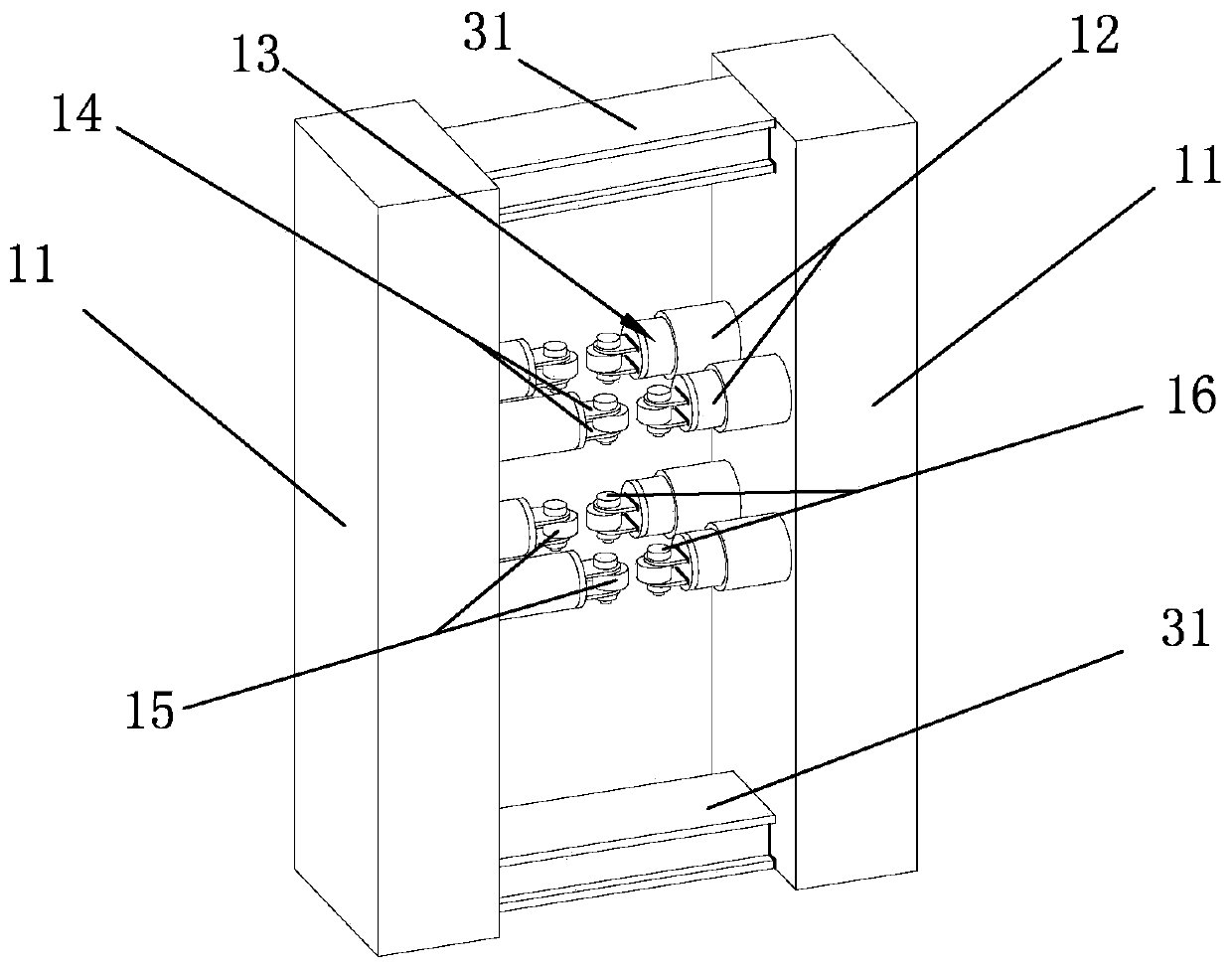

[0043] Such as Figure 1 to Figure 7 As shown, it is the H-shaped steel component anti-side bending deformation control device of the present invention, including the assembled tire frame 1, the anti-side bending device 2, the pressing device 3, the slide rail 4 and the member 5 to be welded, and the anti-side bending device 2 is located in the assembled tire In the middle of the frame 1, the left and right sides of the anti-bending device 2 are provided with an equal number of pressing devices 3, and the pressing devices 3 are distributed along the direction of assembling the tire frame 1, and the pressing devices 3 are located above the assembled tire frame 1 , the pressing device 3 is clamped on the slide rail 4, the slide rail 4 is symmetrically arranged on the front and rear sides of the assembled tire frame 1, the slide rail 4 is fixedly connected with the assembled tire frame 1, and the member 5 to be welded is located on the assembled tire frame 1.

[0044] The assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com