Drill pipe transit box of drilling machine

A technology for drill pipes and drilling rigs, which is applied in the field of drill pipe transfer boxes for drilling rigs. It can solve problems such as long loading and unloading cycles, affecting the service life of drill pipes, and collisions between male and female buckles of drilling tools, so as to improve service life, save labor intensity, and avoid bending. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

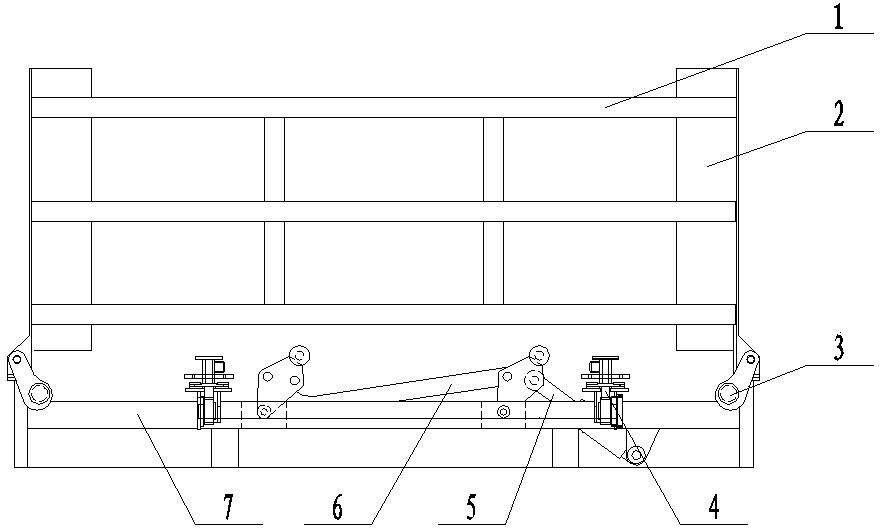

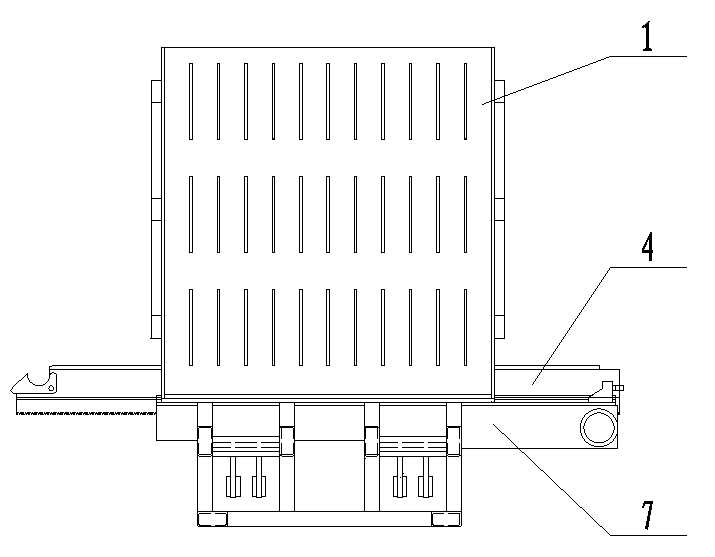

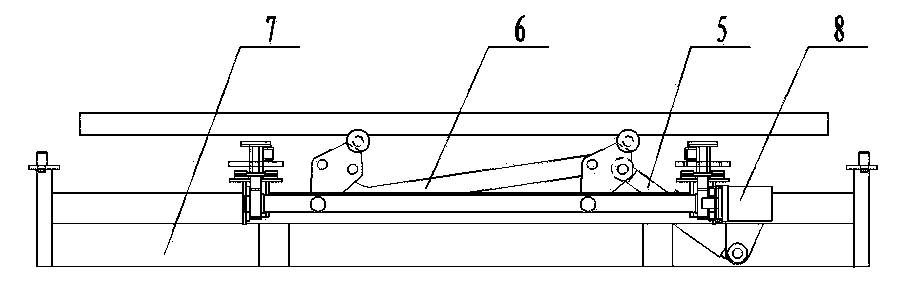

[0017] A drill rod transfer box for a drilling rig, including a box body 1, a number of vertical partitions 2 arranged at equal intervals are symmetrically arranged on the left and right sides of the box body 1, and a space is formed between two adjacent vertical partitions 2. The drill pipe storage room of a row of drill pipes has a base 7 which is detachably mounted on the bottom of the box body 1, and two drill pipe conveying mechanisms 4 for synchronously conveying drill pipes are symmetrically arranged on the base 7, and the drill pipe conveying mechanism 4 includes and The support seat 13 fixedly connected to the base is provided with a slideway arranged along the drill pipe conveying direction on the support seat 13, and a slide seat 9 is installed in the slideway, and the top surfaces of the slide seat 9 of the two drill pipe conveying mechanisms form a The drill pipe support surface, the distance between the drill pipe support surface and the horizontal plane formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com